Everything posted by EuroDat

-

exaggeration or lie?

I think in reality a rust free Zed no longer exists or it never left the factory. A lot of metal was not properly treated to resist long term rust issues and the cars were often exposed to the harsh elements during transport on the ships or docks. It would not be wise to think a used zed will be rust free. Mine was "Rust free" which means I will need to dig a little further to find it. Also the definition of rust should also be mentioned. Surface rust or badly pitted to completly corroded away. I find the biggest problem with these cars is the rust is most often in places you can't easily see until the car is fully stripped. The small tell tale bubbles under the paint are just the surface of the problem and the end result of years of corrosion.

-

Passed a Z on a trailer in SE Michigan today

Welcome to the club. Your 280Z looks darn cold under all that snow. Strange weather these days. We just had the warmest day ever recorded in the south of holland at 15.2 deg C measured in Eindhoven

-

What's in YOUR garage?

Thats one cool hobby tractor you have there Mike. Snow chains and all

-

Discovery Channel Wheel Dealers Episode 240z

Isn't that the third name I have heard him using. It was something else before Califonia datsun llc, can't remember what it was though. I think Bart purchased some parts from him and was happy with it. It might be hit and miss. If you like gambling...

-

Ammeter Voltmeter swap project

Nice work Tamo. Clear steps in the drawings. Just a couple of questions. Where do you plan to connect the "10a fuse block" to? If the car doesn't have AC, you could use that. The fuse cover notes a 10a fuse for the fuel gauge?

-

Save this Z! Portland OR

Mark, Next time you are there and there is a bald kid playing a banjo on the porch. RUN, don't look back, just run. From what I can remember, it doesn't end well. Chas

-

Anyone know where to find those 70's mag wheels ?

Hey Bart, A liitle more background reading on the Ansen slotted wheels. http://www.roadsters.com/wheels/#Ansen Zparts also have some other brands http://www.zparts.com/ads/wheels/ads/wfs-73/wfs-73.html

-

Anyone know where to find those 70's mag wheels ?

My 280Z has Panasports on it with the screwed caps. Not sure which is better - screwed or clip-on. The problem I found with the srewed caps is the screws corrode in the aluminium and break off when you try to remove them. This often happens at the tyre shop because they remove them to balance the wheel and are not prepared to take the time to gently work them out. I replaced my screws with stainless and used anti-seize on the threads. I remove the caps at home before taking the car to the shop for balancing. Slotted wheels may have been the most popular "mag wheel" in their day. 5 slots were most common, but every now and then you would see 6 slots. I don't know which company made the 6 slot version. The caps might just be the hardest thing to find, if you go for a used set of wheels. http://www.speedhunters.com/2014/10/cool-collectable-wheels-jccs/

-

Anyone know where to find those 70's mag wheels ?

Goggle slotted mags or ansen mag wheels and you should find them easier. I have them on mh Zed and also hac them on a Holden Monaro back in the eighties. Back then they were common aftermarket wheels. This was a set I was thinking of to be able to use 15" tyres. Im happy with what I have atm. http://whiteheadperformance.com/products/american-racing-15x7-polished-slot-mag-wheel-kit-0-offset-4x114-3-vna695748-datsun-240z-260z-280z-280zx-510/

-

clutch pedal

Sites idea with the grip tape sounds like a good cheap fix. I have a spin off on it. An alternative would be a piece of "emery cloth" and a small tube of glue. Most hardware stores will sell it off the roll. Its an inch wide, about 5 inches long would be enough. Ask them for a suitable glue to glue it to rubber. Use the emery cloth to rough up the rubber so the glue will bond better. Then cut the emery cloth to size and glue it on drit side up. Probably 60 or 80 grit would do the job. I would use emery cloth, not emery paper.

-

Bleeding Issues

Try bleeding the master cylinder first. There are two bleeders on the side. When you bleed it, close the bleeder and release the brake pedal slowly. The holes in the MC bore to the reservoirs are very small and need time to fill the MC bore. Completly disconnecting the brake line will probably not help you much because an open line will allow air back in a lot quicker than fluid via the holes from the reservoirs. The fluid will just go back and forward when you pump the brake pedal. Keep at it. A dry brake system can take a while before you get the fluid down to the rear drums.

-

Fitting 240Z bumpers and Valences to a 280Z

It would work. I think it would be a little lower than the 240Z bumper centerline. That is because the shock mounting bolts are, all except the top rear bolt, under the shock. And the thicker bumper has a lower centerline making the shock position lower. You could probably overcome that problem with brackets. One thing to take into consideration if you would do that is the bumper mounts are further towards the center. I wanted to close the gap behind the grill, but these brackets stopped me from doing that. That is why I made the brackets for under the 280Z indicators.

-

Fitting 240Z bumpers and Valences to a 280Z

I haven't had much time lately so any progress has been slow. I did manage to cut out a template to do some test fitting and determine where bolt should be mounted. The top bolt will need a spacer behind it to compensate for the height difference, but it fits nicely.

-

Selling an OHC engine.. and looking for info

Selling it as parts would get you more, but it takes more effort on your part and you will be let with odd parts no one wants. You need to post more info on the head ID (E31, E88, N42) and which block is it L24, L28 etc. Then people will know what the aee buying. Does the engine still turn? What is the gearbox, most probably a 4 speed (F4W71B) or maybe a 5 speed (FS5W71B). If its a 5 speed post some photo's of the rear extension housing. There are several variations in the ratios and the rear extension helps identify them. If you add that info to the thread, you might even find someone here interested.

-

OFFICIAL 280Z "Fuel Damper" thread!

If is was fizzing out around the adjustment bolt, then the diaphram was ruptured or perished to a point where it started leaking. Would have been interesting to cut it open to see if the rupture was fuel or age related. Could be an early sign of things to come with all these new fuel mixes.

- Selling an OHC engine.. and looking for info

-

Selling an OHC engine.. and looking for info

I agree with Site. If its all original it's before July 72. I can't see the details all that good, but the screws on the carbs look square from each other which could mean the 4 screw type. If they are four screw, it would put it somewhere before August 71. Good chance this engine has an E31 head. If they are 4 screw carbs, it should have an E46 inlet manifold. The carbs don't have the water heating the later version had. That came in on the 3 screw carbs. The air pump valve thingy with the pinkish red hoses is for the pre July 72. They moved it to the back on thd flat tops. You might want to check thd gearbox. Small change, but someone could have fitted a five speed from a latrr model. If its a four speed, its the original.

-

OFFICIAL 280Z "Fuel Damper" thread!

I don't think your new damper solved the pressure drop. That would be the check valve in the new NOS pump. The damper could slow the pressure drop if the check valve had a slow leak down rate. The damper does have capacity to compensate for pressure fluctuations and that would keep the pressure depending on the check valve leak. I wonder what you would get if you ordered that A/C compressor shaft?

-

GL-4 vs GL-5 Gear Oil in Transmission.

Every now and then I come across that "forum" website and I wonder the same thing. It's jusg a feeling, but my subconscious keeps telling my not to trust it.

-

Fitting 240Z bumpers and Valences to a 280Z

Thats it exactly. I would like something that you can screw in when needed and store in the tool roll when not. The bracket will have something like an M20 female thread so a bolt with a tow hook (eye) can be screwed into it. I am basically copying our Renalt. Since its about 250kg heavier than the 280Z the tow bolt should be strong enough. Google "Renault 8200519463" for an idea. Now trying to make a bracket with as many contact points possible to spread out the "jerking" stress/load from being towed. And making it a bolt on addition, not something you need to drill and weld to fit.

-

Fitting 240Z bumpers and Valences to a 280Z

Mike, Update We have been playing with the design a little. My first design was mounted in top of the frame, but that meant you would need to remove the 280Z indicators and the frame support. This design would require 240Z / 260Z indicators undr the bumper. The second design is under the indicator support in the box section. This way you can drill holes through the support and mount the bumper bracket undrr the indicators. It's a pita determining where to drill the holes because you drill from the top. I'm trying to make a cardbourd template that you can place on top to mark where the holes will be. The next thing that I want to make is a bracket for a tow hook. Now the air-dam and extended grill are fitted, I can't use the old tye down brackets. This new bracket will fit where the old bumper shocks bolted to the frame. You can than screw a tow eye into the bracket for towing the vehicle. Its fallen into the background with christmas and all the family activities, but Im planning to get back to it this week. Draw my templates in Acad and compile them for the watedjet cutter. Once I make some progress and photo's Ill let you know. If you are still intrrested, Ill add you to the list.

-

Clutch/Transmission Fitting Issue

The adjustable push-rod version is from the 240Z series I up to around August 71. Drilling the clutch folk for the adjusctable push-rod will be challenging, specially if its in the car. You will also need to drill is oversize to allow movement. It works like a fulcrum. Drilling it out to 1mm bigger than the push-rod will probably make it bind up. I would buy a later version slave cylinder and leave the clutch fork as it is. Advice: Dismantle the slave cylinder and clean it before you install it. It's very common to find remnants of the machining in the bore and that will only reduce the life of your new slave cylinder.

-

U-Joint removal

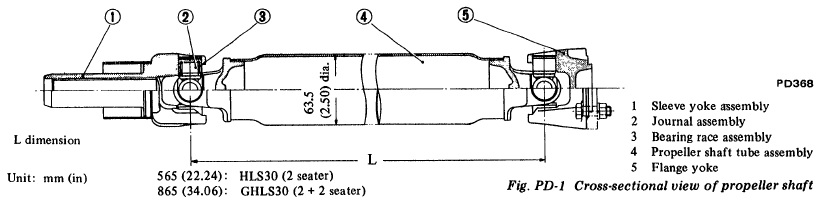

The Serie II through to the 260Z propeller shaft is about 5mm longer than the 280Z shaft. It should fit and IIRC you have about 20mm free movement to get the locating flange in place on the diff flange. Removing the burrs with a dremel wouldn't be the problem. The biggest problem is in the U-joint cup diameter. U-joint cap diameter: Propeller shaft 240Z/260Z: 25mm Propeller shaft 280Z: 22mm Halfshafts: 28mm Propeller shaft lengths (Coupes) 240Z Series I: 525mm (I have not measured one to confirm this measurement.) 240Z Series II up to 260Z 11/74: 573mm 280Z: 565mm

-

U-Joint removal

You might want to check your propeller dhaft. If its still an original 280Z, its non servicable. The uni-joints are smaller and locked in by means of 4 burrs at the outer end of each cap. I have a 240Z propeller shaft and rebuilt it with the OEM parts. They also have diferent thickness circlips to get the right tolerances and help reduce vibration. There might be aftermarket kits for the 280Z, but nissan don't make them. Nissan only quotes a complete propeller shaft.

-

Could it be a slipping Clutch?

The thread wss originally about a slipping clutch, so I think we have sucessfully hijacked the thread. The biggest challenge identifying these transmissions is when you have a gearbox that has been removed from the vehicle. Or you don't know the history of the car it came from. If we are talking about the ZX, it's like 30 years since the last one rolled off the assembly line. A lot can happen in that time. The difference between the Z and ZX are the "ears" and the speedo adapter bolt position. If you look at the truck boxes, the Z20, Z22 and Z24 all have the "tilted" transmission. The L20B will fit without any changes but the 1st gear is so low compared will any Zed you would have to notice the difference. The maxima was the same as the 280Z. I don't know much about the Skylines, but I have heard they were fitted with the FS5C71A and the FS5C71B transmissions. BTW the "C" means Competition synchros, commonly referred to as the Porsche type steel synchros. The W is for the Warner type bronze synchros.