Everything posted by EuroDat

-

Could it be a slipping Clutch?

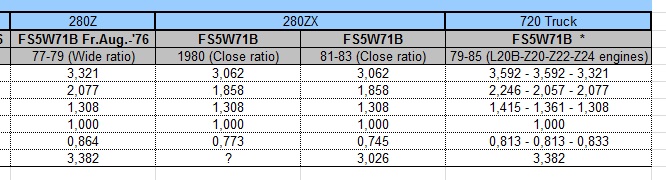

Leon, So true, it gets to be a big list when you include the roadsters, trucks, skylines, & 810 maxima. The FS5W71B close ratio only came in the S130. One other thing to keep in mind: We are talking about the S130 coupe non turbo version. The 2+2 had the wide ratio box like the 280Z and the turbo had the borg warner T5.

-

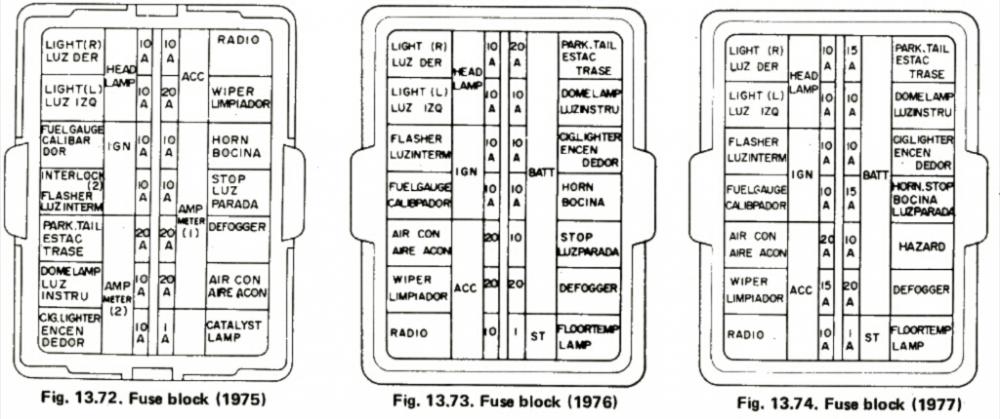

Need fuse box cover

According to carpartsmanual the first one in the diagram I posted is the 25420-N4200 & 25420-N4201 for 12-74 to 08-75. The 25420-N4202 is 09-75 to 07-76. The 25420-N4700 is from 08-76. They swithed around the middle of 1976 so it could be both. They both will fit, but the radio could be in the wrong place. I can't remember what month Jai's 280Z is.

-

Need fuse box cover

You have two types of cover. They changed in August 76. I think its only the fuse layout diagram that is diferent. The shape is the same. If you see "Radio" in the top right, its the later version. If the radio is lower left than you have the pre Aug-76. The later version is most common.

-

Could it be a slipping Clutch?

There are a couple of things that will help you identify which transmission it is. Like Mark already said: Two "Ears" is the early model and one "Ear" is the late model. The second is the bolt used to secure the speedo. If its above the speedo, its early. If it under the speedo, its the later. The later is often referred to as a "Close Ratio" and there are two varieties. The early "Close Ratio" 1979-80 280ZX has the 0.772 fifth ratio and the 1981-83 280ZX has the 0.742 fifth gear ratio. They are hard to tell apart. Edit: Trying to get this attaching files under control Identification FS5W71B.pdf Identification FS5W71B.pdf

-

Could it be a slipping Clutch?

I measured 92mm on mine a couple of years back, and I have seen others quote that number.

-

Could it be a slipping Clutch?

I agree, not much original stuff out there anymore. The S30 series gives people the opportunity to swap around a lot. The important thing to remember is the collar fits the pressure plate, not the transmission. You need to know which pressure plate your using and match the collar to it. I'm wondering if the PO changed the collar and if so what combination he now has to induce this slipping problem. If the slave cylinder has no freeplay in the push rod. It's a good chance the problem is then in the collar.

-

Could it be a slipping Clutch?

This might be side tracking the thread a litle bit. Site, your clutch fork with the hole is a pre July 1972 clutch fork. It goes with the adjustable slave cylinder push rod and return spring. Back in the early days manufacturers didn't won't the clutch release bearing running all the time. It remains stationary until the clutch pedal is depressed. Maybe because of the high speeds involved and low temperature grease. I have heard people say low quality bearings, but I think that is a fable. The low temperature grease getting overheated and not lubricating the bearing seems more feasable. Remember this bearing is running three times as fast as the wheel bearing. A lot of people refer to the collar by the transmission, but that can be misleading. Its better to go by the year. Datsun changed the pressure plate the same time they changed the 71A to the 71B transmission. After that its all over the place. You can get a 71B 4 speed with thre different collars, just depends if its in a 240Z, 280Z or a 2+2. The to drawing below show how you can get confused by using the transmission to determine collar height. The second drawing show the same, but per model Zed.

-

Problems leveling my 240z

Darn, pitty they couldn't find anything. I would have thought 2-1/2" would show up easily when its up on a hoist and you can quickly compared both sides. I keep coming back to the 280Z strut theme. You can fit the 280Z struts to a 240Z and have no problems with fitment. I measured mine and its 305mm from the lowerst weld on the spring perch to the spindel pin. If you mesure from the top of the spring perch, its about 415mm to the spindel pin. If they are both the same its easy to check and something to cross of the list.

-

Could it be a slipping Clutch?

I take it you are driving hard to get this problem. From your description, it sounds like it is an adjustment problem. I don't think it would be the clutch peddle because it wasn't slipping before and changing the transmision doesn't effect the peddles. Did you keep your throw out bearing and clutch fork or are they from the 5 speed? The throw out bearing collars can be different and if it doesn't match the pressure plate (the Zeds have three different pressure plate heights) it can keep the pressure plate from releasing completely. Are you using an original 280Z slave cylinder or an adjustable one? If it's adjustable, check the free play at the clutch fork. If it's the non adjustable type, you should be able to push the clutch fork into the slave cylinder about 5 to 15mm depending on clutch wear and tolerances. Apply constant pressure and it will push in slowly. You are pushing brake fluid through a small hole in the master cylinder. I have some data on clutch fork distance measured from the front of the belĺ housing. That would give you an idea if your pressure plate and bearing collar match.

- 1976 280Z Restoration Project

-

Exact under hood decal placement 1978Z

I also have a 77 model and the sticker is in the same position as sites. I would seem likely they would be in the same position on the 78. The BPT valve recall sticker is on the front radiator support at the AFM side. I think the dealer just place them at their own discretion.

-

1976 280Z Restoration Project

I didn't know there was so many variances for the 260Z. I thought it was two. Does this mean the radiator is also different for all the changes. The 280Z core support drops down to fit the bigger radiator. I ran into this problem when I tried to fit a 240Z valance. I think I might have some measurements somewhere from a friend 240Z and my 77, 280z. If I can find them Ill post them here. At least you have a bit of luck here. All the 280Z are the same, not like you gas tank.

-

OFFICIAL 280Z "Fuel Damper" thread!

From what I have read and heard from Mercedes fans here. The damper was used to help reduce pump noise. Once the pump has worn a bit, there is enough slip in the pump so if you removed the damper it would have little effect. I must admit I don't have a new pump to confirm this theory. These pumps are getting old and the internals are showing signs of wear. They have so much over capacity for the 280Z that you don't notice anything until they are almost completly worn out. Remember the original "Bosch" pump design was also used in Mercedes V8. The Bosch version can be identified by the black terminal insulator section. The Hitachi has the light blue terminal insulator section. They look very similar, but there are enough small differences the make most part non interchangable.

-

Parts for OEM NP-Valve and Brake indicator switch unit

I know you can get scotch brite tips for a dremel and that would work well. Probably should ask for one for Chrissy. I ended up using a cordless drill and a small container with kerosine and not forgetting my hi-tech bic pen hone. I tried scotch bright, but didn't have much sucess. The diameter is so small and it kept getting cought up on the ports. The emery paper wears down very quick because its such a small circumferance. Within a minute it felt like 1200 grit. Its been almost two years now and I had the switch out in September just to check. The cavity was still dry (cotton bud test) so the o-rings are holding up nicely. The method used to restore aside, its good to see you dismantle, clean it and refresh the o-rings. After all it is a safety device with its sole purpose to warn you of inbalances within the brake system.

-

Parts for OEM NP-Valve and Brake indicator switch unit

How does the bore look inside? Mine was corroded with light pitting. I cleaned it with a homemade hone. Made it from bic pen with a slot in one end so I could slide a piece 400 grit paper in it and wrap it around the pen. These switch doesn't need to be perfect like the other cylinders in the brake system. The piston does't move very much, if any at all during normal service. The o-rings will settle and seal it mild pitting.

-

Parts for OEM NP-Valve and Brake indicator switch unit

After removing the big plug nut on the end, the part you circled is a snug fit and should fall out with a couple of firm taps on a block of wood. Mine wasn't being very friendly and I used a little heat (hot air gun) on the aluminium to help it. Don't heat it too much, just enough so you can still hold it with your hands. The aluminium expands enough at that temperature to help it come free. It will be full of gunk and sludge and that will be holding the sliding piston so it won't come out easily. Leaving it soak in some brake cleaner over night would also help loosen it up. I used a piece of rubber sheet to clamped it in a bench vice and block to (rear brake) two ports and brake switch port. The switch port needed an extra layer of rubber because there is a little height difference. It came out with a little air pressure on the front two ports. Since you have been experiencing problems with the brake witch, you might not get it out so easily. My next step, if the air didn't work, was going to be a zerk fittng and the grease gun to push it out. Here are some extra phots. Hope that helps you.

- Problems leveling my 240z

-

Problems leveling my 240z

The spring perch height was what I was thinking too. I wanted to post a photo, but the thread went quiet and I forgot about it. A member here had a strut that was adapted (by previous owner) from a 280Z to work in a 240Z by welding and extra spring perch to it. That was the general conclusion. Anyway the photo shows the difference in height clearly. This would be hard to see if you rebuilt one strut at a time and didn't have them next to each other. Here is a photo of it. The members name is Ksbeta.

-

Finally got some shots of my Z

Very nice indeed

-

How rare is an original 5 speed manual 240z?

Good point. It doesn't add much to this thread. It would only be relavent if someone changed the original tranny for a us model.

-

Bringing back the RedZ

Longer? Not saying that it happened, but just to be sure. It could be differences in MC's, but it could also be the reaction disc. Check your reaction disc hasn't droped into the booster. Its a rubber cushion on the end of the push rod. Originally glued in place, but over the years it comes loose and fall off when we change MC's. People adjust the rod and wonder why it needed adjustment until they go for a test drive. First time you touch the brakes, brace yourself. Otherwise you could headbutt the steering wheel. Without the reaction disc, they are very touchy.

-

How rare is an original 5 speed manual 240z?

If you are seeing "ears" in the selector, it's not the "euro" FS5C71A. The "A" transmissions have a rubber insulated shifter. The "B" trans uses the cross pin selector. To identify your 5 speed, it's best to look forward of the selector. If you see a long plate with bolts holding it in place, it's the 280Z model. The speedo gear retainer bolt will also be at 12 o clock and it will have twoo ears under the selector for exhaust support brackets. The 280ZX (not 2+2) doesn't have the plate. The speedo gear retainer bolt is at 6 o clock and it has one ear on the drivers side. Note: You will read about a mixed version. It has the speedo retainer at 12 o clock, both ears like the early model, but doesn't have the plate in front of the selector. This is the FS5W71B out of the 620 with the L16 or L20B engine and the 720 with the L20B engine. I think this version might have also found its way into the 280ZX 2+2 in the later years. If you take some photos of these areas, it would help a lot identifying which version it is.

- 1976 280Z Restoration Project

-

I open myself for you criticism!

I agree. Thats why I don't plan on painting the outside. Engine bay and reserve wheel area on't matter that much if its not perfect. I did the rear bumper body work and it took me a long time to get it right. Its painted, butIll sand it back again when the time comes. Sorry for highjacking your thread ksechler. Just comparing my sub standards to the great job your doing.

-

240Z Resto - 01/1970 Car

Im with ya now. The two I have for a 280Z look very much like the plugs have silver zinc plating. The bolt and spacer washer is yellow zinc. I dont know if Nabco would have changed the process over the years.