Everything posted by EuroDat

-

My Datsun 280Z "Rustoration"

Thanks. I can't remember what the 280Z pressure plates weigh. I think a bit under 10kg, but I might be thinking of the thinner 240Z early model. Its a nice looking set-up you have. Cheers Chas

-

Dead cylinder #3! Ignition or Fuel?

That clunk sound "smells" like diff related to me. Along with the uni-joints you can also check things like the front diff mount, rear diff cover bolts, rear transmission mount or if could be just play (backlash) in the pinion/crownwheel. These diffs are known to be a little whinny. New oil can quieten in down, but won't do much to reduce backlash. Most of us use extra insulation in the rear to reduce the noise. Note: a little of topic but if you are considering replacing suspension bushes in the future, consider the effects of PU (Poly Urethene) as well. Other than reducing flex they also tranfser road and drive train noise a lot more efficiently. Some people regret the move to PU because of this reason. The rubber diff and rear transmission mounts can sage over the years, although they look good the metal in the rubber mount can tap each other causing clunk sounds and transfer vibrations to the body. My old ones had dropped about 10mm IIRC compared to the new ones I installed and the old ones didn't look half bad. I think Blue has a how to on AtlanticZ that shows the difference between old and new. http://atlanticz.ca/zclub/techtips/suspension/rearend/index.html The two bolts on the diff cover (mustache bar) becoming loose over time is another source. Tighten them to FSM spec. Chas

-

My Datsun 280Z "Rustoration"

Out of curiosity, do you know the the flywheel, clutch and pressure plate weighs? I see different fiqures quoted for the presure plates and can't remember seeing what the clutch disc weighs. Chas

-

Replacement tar mat

I like the sound of that. Finnally something I don't need to pay all the shipping and import taxes on:D Chas

-

240z three piece lower valance

I have a set of the two side sections, but no middel section. Not much help, sorry. They should not be to hard to find, they need to be remove to fit the air-dams like the Xeon fibreclass en pu models

-

Replacement tar mat

Brilliant job. Looks neat and tiderly done with lots of attention to detail. Thanks for sharing. Murder mat is hard to find here, maybe this stuff is easier being a porche approved product. Chas

-

clutch slave keeps blowing apart

I presume it started after you change the slave cylinder? It sounds like what olzed said. If the pushrod is too short the slave cylinder travel will "try" to compensate by moving further down the cylinder, but in turn litterally spitting out the piston in the process. Try pushing the clutch fork and push rod back into the slave cylinder. It should go approximatly 10mm for a new clutch, older worn clutches will be less. If you can get 20mm of travel, you know it too short. This problem can also be caused by mis matching throw out bearing collars and pressure plates. Common when people change transmissions and think the collar goes with the transmission. It doesn't seem to be the problem here though. Chas

-

Dead cylinder #3! Ignition or Fuel?

Have you changed the transmission fluid since it came out of storage? If its been standing for 9 years it might be a good place to start. Clutches don't start vibrating because the engine runs better and has more power. Slipping is a different story though, you will notice that when you engage the clucth and it takes a lot longer to grab when your driving harder or in your case the engines has more power. Poor quality oil in the transmission will create more noise and can increase vibrations. To change the oil, get the transmission warm and drain it over night. I use a cooper 90degree water pope elbow, a hose to and funnel to fill it from the engine bay. Redline MT-90 and Royal Purple Max gear are recommended by many Zed owners, but there are lots of other good brands out there. It should be a GL-4 or a GL-5 suitable for yellow metal (synchros). Chas

-

unmolested original 280zx 11/80 build date

I noticed the number 39 coincided with the diff ratio. It was maybe wishfull thinking that it was relat to the tranny. Thanks for the link, intersting info. I dont recall seeing it on the models after 81. Chas

-

Fighting Transmission to get in Gear

A general rule. Clutch related: Grinds into reverse ALL the time. Hard to get in gear and maybe slightly easier when transmission wams up and "thick" oil thins out. See Leons post #2 and if you have a sreie I slave cylinder with the adjustable push rod, check the free play. Oil related: Grinds into reverse, but is a little easier when transmission is warm. (say after 30 minute drive depending on outside temperature.) Gears are hard to engage when cold and normal or much easier when transmission warms up. Look for oils like Redline MT-90 or Royal Purple Max Gear. GL-4 rated. I think a lot of the GL-5 oils can be used in our transmission, but they must be suitable for yellow metal. Outside these the two above mention symptoms (clutch or oil) there are several other things that can cause dificult shifting: If the shifter mechanism (striking rod guide or striking rod) in the housing is dry and binding, it will influence the force needed to change gear. The gears won't grind including reverse, but hard pressure is needed to engage them. It will also mean you will need more force to disengage gears. Pay attention when disengaging (pulling it out of gear) to neutral. If that is hard chances are thats it something binding in the selector causing your problems. If the transmission has been standing for a long time on its (bellhousing) end the selector section can dry out and increase this phenomenon. The palstic bushes can bind, but I havn't seen it yet mostly worn out with excessive play. The typical stick in the mud syndrome where the gear stick is very loose. Certainly doesn't mean it can't happen it dust gets in and it dries out. I have seen people use the brass or aluminium bushes and they can cause problems if the rubber boot is damaged and allows dust to enter. I prefer the plastic bushes, because the plastic doesn't "need" lubricating and they cost less than $10 and easy to replace. It could be something with the rubber boot tunnel boot. Maybe the rubber is hard. Unlikly to get that hard that its causing this problem and you didn't have it before. I doubt the detent springs or interlocks are the problem because its affecting all the gears. Chas

-

Help with yogurt cup test please...

Didn't someone here start a thread here on repairing the diaphragm in his BCDD? I wonder how it held up. It was some time ago now. It would be an alternative to disabling it altogether. Chas

-

unmolested original 280zx 11/80 build date

Does anyone know what the RC39 after the FS5W71B means on the VIN plate? I think its on the ealy 280ZX models, but not sure. Could it be the first version of the "close ratio" 71B's?

-

Sorry to be Redundent - Help

Thats indeed strange. They changed the pvc design and the hose in May '77. Maybe it was changed by a PO and thats all he could find? Chas

-

Hello from ze Germany!

Hi Luke, You don't see many here in NL these days. Bart is the only one with a 240Z on the road that I know of in my area. A friend in a town nearby town had a 260Z in the same original 305 blue my car was. I know a threw guys with projects in different stages of completion and there are 14 or so in our club Z&ZX Club but the members are dropping each year. The last time I seen a Zed on the road was two years ago. Chas

-

Dead cylinder #3! Ignition or Fuel?

If you are thinking of buying a set of injectors there are cheaper suppliers on ebay. The Standard FJ3 it a common replacement. If you are not out for high performance they seem to work fine unmatched out of the box.* 75 76 77 78 79 80 81 82 83 Datsun 280z Fuel Injectors | eBay Its worth buying the o-ring gasket set from MSA and replace them while you are doing the injectors. My connectors were all badly worn and damaged. They were aftermarket and the cable was so short I couldn't swap injectors. I had problems with 3 and 4 were partially blocked and I found them using the 9 volt battery and the fuel gauge. I ended up reverse flushing them to get them back up to the other four. I got a set of these connectors for mine. This seller was really quick, 5 days to Europe. The quick release makes it easy to do any testing and I made the cable a little longer so I could switch cables on injectors for testing if needed. 6 Injector Connectors Datsun Nissan 280z 280ZX Z31 300zx EV1 Quick Release | eBay Chas

-

Hello from ze Germany!

Welcome to the club Luke. Not many of us europeans on the forum, not active anyways. Sounds like a nice Zed. Any photos? Chas

-

Dead cylinder #3! Ignition or Fuel?

The RPM is always the same. You don't need to compensate for a dead cylinder. The tacho gets its signal from the coil negative. Its the same trigger the ecu gets to tell it what speed the engine is doing. The only way it would read 1/6 slower is if the coil was missing a pulse on number 3 spark plug. I would check the plug like Bart mentioned to be sure, but it sounds to me like an injector problem. It could be a number of things, blocked injector, injector coil open circuited, injector dropping resistor or wiring to injector open. If you have a fuel gauge in the system reading the pressure you can do a simple test on the injector to see if its working or blocked. Disconnect the injector plug and use 9 volt battery to activate the injector. If the pressure drops, you know its opening and it is not blocked completly anyway. You can compare the rate of pressure drop with one of the other injectors to get an idea what is normal. You might need to run the car between tests to build up pressure reduce the chance of flooding. Dont use 12 volts to activate the injector. They normal see a lot less voltage (around 7 to 8 volts average) during pulsing. You can also do a bunch of tests in the FSM to varify everything is working ok. Chas

-

Transmission Temp

I remeber a transmission specialist telling me that "normal" operating temperature for a manual transmission is around 60 to 65 degC. Thats about 140 to 150 degF. 60degree C hot metal is to hot to hold on too for long and can give you the impression its too hot. Still wouldn't hurt to check the oil level to make sure its not too low. Chas

-

Need Help

Double post. On holiday and interent is not all that great. Can be a bit buggy. Chas

-

Need Help

Hi, Welcome to the club. That hose goes to the distributor advance and the BCDD (Boost Controlled De-acceleration Device) going on you discription. Its probably been blocked because the advance diaphragm in the dizzy is torn and leaking vacuum. The EFI doesnt like vacuum leaks. Here is a link to the FSM (Factory Service Manual) and if you scroll down to the "others" section you will find the EFI suppliment. Its often called the EFI bible. Once you get to know your 280Z you will know why it called that. XenonS30 If you google "datsun 280Z bcdd" you will find info on that here too. Chas

-

This flywheel is rubbing me the wrong way.

When you remove the transmission make sure the torque converter was fully engaged in the pump. Its very easy to do. The converter has two tongues that drive the oil pump. If you push hard on the converter when fitting it, it will turn the gear and not engage properly. The tongues ride on top of the gear. If that is what happened, it will push the flex-plate back onto the engine block. Chas

-

My Project Z.

Well Im gob smacked. Never thought you would get her going again. Parts car for sure. Hats off to you for getting it so straight. It sits nice with those wheels and flares. Chas

-

Under the fender rubber

Chris That a good point to mention. Its the exact reason I used the Armaflex. Can't remember if I used the 10mm or 15mm thick sheet, since I had offcuts of both and the 20mm from work laying around the garage. Even if you have some 20mm thick sheet its easy to slice with a sharp knife. Chas

-

Under the fender rubber

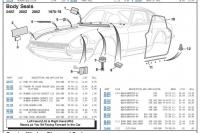

Hi Jim, I think they changed the design somewhere between the 240Z and the 280Z. I browsed through my photo's, but couldn't find anything on the rubber. I did find some photo's showing the difference between your fender supports and the 280Z. The 240Z has one that I can see and the 280Z has three. See photo's. Hope you don't mind me using your photo. If you are refering to POS 4 in BD catalogue. It is a small rubber strip about 50mm long 12mm wide and 6mm thick. It fits in the "U" section at the front end of the inspection lid. Well I had to glue it in or it would fall out because the bonnet just didn't reach it to hold it in place. Chas

-

Fighting Transmission to get in Gear

+1 on Leons post. Does it grind into reverse? Isit worse when the engine/gearbox are cold? It could be the gear oil you're using is too thick. That should improve once the oil has reach normal operating temperature. Chas