Everything posted by EuroDat

-

Pushing for more HP on the L28

Hi @280zxSpectrum Don't be too offended by the comments on this forum. It's just some members having a little fun. It's known as "posting to a zoombie thread". I made the same misstake on another forum and the admin, name starting wit T and ending with D gave me a trashing. Anyway, welcome to the club. Once you get use to us, some of us can be a little like the two old guys in the muppets, you will be fine. I see on your profile you are a brewer. Hobby, boutique of commercial brewer? Just being curious, I work for, dare I say, Heineken.

-

Unidentified part after removal of front supension

-

MIRROR FINISH ON PISTON WALLS

Yeah, That is the thread alright. I remember first reading it about ten years ago and made a copy for my own use, just can't seem to find it I have not found anything serious dating before this thread. It looks like this might be the first seriously thought out explanation. @siteunseen Thanks for posting the link.

-

MIRROR FINISH ON PISTON WALLS

Yeah, I like his fix for the idle. Attack the AFM with a dremel to increae air flow at idle. And then fix the next problem you created when the AFM vane drops to low and cuts the fuel pump....

-

Barefootdan's 280z Build

Yeah, I got that too. Kind of doctor Jekyll and mr Hide theme. Sorry officer, I just lost control for a minute. Not the car, just lost control of myself.

-

MIRROR FINISH ON PISTON WALLS

I remember a guy on Hybridz that did a lot of testing and wrote an instruction on how to tune the standard L28 efi system. His conclusion was the standard efi manifold was your biggest challenge to improving the horsepower performance. He measured the internal diameter of the runners and his conclusion was the runner were somewhere around 55% of the intake valve. The N42/47 being maginally worse than the P82. The turbo manifolds being slightly better. I don't think he was saying the efi system was not tunable, just the intake manifold was already at its limit and would limit the benifit of any "more than moddest" modifications. I think he went by the naame Braap on Hybridz, but it's going 10 years back. I think I coppied the tutorial he wrote. I'm on holiday atm, can't seem to find it on my tablet.

-

MIRROR FINISH ON PISTON WALLS

Im 100% with dutchzcarguy. It looks a lot like reflection and hone cross hatch and that is a good sign. If you can't see any vertical scores in the bores, it shouls be ok. Nissan had a good reputation with the iron they used in the blocks.

-

1983 280zx Flooded so bad it wont start. ECU compatability, Diagnosis and fix.

We were in North Italy around Lucca, Siena Pisa etc in October for two weeks. We decided to jump in the car drive down and book B&B's or agriturismo's. Great time.

-

Front Sway Bar End Links....Too Short

I had the same problems with my energy suspension poly bushings. My solution was a block of wood cut to length and wedged between the body and the swaybar. The top nut was fastened a couple of turns and then I used a jack to push the control arm up and compress the bushes enough to fit the lower nut. The photos might make it a little clearer🤔

-

Which Clutch Slave Cylinder To Buy?

If you can push it in and let it go. If it iscoming back out and pushing against the fork than it is functioning perfectly. I mentioned this test earlier. I am not sure what you mean by this: Please keep in mind that the engine is not in the car at this time, so that eliminates any issues with clutch, etc.

-

280z Bumper Conversion: Who Kept 280z Lower Valence?

Sean is using an extended 280Z grill and an aftermarket 240Z air-dam. If you want to use the original 240Z valance it will not fit. The center section should go under the radiator body frame, but with the lower 280Z radiator body frame it is impossible. You can see on the last photo Sean's Air dam top section of the air gap is in line with the top section of that body frame. The extra lip on the air-dam drops down enough the cover the frame from visability. It is not an original 240Z valance. That is why I used the 240Z air-dam and extended a 240Z grill by adding 2 extra horizontal bars. The air-dam I chose still needed some relief along the back edge to clear the 280Z radiator body frame. Keeping the origjnal indicators or using the 240Z indicators under the bumper is personal preference. I fitted a 240Z valance to mine, but the ceter section would not fit. See photo. The yellow line is where the center section bottom edge would hit the frame. Unfortunatly I don't have any photos of mine attempts to hold it in place.

-

1983 280zx Flooded so bad it wont start. ECU compatability, Diagnosis and fix.

Not wanting to read it all again😨. To sum it up. The engine ran so rich it flooded with the 83 ECU. It runs well with the 80 and 81 ECU' s, but to use them you need to add dropping resistors to the injector harness. Grannyknot. I think there are two kinds of flooded in the story, but I could have missed something on the way.... Interesting about retrieving the 80 ECU from a ZX that was in the river flood zone and therefore several periods under not so clean water. After cleaning it ran the engine.. Try that with a modern ecu. Ofcourse we are comparing analog to digital.

-

Which Clutch Slave Cylinder To Buy?

What do you mean by "push rod still makes contact with the lever"? 1. Is the pushrod loose at all or is it under tension? 2. Can you push the pushrod into the slave cylinder? Have youchanged the clutch recently? Could be an issue with the pressure plate and throw out bearing collar height. Because the internals of the slave cylinders are different, The none adjustable version has a longer piston and a shorter pushrod. It's only a couple of mm so the adjustabie pushrod should compensate. Still if the piston is bottoming out you could shorten the pushrod by cutting more thread to give yourself more adjustment or shorten the pushrod. If the pushrod is under tension you can shorten the rods travel. I would meassure the fork and slave cylinder with the rod in place. Remove the rod (re-mount slave) and measure again. That will give you the over tension. You will need to shorten the rod or cut the thread that much plas 10mm to get an adjustable situation. Remember when you are finished adjusting the rod. You can push (slowly) the clutch fork into the slave cylinder about 5 - 10mm and the internal spring will push it back out and take out any free play within 1 or 2 seconds. It moves slowly due to the small port in the master cylinder.

-

Parts Wanted: 280z stock right front lower valance

Hi John, I will call the guy I gave my valance panels to. He is still building his 280 and as far as I know he decided on a air-dam and has not used them.

-

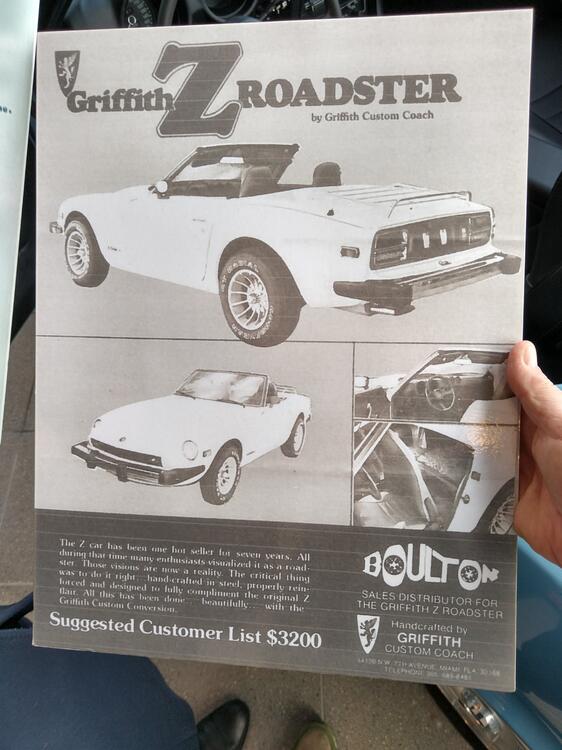

1978 280Z FACTORY convertible!! Looking for some info

This 280Z roadster turned up at a local classics dealer. It's a Griffith convertable. Asking big bucks for it..... €69k It seems like a rushed build. No boot and the convertable cap is thrown under the rear lid. I wonder how you get to the rear taillights to replace the bulbs etc? Griffith custom coach also converted the 280Z bumpers to the 240Z style. Insteresting how they left the 280Z rear bumper gap shield. Like The design looks a little rushed. There are 39 photos on the ERclassics website and an article in Autovisie.nl but not one photo of the undercarrage and required reinforcing. I should have taken some when I was there, but the sales rep rushed over to what het thought a potential buyer (me)..... €69k uuummm don't think so. The front is a simple job of removing the old 280Z bumper and fitting the 240Z bumper. It looks a little odd with the big air gap under the bumper. https://www.erclassics.com/datsun-280z-1977-d9195/

-

Which Clutch Slave Cylinder To Buy?

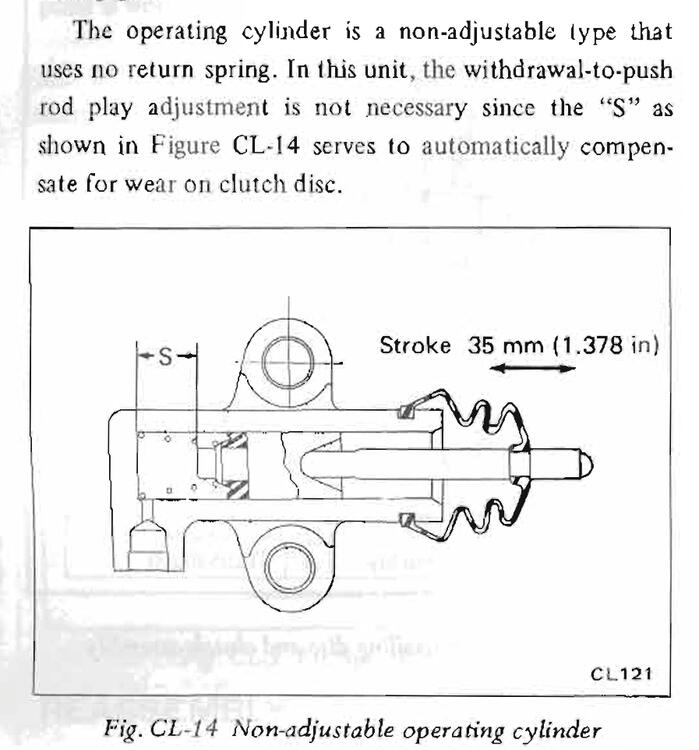

Zedhead is corect. They changed the slave cylinder somewhere around July 72. All the manuals after that will have the not adjustable type slave cylinder,but it could have a different figure number. The 240Z 73 manual has this figure nr. CL14. And the 260Z shows this diagram with fidure nr. CL16 Reading my step 4, I will changed the text to avoid any confussion later. The objective is to remove any play in the mechanism, but not to completly compress the small spring. When you adjust the push rod to remove all the free play, turn the nut another 1 to 2 turns and lock it into postion using the lock nut. Then check you can still push the push rod into the slave cylinder about 10mm (distance "S"). The distance "S" will reduce with clutch plate wear.

-

Trying to source 280Z tail lamp assembly

Yes, It's easy to remove with hot tap water. Just hold the assembly under the kitchen tap for a minute or so and the white glue will let go. I have photos somewhere. Ill post them later. I made my amber replacements 4 or 5 years ago and I think I have some of the first examples. They are not perfect, but if someone wants to try them you can have them. I just need to find them.

-

280z Bumper Conversion: Who Kept 280z Lower Valence?

After some searching finally found his thread. It was 6 years ago..... I could remember the build thread well, because we were both going through the same drama purchasing really crappy bumper brackets and then making our own. In the photo the two identical bars go from the mounting points for the old lower two bar grill. The big bracket is in the center section. You can read all about it in his thread.

-

280z Bumper Conversion: Who Kept 280z Lower Valence?

Oke guys. There is a guy on this forum (or he was, he sold the car shortly after completing the build) that had the same high air speed deflection issues with the Xenon pu air dam. It was a white 280Z and he fixed the problem by making several brackets to support the lower lip and that connect to the old lower grill mounting points. It might offer a solution to your problem. Just can't find his build thread. The clearance issues with the 240Z valence is not the 280Z bumper shock mounts. It is the lower frame section that goes under the 280Z radiator. The center section of the valance goes under the frame on the 240Z, but the 280Z is about 50mm lower than the 240Z valance panel.

-

Putting in a replacement L-28

Hi John, Your wiring harness looks great. Top work. Can you give some tips on how you went about it? The car is coming along great btw🏆

-

Dumb Question: Are Fuel Dampers adjustable?

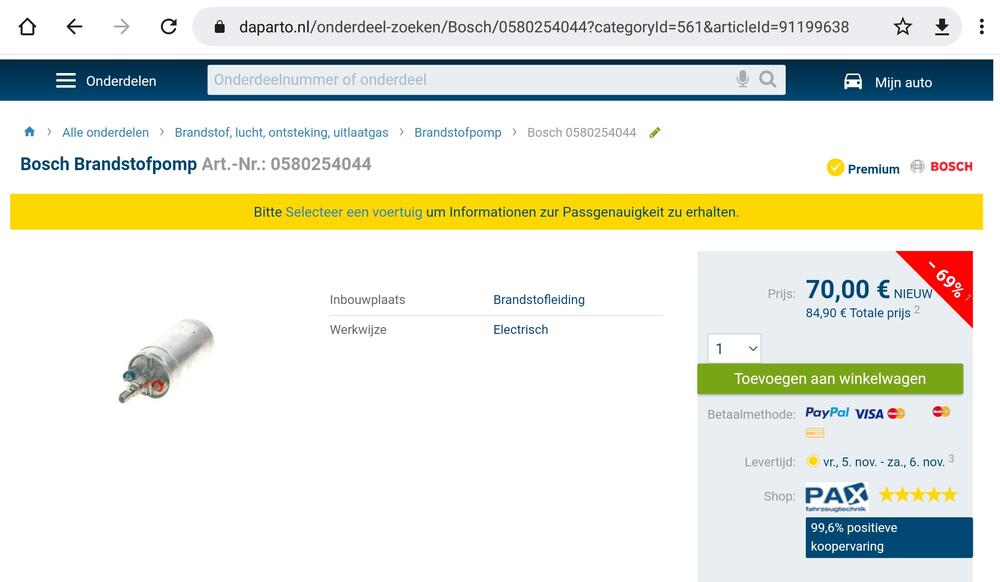

I don't know of any flow rate test in the FSM, but I made a simple write-up when I was having trouble with my EFI fuel system. There is a simple flow test in it. The document is in the Knowledgebase section on this site. I haven't checked, but there could be something on the atlanticz site tech tips section. There is a lot of info on that site if you brouwse through it. It's easy to come across something and forget where you read it. Looks like the OP has a Bosch 044 or similar aftermarket fuel pump. The 044 is a very good alternative to replace a defective original pump. It's also the pump Bosch reccomends since theis original pump is NLA You can find them from €70 upwards. Back in 2017 I paid €35 * €4,95 shipping.🤔 That is inflation....

-

280z Bumper Conversion: Who Kept 280z Lower Valence?

Skillard make excellent grills, but you need to know what end result you want before ordering. You have quite a thew options to play with.

-

280z Bumper Conversion: Who Kept 280z Lower Valence?

Hi John, Just reading your remarks on the 240Z valence. The outer sections of the 240Z valence bolts up no problems. The problem is the frame under the radiator. The frame protudes about 25mm under the 240Z valence center section because the 280Z has a larger radiator. To make it more challenging, the valence normally goes under the support. I played with the idea of cutting out the section of the valence panel around the frame and buying a BRE spoiler and fitting that to hide the frame. In the end I went with the 240Z spoiler, because it had a smaller gap under the bumper and had a little extra ground clearance. If you want more photos, I can post them. Sorry mate, gave the valence to another member 3 or 4 years back. Wish I didn't. I haven't seen that member since and he didn't even say thanks🤔. I think I gave the bumper ends to Bruce @Captain Obvious so he could play with them.

-

280z Bumper Conversion: Who Kept 280z Lower Valence?

I was all over the place when I started. First tried a 240Z valence, but it is way to high and does not clear the 280Z frame under the larger radiator. Ended up going with the 240Z fibreglas air dam because it is stiffer and self supporting at high speeds. The Xeon PU air dams tend to fold up under the bumper at high wind speeds. You can solve that problem by adding brackets to support the lower edge of the air dam. The 240Z version which will need some trimming to fit the 280Z. No big deal and easy to do at home. See Airdam-2 & 3. The grill is a modified 240Z / 280Z combination with 9 bars instead of the original 240Z 7 bar version.

-

280z Bumper Conversion: Who Kept 280z Lower Valence?

I did it in the beginning, but didn't like the protruding valence under the bumper. I'm with @cgsheen1 on the looks. I decided to go with the 240Z air-dam and 240Z indicators under the bumper.