Everything posted by EuroDat

-

5 speed transmission grinds on reverse when I pull it out of 5th gear. Why?

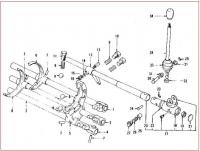

Your problem is caused by a worn, broken or missing detent spring on the bottom selector. Its POS#9 in the attachment. You should feel the detent working when it centers in the neutral section of the gate. Its easy to check it with the transmission still in the car. There are two plugs on the side of the metal centre section. The bottom one is for reverse/5th. Check the spring and ball are in good condition. You can also compare it with the one in 3rd/4th which is the top plug on the side. 1st/2nd is on top and hard to get out while transmission is in the car without a magnet. If the gear shift doesn't pop over and line up with 3rd - 4th then it will be the centre return spring POS#26 in the attachment. Chas

-

Steam Powered Z???

I agree, but the N47 head will mean you need another header. N47 has round exhaust ports and N42 square. The N42 has better chambers and if its still got the silicon/bronze seats they will need changing. Another common change is to go to the P79, shave it 2mm, use the N47 valves and shim the cam towers. The P79 seems to have less problems with cracking. Chas

-

Clutch making crazy loud noise

The bearing are pre-lubricated with high temperature (HT) grease from the factory. The HT grease is the difference between the Series I and the bearings after. The series I had normal grease which could stand up to 65 to 80degC. They would overheat if they had were constantly rotating. To adjust them you simply tightened the slave push rod using two 12mm spanners and vice grips until all play is gone and then back off the nuts 1.5 to 2 turns. I don't think you have a bearing with normal grease. I don't think anybody makes throw out bearings with normal grease anymore. If your bearing was making strange noises since install, it might be a defective bearing from the start. Chas

-

Clutch making crazy loud noise

Your model 240Z should be a series III or series IV. The throw out bearing keeps contact with the pressure plate. The slave cylinder should not need adjustment providing you have the corract pressure plate/throw out bearing collar combination. You should be able to push it 5 - 10mm back into the slave cylinder. One thing to note: When an engine is on a dyno its no leisurley drive. The engine works hard and probably beyond what you do on a typical drive. That also goes for the drive train, but I can't see how that would effect a throw out bearing. Another thing to note is that when you disengage the clutch, you will push the crank forward. The number 4 main journal has thrust washers to to counter act this movement. Highly unlikly, but the noise could be coming from there. Oh and Fast Woman is right. Make sure its safe to work on. Hand brake on, Wheel chocked and someone that can follow directions and stay away from the gearstick. Chas

-

Clutch making crazy loud noise

Sounds like the throw out bearing is gone, going from your description. Its always rotating (with exception of the series 1 which has the spring return to release the bearing) and if the bearing starts to seize it can make a lot of noise when depressed. If it gets bad enough the tight bearing will even start to spin on the clutch fingers. That can damage the pressure plate fingers as well. You shouldn't wait to long in changing it. You can try this to determine for sure. Warm it up and raise the car so you can get under it. If you slide the clutch fork dust cover back and run the engine. Get someone to lightly press the clutch pedal you will hear is better. Also push the clutch fork into the slave cylinder to release the bearing completly and you should hear it change in pitch (check the clutch master has enough room for the fluid). You can then play with the clutch fork pushing the bearing onto the pressure plate to hear what the bearing is doing. If its only a year old you will hear it contact the pressure plate, but its bearly noticable with the engine noise. Chas

-

Replaced Steering Rack Bushings

Thats a lot of movement in the old bushes. Can understand why you didn't have much feel in the steering. Must of felt like steering boat. Must feel like a new car. Chas

-

Just ordered my Rebello 3.0, now what

Ouch, sorry I mentioned it now. I don't how he could not see if it was a 240mm. How hard can it be to measure a clutch disc? Chas

-

My Project Z.

WOW That drivers door took a hell of a hit. Hope you got out of it ok. Thats Lessons learnt the hard way. Chas

-

HellFire Status & release date annouced

My two are now right in the middle of it. Nice to hear everything is going well. Looks great. Chas

-

280Z Full Restore in 5 months, hopefully.

I used a 2k ohm pod from Alpha p/n; B2K. Its adjusted to about 1000ohms. RV16AF-10-15R1-B2K Alpha (Taiwan) | Mouser Chas

-

HellFire Status & release date annouced

Our first child was a breeze. He slept through after the first week. the second was like WOW, is there only one of them. Thats when we dissappeared for about two years. our two kids are 15 months apart, wasn't intended just worked out that way. Lenny seems to have vanished the last couple of weeks. Hope everything is going ok and he is just too busy and lack of sleep. With a bit of luck Captain can get in touch and you will have your AFM. Finger crossed. Chas

-

280Z Full Restore in 5 months, hopefully.

I made mine with enough cable to tweak it in the cabin until it seemed right. After that I mounted it along the fuel rail. This pod is a 5k ohm unit I had a 20k ohm, but it was a little course and harder to fine tune. Chas

-

Clutch/Tranny Noise

It could be loose pressure plate bolts, Ive seen that on another car (not a Zed) and it made a similar noise. That clutch was replaced 2 years before and came loose over 30k km. The throw out bearing is also a possibility, but a failing throw out bearing generally makes more noise when the clutch is depressed. Either way, you will need to remove the transmission to find out.

-

280Z Full Restore in 5 months, hopefully.

You can use a similar gauge to the one in the fuel system to get an idea what the pressure really is. Or remove the sender and test it with a air and see if the gauge is moving accordingly. The gauges in the dash are not all that accurate and the oil pressure indicates 0 to 90 and no makings between. I agree with Blue, it seems high for idle. Chas

-

280Z Full Restore in 5 months, hopefully.

You might want to change to the high volume oil pump from the 280ZX turbo. Its a bolt-in upgrade and will help maintain pressure at idle.

-

Some funny wobble in my steering... Input??

When you get the new tyres, tell the tyre shop about your vibration and ask them to check the wheels for runout on their balancing machine. Its a simple check to do and will eliminate the wheel as a source of your problem. You didn't mention if you have alloy wheels. If you do have alloys, check the the wheel nuts don't have too much clearance around the shank of the nut. Too much clearance and you can tighten the wheel out of centre and cause vibrations. Although such a vibration will get worse with speed. Good luck with it. Chas

-

280Z Full Restore in 5 months, hopefully.

Good to hear you got it sorted out. Sounds great on the vid.

-

My Datsun 280Z "Rustoration"

That stuff certainly cleans up the insulators well. Impressive results. Love the neat yellow zinc:love: Mine were too far gone to do anything but replace. Since they are NLA, I ended up making them. With a little bit of trial an error the results look great. First trail runs: Chas

-

Just ordered my Rebello 3.0, now what

Their is a guy on zcar.com parting out a 280Z 2+2 if anyone is interested in a 240mm flywheel. Parting out 1978 280Z 2+2 - Nissan : Datsun ZCar forum :Nissan Z Forum: 240Z to 370Z

-

My Datsun 280Z "Rustoration"

Top quality workmanship and plenty of bling bling. Your Zed will look better than when it rolled out the factory.

-

Fuel Rail Question/cant get it started

Hi Jimmy, Some how missed your posts on the compression test 0-5psi. I find it hard to believe its the rings considering it ran for a period. Are you sure the guage is ok? Have to agree with Mark on this and wildman's advice is spot on. Squirt some oil in the cylinders and do the test again, if its rings the compression should jump considerably. I would do some more investigating before giving up on this engine. Another thing to remember when doing compession test is to hold the throttle full open. That way the engine can breath and get a fuul charge of air. What ever you do, make sure you repeat it for every cylinder. Most pressure test gauges are not that acurate and can read 150 when the pressure is 170psi. More important is that all cylinders are close to the same pressure. Chas

-

Making Fusible Links

Zed beat me to it. If you deal with electro motors, you can get up to ten times the current when they start up from rest. Its only a very short time, but its enough to blow a set of noraml fuses. In that case the fuses are "Slow blow". Google it and you will find all kinds of info on them. I think modern cars use them on the primary circuits. You generally find a couple of 80amp fuses, which are most probably slow blow to cope with surges. Like Zed Head mentioned, calculating the size fuse required is the problem. Chas

-

Modernized Z Shape Project Revived

WOW. Apart from being gob smacked and thinking what a slacker I am for doing so little on my Zed the last three years. I was wondering where does he get the time to do all this. Oh now I remember, he has been at it since the ninties. Talk about dedication. Its one of these projects that defies all logic and most would have "thrown in the towel" long time ago. I remember the thread on CarDomain and he memntioned he was going to lower the floor to get more head room. I wonder if he is going forward on that idea or shelved it?

-

240z Brake bleeding issues. Faulty master cylinder?

Your welcome. Only thing is none of us mentioned the two causes that gave you this problemLOL. They have been suggested before, but not in this thread. Glad to hear you solved it. Now you can enjoy the summer driving safely. Chas

-

Swell!!....

I can think of three, just from memory. The one on the alternator. Another is located near the voltage regulator, A/C relay under the metal bracket the fusable links are mounted on. The third is mounted on the coil and has two wires coming out of it. I have seen a thread here from a member in Italy and he thought it had 6 or 7, but I can't find the thread right now. There could be more under the dash, need to dig through the manual to find out. Chase