Everything posted by EuroDat

-

Prop shaft and half shaft phasing

Back in 2016 we had a similar discussion about propeller shafts and half shaft uni-joints. Might be helpfull to link it here. U-joint cap diameter: Propeller shaft 240Z/260Z: 25mm Propeller shaft 280Z: 22mm (Rockford type 430-10) Halfshafts: 28mm Steering column 280Z (Staked Dia:15mm x39mm)

-

Prop shaft and half shaft phasing

The tolerance is 0 to 0.02mm If you can get the circlips in without forcing the circlips in willbe OK. A little tap with a screwdriver to send them home is normal. To measure the tolerance, tap the yoke with a hammer like in figure PD-2 in your post nr.7 to pusn ghe caps ouf against the circlip. The 240Z used the same uni-joint in the half shafts and propeller shaft. The 280Z used a different staked non replacable uni-joint in the propeller shaft. That might be while some manufacturers are quoting only the half shafts or propeller shaft.

-

Prop shaft and half shaft phasing

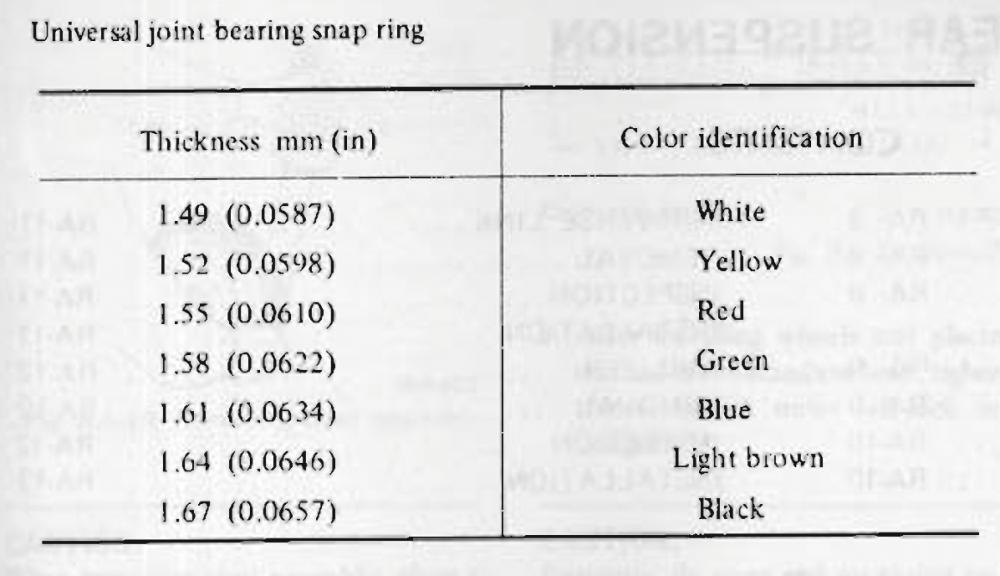

I'm not sure what you mean by phasing the the propeller shaft or halfshafts. The half shafts yokes should be in line, but that is very visable if they are not. The main source of vibrations after changing uni-joints is the tolerance in the uni-joint. The uni-joint should have 0,02mm endplay. This is important to keep the shaft centered and balanced. Nissan make 7 different sizes (1.49 to 1.67mm) to calbrate the tolerance to the correct specifications. This could be your source of the vibration.

-

Barefootdan's 280z Build

Another thing to ask when you contact the head rebuilder. Ask him which model the valves are designed for. If he is a Datsun head specilist he should know the difference in valve stem lengths and probably not an issue. The L28 was used over a period of 8 years in the Z & ZX, but with different head combination. The N42 and N47 heads had valves with 2mm longer valve stems. These valves are often used when people shave 2mm of the later P79, P90 or P90a heads. These valves eliminate the need to shim the cam towers. 280Z 75 - 78 & 280ZX 79 to Jun 80 with NA engine had the longer correct valve stems. 280ZX Jul 80 to 83 NA and all torbo engine had shorter valve stems and will need larger lash pads.

-

Barefootdan's 280z Build

SBI is a well known valve seat supplier. I think you would have to special order brass inserts. More than likely he used steel alloy, but would be good to check. If you have braas inserts, you should use an additive to extend the seat life. Sorry if it sounds like I'm nitpicking, but now he knows exactly what he did. If you call him over a year, it could be a best guess response.

-

Barefootdan's 280z Build

You have done a wonderfull job bringing the engine literally back from the dead. The workmanship looks good and he shimed the towers, so he knows what needs to be done when you shave the head. I would still have a few questions for the head shop. He replaced three valves (inlets on 5 & 6 and exhaust on 6) with a completly different aftermarket vavle. The form could change your compression ratio. The originals cost $20 each through nissan. Why did he use those after market vavles? Are you sure he used brons seats? Maybe brons guides? Brons seats don't work well with todays fuel. The L28 changed over to steal alloy seats in the N47 to run unleaded fuel. The lead "lubricated" the valve seats and helped transfer the head. The brons P/N:11098-N4200 and steal alloy P/N:11098-N4210 seats are interchangable. It could be a cost factor that made him just replace what was needed with brons (3x $22) as to replacing all seats (12x $18). I would not grind the scratches away. Grinding them away will could alter your compression ratio and with the different valve head shape? You can use a scraper to remove the burs, I wouldn't do any more than that. Looking forward to seeing this project progress.

-

Zx 5 speed rebuild

I wouldn't weld it. It could make the chipping worse. The chips are not as bad as I thought they were. I assure I have seen worse and they worked fine for thousands of miles without giving any trouble. The most I would do is clean them up a little with a dremel grinder. Be a little carefull using reverse and definitely don't try pulling it into reverse while the car is still rolling forward. The most probable cause of those chips is people hitting reversewhen they come outof 5th to go back to 4th. It tends to happen more when the selector bushes are worn. That is why they added the reverse lockout in the later version of the FS5W71B and C transmissions.

-

Zx 5 speed rebuild

That is unfortunate. Good you checked that before ordering the parts. I was hoping the slider would match, but that kit is for a C version and later versions seem to have "improvements" that look very much the same but not... Can you post a couple of photos showing the chipped section of the idler gear? It's is good to check if they are just chips and not shattered. From what I remember it wasn't that bad so it should clean up ok.

-

Zx 5 speed rebuild

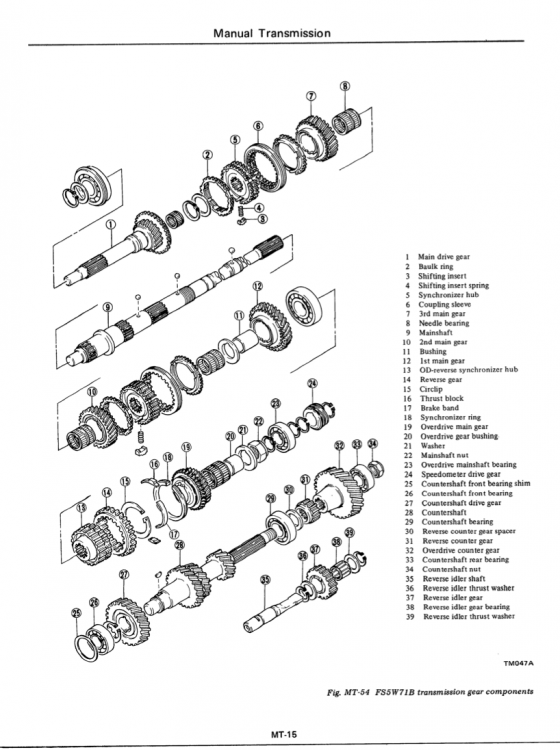

I corrected that in my FSM and posted it in a thread here somewhere 3 or 4 years ago. The problem I had was the original document has a password. I could not change it or add any comments. To get around that I printed it and scanned it in. The only problem with that is you loose quality of the whole document or increase file size considerable just to fix two diagrams (this one and another on the following page). Thinking about it, I could make it a supplement document with just those two pages. Then you can download the two MT documents and if you decide to print them, simply replace the pages.

-

Z's on BAT and other places collection

Lol. That was, is @bartsscooterservice

-

Cody's Goon

Well Charles. Hat off to your paitence and soldering on. If it was me I think I would have invented a thew new words in the process. The end result looks great.

-

Zx 5 speed rebuild

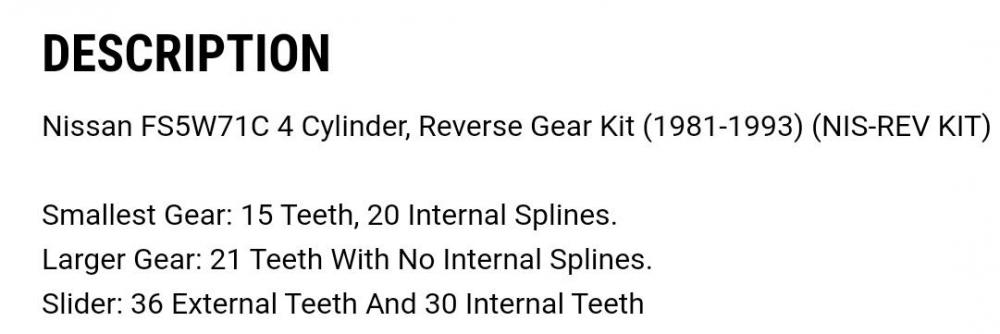

An alternative could be just replace the complete reverse gear setup. The kit for the 4 cylindrr FS5W71C uses a 21T reverse idler, so you will need the slider and cluster gear. Complete for US $79. I'm almostcertain the splines on the cluster and the inner teeth on the slider are the same on the 71B and 71C, but just to be sure, count the the inner teeth on the slider and the splines on the cluster gear. https://cobratransmission.com/nissan-fs5w71c-4-cylinder-reverse-gear-kit-50042095-1 The other alternative is to have the teeth ground down and de-burred/rounded, but it is a lot of work and will cost more than buying another set with a slightly different ratio.

-

wide ratio FS5W71B slipping out of 3rd & 4th

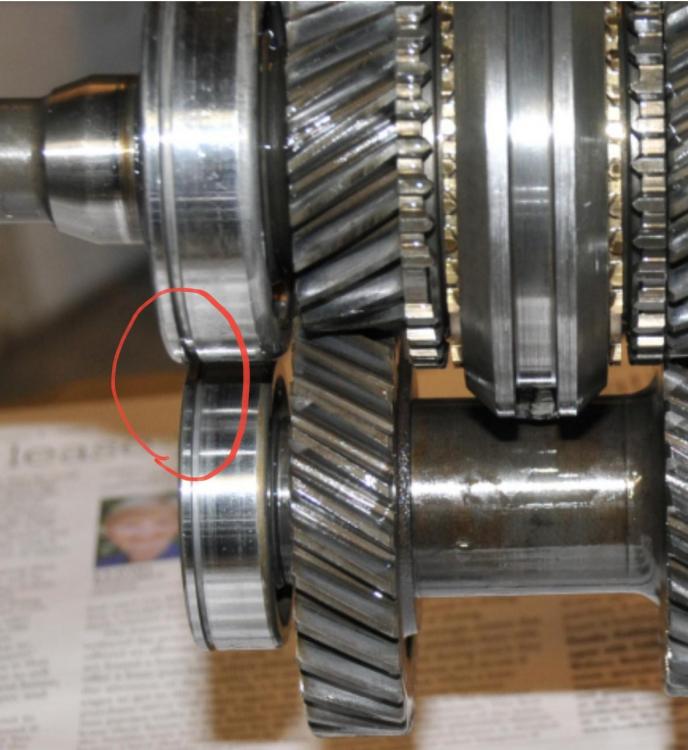

Looking at your photo. I see a Circlip between the input shaft bearing and gear. I shouldn't be there. It should be on the outside of the bearing. Gear - Bearing - Spacer ring - circlip. See exploded view pos#1. The circlip between gear and bearing will push the bearing out too far and the bearing cover will then push on the outer circlip and the input shaft will bind up on the main shaft. The input shaft is held in position by the circlip on the outside of the input shaft bearing. It has absolutly no pre load and without the circlip, you can push it into the gearbox a mm or so. Check this before you fit the bearing cover. This is important otherwise the input shaft will bind on the main shaft and the metal filings will damage the needle bearing and the synchro on 4th. The bearing on the counter shaft should be up against the cluster gear shoulder (the circlip holding the gear in place is a little further along the shoulder) and the bearing should protrude just passed the circlip groove on the input shaft bearing. See input and cluster shafts photo. Follow the steps Zed Head posted the determine the shims needed. The bearings don't require preload. That will destroy the counter shaft bearing in the adapter plate, but too much end play will create slack and clunking as the counter shaft moves back and forth from engine load to no load. Take your time to get it right. If you are new to these transmissions the FS5W71B manual is not your best friend. If in doubt keep firing questions at us.

-

Shifter Rattle

Yes, 240mm has the 9 bolts. The fandanza flywheel is for both 225 and 240. I think the difference in the 240mm clutch kits is the 280Z/ZX 2+2 and the 280ZX Turbo. The 2+2 used a 71B wide ratio gearbox and the Turbo used the BW T5 and clutch disc to suit.

-

Suspension Cleanup and Refurb

I think there are some minor casting differences between the 240Z and the 260Z/280Z calipers, but they all use the same revision sets, brake pads and the pistons are the same. With the pistons and brake pads being the same, you should not have any issues using any combination of calipers. Aftermarket kits have the sealing ring between the halfs, but Nissan does not supply them. Same for the chewed up bolt holding the two halves together. If you want to rellace it you will be in the aftermarket parts. Nissan reccomends replacing the complete caliper if you need split then apart for any reason.

-

Shifter Rattle

I went for a standard 280zx 2+2 clutch and a lightened flywheel out of the same car. That gave me a normal clutch peddle feel, but with a heavy duty clutch. I think the Fidanza is about 11lbs compared to 23lbs for the original 225 and 240mm flywheels. The Fidanza will be touchy off the mark. My flywheel is about 16lbs, but the 240mm clutch is a little heavier than the 225mm. It doesn't add any horsepower, but certainly adds to the driving pleasure.

-

Shifter Rattle

Btw. The brass bushes will rattle if you have play in the pin. That is why I don't reccomend them. If you are doing anything with the selectors, I would change the checking springs (32831N) and the seals. The oil seal and o-ring in the speedo adapter. Basically all the seals and o-rings would be on my list. You might want to give the transmission a bearing kit. That would be the time to do all the seals. Like Dave said, check the play in the rear bush before you do anything with the transmission. Nissan don't sell them, but you can order a replacement through Omega Machine & Tool p/n:71411. The problem you have with getting into reverse in most probably a blunt reverse idler geer. They tend to wear round over time. Have you tried going to neutral , releasing the clutch to spin the transmission and then try reverse again? If you disengage the clutch and try reverse straight after, it might chatter a bit while going in, but it should go in every time. That test will confirm a worn idler gear.

-

Shifter Rattle

The seal that is leaking has part nr. 32850H (32858-U6702) and only costs a couple of dollars at any nissan dealer. Bad news is you will need to drop the transmission and remove the rear extension housing to get to it.

-

Shifter Rattle

A couple of things can be the source of your rattle. Unbalanced drive line components like the propeller shaft, a flywheel/clutch group or even a failing bearing in the transmission. Worn out engine and transmission mount don't help either. The end result is anything with excessive tolerances will rattle. Your gear selector being a prime example. The two bushes for the selector locating pin and the cup on the end of the selector should be replaced. That should fix the rattle.

-

Cut open and reweld fuel tank?

I have welded three tanks in the past and never had any explosions etc. My advice. You plan to POR it afterwards and that is what I did on all three tanks with a similar treatment. The tanks needs to be cleaned before you coat it, if you do that first you will, 1. Clean and prep the inside of the tank, 2. Remove all fuel residue so you can cut it open without any danger to yourself. Just make sure the cleaning solution is water based. My second piece of advies is to cut a section out of the top of the tank directly above the damaged area. Make it big enough so you can get good access to the areas needing work. A weld repair on the top side will not be visable later and less likely to leak if you have a pin hole.

-

wide ratio FS5W71B slipping out of 3rd & 4th

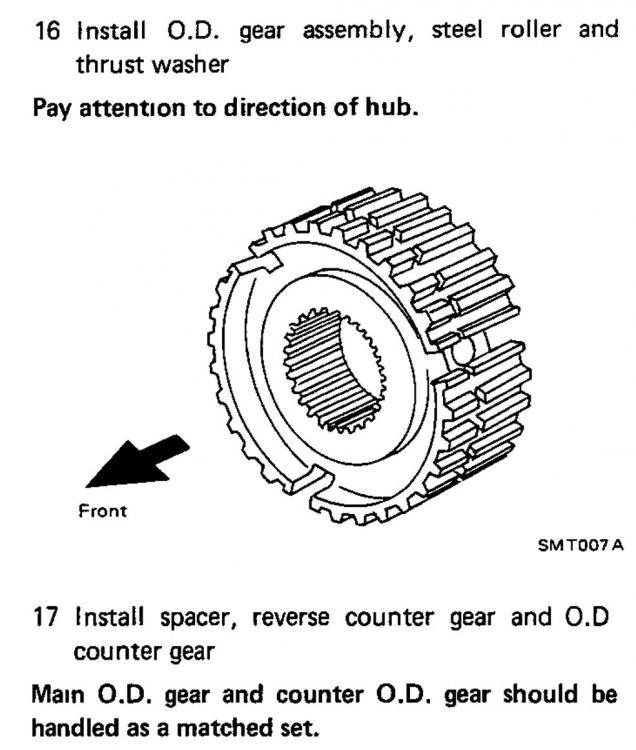

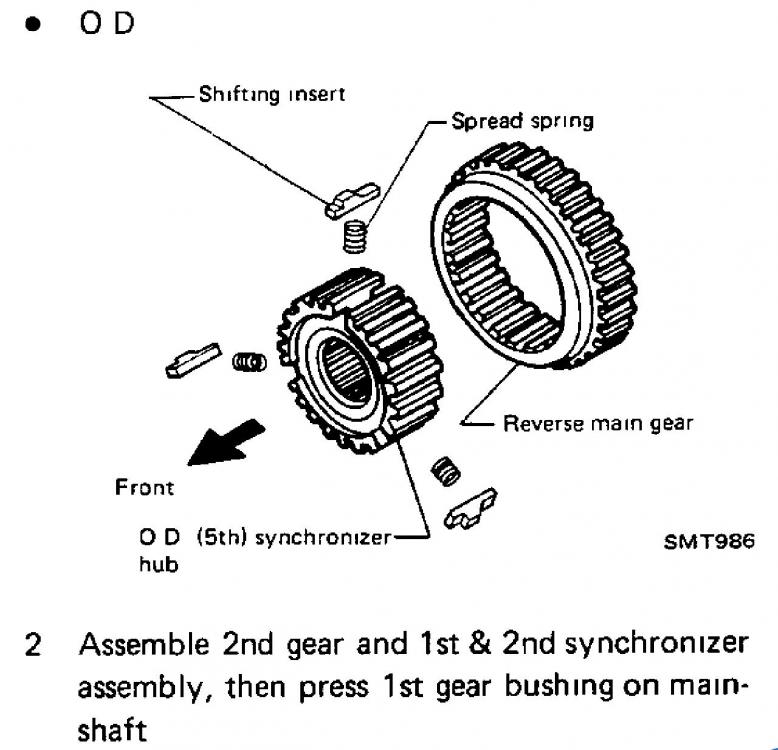

It doesn't matter. Those sreenshots are from a latter edition manual. You can see that SMT986 doesn't have the groove, but it is the same manual. That is what I meant by the manuals came be a little confussing sometimes. Especially when you are in doubt and come across different pictures of the same item.

-

wide ratio FS5W71B slipping out of 3rd & 4th

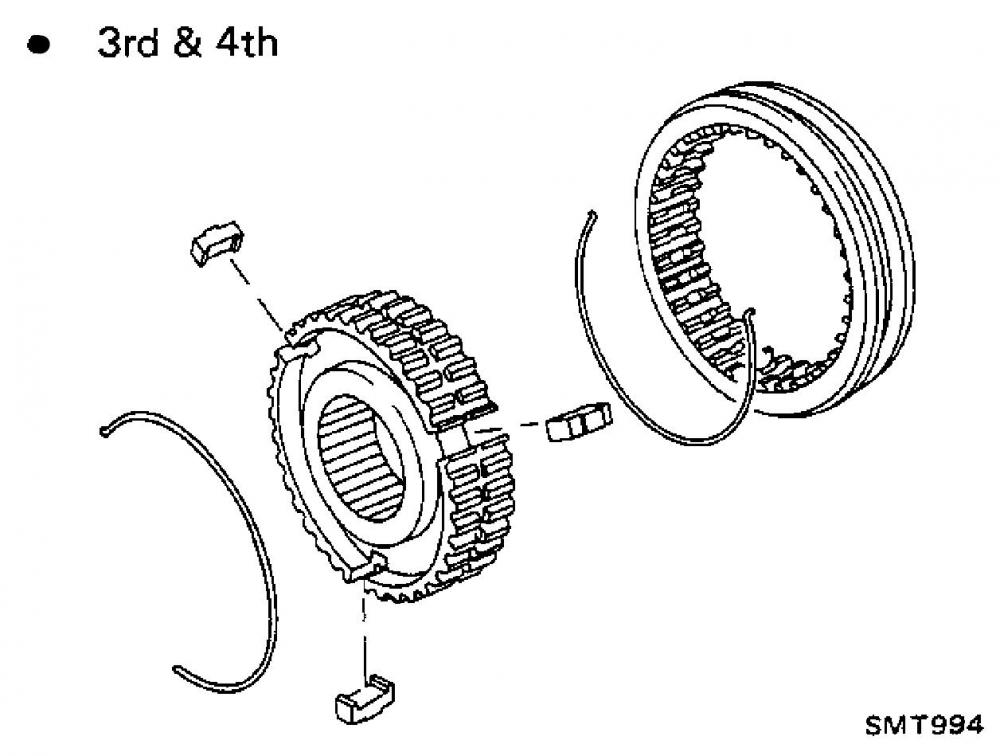

On the other side of the adapter plate you have 1st and 2nd gear. 1st gearhas one of those locking balls too. Are you sure the ball is located properly in the thrust washer between 1st gear and the adapter plate? Something between 2nd gear and the 5th gear hub is taking up too much space. The other thing you should check is the shifting insert on the 5th hub. They can be fitted back to front. The shifting inserts are not like the others on the other side of the adapter plate. It will fit both directions, but it will only work one way. Unfortunately the 280Z and 280ZX manuals are as clear as mud. The long section should face towards the rear. Check the hub is fitted in the right direction. It will fit both ways, but only one aay will work. That can cause your problem. I think I would pull it back out of the adapter plate and do a quick check on 1st and second gear just to be sure. I included a shot of the 3rd/4th hub so you can see the difference in shifting inserts. On 3rd/4th they can be reversed without causing any problems

-

Sabine schmitz died, only 51 years old after battle with cancer

Very sad day indeed.☹️

-

Can Anyone Identify This Part?

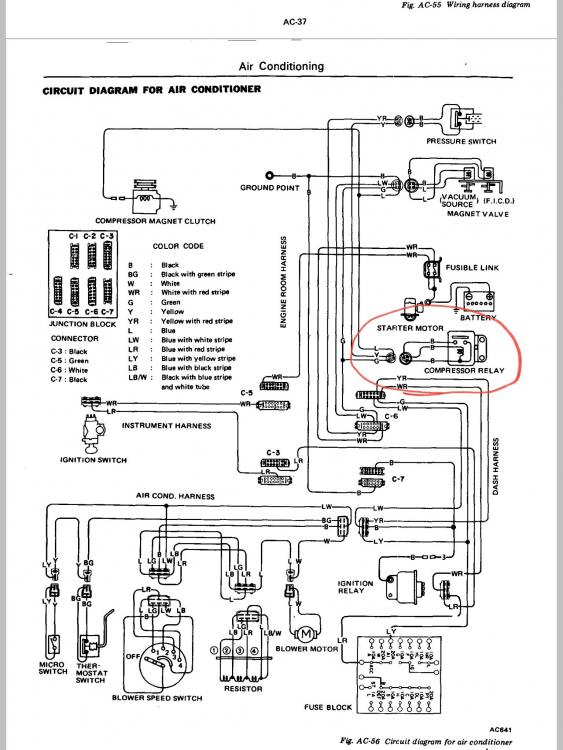

If you are not concerned about keeping it original, than you can use any stanard relay. The relay isceasy enough to test to see if it is working properly. If you look for one in a junkyard, you will need the model 280Z up to August 77. After August they changed the relay connector plug to a rectangular 4-pin connector. It does the same thing, but it has two power supply wires were the early version with round connector has one power wire and it is bridged to the relay coil internally. I hope that makes sense...

-

Can Anyone Identify This Part?

It is the 280Z air conditioning compressor relay.