Everything posted by EuroDat

-

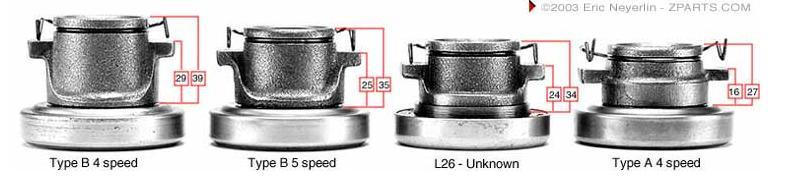

Clutch fork throw

If you order the collar, it should be the matching collar for the pressure plate. Unfortunately most parts stores don't know this and do not offer the option with the collar.

-

Clutch fork throw

150mm is way to much. It's an easy misstake and happens a lot. The aftermarket industry make one type of pressure plate, but in the S30 series Zeds they had 4 different heights over the years. Each type had its own matching collar. The bearing and fork have the same dimensions.

-

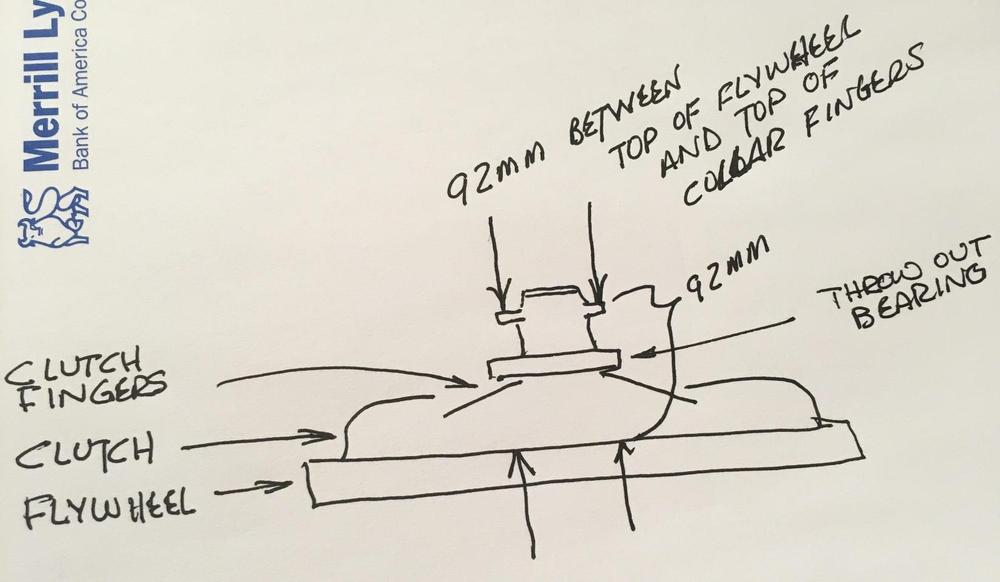

Clutch fork throw

If you pull the clutch fork back until the throw out bearing touches the pressure plate fingers and then measure the distance away from the front of the bell housing, you should measure about 115mm give or take a couple of mm. If you read more, then you probably have a mis match pressure plate / throw out bearing collar. If you measure the height of the pressure plate and throw out bearing, they should add up to 92mm. You will need to dismantle the transmission for that.

-

New mustache bushing updates?

What about the steering column coupling. That has been NLA for years, 10 years at least. Trying to find a NOS or near new condition example is like trying to find a wholly mammoth. http://www.carpartsmanual.com/datsun/Z-1969-1978/steering/steering-column/28

-

280 crank pulley

M6x1.0 bolts. IIRC You will only get 4 or 5 turns into the pulley before it bottoms out against the timing chain cover.

-

New mustache bushing updates?

We are talking about replacing the original bushing with something that has similar characteristics. We know the PU aftermarket bushings transfer a lot of diff noise to the body so making any bush out of PU doesn't seem to has any advantage. I have made PU insulators for the fuel lines and other stuff for my own 280Z, but getting it to hold to the metal components enough to take the stress would be hard to achieve. It would need to be a part from another car with a similar purpose. For example the original positon for the bolt was in the vertical position, otherwise it would probably fail quickly due to stress it was not designed for.

-

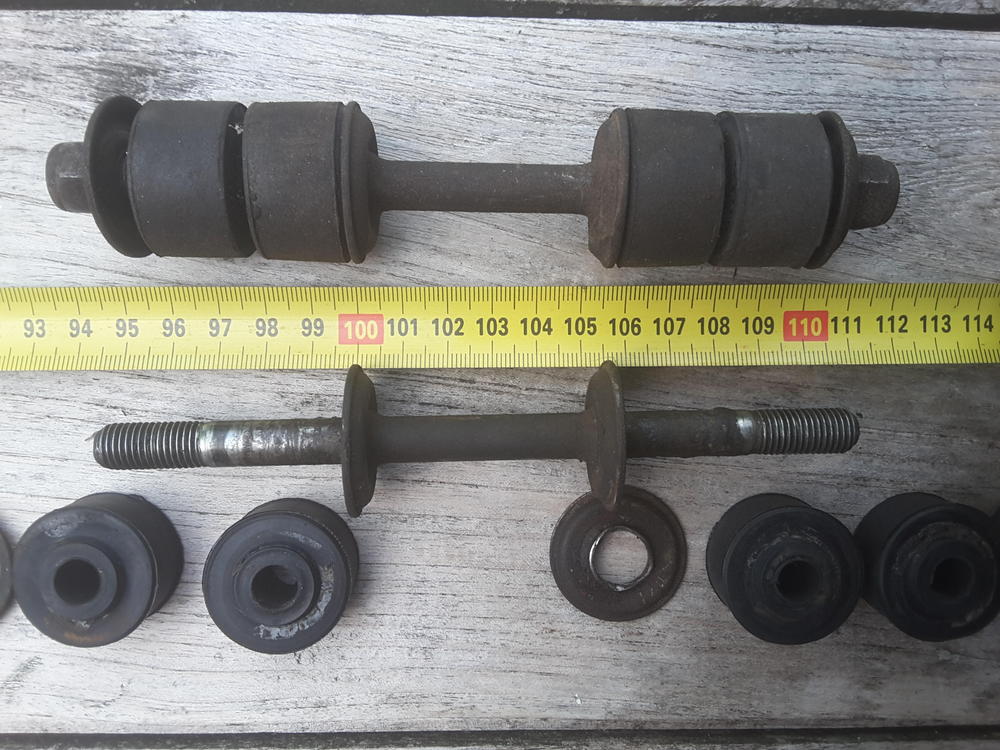

Stock Sway Bar End Link Length

I have a set spare thatcame off my 280Z. The spacing is 55mm. Total length is 158mm. Is that what you mean?

-

New mustache bushing updates?

I did a bit of searching and found the thread on the mustache bars where I had downloaded the photos for the 280Z bushes a couple of years back. . The thread was about the bushes and possible alternatives. @kats posted a lot of photos of all the different variations he came accross on page 2. These is also a tool on page 3 made by a someone back in 2011 to flare the outer ring over the mustache bar

-

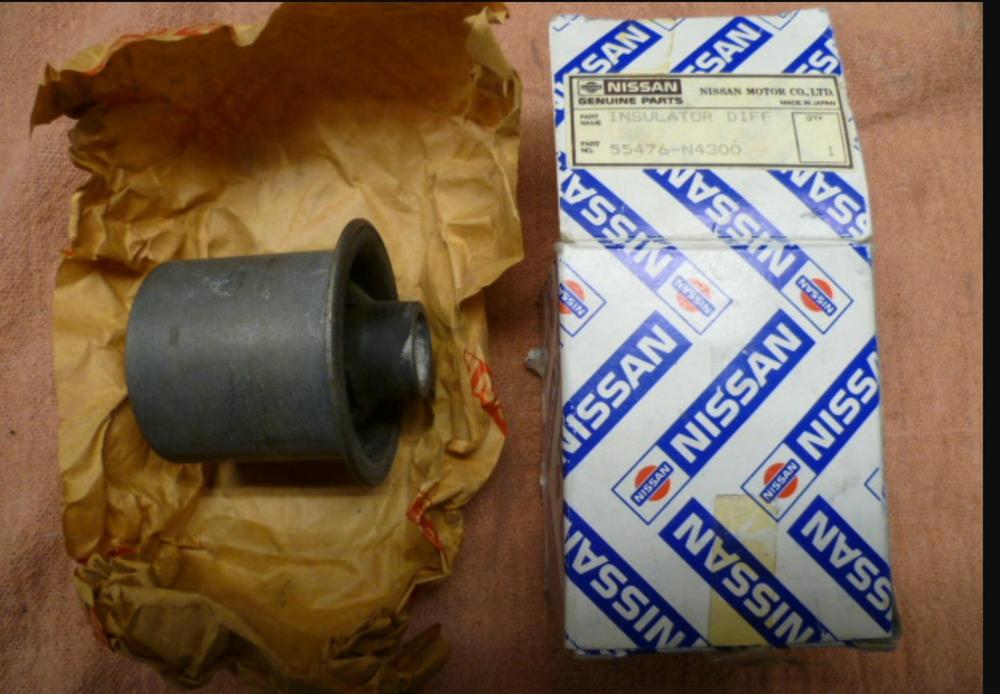

New mustache bushing updates?

I think they started making for a time, but they stopped about ten years ago. Here is a photo of one and the box with part number.

-

New mustache bushing updates?

They are the correct part numbers. The top serrated washer is flat and the lower serrated washer is slighting concaved.

-

New mustache bushing updates?

I don't understand what you mean by pointing inwards. The outer sleeves on the original bushes were flared over the mustache bar, unless someone replaced them in the past and didn't flare it properly. Can you post a photo?

-

A/C Idler Pulley Rebuild

The other thing you might want to know is the nut flats are 14mm opposed to the standard M10x1.5 nuts with 17mm flats. 17mm should still clear the bearing. The flat washer also has a small outside diameter OD: 16mm, ID: 10.2mm, thickness 2mm. The spring washer is normal size.

-

A/C Idler Pulley Rebuild

The nut is a M10x1.25. The pitch is fine compared to the normal nuts (M10x1.5) you will fined in a hardware store. You best bet would be an autoparts shop or machine shop. You could ask a garage is you can hunt through a nut and bolts tin.

-

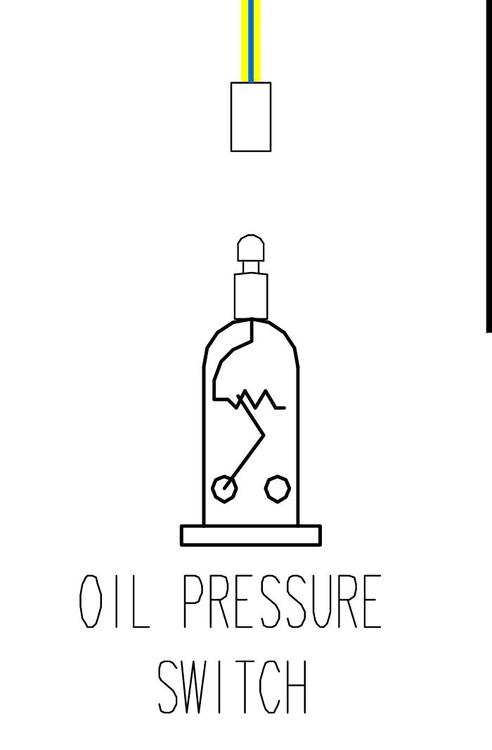

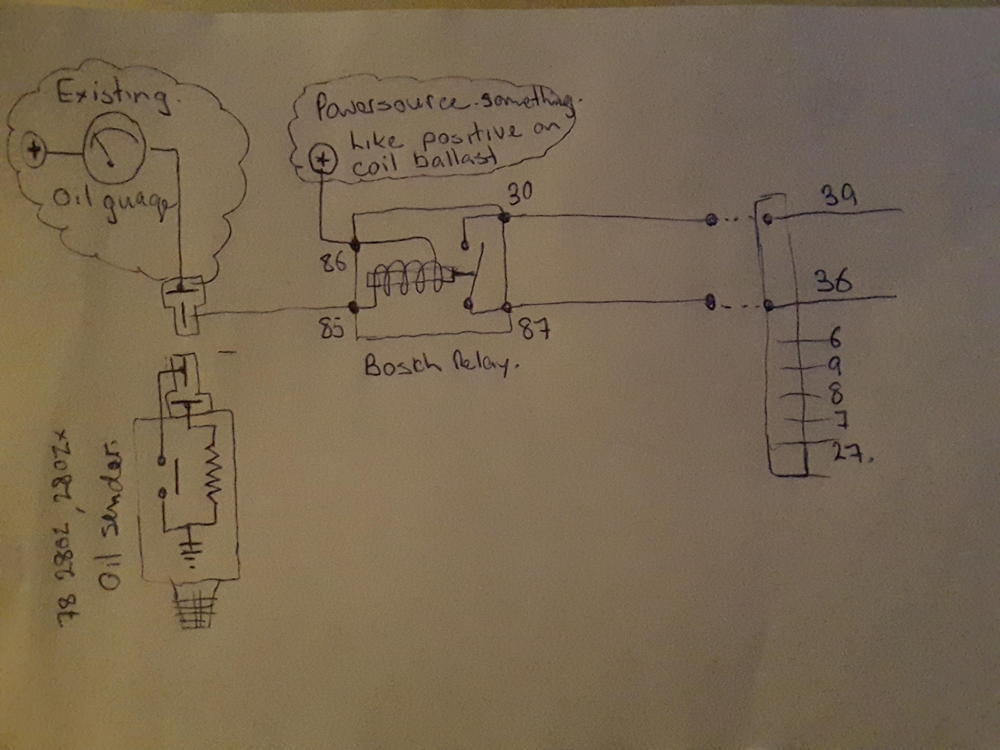

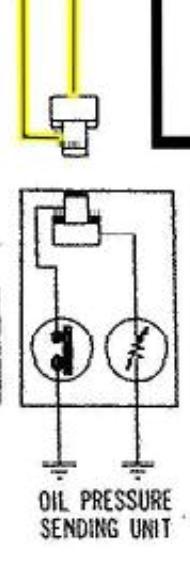

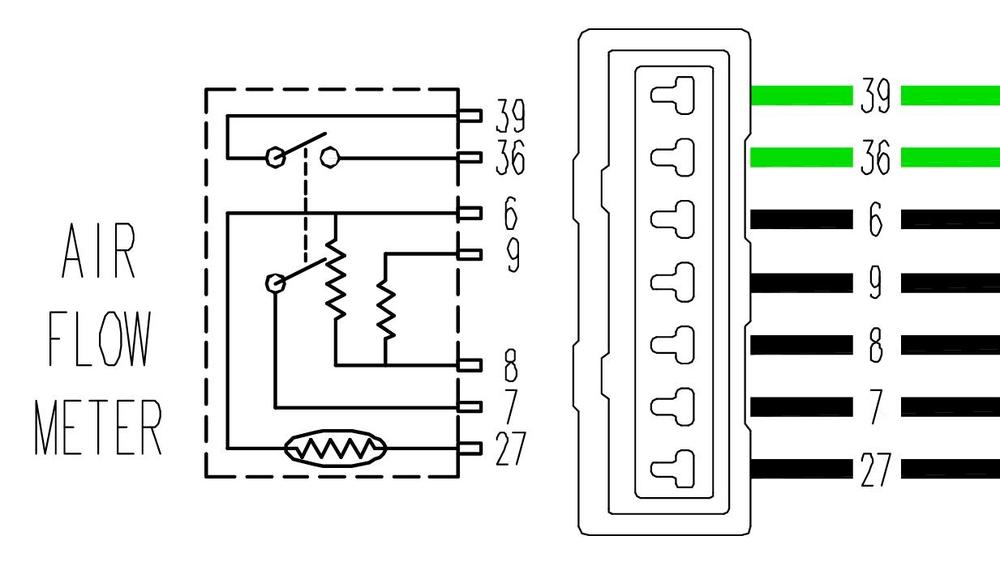

AFM/ Fuel Pump

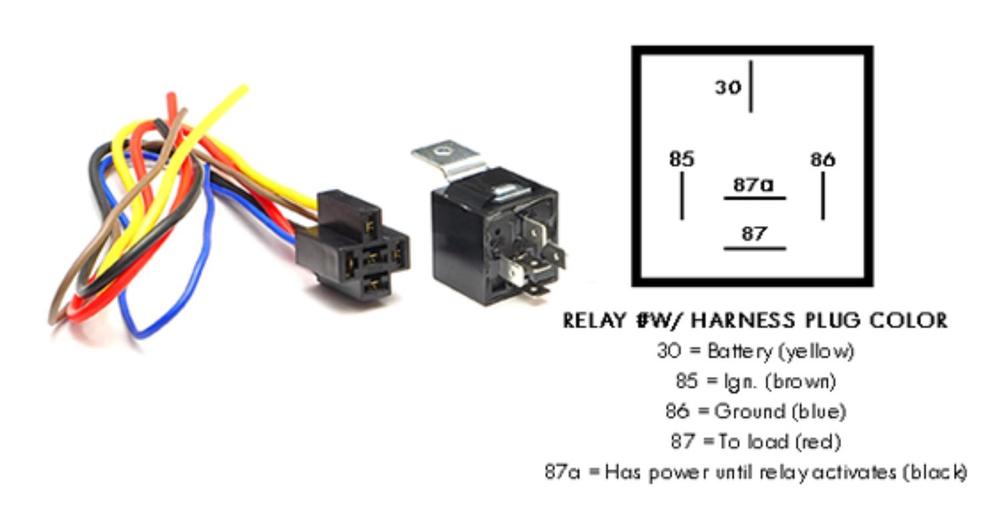

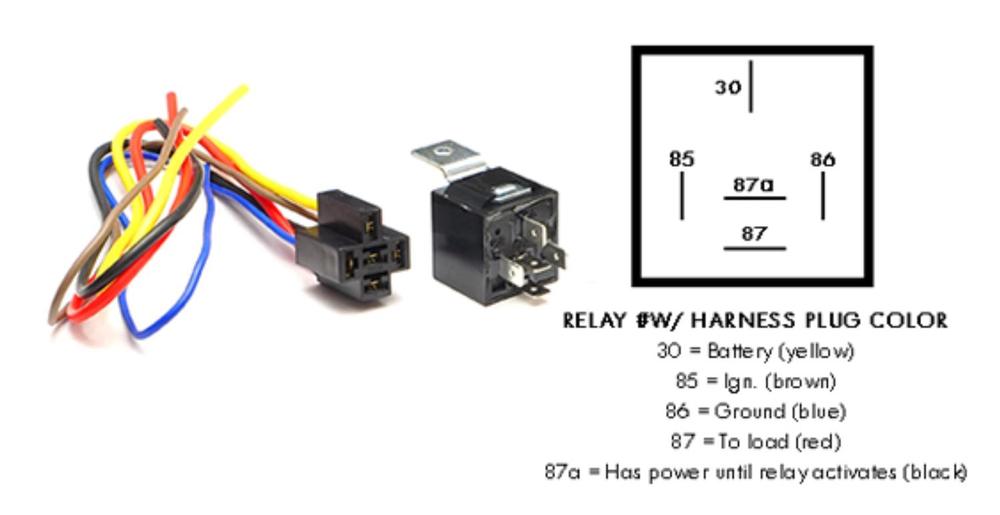

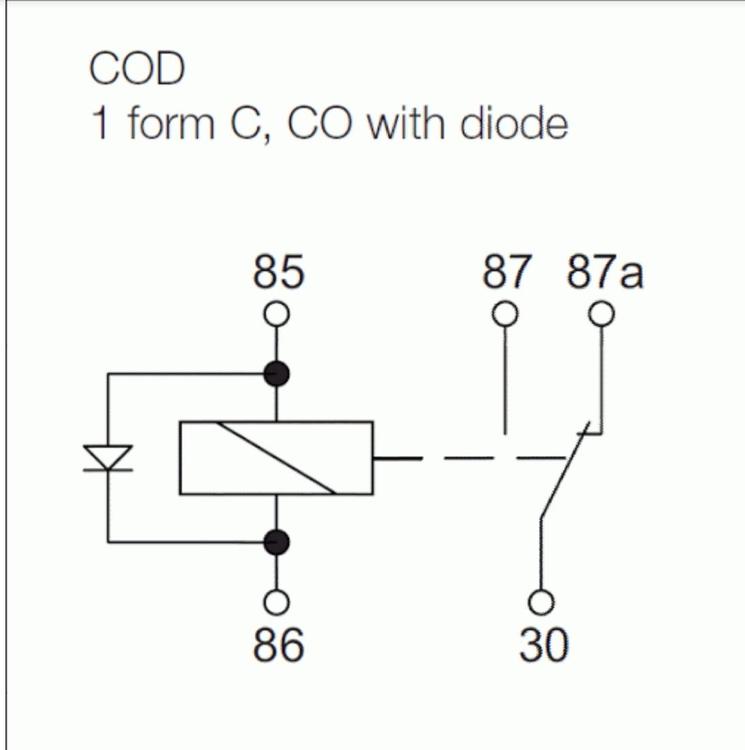

Hi Doug, Wire the relay as follows. Relay terminal nr. 85 (Brown) goes to the positive side of the ignition coil ballast. Relay terminal nr. 86 (Blue) goes to the oil pressure switch. See photo with red circle for correct terminal. (Vertical terminal in "T" figure layout) Relay terminal nr. 30 (Yellow) can go to terminal 39 in the AFM harness Relay terminal nr. 87a (Black) then goes to terminal 36 in the AFM harness You will then need to re-connect the oil sender' remaining terminal to the original wire (Yellow/black) going to the oil guage.

-

AFM/ Fuel Pump

If you look at yhe circuit diagram here, the terminals form a "T". The vertical spade terminal will go to the switch. The other horizontal spade terminal will go to the guage. You need two spade terminals on the oil sender. They are two completely different circuits with differant functions. Yes the oil sender goes to ground through the threaded section. @Zed Head could be right. I'm not 100% on the 78. Mine is a 77. If that is true, instead of using the 87 terminal you can use the 87A terminal on the bosch relay.

-

AFM/ Fuel Pump

The first option is what you want. Replace the bullet with a insulated spade terminal. Use another spade terminal to ground the relay. You need the 78 oil pressure sender for this. The oil sender has one terminal with a varible resistance to ground which is determined by the varying oil pressure. The other spade terminal is a switch to ground and closes when the oil pressure reaches a determined set point. It is a safety feature. If the engine stops the pressure will drop and stop the pump.

-

AFM/ Fuel Pump

Btw. The terminal 87a is not used. Just fold that wire back over itself and tape into the harness.

-

AFM/ Fuel Pump

It doesn't have to be a Bosch relay. Any 5 pin relay will work. Easiest is to buy one with the harness plug. The relay in your screenshot will work, no problems. They call them bosch style relays, not necessarily a Bosch manufacured relay. https://heielectric.com/shop/electrical-products/relays/5-pin-relay-kit-12v-30amp In this example the 30 (yellow) would go to your trrminal 39. The 87 (red) would then go to terminal 36. The 85 (brown) would go to the ignition coil power and the 86 (blue) would go to the terminal on the oil sender. I would mount the relay close to the AFM , somewhere between the AFM and ignition coil. That way the wiring will be as shorg as possible and only one long wire to go over the engine to the oil switch. A 30A relay is overkill, but that is standard issue. You are only bridging the 36/39 terminals to activate a coil in the EFI relay very similar to the coil on the 85/86 terminals.

-

Help identifying 5-speed

You didn' circle all the important bits to determine it's a close ratio, but it a close ratio.

-

AFM/ Fuel Pump

If you still have the original oil pressure sendrr for yhe 77 it will have one wire. You can connect it to the 78 sender by swapping the wire terminal to the spade type. I made a simple diagram to explain it better.

-

AFM/ Fuel Pump

The fuel injection relay is a complicated unit and has safety features which you should not bypass. Simply bridging the 36 & 39 terminals in the AFM is not a good idea. An easy way to fix it would be to use these wires to activate the pump thruogh the original efi relay. Basically if air flows thruogh the AFM these contacts close and allow the pump to run. Terminal 36 needs 12 volts to do this. I would use an oil pressure switch from a 78 280Z, 280ZX or 84 maxima. It has a sender unit plus a contact to ground. You could find one in a junk yard or buy a new one. Use that to activate a bosch relay coil 85 & 86 and run the AFM 36 & 39 terminals through the bosch relay 30 & 87 terminals.

-

r200 pinion nut torque

Just seeing this thread. No howl, look like you nailed it. Pre load is done by shimming between the to pinion shaft bearings. What ever torque you put on that nu won't, or shouldn't change that. Changing the seal shouldn't effect the patern anyway. When you start changing bearings and stuff, that is when you run into trouble.

-

5 Speed Transmission inspection and possible rebuild.

The last transmission I rebuild was leaking from the o-ring. It wasn't dripping on the floor, but it did attract a lot of dirt and grime. Like Dave said, if you don't see any oil around the shifter, it should be ok. Unfortunately you can not replace them with the transmission in the car. The othrr thing I would like to mention regarding oil leaks around this area is the pin that locks the stricking rod in place (p/n:32847 & 32847A). Use some sealant to cover the end. It won't leak much, but it can attrack dirt and grime around that area.

-

5 Speed Transmission inspection and possible rebuild.

You are right Dave. There is about a mm difference in distance from the shank iirc so it should not be possible to fit it backwards.

-

AFM/ Fuel Pump

Could use a 78 280Z oil sender switch to activate a relay and the relay then bridges the two wires in the AFM.