Everything posted by EuroDat

-

Re Plating my horns

Yes. It has a thin "gasket" somewhee between 80graam and 120gram/m3 paper. I made a set out of 120gr, but it was a little thicker than the original. Plenty of rebuilds showing horn restoration, only problem is that the horn restoration is buried in the rebuild threads. Just need to be a little creative with google and search through the results.

-

Modern Relay replacements for 280Z Fuel Pump Control Relay and Electronic Fuel Injection Relay?

Just google Bosch 0 332 514 120 and you will find them for the Porche 912E, BMW's, Mercedes, Opels, Volvo, Peugeot etc. It will plugin and work perfectly.

-

280Z fusible links

A fusible link is designed to withstand an overcurrent for a short period of time before burning through where a fuse will blow very quickly at it's rating. They say that a fusable link is rated to about 4 gauges under the wiring it is protecting. Sizing a maxi fuse to compensate for the brief overshoot could result in a contant overload. Manufacturers do a lot of R&D when designing the wiringloom, but there probably is some room for "error" in the gauging of the wiring loom and the systems can be unbalanced these days with all the led lighting and lower current consuming accessories we can use. You could probably go under the original fusable link rating and not have any issues.

-

1973 240z Custom Wiring From Scratch

You might want to read the other thread Tamo had. He did more upgrades and included more photos of the voltage meter as well.

-

Chat GPT - AI Bot

School kids use it here to make their essays for school projects. The schools are having a hell of a time trying to sort out what is done by the students and what this bot has generated. Some things fail the test quickly, a little like the statement in the first post: In 1972, the engine was upgraded to a 2.6-liter unit that produced 162 horsepower and 157 lb-ft of torque.

-

Steering column lower u-joint replacement part

I used a piece of chisel steel in a press and staked it in between the original marks. It's not as easy as it sounds to replicate the original staking. The uni-joint will bind up and you will need to press the cups out a fraction to give them some clearance to move freely. I have seen someone tack the edge of the yoke with a mig welder. Concentrating most of the heat in the yoke. These uni-joints rotate at low speed so balance is not an issue.

-

Steering column lower u-joint replacement part

-

Looking for the Hand Brake dust boot replacement part

You will have trouble finding replacements and if you do it will be a pita getting them over the clevis. My cable is in good condition, but the rubber bellows are long gone. All the aftermarket products don't use the bellows type sealing, which I consider a better seal. They use a cup style cover the end of the cable sheath with a hole through it were the cable passes through. The twitched cable can pull road grime and water into the sheath and eventually seize up. If you do find a solution, I would like to see it.

-

1971 HLS30-14938 "Lily" build

Hi Bart, Is that the same company you used for the harness in your Mustang? Neat and clean harness in the Mustang. The one in the link covers a lot of models. S30 and the S130. Bold statement they are making.

-

1971 HLS30-14938 "Lily" build

My experience back in 2015. YES you need both ends of the connector. The VC connectors are the same, but diffrrent. If you know what I mean. I couldn't get the little bugger to fit (probably used other words at the time) and had to order the other side to match. Lucky I could order them through a local supplier Rick Donkers auto electrics. VC suggested him.

-

1971 HLS30-14938 "Lily" build

That is why it is very important to adjust pedal travel correctly. That valve has a necessary job when initially installing new components, clutch disc wear and eventual minor leaks. Poor adjustment leads to reduced clutch travel, which leads to poeple adjusting the pedal more to "compensate" for the reduced travel and the cry for help "my clutch won't disengage."

-

Yet another mustache bar bushing thread

Puzzling. Looking through the old thread that CanTechZ posted you can see the washers had slightly different functions in there design. The lower bush loks like it is still in good condition

-

Yet another mustache bar bushing thread

It's not original type. Could be a Nissan competitikn or an aftermarket " upgrade". What's the bush in the mustache bar look like?

-

Datsun 5-speed transmission question (FS5W71B)

Are you using the shifter stick from the F4W71B 240Z transmission or the one that came with the FS5W71B transmission? There are different lengths between the horizontal achor pin (with the two plastic bushes) and the lower cup bush that fits jnto the striking rod. If that distance is too short it can slipe out of the striking rod in 5th and you will experirnce what you are describing. If you look at the striking rod. The hole for the shifter is machined in a round striking rod. That means on the left and right side of the hole there will be a curved arch. This is where the cup can slipe out. I hope that makes sense..... This could be your problem.

-

2 piston front calipers on 77 280z

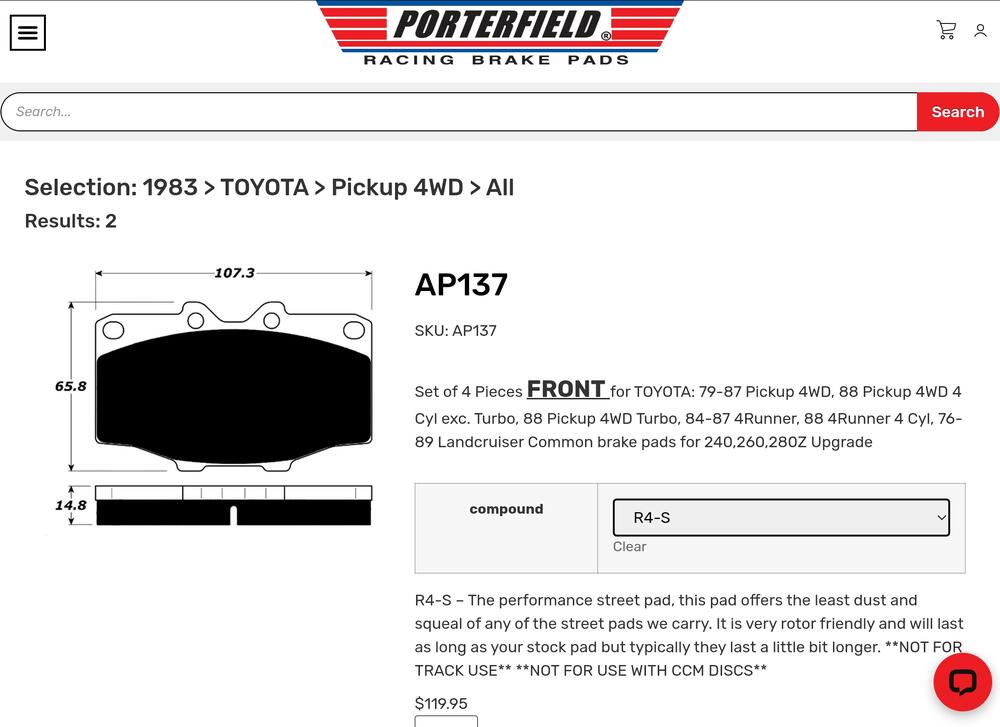

Another tip. Be carefull buying a replacement set. A lot of sellers really don't know what they are selling. You should look for the S12-8 system. Calipers are left and right, marked with a R and L. There should be two sized pistons. 2x 43mm pistons and 2x 34mm pistons. That is not a typo no matter what the sellers tries to tell you. 4x 43mm is the Wide version and won't work on the 10.5mm thick solid rotor. Buy a set of Porterfield pads R4-S brake pads. Well worth it.

-

2 piston front calipers on 77 280z

They are bolt on replacements/upgrades, but you will have a deeper brake pedal due to the extra fluid required in the calipers. That can be corrdcted by replacing the 7/8" master cylinder with a 15/16" 280ZX master cylinder. If you go to the S12W with the 4x 43mm pistons, you will need the vented discs and the 280ZX 15/16" master cylinder or the 1" Wiilowood MC. The 280ZX MC is slowly but surely becoming a unicorn.

-

2 piston front calipers on 77 280z

No. The link Steve posted is for the S12W calipers with the 4x 43mm bores and vented rotors. Your calipers in your post #6 are the S12-8 calipers with 43/34mm bores for the non-vented solid rotor. The S12-8 calipers are getting hard to find. S12-8 - 1984-85 Toyota 4 Runner and 1979-84 Toyota pickup S12W - 1985-95 Toyota 4 Runner

-

L20b Cody's Goon

Hi Charles. It's a little late, but the trick I use to drill holes through a head gasket or something similar is to sandwich the gasket between two 1/2" thick MDF blocks or similar. 1. First drill a 1/8" hole through the blocks and a 1/8" hole through the gasket where you want the new hole. 2. Push the drill bit through the first MDF block then through the hole in the gasket and finally through the other MDF block. 3. Clamp it all together with a bench vice or a pair of g-clamps. 4. Remove the 1/8" drill bit and drill it out to the required size. 5. Repeat procedure for each hole. Clamping the gasket between two pieces of wood stops the drill from chewing up the edges as the bit passes through. It might be handy for someone else doing this.

-

280z Rear Strut Spacer?

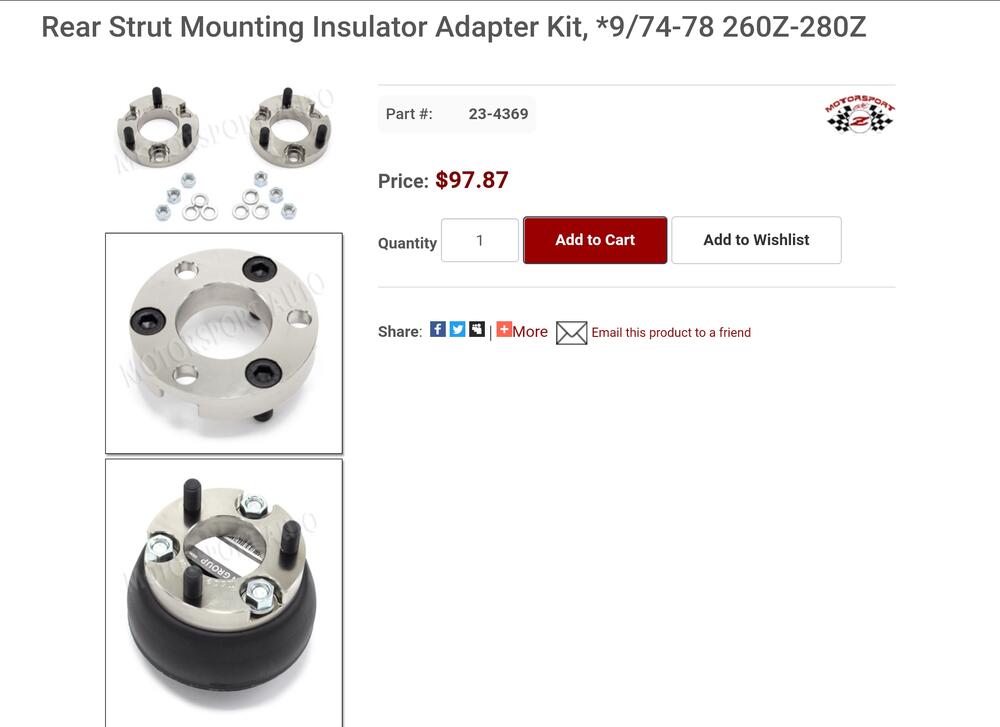

The rear spacers on the US 260Z and 280Z are 25mm longer than the 240Z. You can use the 240Z, but it will lower the rear by 25mm (1"). That spacer in the link will correct it. I was planning to lower my car by 1". To do that I want to use the 240Z insulators on the rear and lower the spring perch 1" on the front struts. Just have not got around to it yet. I have no idea why they increased the height on the US version 260Z and the 280Z.

-

240 Differentials

@Carl Beck website has a good overview of the diffs and ratios ued in 240Z through to the 300Z. Standard Differentials & Rear Gear Ratio's https://www.zhome.com/ZCMnL/tech/GearRatios.html

-

New to me, 280Z...

That can happen if the POR15 hasn't had enough time to harden before top coat. Like you said, It will be covered with carpet and barely visable.

-

New clutch issue 280z

This photo looks like it was taken with clutch disengaged (pedal up). Can you push the rod into the slave cylinder with the palm of your hand on the clutch fork? Is the clutch fork against the housing? Engine side of the fork hitting the opening in the bellhousing. You should be able to push it in some. Maybe 1/8" to 1/2". If not then there is your problem. Like Zed Head said, with the wrong throwout bearing collar the slave cylinder push rod will bottom out and not let the clutch fully engage.

-

280Z bumpers on a 280ZX?

I don't believe it will be an easy swap. I have not heard of anyone doing it. Noyt saying it's not possable, but I doubt it will be an easy modification. Which version of the 280Z did you have in mind. They came with two variants. 1975 to 1976 and 1977 to 1978. The most common bumper swap is the 240Z bumpers on a 280Z. That is a relative easy swap because both the 240Z and the 280Z are both S30 chassis variants. The 280ZX is the S130 chassis

-

Picked up a 73 240Z. Need help changing all the fluids

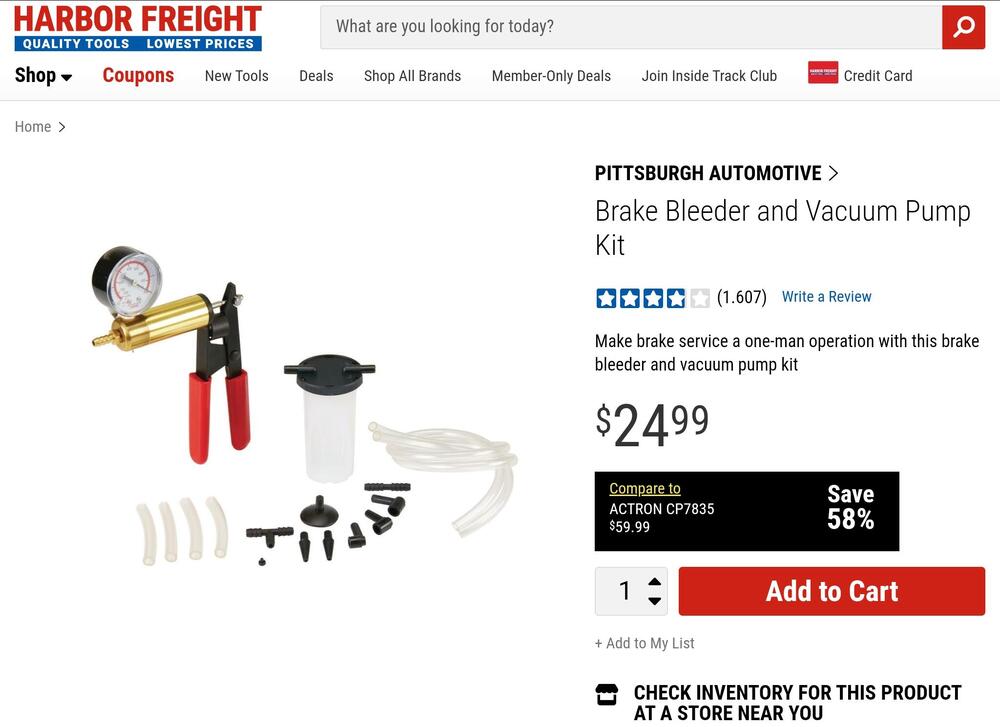

There are two ways you can change the fluid in the brake system. 1. Using the master cylinder / foot peddle method 2. Using a vacuum unit to refresh the fluid. I prefer the vacuum system because it doesn't require the master cylinder. The method using the master cylinder can damage the master cylinder rubber seals. The master cylinder normally only uses half its stroke and when you bleed the brakes using the master cylinder method you use the full stroke. Old fluid can corrode the cylinder section that is not wiped regulary by the seal. That corrosion can sometimes damage the seal when the seal goes full stroke.

-

Picked up a 73 240Z. Need help changing all the fluids

A couple of tips. 1. Before draining the transmission or the diff remove the filler plug first. Sometimes the filler plug is very hard to near impossible to remove. Once you drain the oil, the car is inmobile and all your options are gone with it. 2. Transmission: Try oil from AC Delco or GM. Yes, it does wonders on these old trannies. The part numbers are AC DELCO USA part number is: 88900399. GM USA part number is: 12377916. I can not order the GM or AC delco oil here in Europe. I'm using Redline MT 75W-90 and find it very good.