Everything posted by EuroDat

-

Found metal at the bottom of my 5-speed. What next?

You don't need to pull the diff out to check the ratio. You probably have the standard 3.54. The 280Z and 300ZX had 3.7 and later 3.9 in the R200. Its easy to check by turning the wheels like in the video. I like his method turning ten wheel revolution. You know the number will be a little under 34, a little over 35, 37 or 39 etc.

-

Found metal at the bottom of my 5-speed. What next?

Thats was my conclusion as well. The problem with the 620 transmission is it has a short rear extension. Well that is what I have read about them. The F4W71B was build for a 3.364 diff. That can explain why it uses the lower gearing. The 5 speed in the 280 wss for the 3.54 diff. The 5th ratio just doesn't make sense in you tranny. Something must have been changed somewhere in its life.

-

5 speed tranny, any ideas?

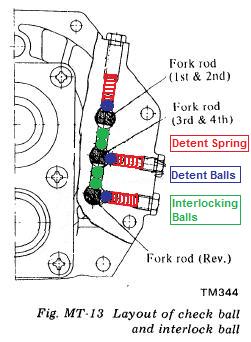

Hi Cliff. I have heard of the shaft nut coming loose, but I have never seen it happen (yet). Like Zed said, only way to fix that is to pull it apart. Before that I would go through a couple of easy checks first. You are now running a 5 speed in your 240Z, so things can be a little different. - Check the clearences around the selector. Its not hitting the tunnel etc. Wrong shape (S, no S bend) selector can cause problems. You have 72's (F4W71B) so it shouldn't be a problem, but shinning a torch up there will eliminate it. - Is the console and leather boot giving it enough room and not pulling it back? Remeber, the engine can twist things around a bit under load or clutch engaging and that in turn can reduce clearences. - Check the detent spring. Its the lower one of the three and easiest to check. I have seen one broken (not in a Zed transmission) and that can cause this too. The 5th hub clicks in and feels ok, but the detent is what holds it there. You can increase the tension with washer between the spring and cap. It can even be a combination of things. Worn detent spring, console pushing the selector and then clutch engaging. Those checks shouldn't take more than an hour. After that, its pull the transmission. Goodluck with it.

-

Found metal at the bottom of my 5-speed. What next?

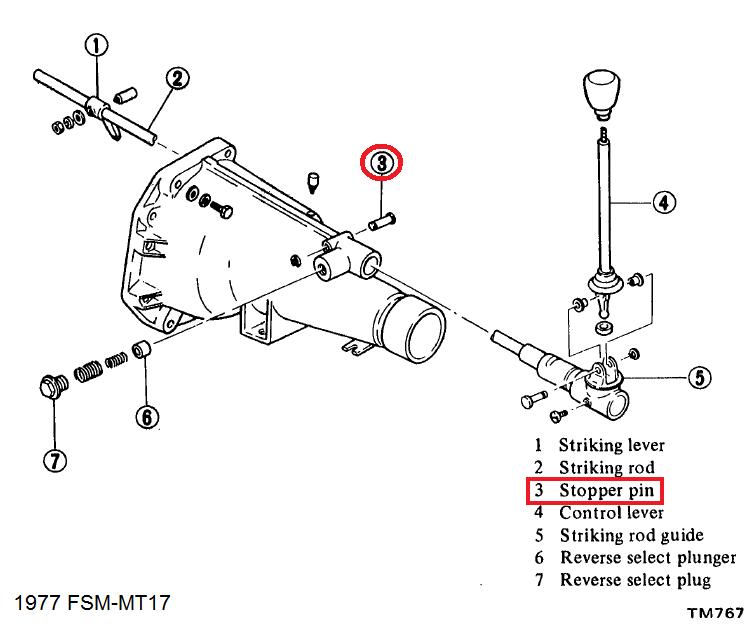

Those ratios are from a 820, but the input shaft is from the 720 truck. I think its the combination that came omn a limited number of the 720 trucks. Normally you would have a 22/31 input ratio, but you seem to have the truck version which gives you the low first gear and an odd final 5th ratio. Aarh btw I'm no expert on trucks so I'm going on approximate knowledge here if you know what I mean. One thing I can give you is a calculator for your ratios. Its an Excel file you can play with. (Had to zip it to upload). I guesstimated the reverse for the form. If you change the input to 22/31 you get the Datsun 810 (from June 78). These transmissions are getting old and if you like to play with them, you can make some wierd combinations. It is possible someone changed the input shaft or it could be original Datsun (Not from a Zed). BTW. Looking good. Not parts left over when you are finished is a good sign. Calculate ratios (Excel97-2003).zip

-

Found metal at the bottom of my 5-speed. What next?

Yer, Thats on my list with electricians using pliers as spanners.

-

Found metal at the bottom of my 5-speed. What next?

Try two blocks of hard wood cut to the length between the adapter plate and the bearing. Heat the bearing and use two jimmy bars of big screwdrivers on each side to pry it off. If you use some heat it should come off without too much force. You just need to break it loose and with heat it should come off.

-

Found metal at the bottom of my 5-speed. What next?

I agree with Dave fully. A simple hot air gun can make all the difference. Almost forgot. The main shaft nut in your transmission should be a normal right hand thread. The close ratio in the ZX coupe had the left hand thread, but there are always exceptions to the rule. Someone could have swaped it. You can simple check it by loosening it first before you order one. Its a good idea to do that now while you can still lock two gears so it won't turn. The left and right hand versions are in my list. I think the right hand thread version 32354-E9804 has replaced the older 32354-A7400. Not sure what the difference is between the two.

-

Kia Sportage weatherstip rocks!

Here are some photo's of the the lip you mentioned and the seals I used. You can also see a test piece (left over from the drivers door seal) to see how it would fit. They only cost €85 for all three and I am happy with the results.

-

Found metal at the bottom of my 5-speed. What next?

That rear bearing is a bit of a challenge to get off. My standard bearing puller was also too short, so I made one from 10mm plate with two threaded bars to do it.

-

Kia Sportage weatherstip rocks!

Im using the Kia door seal on the hatch (and doors) and I can't remember having that problem. I do remember rolling it on, sought of like it had to go around a corner because of the small lip. I also managed to get it in without cutting the seal. Btw: The Kia seals are an excellent alternative. Doors shut easy and firm, no slamming the door to get it shut.

-

Found metal at the bottom of my 5-speed. What next?

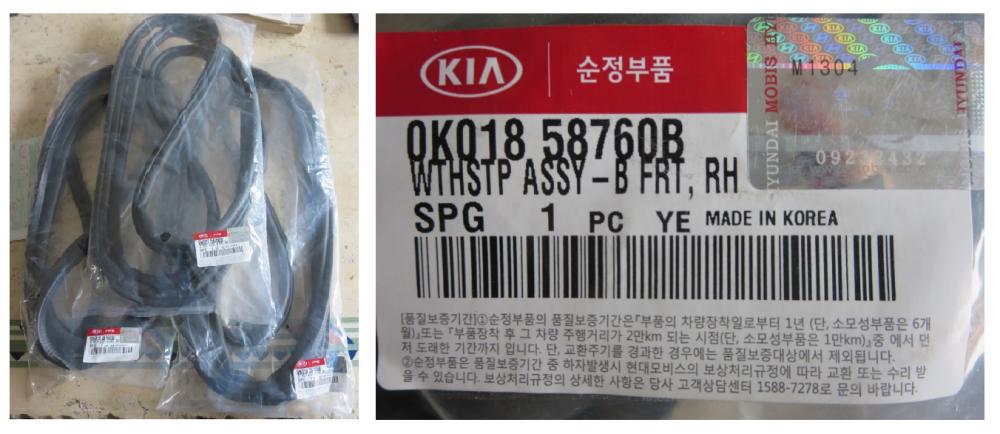

You are right. I mixed up the close ratio box from the ZX. Its not mentioned in the parts catalog and that throws people a bit. You have the neutral detent on that side back in the rear extension. Its the one with the drain hole Dave mentioned. It's purpose it to centre the selector to the 3rd, 4th line. Nissan calls it the reverse selector plunger. I don't have a good photo of it, but you can see it in this diagram as POS 6 & 7. Note: When you put it back together cover the ends of the stopper pin with a good sealant. The is a place that can weaping oil over time and make a mess. It won't run out of there, but it will be enough to gather dust and build up over time. A drop of oil can spread a lot.

-

Found metal at the bottom of my 5-speed. What next?

-

Found metal at the bottom of my 5-speed. What next?

-

Found metal at the bottom of my 5-speed. What next?

The bearing is listed. Its the second bearing in the Counter Gears section. P/N: 32219M (32203-E9800). I use SKF, just make sure the tolerance is C3 which is most common. You can remove all the gears behind the adapter and pull the front gears with shaft out of the center bearing. You will still need to remove the front cluster gear and you will have to pull the counter shaft out at the same time. The selectors will need to be dismantled before you start pulling the shafts. I don't know if its going to save much time. The whine you heard in neautral it very possible the bad counter gear bearing in the adapter plate. Its good news when you find something, but it always pays to run through the checks. You could find something else and now you have it apart its easy to replace. Checking the ratios will tell you more about the transmission. Take a photo, count the teeeth on all the gears and note it on the photo for future reference. Excel can workout the ratios and then you know for sure. No more guessing and in the end its not important where it came from. If the ratios are what you want, thats important.

-

Found metal at the bottom of my 5-speed. What next?

Here is the list of all the parts I used and a couple of extra parts to make it complete. I have incuded as much extra information as possible so other vendors can be used for parts like bearings and seals. You don't need to replace all the parts That will depend on the condition of the transmission. Don't be tempted to buy aftermarket synchros. Its very tempting, but you will very likly notice the difference. I was thinking it will be the (32276) 6306 C3, but the bearing under it (32219M) 6305 C3 on the countershaft was going to be my second bet. Both are in the transmission case adapter plate and seem to be vunerable. See the pfd for a detailed parts diagram on page 2. BTW. That mystery part is the reverse checking assembly. Its not mentioned on the parts diagrams, but it is in the 280ZX FSM. Make notes of things like the front cluster gear direction. It fits on both ways, but could cause a whine if it goes back on backwards. It will work both ways. Warming the front cluster gear up a LITTLE will help a lot with getting it off. Just hot enough that you can still hold it (60 degrees C). Makes it easier to pull off. You could be right about it being a 720 or it could be a 280ZX 2+2. The 720 2wd with the L20B engine had several sets of ratios. I think one was like the 280Z and the 280ZX 2+2, but the other one is very low in first gear: 3.592 - 2.057 - 1.361 - 1.0 - 0.813. There is also a possibility it could come from a 79/80 620 truck with the L16 or L20B engine. It supposably had 3.592 - 2.246 - 1.415 - 1.1 - 0.813. I'm no expert on trucks, but came across this info a lot and it doesn't seem to be rejected by the guys in the know on ratsun. Chas Tranny_Rebuild_FEB2012.pdf

-

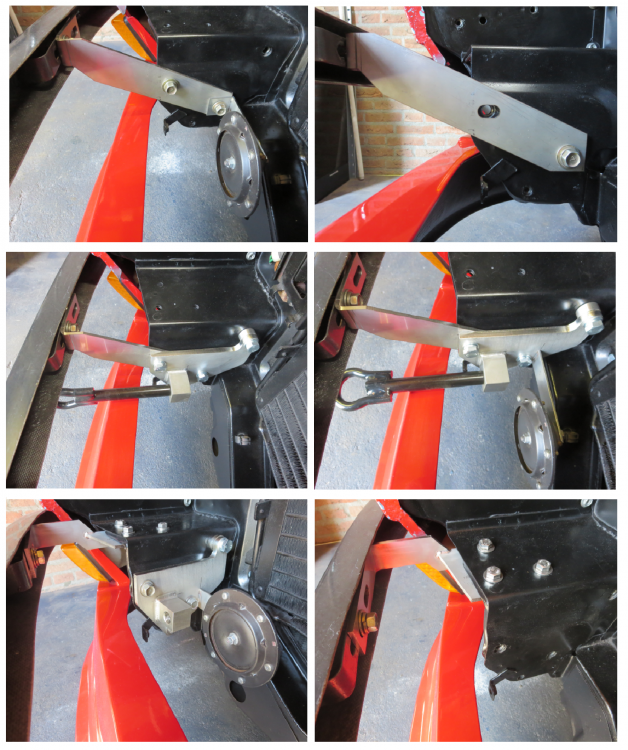

Fitting 240Z bumpers and Valences to a 280Z

Its been a while since I last posted something here about the brackets. Mostly been busy in PM's with people interested in brackets, Tried some different combinations today. Now to put mine back together so I can drive it again.

-

Found metal at the bottom of my 5-speed. What next?

Those casting numbers don't mean anything much. The L 3 means it will fit an L-series engine. The 200SX had a ZL-71B stamp for the Z (NAPS) engines. The tranny in the photo's looks very much like it came out of a 810 Maxima L24E (P/N: 32010-W2411) or the diesel LD24 (P/N: 32010-W2411) Total length should be 800mm (31.5") for the long extension transmission. The "Stumpy" is 675mm. I'm no truck specialist, but I think if it was out of a 720 it would have to be the 1980 model because the 81-86 used the NAPS Z-type engine (12 degree tilted bell housing) and I don't think the 720 had the extra switch.

-

2nd gear shifter wobble/shake

Have you tried changing the oil in the transmission. A member on this forum "Chickenman" recommends an oil from AC Delco or GM. The part numbers are AC DELCO USA part number is: 88900399. GM USA part number is: 12377916. I can not order the GM or AC delco oil here so I have no experience with it. I'm using Redline MT. Here is a thread on the oil subject. Another thing you can try is increasing the pressure on the detent springs. There are three in the Adapter plate, but the one you need to look at is the 1st, 2nd selector detent spring. You can increase the tension by adding washers behind the spring. It's easy to do with the transmission in the car. This thread discusses the detents springs. His transmission was popping out of 3rd gear, but if the detents are loose they allow movement and transfer that movement to the selector stick. They are all simple things to do and you can do it with the transmission still in the car and relatively low expense. I would try them before pulling the transmission out for a full rebuild.

-

2nd gear shifter wobble/shake

You have an F4W71A which is the original series 1 transmission. The selector can wear just like the F4W71B and FS5W71B, but the components aee a little different. That free movement you are feeling is what is making the chatter sound in second gear. The problem you are experiencing is an accumulation of wear allowing things to more out of harnomy of each other and increacing frequency magnitude etc. This is a similar problem Nissan had with the 280Z and to cure it they bolted a huge block of metal to the diff mount cross member. Your transmision has wear and that is now showing in second gear under load at certain revs (frequencies). I would try to replace all the bushings and the two rubber cones in the selector. I'm not sure if that are available. Reduce the free play and it wil most probably cure your rattle. Have you tried removing the gear knob. That changes the momentum of the gear stick and can confirm that selector free play is a cause. What does the codering mean.pdf

-

1981 280zx 5 speed

Yes. That is the risk you take when you remove the collector pipe. There many opinons on how to go about this. Like Mark said, heat the nut red hot and cool the stud as much as possible. This will create clearance by shrinking the stud and expanding the nut. Another way is to heat the stud red hot and then let it cool down again. Then heat the nut. This will cause the stud to stretch, expand and creap out where there is room. The tension on the nut relaxes a bit when the stud is red hot. When it cools it will shrink again, but not as much tension on the nut. Heating the nut will than expand the nut. When you try to undo it then the stud will be cool and at its strongest. Another option you can try is heat the manifold where the stud is and get is really hot then try to screw the nut with stud out of the manifold.

-

2nd gear shifter wobble/shake

There are lots of things that can cause a chattering gear stick. This is a typical frequency related rattle and can be caused by several things. Frequency and momentum. If you have worked on gas turbines you wil, have heard of critical speed or critical frequency. Google "critical speed", "rotordynamics" or "Rayleigh and Ritz theory" and read all about it. Certain speeds in second are ceating a critical speed for the transmission and selector components. Worn selector bushings are a common cause of noise in such a situation. Check if someone changed the gear selector knob for a heavier version. That can change the dynamics of it all and generate noise. Try removing the gear knob and take it for a test drive. Siteunseens transmission mount is another good one. A sagging transmission mount may look good, but because it has saged so much the metal pieces in the mount contact at certain frequencies. Check the selector for excessive movement and the transmission mount. Check wwwatlanticz.ca in the replacing diff mount tech tips for an examlle of a bad mount. Its a diff mount, but gives you an idea of the problem.

-

1981 280zx 5 speed

If your propane torch is enough for plumbing solder, it should have enough heat for the brass nut. I would get as much heat I could into the nut and try to spread it by hitting it in the middle of one or two flats with a chissel. Hit it in the centre of the flat in line with the stud, not across. That will help spread the stud and create clearence. No garantees you will get it off without breaking the stud. I had one come loose but lock up on the dirty threads on the way off. Good luck with it.

-

Found metal at the bottom of my 5-speed. What next?

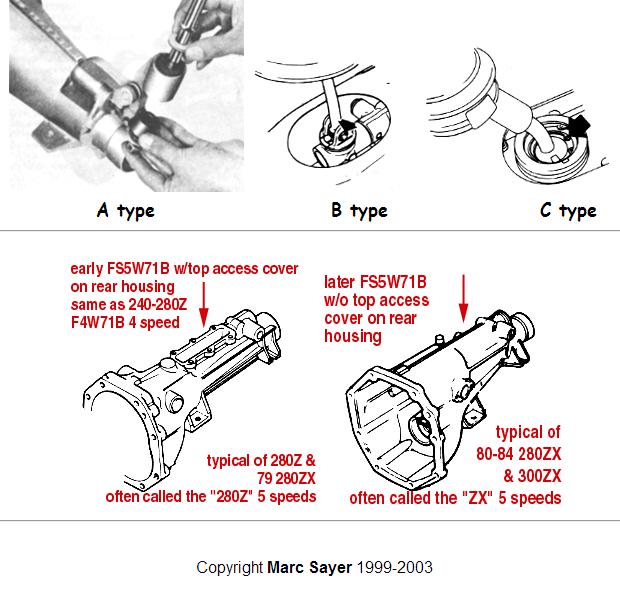

Just read through this thread. The pieces you found are from a bearing cage. Its probably from the centre bearing on the main shaft. I have seen a couple go there. If the transmission was running good, I would defenatly cosider rebuilding it. Buying one from ebay is a bit like buying a raffle ticket. You don't really know what you have until you put it in the car and drive it. You could pull yours out and flog it on ebay and no one would know. Pulling the drain plug wouldn't tell them anything. Not saying you should do that, but people do. You have to except that risk on ebay unless its a reputable dealer and then it will cost more. Rebuilding it is not all that hard. Like Mark said, you can find lots of info on you tube. I can post a list of all the parts you need to rebuild it. The bearings are easy to find and the seals and gaskets aee still available at Nissan. You will need a bearing puller set, a good set of circlip pliers and metric spanners. A bench vice is enough to hold the adapter plate. You can also identify which version of the 5 spped you have by looking at the rear extension housing. The bolt holding the speedo adapter above is 280Z and under the adapter is 280ZX. The two "Ears" for 280Z and one "Ear" for the 280ZX at the end of the extension housing will also tell you enough to know if its a wide ratio or close ratio (ZX) transamission. See the pdf for details. Im just back from holidays, so I will post the list later if you want. Good luck FS5W71B 280Z and 280ZX transmissions.pdf

-

Need some advice on selling

Good luck selling. Sad to see her go after all the work you put into it. Chris, you might not know it, but you have John's last word of advice on this site. Post#31.

-

1981 280zx 5 speed

What do you mean by fork and sleeve? If you meant clutch fork and throw out bearing collar than its no issue. Use the one in the car, it wiil fit. You only get problems when you start mixing pressure plates with different collars. The bearings and the fork are all the same, only the series I has an extra tab for a return spring.