Everything posted by EuroDat

-

Keep water away from under hatch flat area?

Werup, That got wow factor. Looks neat and when painted you would think it was originally made so. Are you going to fill the seams around the panel like in post #5?

-

'75 280Z Headlight Relay Upgrade

Actually two fuses would be enough for safety reasons. I was thinking one group of Fuse + two relays for the left side and Fuse + two relays for the right side. Of course if you don't use it at or very rarely then one fuse would be enough. I don't drive at night much at all, but some countries in Europe are demanding lights during the daytime. Won't be long before The Netherlands joins the band wagon. Then it will be an issue for me. Chas

-

Just ordered my Rebello 3.0, now what

I bet you feel like superman after finding a simple fix to what looked like an enormous problem. Good start to the weekend.

-

'75 280Z Headlight Relay Upgrade

Hi Tamo, Looks like it will make a nice clean setup when you finish. Be sure to take some photos when you fit it. My headlights have been changed to meat european regulations and the PO upgraded to H4 with 60/55Watts bulbs. The original system uses 50/40Watts. I would like to do something like this to protect the combination switch now the system is using 20% more energy in high beam.. I have one small issue: The system will work on just one fuse. That means if it blows you will have no lights. Could you double the relay bank for a left and right system. That way if a fuse should blow you will only loose the left or right (Hi and low beam) headlight. It would mean you will have two reserve relays for fog lights and fan etc. I do a lot of HAZOPS, RCFA and FMEA where I work and its second nature to prepare for the worst.

-

Fitting 240Z bumpers and Valences to a 280Z

I have thought about that as well. They are held in place by 4 big spot welds of about 1cm in diameter. If I do that, I will need to make brackets to hold the grill.

-

Fitting 240Z bumpers and Valences to a 280Z

Hi Tamo, Im trying to convince myself its not that hard to do, but your not helping with that remark😠Only joking, I realise its not that simple and I don't want it to look like a hack job when its finished. I want to do it so I can set the grill a little further back. Because its moved forward the bonnet just misses the grill when you open it. Ill take step by step photos if and when I decide to go that way.

-

Fitting 240Z bumpers and Valences to a 280Z

Hi Charles, The grill will be coming apart again. Your remarks got me thinking about it again, sometimes not a good thing. I want to put two of the 240Z bars under the two short ones so the grill will go all the way to the airdam. The short bars are needed because Im using the old bumper shock mounting position. That is about 80mm closer to the car centerline. Ill take some photos tomorrow so you can see what I mean. I am now considering some more alterations like cutting a section of the old turn signal supports (see red line in photo) away so the grill can be set a little further back towards the original position. Also looking at straightening the bent up panel to the left in the photo (red circle) so I can mount the bumper like the original bracket position on the 240Z. Plenty of experimenting to do over the weekend Chas

-

Just ordered my Rebello 3.0, now what

I was getting mixed up with Oranngetang. There has been a lot of posting back and forth about noisy valvetrain and dizzy at 180degrees. I got lost i the trees. Back to the starter. What made me think of that. You are using a fidanza flywheel and ??? Starter. Maybe there is a high spot in the meshing of the gears or the tolerances are really tight and that is causing a tick in the starter motor stator. The starter is flexing with it goes over a high spot. Now you found hard spots when you turn it by hand, makes me think it could be something else. If you put your hand on the motor, can you feel it when it clunks? You could buy one of those industrial stethoscopes and try to localize it with that. That don't cost must $10.00 and they can tell you a lot more than listening from a (short) distance. https://www.blackwoods.com.au/part/00372602/stethoscope-industrial

-

Just ordered my Rebello 3.0, now what

Strange and frustrating at the same time. It was tested on their dyno so its hard to believe its coming from in the engine and why would it start doing it now. Could it be something in the ringgear on the flywheel? Have you sent the video to Rebello and ask what they think.

-

77 and 78 door weatherstripping NOT SAME?

I think it could be just small improvements made over the years. Nissan then issues a new part number no matter how small the change. The courtesy guy is probably not an expert on these old cars and is simply quoting what he sees on his computer. His conclusion: 77 part number is different to the 78 so part must be different and won't fit. I have nether heard of people haveing issues with different type of door seal on the 280Z. Its mostly the quality of the aftermarket parts that caused most people grief.

-

Fitting 240Z bumpers and Valences to a 280Z

A little more progress on the grill today. The M3 thread die didn't come in today, so ill have to wait until Friday to pick it up. I need to shorten two long bolts and recut the threads. Its not needed for testing. I had to do some drill in the horizontal bars to get the 280Z sections and the 240Z grill to match up. See red circles for where bars needed to be drilled out. The two outer vertical section from the 240Z had to be shortened as well and the short 280Z had to be altered for the end of the top bar. I drilled the top bar, but I didn't want to try to form it like the other holes. I was afraid it would distort and go out of shape. Now its back together for testing. First problem. Its hitting the old turn signal indicator supports. I used two 20mm tube spacers to move it out and clear the supports. Just misses the bonnet by a couple of mm when I open it. Ill have to look into this further. An option would be to remove a section of the indicator support thats hitting the grill. Next problem; The lower support hits the back edge of the air dam. Might need to take another 20mm of the back edge of the spoiler. Chas

-

Out with the new, in with the old...

So it a case of the 7 P's Prior and Propper Preperation Prevents wizz Poor Performance Edit: Wtf "Wizz" is not what I wrote. Dam site census. Now it does sound right.

-

L24 vs L28ET

If you want to go with an L28ET, I would suggest buying a runner, drive it home and then do the swap. Anything else is truely high risk. All these EFI systems are getting old and you shouldn't compare them to any EFI system today. I wouldn't limit my search to an L28ET with a manual transmission. If you buy an FS5W71C you will have enough parts with the 71B to do the swap. There are some modifications, but there is plenty of forum information to help you through and you can always ask. The 71C is considered by many to be a better transmission than the T5, even the one out of the 300ZX. Mmmm. Why not a 300ZX twin turbo...... Now where thinking out of the box. Chas

-

Out with the new, in with the old...

Congrats Rossiz, Looks like a painless transplant, if such exists. I have seen others having nightmares for weeks after, but you seem to have nailed it. Chas

-

Fitting 240Z bumpers and Valences to a 280Z

Thanks Tamo, It was your advice/comments in post #5 the convinced me to go with the 240Z air-dam. Ive had the air-dam since november last year, but been too slack to fit it. One of the long bolts (M3x230mm) on the 240Z grill broke off just above the nut, so I had to get a section of M3 thread brassed onto it. I hope to have some time tomorrow so I can start doing the adjustments and fitting it. Hi 2050-Z, I have never seen a full 240Z valence swap on a 280Z. I think the front frame section scares most people off. I don't know exactly when they dropped the front frame, I think it went in stages. 240Z was almost straight across. Not sure about the 260Z. They still have the 240Z style valence panels with turn signal indicators so I presume they are somewhere between the 240Z and the 280Z. The 280Z has a deeper radiator and that is why the frame drops down so low. Its about 80 to 100mm under the 240Z center vlaence panel. See photo. The two side sections bolt on, but you have to remove a nut that is spot welded to the back of the headlight bucket. Its there for securing the Sight Shield Assembly panel. Its the red panel in these photos with the dog ear on the end. I was using it in combination with the 280Z grill because the 280Z grill has 2 bars less and a large gap behind the 240Z bumper. Here are some photos of the 240Z valences mounted on the car. Can't find any photos of the center piece, but it was never mounted. To fit it you would have to cut a large piece out of the rear of the center piece. The back third if I can remember orrectly. I don't know if the BRE spoiler would still fit after such an aggresive trimming. I couldn't figure out a way to modify it without making it look butt ugly. Chas PS: HaZmat has the Xeon PU airdam with the brake vents; MSA P/N: 50-1411 http://www.thezstore.com/page/TZS/PROD/classic02a01b/50-1411 I wanted the version without the vents, but MSA only has it in fibreglass. It doesn't have the deflection problems the PU airdam have. Although you could hit a speed bump, break it off and then run over it and doing all kinds of damage in the process......

-

Fitting 240Z bumpers and Valences to a 280Z

Hi 2050-Z, That was my thoughts exactly. I wanted the 240Z valance and even bought a full set (the blue ones). I stripped all the blue paint and started fitting them, but the problems with the lower 280Z frame were just too big a "show stopper". You can see the height difference in post 4, 3rd photo. You would have to hack the centre piece up a lot to get it to fit around the frame and the frame will always be visible even with a bre spoiler. I thought about cutting the side valance panels and adding a V section so I could tilt the centre section downwards to cover the frame. I might even try it one day. For now I just took Tamo's advice and bought a airdam from MSA. I have some more photos showing the differences when mounted on the car. I can post them if you want to se it. Chas

-

surprise in not seeing any comments on two 1973 Z' s that were on BAT .

I thought it might be goed to post some of the photos. The links work for a couple of weeks and them fail which makes the thread pointless. Pitty. It is interesting to see an automatic go for so much, but I must admit it is in very good condition. It hasn't been messed with in anyway. Chas

-

Fitting 240Z bumpers and Valences to a 280Z

I made a little more progress on the airdam this afternoon. The airdam needed some trimming along the back edge to clear the frame where the 280Z lower (two bar) grill mounted. I took 20mm off the back edge, starting 50mm in from each side. After that it fitted much better. Clamped it into position and drilled all the holes. I also had to drill out a nut in each headlight bucket. The 280Z Valances have a U section cut out to clear these nuts. They are spot welded on the back and were used to hold a trim between the bumper and grill to fill the gap. Now to start on the grill. I think I will have some interference problems with the old indicator mounts. Looking at the 280Z grill, the bars will have to come forward to clear. That might couse problems with the bonnet when it opens. The bonnet tilts downwards, but clears the grill because the grill is set back. Anyway the first step is to reassemble the 240Z grill with the 280Z grill parts. I replaced the top section with the 280Z bar to mount it on the 280Z brackets. Them swapped the bottom two bar so I could use the 280Z bumper mounts. They are about 100mm further inwards and don't clear the 240Z grill. I was tempted to start cutting all the structure for the 280Z bumper shocks, but I can try this without cutting or modifying the 240Z grill. It is only assembled with 280Z grill parts. It will be a couple of days before I can get back to it. Them I will be fitting the grill. Cheers Chas

-

Fitting 240Z bumpers and Valences to a 280Z

Removed the 280Z valance today and tested the Air-Dam. Im using the 240Z - 260Z Type 1 fibreglass airdam without the airducts from MSA. (Part nr. 50-1401). There are some obsticles to tackle before it can be fully mounted. 1: The top section is hitting the bracket wear the lower outer mounts for the grill mounted. 2:The 240Z grill is also hitting the old 280Z indicator supports. Im now debating what to do there. - Remove the old 280Z indicator supports and make new brackets for the 240Z grill or; - Replace the top bar in the grill with the top bar from the 280Z grill and check fit again. 3: The 280Z indicators have different buld adaptor for the lens housing. Now I have to try and find some 240Z indicator harnesses and splice them into my plug connectors. I have a spare harness for the rear taillights. I can use the turn signal cables in them. If anyone has a spare set of harnesses they want to sell. I would like to buy them. Chas

-

Turning Engine by Hand

You are going to have problems with your leak down test as well. Normally the engine is in the car and you can lock the piston at the top but putting it in 4th gear and hand brake on. On the stand it will push the pistion down to the bottom of its stroke unless you can stop the crankshaft spinning. If the piston travels to the bottom a inlet or exhaust valve will start to open and the leak test wil fail. Your idea with the spare tyre for a tank will do. You may need to refill per 2 cylinders. Another thing that could be causing the possible leak is turning by hand is too slow and the pressure doesn't build up enough to force the rings out against the cylinder walls and create a better seal. Chas

-

Brake Proportioning Valve

I dismantled mine and tried to find replacement cup, but had no luck finding any. Did find the o-ring seals. In the end I cleaned all the parts in the proportioning valve and the brake switch, changed the o-rings and reasembled them. Here is a link to the thread with photos. I also did the brake switch and they are both still leak free. http://www.classiczcars.com/topic/45461-parts-for-oem-np-valve-and-brake-indicator-switch-unit/ Chas

-

Throttle issues and now car won't start

0 compression doesn't sound good. Could be a stuck valve, hole in the piston, burnt valve or something wrong with the rockers not opening the vavles. You can narrow it down with a leak down test. That is what I would do before opening it up. A quick description on how to do it. Turn the engine to TDC number one cylinder. Check it on the compression stroke by checking the rotor button in the distributor is pointing to number 1 sparkplug lead. Put the car in 4th gear and handbrake on to stop the engine turning. You will need a compressor and a fitting for the sparkplug hole. My compression tester has an adapter that does the job perfectly. See photo, Its retro but I like it. The engine can spin a little, maybe not in this case, because the air pushes the piston down until the slack in the drivetrain is gone. Apply air via the sparkplug hole and listen to the exhaust, Oil filler cap and carburetor. It should be cushing out one of those. Hopefully its not the oil filler cap. That most certainly means piston failure. If its valves, I would then take the cover off and investigate further. Chas.

-

Fitting 240Z bumpers and Valences to a 280Z

Hi Jim, I know what you mean. Been there done that as well. I ended up making them first out of 50x2mm aluminium strip from a local hardware store and then out of stainless steel. The aluminium made it easy to drill and shape. You could do that and take them to a shop to duplicate in Stainless steel or coated/zinc plated steel. Chas

-

Fitting 240Z bumpers and Valences to a 280Z

Hi Mike, I experimented with an old lens first and found Polyester resin had attached better to the old arcrylic and gave the best holding power. The Polyurethane let go easier. You can find the polyester resin at hobby shops for around $10.00/kg. I found it at a local arts supplier for €8.00. The polyurethane is a lot more expensive at around €35.00 a liter. I didn't use any coloring in the resin and its hard to notice on the outside. The releasing agent costs around €15.00, but you can use silicone or teflon spray on the screw. I have tried both and they work just as good. Just a quick spray, let it dry and wipe away any excess. Otherwise it can fill the threads in the small screw. That black stuff was the most expensive . Playdoe for the local toy store at €1.50 a pot. I fashioned it into shape with a paddle pop stick and when it cured removed the playdoe and washed away any leftovers. Then filed it into shape and finished it with 500 and 800 emery paper. Don't forget to rough up the surface wear the resin bonds to. I used the Bick ArtSupplies resin in the centre photo. Goodluck Chas

-

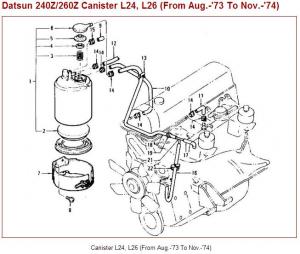

EFI to Carb Conversion: Hose/Vent Questions

Hi Rossi, The carbon canistor doesn't have anything to do with the EFI. It is part of the emmision control system introduced introduced in the 260Z. Maybe the late 240Z's with the flat top carbs had them as well, I not sure. If you want to see how to plumb it for carbs. Download the 260Z manual from XenonS30.com and check it out. It is simple. The canister has a purge valve with two tubes going to the inlet manifold. The tube coming out the top of the purge valve goes to a Tee piece in the line to the distributor vacuum advance. The second tube (slightly larger diameter) coming out the side of the purge valve goes to manifold vacuum. I don't know what the government regulations say in your area, but it wouldn't hurt the enviroment if you left in on. You will need to consider venting the tank if you remove it. Fuel line: Im an EFI man. I have heard of people going for a return line and others just dead heading the system. If I did it, I think I would go for a return line to keep the fuel fresh, cool and reduce the risk of vapour lock. Have you thought about how to run the pump? The fuel injection pump relay has some wiring to the ECU system for safety reasons. Chas