Carl Beck

Member-

Posts

5,022 -

Joined

-

Last visited

-

Days Won

16

Content Type

Profiles

Knowledge Base

Zcar Wiki

Forums

Gallery

Events

Downloads

Store

Blogs

Collections

Classifieds

Everything posted by Carl Beck

-

I have the Carter Rotary vane type in one car - and I have a Holly Red Rotary vane type that I use outside the car (to empty the fuel cell when the car sits for prolonged periods) The Carter puts out a very loud Buzzzzzz as installed in the car - I can hardly hear the Holly run with it sitting outside the car. Because of the base design on the Holly, I couldn't use it in the space provided in the car... On my Blue 72 - I ran a Carter electric - only the gear and rotor eccentric mechanism type. You could hear it run when you first started the car as it pressurized the lines - then only at idle you could faintly hear it pump..........pump.........pump... or as Big sam said."clonkclonk clonkclonk clonkclonk".. OEM pumps are usually designed to be quite... many today are put in the fuel tank to keep them cool and quite.. so the RX-7 pump mentioned by Gary sounds like a good idea. FWIW, Carl B. FWIW, Carl B.

-

Replaced Rear Wheel Bearings - Problem / Question

Carl Beck replied to Oiluj's topic in Suspension & Steering

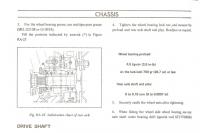

Hi Jim: No problem - I was asking Julio or anyone that perhaps understood his first Post better than I, and I'm glad you answered. Below are copies of the pages from the 72 Manual... my 73 Manual is in the garage right now - so it was easier to scan the 72 Manual in the office.. It is most likely the same as the 73.. No mention of the fishscale in the rear.. FWIW, Carl B. -

Replaced Rear Wheel Bearings - Problem / Question

Carl Beck replied to Oiluj's topic in Suspension & Steering

AND Hi Jim: Yes, I had that same picture of the FishScale in mind when I ask if Oiluj had used that method. From his words I couldn't tell if that was the case or if he was using a torque wrench (on a lug nut on a stud) - as he used only the term "torque" to slowly rotate the hub -in that sentence. At any rate.. the FishScale is used in the FSM on the Front Wheel Bearing.. now that I check my 72 FSM... for both new bearings and re-using the present one... PS - This is what happens when 85% of your memory is "graphic" rather than textual. FWIW, Carl B. -

Replaced Rear Wheel Bearings - Problem / Question

Carl Beck replied to Oiluj's topic in Suspension & Steering

Was a fish scale used to take the measurement in the first place? Or was some other method used? Interesting thread... but the use of aftermarket parts may be what is throwing the Nissan Spec.'s for Nissan supplied parts - out of wack. Were Nissan supplied parts NLA? FWIW, Carl B. -

In my opinion that Carter pump is anything but quite. It is a constant buzzzzzz in my car.. a loud buzzzzzz too. Could be partly where I had to mount it (in the tool pocket behind the seat... but it was mounted with rubber isolators etc. If you don't really need a competition pump - I'd be looking for one that is quite.. or less noisy. just my experience.. Carl B.

-

OK - you are correct. Sometimes people expect the VIN to match the Engine Number, which of course is not the case with the early Z's. I just wanted to make sure that you no longer had the original engine. In that case there is no real downside to swapping any engine into the car that you want. The future value of the car will be determined mostly by the quality of the work that is done, and the size of the market for that specific type of work. You just don't want to put a lot more into the car, than you can afford to write-off as the cost of having fun later. good luck with the project. Carl B.

-

I would feel better - if I knew for sure, specifically what you mean by "is not a matching number". What numbers do you expect to match? FWIW, Carl B.

-

Check your local Nissan Dealers Parts Department?

-

The reason most people took those old piston type compressors out - was because they can shake the whole car and it takes about 5HP to run them. If you just want to put the optional Dealer Installed A/C back on the car for "show" - go for it. But if you want A/C that works... I'd switch to the later "Factory Air" rotary type compressor mounted with the factory type bracket on the other side of the block. The newer rotary type compressors are far smoother in operation and take far less HP to run. FWIW, Carl B.

-

You just want to make sure that the car thieves aren't the people selling this service. We've all heard about the Cops mailing lottery prize winning notices, to people that have outstanding warrants - - then arresting them when they show up to claim their prizes... Nonetheless - neat solution - and it will only get better with time... thanks for the info.. Carl B.

-

Hi Randy: Don't forget to let me know what the serial number is. Looks like you found a car in pretty nice shape - just by chance. Have any idea why the car was being sold or what it's background is? good luck with it.... Carl B.

-

Bob Sharp was a Datsun Dealer - and many of the parts you have listed are Nissan Part Numbers. Usually the 99996 prefix indicates aftermarket parts that the Datsun/Nissan Competition Parts Department supplied through their local dealers, to customers. I think you need to see the Datsun/Nissan Competition Parts Catalogs. As I recall, BSR special parts had parts numbers that began with BSR- FWIW, Carl B.

-

In case Curtis240Z doesn't have a scanner, and a few hours to spend scanning pages - - -Scanned copies usually run about $45.00 to $95.00 on E-Bay, depending on what years they were published. But then, if you list them on E-Bay... usually someone will let you know what the BSR Part numbers are... FWIW, Carl B.

-

Great.. now you'll have to go back and get the Build Date. #789 and #793 had 12/69 build dates... If you get a chance to look it over - see what the original engine serial number is as well. thanks, Carl

-

Anyone own a 4 post garage lift for their Z?

Carl Beck replied to mgmoreau's topic in Open Discussions

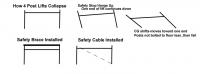

Hi Doug: I think the wheels go under the ramps.. so when you put the ramps all the way down, they lift the four corner posts up off the floor. IMHO - if you have a 4 Post lift, that is not securely bolted to a 6" to 8" thick concrete floor - you need to have either a Safety Beam connecting at least one side, front to rear for the corner posts, or Safety Cables affixed to them. The Safety Beam is bolted to the top of the corner posts - where both the bean and posts have properly welded mating plates, that can be bolted together. Regardless of the built in safety features - these lifts are man made, and price is a major consideration of their design. Put a 2,000 or 3,000 lb load on the ramps, and look at the ramps as 18' long levers, with the corner posts as fulcrums and its easy to see the huge amount of force that can be generated "if" something goes wrong. From personal experience I can tell you that things that are not supposed to be possible - are. The ramps that go up/down are in no way fixed to the corner posts, so they really offer no structural rigidity/strength. These lifts are designed with the idea in mind, that the load will be carried directly downward via the four upright posts. When that happens everything is fine and dandy. Shift the center of gravity of the load, when one end or one corner of the ramps dips 6" to 8" below the others and you have a completely different situation on your hands (or head as the case might be). I had two Ben Person (now BendPac I believe but not sure) 16,000 lb. 4 post commercial lifts in the muffler shop I owned/ran for a time. When a "safety" lock hung up on one post.. the other three corners went on down.. the load shifted, the ramps shifted and everything started to slid toward the low side/corner,.... and two of the four Posts twisted like a pretzel The only thing that saved me was the fact that the commercial lift had a Safety Brace between the tops of two uprights on one side of the lift that prevented the whole thing from collapsing - - plus I had them properly bolted to an 8" commercial concrete floor but I seriously doubt that would have stopped it from just bending the uprights over. Some of you may recall years ago that a "Park" lift failed in a man's home garage, and destroyed two of his Corvettes. He raised hell on the Internet for a few years. sued them.. etc. I have no idea how that turned out - but from the pictures he posted it was easy to see why his lift collapsed.. and mine didn't. No top safety brace on his. Personally - I wouldn't have a roll around 4 post lift without the Safety Brace tieing at least two of the side Uprights together. Likewise I'd want that Safety brace with any lift bolted to the standard 4.5" to 5" concrete garage floor in a residential home. Just my experience.... BTW - at the time Ben Person stood behind their product, had service tech's in my shop within 48 hours. Changed their design on the safety latches, and replaced two of the uprights that had been twisted (although they looked OK after I ran the lift back up). I don't know if BenPac is still the same or not... FWIW, Carl B. -

If you have "mag.'s" on your Z - I hope your tool kit contains 4 OEM lug nuts. You need them to put the spare on if/when you need. FWIW, Carl B.

-

Hi Dan: Bare steel parts, when electroplated with either Cadmium or Zinc have a dull gray to dull silver appearance. Cadmium offers about three times the durability of Zinc in terms of corrosion protection. Both Cadmium and Zinc are sacrificial coatings.. that give themselves up to protect the steel from corrosion and thus prolong the life cycle of the original part. So why use Zinc? Cadmium is a heavy metal, and listed on most of the worlds "Restricted Substances Lists" by the various environmental protection agencies around the world today. About the only plating companies that can supply actual Cad. plating services - are MilSpec. vendors and they are usually far more expensive to deal with. All the government controls/regulations etc on the handling of the Cad. plating solutions add a lot of cost to the process, as well as liability to the vendor in terms of physical harm to their employees from exposure to heavy metals. To either Cadmium or Zinc plated parts, a farther protective finish can be applied to forestall oxidation of the Cad. or Zinc ( oxidized zinc plating will turn an unsightly, sticky, white salts appearance). This is done by dipping them in a chromate/dichromate bath. The chromate/dichromate (either are the same to the platter - as the process and result are the same, although there are very slight differences in the chemical make up). Chromate coating can be clear or a number of different colors. In the case of the original parts produced back in the 60's and early 70's for our 240-Z's, the bright yellow or gold appearing parts were bathed in a Yellow Chromate bath. That yellow chromate bath was a Hexavalent Chromium. That (hexavalent) chromium is today also being banned by most EPA's around the world... and instead a trivalent chromium is being used (that is what was always used for clear chromate coatings). The bad news is that the hexavalent chromates are far more durable than the trivalent chromiums, or other modern substitutes. So... the bright yellow/golden parts that you used to see on the 240-Z's when they were produced.. the one's that look like they have a bit of oil on them, that reflect the deeper blue, yellow, gold, red hues.. were most likely Cadmium plated then bathed in a Yellow Chromate bath. All done to very high quality controls over the process and chemicals. That can still be done - but very few platters offer the service, and it is expensive relative to Zinc with the newer trivalent (or other newer chemical processing) yellow chromate. Yellow Zinc as it is commonly called - can be made to look very much like the original Yellow Cad... but only with strict attention by the platter to the chemical mix and process used. Most of the time Yellow Zinc plating lacks that original rich luster found on the original parts... it's close and most likely close enough for most .... but many of us noticed the subtile difference upon close examination or in the sun light. The original Zinc plated parts - that look gray/silver were also bathed in a clear chromate solution.. they still look gray/silver, but after several years you can see a slight yellowing of the original clear coating. The guys in the materials lab tell me that is a sign that the original chromate coating is reaching the end of its lifecycle.. They also tell me that one can not stress highly enough how important quality control of the chemical solutions and the entire plating process is - to the end result, in terms of finish and durability. Likewise the quality of the part you start with... FWIW, Carl B.

-

That's what happens when I start writting something - then don't get back to it until several hours later....da... I'll copy my Post and use it next time.... and we all know there will be a next time... FWIW, Carl B.

-

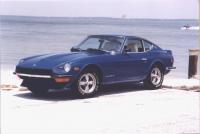

Metallic Blue with the white interior has to be one of the most beautiful colors offered on a 240-Z, that's one reason I never wanted to part with mine. Good to see you here and good luck with the restoration. Do it once, the right way... take your time and enjoy the process. FWIW, Carl B.

-

2 or 3 slow pumps are enough - and your son has to stop and hold the pedal to the floor - while you open then close the bleed valve. You should see some spits of air, then fluid. 2 or 3 more slow pumps - your son holds the pedal to the floor - you open/close the bled valve.You should see less spits of air, then more fluid. 2 or 3 more slow pumps - your son holds the pedal to the floor - you open/close the bled valve. By this time, you should be getting NO Air - and only clean fluid out of the valve - if so you are done. If not - check to see that the master is full - and repeat one or two more times. When your son pumps the clutch pedal, and is then holding it on the floor - he should yell "FLOOR!" and hold it there. After you crack/close the bled valve you yell "PUMP" and your should should pump then hold the pedal to the floor and yell "FLOOR" again. Having your son yell "FLOOR" also reminds him to hold the pedal to the floor until you yell "PUMP" again. With young people it is very important that they understand this procedure... This concerns me - if that is the case - either your son wasn't holding the pedal steady on the floor - or you are sucking air from a bad rubber line, or loose connection. Or the clutch master went dry and allowed more air back into the system. The lines from the Master to the Slave aren't that long, and it shouldn't take much pumping, to clear any air in the lines. Forget about "resistance" for a minute. The real question is "is the push rod from the Slave, moving out about an inch to an inch and a half- and thus moving the clutch fork about an inch toward the rear of the car? If the answer to that is "yes" - you don't have a problem with the clutch hydraulics at this point. From your description - where you failed to note the clutch pedal held at the floor... I'd have to say "maybe". Re-bled the system, per the exact procedures above - and try it again. {Forget resistance} Check to see that the rod from the slave is moving out and pushing on the clutch fork. If the rod and clutch fork are moving - Start the car in neutral - step on the clutch and see if you can put the car in gear. If you can't... let the engine warm up fully... then pump the clutch pedal at several different times as the engine comes up to full operating temp ... and see if the clutch disc breaks free from the flywheel - you'll know it did because at that point you'll feel the resistance that should be there from the pressure plate. If that doesn't work - turn the car off. Put it in second gear... hold the clutch in.. hold the brake pedal on firmly - - bump the starter several times. The car should buck, it won't hurt anything.. but it "should" break the clutch disc free from the flywheel. In extreme cases - you have to start the car in gear and let it run down the street at slow speed. Holding the clutch pedal to the floor.. you yank up hard on the E-Brake handle, while at the same time giving it some gas. This may take three or four of five tries... but the clutch disc will break free from the flywheel - and at that point you'll feel the resistance your looking for - and you should have a working clutch.. Absolutely no resistance in the clutch pedal, especially when you have a new master and slave - normally indicates the disc is rusted/frozen to the flywheel from prolonged non-use. FWIW, - just as I see it from the previous discussions Carl B.

-

New member here, I might have a ZZZap, but I need help to make sure

Carl Beck replied to ZDemon's topic in Body & Paint

I know the thread is about the ZZZAAP Z's... I'm still looking for original window stickers for them.... but a comment about the Black Pearl's... 1978 280Z Black Pearl Edition The Black Pearl Metallic Paint is listed on the Factory Window Sticker as a $90.00 option. So any 280Z produced with the Black Pearl Metallic Paint - is a Black Pearl Edition. I don't see how there can be any question about that. Very few were produced, because it was the first Z to be offered with black as an optional factory color. It was more or less a "test market vehicle". Nissan wasn't sure black would be popular on a Sports/GT (how many factory Black Corvettes before 1970 have you seen?) so they produced a few black 280Z's to see how they would sell in America. As it turned out - the Black Z's sold like hot cakes with demand exceeding supply. The result was "Black" for the 280ZX's.... as a standard color. The SAP was an additional cost option, over and above the Black Pearl Metallic Paint. The SAP was around $149.00 and like the extra cost Black Pearl Metallic Paint, the SAP was listed on the window sticker. So either with or without the SAP - a Black Pearl is a Black Pearl. The highest prices are paid for the Black Pearls with the SAP and optional 5spd. listed on the original window sticker - and the car in #1 or #2 condition. (factory A/C doesn't seem to greatly effect price, but it makes the car easier to resell). Can you duplicate/re-create a Black Pearl with the SAP? Sure, but to do a good enough job to fool knowledgeable buyers - it would cost you more than just buying a Collector Example with full documentation. Anything less than all original - Collector Quality - and the value goes down extremely.. Of the thousand or so produced, only a handful remain in near perfect ORIGINAL condition, with less than 30K miles, and full original documentation. FWIW, Carl B. -

Hi Jared: Looks like the Miller Brothers are doing a wonderful job for you. It will cost a little more than a new GT-R, but in the end you'll have a beautiful Z...... and ten years from now it will still be a beautiful Z. thanks for sharing it with us. Carl B.

-

Another Dumb Question...are they 71's or 72's

Carl Beck replied to 71 240ZHawaii's topic in Carburetor Central

Hi Tony: What is the VIN on your car? What is the Date of Manufacture? Cars manufactured in either 1969, 1970 or 1971 could be titled/registered as "1971 Model Year" vehicles. What are known as the "round top" S.U.'s were used on 1970 through 1972 Model Year Datsun 240-Z's. So when you order parts you need to know the Date of Manufacture of your car. FWIW, Carl B. -

Good decision Randy.... BTW - no resistance to the clutch pedal - could also be caused by the clutch disc being rusted to the flywheel. Sometimes if you get the car running and warmed up - you can break them free by turning off the engine, then holding your foot on the brake, putting the car in gear, and tapping the starter. You can tell if that's the problem, by having someone push the clutch pedal in, while you watch the slave cylinder to see if the piston is pushing the rod out... Carl B.

-

Now there is a sign of a seriously split personality!! Carl B.