Everything posted by Carl Beck

-

Filler Cap...

Hi Brian (everyone)) To each his own.... but for the life of me, I can't understand why anyone would replace, rather than eliminate the fuel vapor hoses that run into the cabin. It was a stop gap measure at best, to comply with the California ARB rules in effect in 1970. Wasn't even required in the other 49 States nor Canada at the time. You can't see any of them without taking the car apart either... If you have fuel dripping down the side of the car, just behind the right rear wheel - you most likely need to replace the Fuel Filler Neck - the long, large rubber hose that connects the fuel filler to the fuel tank. They dry out and crack, when you put the nozzle of the gasoline pump in them, then lean on the pump handle. FWIW, Carl B.

-

Stock Rear 240Z springs

Hi Lee: Thanks. That is pretty much the spring spec.'s we used to have the OEM Stock springs reproduced. FWIW, Carl B.

-

vin number

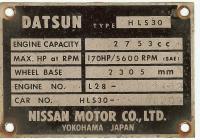

OK - now were at least making progress... I'm not sure exactly when Nissan stopped putting the original engine serial numbers on the Data Plates. I was thinking it was with the begining of the 280ZX's ... but it would seem that the 78's are quite different than the 75's. As you can see from the Data Tag I posted a picture of VIN HLS30 200207 had Engine Number L28-001482 As the VIN's on the 280Z's started with HLS30 200001 - the car above was the 207th one built. Given the VIN on your Z - of HLS30 451125, we would expect to see an engine number about 251xxx higher (451125 minus 200001 = 251124) ... and sure enough you have 254234. (they don't run in exact numerical sequence). Also - HLS30 452525 has L28 259635 as it's original engine... So I would say it is most likely the original engine in your Z. FWIW, Carl B.

-

vin number

Either you aren't looking hard enough at the Data Plate on the Strut Tower.... or someone has cut it down to only the VIN... and the entire top part of the Data Plate is missing... Take a pencil and piece of paper with you - and maybe a flash light... The Data Tag on the car should look a lot like the one pictured below ... As you can clearly see - the ENGINE NUMBER 001482 is listed just above the VIN.... HLS30 200207 There are TWO little pads cast into the block - it would seem you took the 254234 number off the second one, and failed to see the L28 stamped into the first pad (first being the one on the left). Go look again... BTW - it would help of you stated what the VIN on the car is... FWIW, Carl B.

-

Clutch Problems

It might not be overkill , IF you were converting to DOT 5, while retaining all the original parts. Frankly I wouldn't bother at that point. I'd just flush the brake system with clean DOT 3/4. I do convert the brake systems on my cars, the first time I do a complete rebuild of the brake system, and I only flush out the hard lines with DOT 5... I've never bothered to clean them out with alcohol and blow them out with air... I've always felt that the pressure exerted by the brake master/and your foot on the pedal - forced the DOT 5 though the hard lines with enough pressure to clear out all the old DOT 3/4...... I could be wrong, but in 35 years I've never had any problems result from that process. Most of my 240-Z's sit a lot, it is very humid here in Florida all the time.. and if I don't convert to DOT 5 - I have to replace or rebuild the rear wheel cylinders every couple years (they are getting very expensive!!). Being aluminum, the rear wheel cylinders are only repairable (rebuild-able), IF you catch them before the corrosion has pitted the cylinder walls... which usually is not the case. Also the front calipers do tend to hang up and drag when left sitting with DOT 3/4 type fluids. That too has been eliminated by the use of the DOT 5. DOT 5 is NOT recommended for competition use - where you are going to heat the front brakes up to the point that it melts the bearing grease etc... Besides, you change the brake fluid after each track event anyway.. FWIW, Carl B.

-

Clutch Problems

If the clutch master is holding the clutch fluid - and the push rod at slave is in fact moving the clutch fork rearward about an inch and half..... all that is working at this point. If the clutch master was getting low - due to a very small, slow leak somewhere, when you were driving the car - then when you pushed on the clutch pedal to shift gears - the clutch itself may not have been fully disengaging at that point.... and you could have damaged either the clutch itself or the transmission. Since you said that the clutch pedal offers no resistance (even after bleeding it, even with all fluid levels full)..... I'd have to guess that the clutch disc or the pressure plate itself failed. With a good transmission - it is possible to start a 240-Z in first gear - and let it roll forward, then to build the RPM's up to around 2800... and shift it from 1st to 2nd with no clutch... This however is something that takes some practice, to get the right feel for the needed RPM's etc. .... Not something that is easy to explain, nor walk you though with words here... If you can start it in gear, and shift from 1st to 2nd without the clutch - then you know the tranny is OK, and it's the clutch itself that when out... But like I said - it is not something you want to try to learn with the car in its current condition... It won't hurt anything to go ahead and change the clutch master and slave out at this point - but if that doesn't do it - you'll more than likely have to pull the tranny and inspect the clutch assembly. FWIW, Carl

-

vin number

Z or ZX if it is an L28 the engine serial number will begin with "L28" Get the Engine Serial Number - and we'll see if we can match it up with something close - for which we would have an idea of the date of manufacture. The "F54" is one type of casting number found on the lower part of the block. Carl B.

-

Clutch Problems

Oh.. btw .. I hope you are correct about it being the clutch master/slave.... but you should be looking at the slave - while someone else pushed the clutch - to see if the slave is able to move the clutch fork or not. If it is moving the clutch fork about an inch and half - then it's not the clutch hydraulics that are the problem. Did you notice if the Clutch Master was very low on fluid or not, when you first looked at it? Does the fluid leak out quickly if you refill the master ? FWIW, Carl B.

-

Clutch Problems

Ok - New Clutch Master New Slave Cylinder New Rubber Line between the body and the Slave Fill with DOT 5 Silicone Brake Fluid. The Silicone will not absorb moisture out of the air like DOT 3/4 Brake Fluid, and it will help preserve all the rubber seals in the Hydraulic Clutch System. My original clutch master and slave lasted 30 years this way. (bought my 72 240-Z new and still have it). If you replace all three parts at one time - and use a little Silicone to flush out the hard lines from the Master to the Slave, before hooking up the Slave - you can switch to Silicone. DOT 3/4 are not compatible with DOT 5. Also make sure you buy pure silicone DOT 5. (not just something compatible with it). Do it right once.... Also agree - either use NISSAN OEM parts or NAPA's best... you have to tell the NAPA Parts Countermen that you want their best replacement parts - not the cheapest they handle... FWIW, Carl

-

1973 240Z in Santa Fe, NM

A 240-Z with that VIN was mentioned in the Feb. 2003 Issue of Sports Car Market... they said it did not sell at auction.... wonder if it's the same car. $20K - - not out of the question if the car is nearly perfect - and if the car checks out clean and straight in the undercarriage. If it is an original 48K mile car - not a doctored up, slickly detailed rag... Looking at the picture of the engine compartment I'd say that the Cad. Plated parts would have to be properly re-plated to make it a show winner.. Nonetheless, better to pay $20K up front for a really nice, clean, low mileage 240-Z - - than to pay $7K for a car then put another $10K into fixing it up - - only to wind up with car that's now worth $12K.... I can't see the engine mounts - but it was common to have a bit of engine blue over-spray on the original engine mounts by 73. If they are painted entirely blue -they have been repainted the wrong color.... FWIW, Carl B.

-

Fan clutch question

Hi Randy: Oh boy... this should be fun. I would say that the "test" you conducted is certainly an initial indication that perhaps your fan clutch is weak, if not shot. But in my mind it's only an indication to check farther. True that a Fan Clutch when new, will give resistance to spinning when it is warmed up to normal operational temps... but with the engine stopped. True also that a fan clutch that is shot - will spin easily under the same conditions. The big HOWEVER is that a fan clutch that is not new, nor shot, but somewhere in between the two extremes can do its job for a long time before it actually does wear out, or leak out. Given the expensive and difficulty of finding, buying a new fan clutch - you don't want to change one out until it is really necessary. Before I forget - - - - Did you write that wrong? "the temp would never go past 120-130" and for some reason you installed a 190 thermostat? I'll guess you meant 220 to 230 degrees F. I don't understand why you would be using a 190 degree thermostat in Knoxville this time of year. The first thing I would do, would be to replace it with a 160 degree thermostat, and add a bottle of Red Line Water Wetter.... then see if the engine returns to its more normal operating temp. In the middle of the Winter in one of the very Northern States, I might be running a 190 degree thermostat to maintain a normal operating range during severe cold.... About the fan clutch.... the "method" used by at least six of the professional "Datsun" mechanics I knew back in the day (the 70's) goes as follows.... YES IT IS RISKY - YOU HAVE TO BE CAREFUL... I'm not TELLING ANYONE TO DO - only reporting the procedures and processes that worked well for the guys you pay to work on your Z - 1. Start the engine and make sure it is up to normal operating temps for at least 15 minutes. This will allow enough time for the fan clutch itself to heat up (ie to catch up with the block temps). This is important. The fan clutch is activated by the hot air coming off the radiator, as well as by the hot water flowing through the water pump. All this has to normalize before the fan clutch - engages. Centrifical force driving the hot and expanding silicone fluid toward the outside of the fan clutch also plays an important roll (part of the reason the "static" test of spinning the fan on an engine that is stopped can give you a false indication). 2. While your waiting for everything to warm up - get a piece of thin cardboard, typically used for product packaging...not the type used in heavy cardboard shipping boxes.... Fold the thin cardboard until its about three or four layers think, two to three inches wide, and about 10 to 12 inches long.... 3. With the engine idling - push the cardboard on a downward angle into the spinning fan, in the direction of rotation, when the fan blades are moving in a downward motion. If the fan simply pushes the cardboard out of the way, and keeps spinning - the fan clutch is fine. If on the other hand if you can stop the fan from spinning by using moderate resistance - the fan clutch is shot. If course replacing a serviceable Fan Clutch with a new one - can't hurt anything. But it might mask, at least for a while, some other problem with the cooling system. FWIW, Carl B.

-

really low mileage 280 on Ebay

How Much $$$ Also - I hope the Cad plating on your engine is in far better condition, than that shown on the 76 280Z.... for that matter I'd expect the entire engine bay to look far more original and clean as a a pin. FWIW, Carl B.

-

girl with windows.

Hi Panamared: The Z looks great... Once the paint and body work are done, it's all down hill from there. Talk about memories of being a kid.... McDonalds.... When I was in college, four of us shared a one bedroom apartment to hold expenses down (that's an understatement). At any given time, at least one of the guys worked part time at the large McDonalds right across from campus. Back then (64-68) if any burgers sat for more than a few minutes (30?) without being served - they were thrown out. After the rush hours at lunch and dinner there were of course always lots of burgers that didn't get sold. "Thrown out"??? no way... the guys always bagged them up and brought them home after work. We all lived on them for four years!!... To this day, I tell people I went to college on a McDonalds scholarship - and to this day I still get cravings for McDonalds cheeseburgers and fries! Nothing else will do..... FWIW, Carl B.

-

Replating Hardware

Be careful there Nissanman!! Years ago, one of our (Honeywell Aerospace) retired Master Machinist's son purchased a basket case classic car project. Car completely disassembled, boxes and boxes of parts all over the place. Of course all the chrome parts as well as many bits and pieces had to be re-plated. His son was sending the parts out to a shop a few hundred miles away - paying serious money for the work. When his Dad started looking at the quality of the work coming back - he remarked that it was very poor in his opinion. When his son told him the work was done by what was supposed to be one of the better shops doing "show quality chrome"... his Dad told him he could do a better job in the garage than that!. Within three months of that exchange - Dad had set up a metal finishing and home plating capability in the garage. As friends of the son started to see the quality of Dad's work vs the "professional shops" - - they all wanted Dad to do their parts as well. Long story - short - three years later Dad had 35 employees, two full time Chemists and a very large plating business. He was also doing MilSpec and Space Qualified plating for several aerospace and defense industries here in Florida... So be careful - I'd hate to see a Retired Gentleman sucked back into the fray - kind regards, Carl B.

-

Replating Hardware

Hi Alan: Good point - my bad.... Also, since the original question was ..."...where can I buy new gold cadmium bolts & nut"... I should also have pointed out the fact that many of the new replacement nuts, bolts, washers etc. sold by Nissan are now in fact Zinc plated first...Buy enough NOS parts and directly compare them with the replacement parts manufactured years later and you can see the slight difference. The price we all pay for Environmental controls. FWIW, Carl B.

-

Replating Hardware

Speaking of Electroplating, when you are trying to find the right company to do the job you want done - it is very important that you know specifically, technically and exactly what you want. Otherwise the Sales People will blow you off - and sell you what they have, not necessarily what you really wanted. Most plating shops and the people that sell their services will tell you that the original parts were Zinc plated - NOT TRUE. They will tell you that "yes" they do Cad. plating - NOT TRUE, they'll use Zinc anyway, then they will say that it doesn't matter, or that they are the same etc. NOT TRUE. Cadmium is NOT Zinc. Cadmium provides longer lasting protection and higher durability rates than Zinc. They can be close, but they are not the same. In the 60's and early 70's - Nissan Suppliers originally Cadmium Plated the items, then processed them through a Yellow Chromate bath. This results in the more or less gold looking part that has a rainbow of color flowing uniformly through it just under the surface of the gold color. The "original" finish that you want, if you want a near perfect restoration has to created in the same plating process, and even more importantly that final Yellow Chromate bath has to be exactly controlled. In the Mass Production of the original parts these processes are normally automated, so batch after batch the quality and appearance of the finish is uniform. During a "re-plating" process, done on very limited quantities of parts, at smaller plating shops, that process is most likely going to be done by human hands. Leave the Cad. plated parts in the Yellow Chromate bath for too short or too long a time - and the final finish will look quite different. High quality re-plating takes time and costs serious money, but high price alone doesn't equal high quality. Cadmium is a very heavy metal, and therefore also very toxic in concentrated solutions to the environment. For that reason, the use of Cadmium in electroplating has been severely limited in the electroplating industry in the U.S. Severely limited, but not eliminated - plating companies that do MilSpec. quality and Space quality work, can and do still use Cadmium if specified - - it is however VERY Expensive. (two to three times the cost of using Zinc) Most shops now substitute Zinc for Cadmium. Both Zinc and Cadmium result in a very light gray metallic coating - that are then subjected to the bath of Yellow Chromate that gives them that "Gold" finish we all recognize. Nonetheless Zinc and Cadmium absorb the Yellow Chromate at different rates and to different degrees. If the person controlling the process is very experienced, and very watchful, if the chemical solutions are carefully controlled... they can get Zinc plated parts to come out of the Chromate bath - with a final finish that is very very close to that of the Cad. plated parts... But high quality process control takes time and costs money... Does all this really matter? That's entirely up to you. Remember too that the final quality of the parts coming out of the plating processes -can be no better than the quality of the parts going in. Every nut, bolt, screw, washer and component part have to be clean, with uniform surfaces. Pitted, scarred and worn parts going in, will be just the same coming out. FWIW, Carl B.

-

73 240z spotted on Ebay

Very Interesting to compare the words/description in the first auction by Yutakazz and the second by money$jewelry. You can also see why money$jewelry has a 92.9% feedback with only 12 reports coming in. As I said above at Post #2 - "IF it checks out as being rust free - solid floors, not patched...." It would appear that money$jewelry neglected to mention the "floorboards" having been fiber-glassed, where as Yutakazz made a point of tell you that detail... Nonetheless it looks like money$jewelry did put some additional time, effort and dollars into the car.. Just a good thing to keep in mind - "rust free" - is not the same as "never any rust damage". As Mull found, a "rust free" Z, just might really mean that all the rust was cut out and replaced with fiberglass and bondo... At any rate - in that part of the Country - with all the work and parts on the car - it was still a good buy at $6K, if you want a 240-z to drive. FWIW, Carl B.

-

Turbo Carburated?

Back in the day - - - I had seen about four of these systems installed. Crown sold a kit for both the 240-Z's and the later fuel injected 280Z's. A local Z mechanic, replaced the single S.U. used in the system with a side draft Weber 40 DCOE. He built his own adaptor plates - to mount the Weber in place of the S.U. As I recall these systems recommended no more than 8lbs of boosts... but several of the guys ran 10lbs for years.... O-Ringing the head was also recommended by the kit manufacturers at the time (mid-70's). I agree with Nissanman that the old school kits do not really compare with running an L28ET with the factory or newer engine management systems, ect. Nonetheless, for $300.00 if the entire kit is there it could be some really cheap fun.... as long as you don't over-use it and blow an engine. FWIW, Carl B.

-

73 240z spotted on Ebay

If it checks out as being rust free - solid floors, not patched.. solid frame rails etc - the Buy-it-now seems about right for that area of the country... FWIW, Carl B

-

Turbo Carburated?

Hi Will: What Studebakers used a turbo? I remember in the mid 50's and early 60's they used a belt driven supercharger, that pressurized the carb.. (Golden Hawk and Avanti)... I still think the 63 Avanti was one of the best designs of the decade, and wouldn't mind having one today. I think the 62 Olds Jet-Fire was the first tubo from GM, followed by the 63 Corvair Spyders. FWIW, Carl B. FWIW, Carl B.

-

E31 head question

Hi Bill: The Atlantic Z Club has a good list of OEM Cam's and Marking. <a href=http://www.atlanticz.ca/zclub/techtips/cam/index.htm TARGET=NEW>CAM SPEC.'s</a> Looks like the self oiling "A" cam came with the N42, N47 and P79 Heads before 8/81. FWIW, Carl B.

-

old zman

Hi Daryl: Good to see you here. As everyone has mentioned - it's a great group. Daryl is #139 on the IZCC's Z Car Original Owners Register. I think we have about 156 Original Owners on the ZCOOR now. However we are starting to see some of the Z's being sold, or turned over to the second generation within the family. Good to hear your still driving yours... There must be some kind of Guinness Record for total number of years owned by the original owners for any specific Sports/GT there somewhere. On average that's 1,842.5 original ownership years. kind regards, Carl B. Clearwater, FL USA http://ZHome.com

-

Side Mirror Removal - Replacement

The "easy" way to do it - is to just remove the side window glass. If you have a Snap-On type "wobble" extension, and if you grind down a longer socket, such that it fits over the threaded stud to reach the nut, but is still short enough to fit in the covered area.. it is possible to remove/install the mirror with the side glass in place. Best advice - just pull the glass and be done with it. FWIW, Carl B.

-

Z reclassified from GT2 to GT3!

Hi Mark: What type/brand of racing fuel are you running and what octane? thanks, Carl B.

-

Question about strut mounts (insulators)

Jim is correct - that would be a "Spacer-Rear Spring. 55045-E4100 Most of the time when you remove the rear struts and take them apart - you don't notice the spacer because it is usually stuck up in the insulator. They do however go bad, and they can fall apart or out. If you look up inside the insulator and see metal - it is most likey the spacer has crumbled and fallen out... FWIW, Carl B.