-

For Sale (Used) - Original N42 L28 Engine Parts

Good question - these are the standard sized original equipment pistons. If anyone has interest, I can take the time to confirm with pictures of measurements, or further pictures showing condition, etc.

-

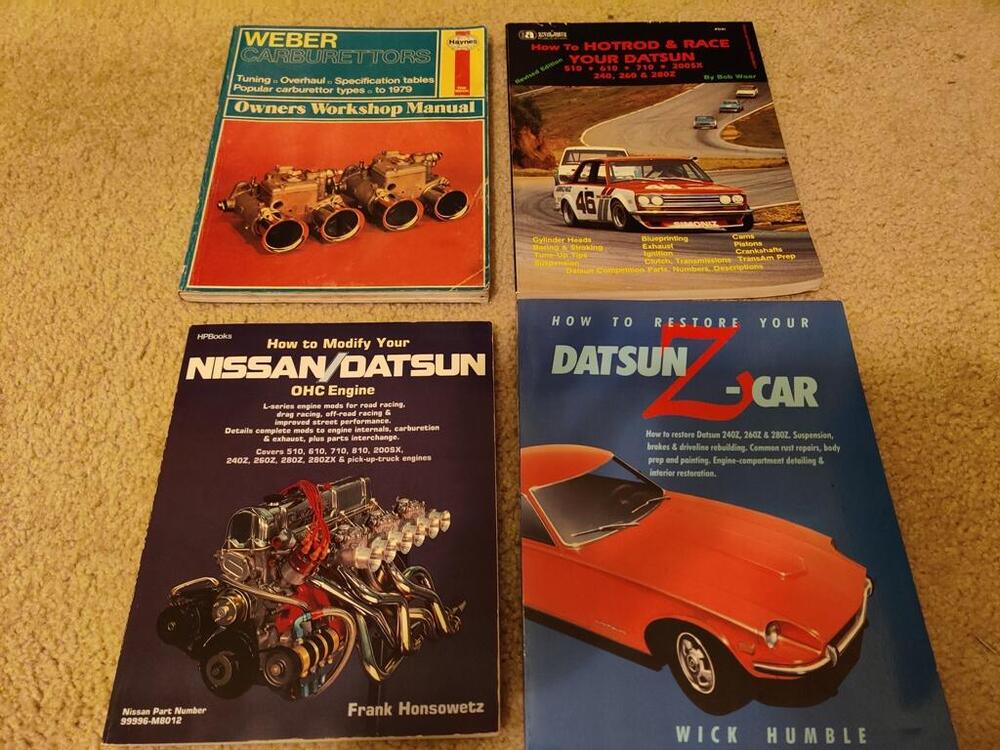

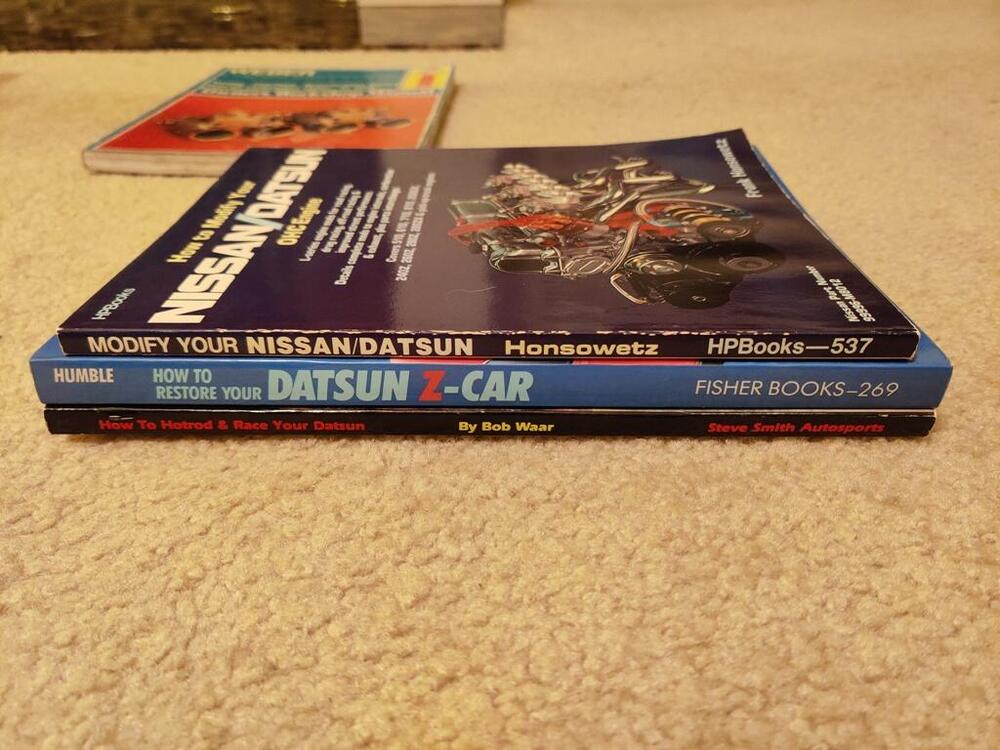

For Sale (Lightly Used) - Datsun Books: How to Hotrod and Race... How to Modify... How to Restore...

How to Modify Your Nissan/Datsun OHC Engine, original edition: has a blemish on the back cover, excellent otherwise: Price is $20 plus shipping How to Hotrod and Race Your Datsun, original edition: In nearly excellent condition: Price is $100 plus shipping How to Restore Datsun Z-Car, original edition I believe (copyright is 1990) - binding shows some light detachment - all info on pages is intact. Overall condition is good Price is $10 plus shipping PM me with questions. ---Garrett

-

-

For Sale (Unused) - Procar Seat

Price: I am unsure how to assign a value to this item. I will set it at $300 plus shipping; however, the price is negotiable. PM me with questions --- Garrett More information about Procar seats that are currently available for purchase new can be found here at this link

-

For Sale (Used) - Original N42 L28 Engine Parts

Price is $1 plus shipping I have several spares leftover from disassembly of an N42 L28 engine. Exhaust manifold in very good condition - all down pipe studs intact ($1 plus shipping): Miscellaneous original engine parts (cam gear, head bolts, dip stick, oil pickup tube, oil pan reinforcement plates, etc. $1 plus shipping for everything in this box, or let me know if you just want one item to save on shipping. Stock pistons (dished) and rods $1 plus shipping: Two pairs of L28 engine mounting brackets ($1plus shipping for each pair). Alternator mounting brackets $1 plus shipping for one upper and lower pair. PM me with questions. ----Garrett

-

These are SOLD ------- For Sale (Used) - Original 240Z Chrome Dash Vents

Price is $20 plus shipping This pair of original dash vents are in very good condition. PM me with questions. ---Garrett For your reference, reproductions are available for $40 each if you prefer to go that route.

-

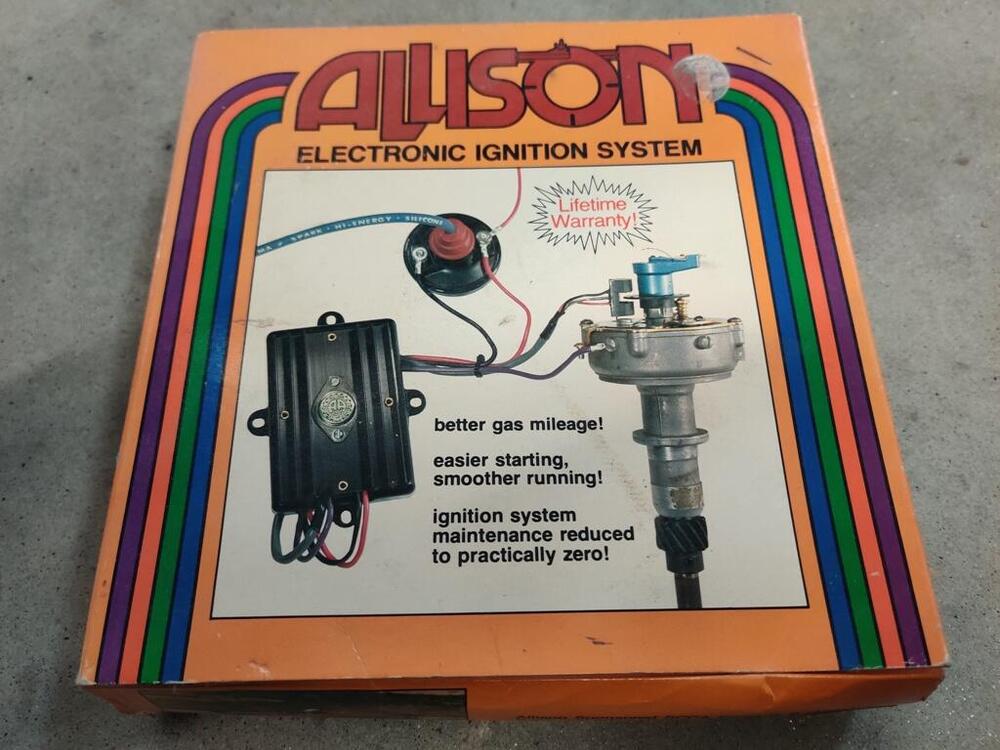

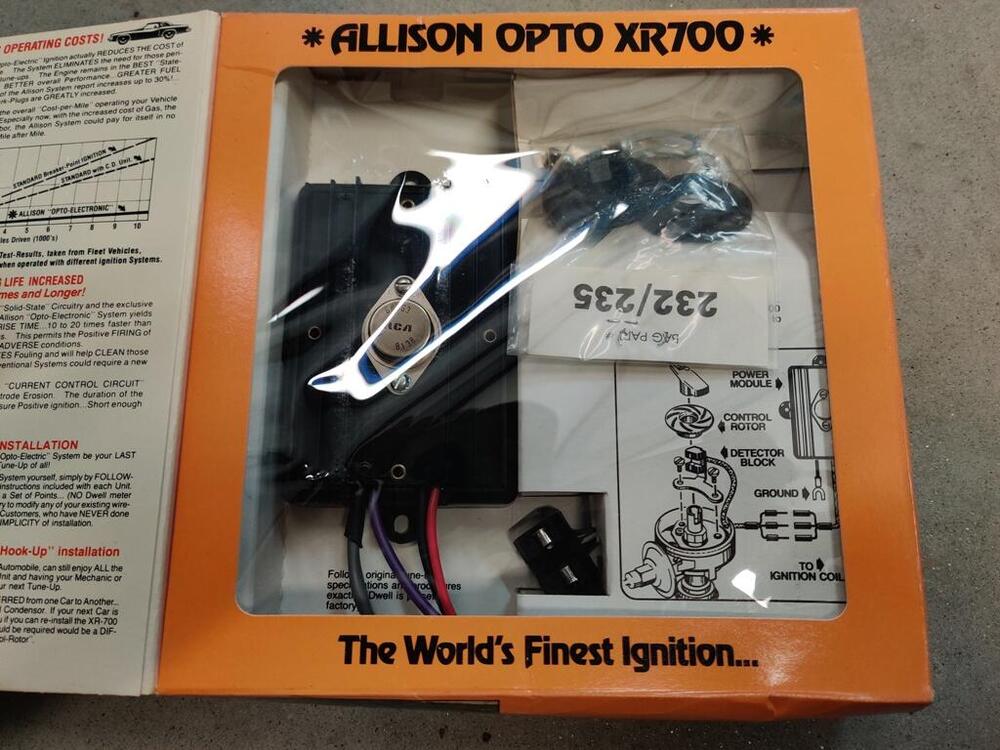

For Sale (Not Used) - Crane (Allison) Electronic Ignition

Price is $20 plus shipping 7Unused Allison (Crane) XR700 Electronic Ignition. PM me with questions. ---Garrett

-

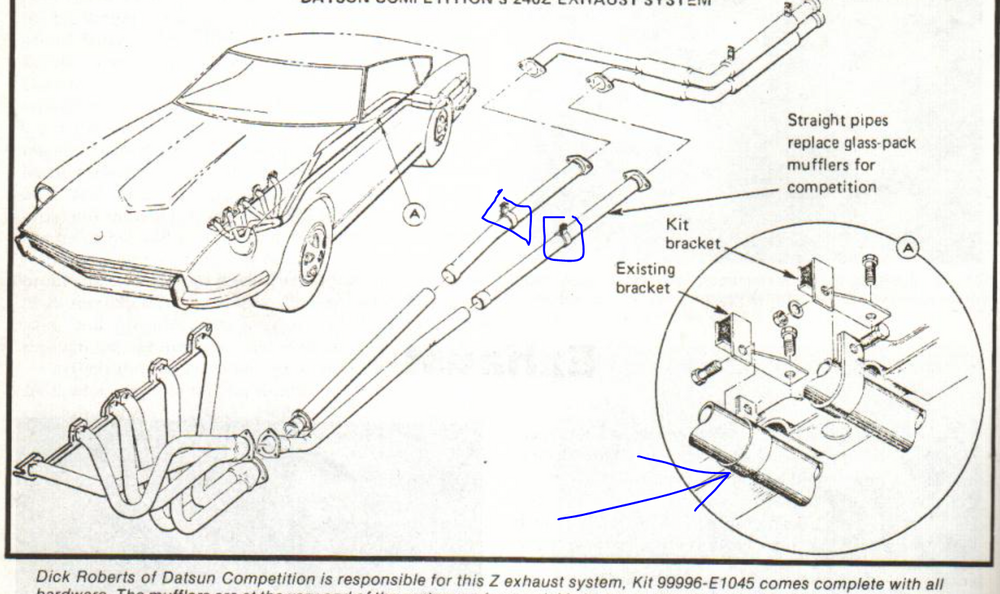

For Sale (Used) - Original Datsun Competition 240Z Exhaust Mounting Brackets

Price is $10 plus shipping for both brackets These are original Datsun Competition exhaust system brackets. Figured I would see if anyone needs them before I toss them in the trash. PM me with questions.

-

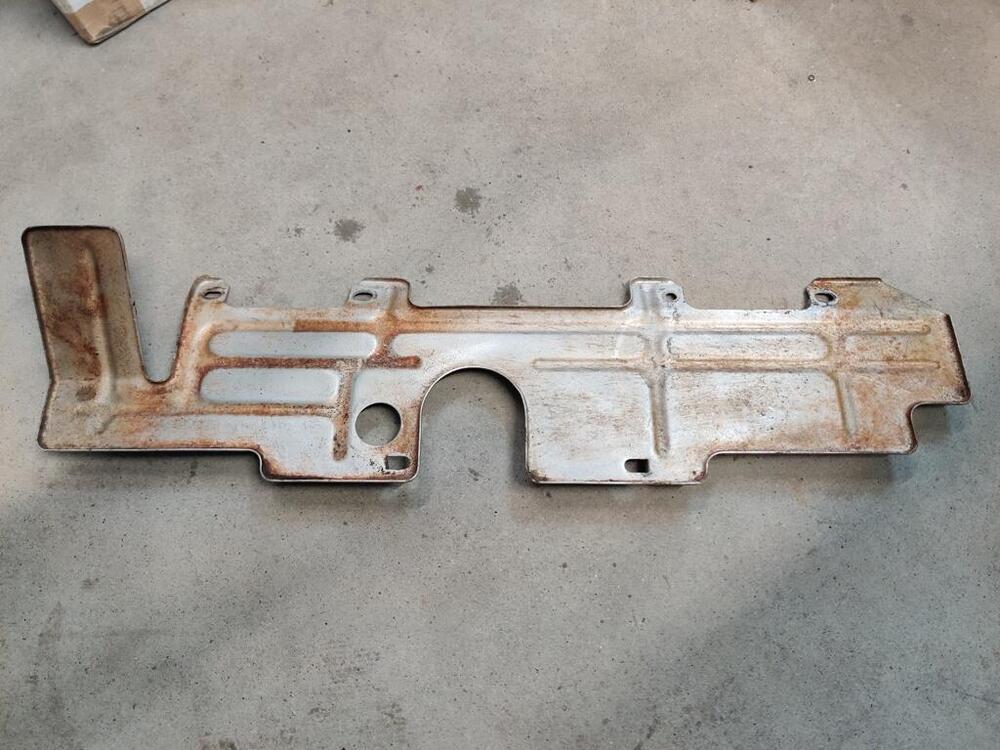

For Sale (Used) - Stock 1971 240z carburetor Heat Shield

Price is $50 plus shipping Stock 1971 240z carburetor Heat Shield - I think this is what you need for the 1970-1972 Z's. PM me with questions. ---Garrett In very good condition:

-

For Sale (Used) - Original 240Z seat belt set (9/70)

Price for the set is $400 for this complete set of seat belts Complete, original Datsun 240z seat belt set from 9/70 in what appears to be very good condition. The webbing is is excellent condition. Chrome looks very good. Buckles are fully functional. Even mounting hardware is present! PM me with questions, additional picture requests, etc.

-

For Sale (used) - Jags that Run radiator with all mounting hardware

Price for the radiator, mounting brackets and hardware is $50 plus shipping Originally purchased from and now discontinued by Jagsthatrun.com. This radiator features a core with two extra large cooling passages. You get the radiator, mounting brackets and mounting hardware. Not pictured below but pictured here are the mounting brackets: http://jagsthatrun.com/products/v8-datsun-radiator-mounting-bracket-kit See this PDF supplied by JTR for more information about this radiator: https://cdn.shopify.com/s/files/1/2586/1438/files/V8-DatsunZ-Cooling-System.pdf?16627445939611620968

-

For Sale (Used) - two (2) 16 X 7 Panasport wheels

Price is $450 plus shipping for both wheels Description: These two wheels are lightly used - straight - correct offset for Datsun Z cars. PM me if you have questions. --Garrett For reference, 16 X 7 Panasports are still available new for about $380 each plus shipping here: https://www.sportsandclassics.com/parts/non-british/datsun-non-british/datsun-roadster-2000-fairlady-16x7-panasport-z-light-wheels-new-production/

-

Need Help with Hooking Up a Speed Hut Tachometer

Well, I certainly could run a new, and completely separate wire from the coil "-" through the engine bay, through the firewall, and to the existing yellow wire to run the Speed Hut tach. But, the existing B/W and G/W wires basically already routed in the stock wiring harness from, and to where I need to go, are made completely redundant by doing so. Why not repurpose one of them and save the time and effort to run another wire? Looking at @SteveJ's wiring diagram that shows after modifications, I see that he chose the B/W that originally went from the coil "+" to the stock tach 4 prong connector as the wire to repurpose for use with the Speed Hut gauge. Of the two original wires (B/W and G/W), only the G/W wire has no purpose after this modification. I've got some other wiring that I need to figure out how to route as well. For example, I need to wire in a coolant temperature sensor and harness for dual electric fans, and the wiring for oil pressure, oil temperature and coolant temperature senders. So, I will be thinking about how best to route those through the engine compartment and where necessary, to the gauges in the dashboard. I am set for information I needed to wire up the tach - thanks to all who responded!

-

Need Help with Hooking Up a Speed Hut Tachometer

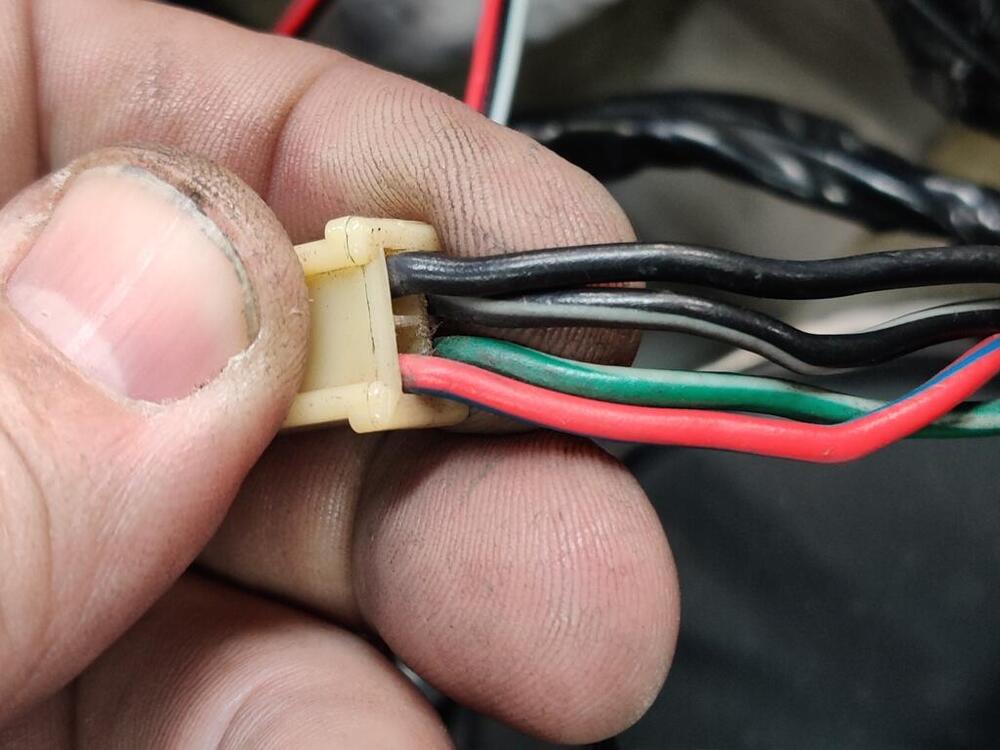

Thanks for the information. So, let me know if my rewording here is accurate: there is a B/W wire going from the ignition switch (routed through the factory wiring harness) to the Ballast Resistor. On the other side of the Ballast Resistor, there is a G/W wire (which again is routed through the factory wiring harness) to the 4 prong tach connector in the dashboard. This is the "re-route" to the back of the Tach (not the B/W back to the Tach). At that connector, the G/W wire connects to one side of the loop in the Tach (white wire with black band which connects in some way with the white wire with the red band - thus the loop). Continuing... in the 4 prong connector, the white wire with the red band connects to another B/W wire. This B/W is again, routed through the factory wiring harness and is connected to Coil "+". So... I am not using the ballast resistor any longer. I have a CraneHi6 aftermarket ignition and a high voltage coil (for mulitiple spart discharge requirements of the ignition). So, if I take the B/W wire that was connected to the ballast resistor, and connect it directly to the Coil "+", I am simply moving the B/W wire which is coming from the ignition and moving it to the coil "+"... directly. Doing so frees up both the B/W and the G/W wires (which already are routed through the factory harness). Question: could I not just attach either of those freed up wires to coil "-"... and then connect whichever of those I choose to the single yellow wire for the Speed Hut gauge? At least that way, I don't have to route a stand alone wire... and I can repurpose one of the now "extra" wires already present. My 12/70 Tach connector (4 prong) definitely has a RL wire in it (I edited my post and added a picture of the connector). That wire is "supposed to be" green according to the wiring diagrams, but it isn't. No doubt, this is a difference when comparing "earlier" 240z's to later ones. I know the gauge lighting (IL = illumination?) is RL as well (both in the wiring diagram and in my car). So, yeah... that certainly added to my confusion.

-

Need Help with Hooking Up a Speed Hut Tachometer

I am working on installing a set of Speed Hut gauges in my 240z (my "track car"). Manufactured in 12/70, the wiring for the tach doesn't match the wiring diagrams I see online. Other than power and ground and illumination wires, the Speed Hut tachometer has a single yellow wire that is supposed to be hooked up to the "coil -". It seems to me, after looking at the stock wiring, I have to not only figure out which wire is "coil -", but I think I may have to connect some of the other stock wires together in order to "bypass" the stock tach. Color legend is: blue = L yellow = Y Black = B Red = R White = W Green = G Ignoring the wires for gauge illumination, I am looking specifically at a 4 prong connector for the stock tach. Here is what I am looking at... on the left are four wires from the harness that are in the 4 prong connector, and on the right are the four wires coming from the tach that are in the 4 prong connector: Harness wiring Description Connection Tachometer wiring Description RL red with blue stripe ---- YR yellow with red stripe GW green with white stripe ---- W white (with black band on it) B black ---- B black BW black with white stripe ---- W white (with red band on it) Additionally, I am running a Crane HI6 (multiple spark discharge) ignition which also has tachometer adapter hooked into the circuit. The ignition and adapter were previously in use and worked perfectly with the stock tach. The wiring for the ignition and adapter has been untouched since the car ran. What I need help with: Which wire is the negative from the coil? Which, if any, wires do I have to jumper together with the stock tachometer no longer in place? My guesses are: Black - connect the Speed Hut yellow wire to the black wire in the 4 prong connector Connect (jump) the green with white stripe wire and the black with white strip wire (to bypass the stock tachometer) But, I am not sure. And don't know what to do with the last of the four wires (red with blue stripe at the four prong connector).

-

New, short video of my restored 240Z

What you see on my car is what the body/paint shop came up with when they mixed the Glasurit paint to the stock 901 Datsun code. I left the inside of the right tool door the original paint. The original paint is a touch darker/greyer to my eye. Garrett

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.

Subscriber

Subscriber