Everything posted by inline6

-

Restoration of BringaTrailer 240z - HLS30-35883

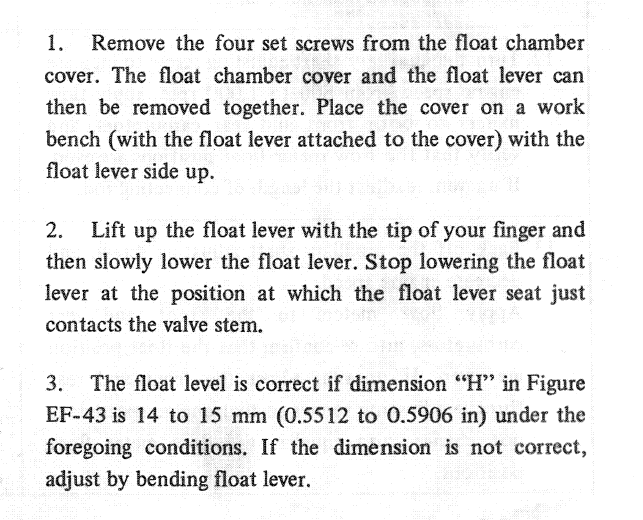

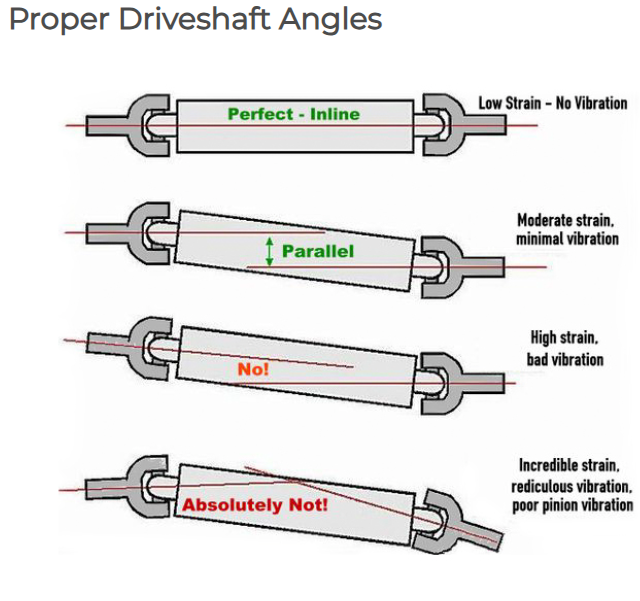

The odometer clicked over 500 miles on Friday night, so I took the valve cover off yesterday and did both the leak down test and adjusted valves. Here were my leak down percentages: #1 = nearly 4% #2 = 2-3% closer to 2 #3 = 4% #4 = 4% #5 = 3% #6 = a little over 1% For my Iskenderian cam, the valve lash is .006" on the intakes and .008" on the exhaust. I set each so that the feeler gauge was a snug fit while the engine was cold. All of the cam lobe surfaces looked great! The next time I fire it up and get the oil warm, I'll change the oil. Today, I removed a portion of the exhaust and the driveshaft and measured the angles of the front engine dampener and the pinion flange on the differential. I believe I will be able to lower the transmission rear crossmember to bring the engine/transmission assembly to the same 87.1 degrees that the pinion flange is at. I will just need to add shims between the transmission crossmember and the car body. Oh! And I just remembered that I should check the angles in the horizontal plane (not just vertical) as well.

-

How vibration free is your 70-71 240Z?

I found the angles today of the front dampener and the pinion flange: I measured these with the car on the lift. The rear moustache bar is locked in solid - there is no vertical movement at the mounting location. Same for the front. So, I don't have to consider suspension movement (doing this with the suspension loaded). The angle at the differential pinion flange is 87.1. And the angle at the engine dampener is 89. I should be able to drop the rear of the transmission, hopefully a small amount, to get the angle at the dampener to match. I am glad I didn't use the original motor mounts, which were shorter, and would make this problem worse.

-

Restoration of BringaTrailer 240z - HLS30-35883

It's been a while since I posted an update on the restoration! I have been driving the car - I have 488 miles on it. I reset both front and rear floats using the method in the factory workshop manual. To do so, I cut some "3d" finishing nails to the approximate lengths of 14 mm and 15 mm and then finished them to size with a benchtop grinder. The procedure from the factory workshop manual: Holding the assembly in its installed orientation (not upside down), I first place the 15 mm nail section in between the flat metal part of the float and the underside of the float chamber cover. I put it in place using needle nose pliers so that it is straight vertically. I pinch it to hold it in place by lightly squeezing the float and the chamber cover together. Note that when held in the installed orientation, the needle in the needle is in "free fall" and is in a fully open position. Then, using a magnifying glass, I inspect the area of the float tab and the tip of the needle. I verify that the tip of the needle is not touching the curved arm (tab) of the float. It does have to be within 1 mm of it however. If not, when you swap to the 14 mm nail section, the tab will still not touch the tip of the needle. I adjust the tabs so that both carburetor floats contact the tip of the needles with the 14 mm section of the nail in place. Interestingly, after I had set the floats this way, I noticed that with the 15 mm section of the nail in place, I could blow through the fuel inlet tube, and with the 14 mm section of the nail in place, I could not. So, what I found was that from fully open, to seated, the needles have less vertical movement than 1 mm. While I have been driving the car to break the engine in, I have been looking at air fuel ratios (AFR) using a wideband 02 sensor. I swapped from what I believe to be stock N27 needles to some SM needles. But, I have observed AFRs moving around a bit which is unusual and not expected, and which I think may be due to the engine still breaking in. I started a separate thread that details more about what I was doing and seeing here: https://www.classiczcars.com/forums/topic/69292-choosing-an-su-needle-if-i-have-needle-station-info-and-real-world-afr-can-i-use-that-to-find-the-right-needle/ This weekend I plan to do a leak down test on the engine to confirm break in is complete, change to standard oil (instead of break in oil), and adjust the valves. If the engine is fully broken in, I will do some more AFR testing and determine how to proceed. I may need to modify the SM needles in the cruising and pick up stages by some very light "sanding" - removing material by chucking them up in drill and using 2500 grit sandpaper only in a certain area of each needle. With the driving I have done, I also noticed a vibration at higher speeds. I started a separate thread for that issue: https://www.classiczcars.com/forums/topic/69334-how-vibration-free-is-your-70-71-240z/#comment-675670 Today, I am going to buy a digital angle gauge so I can check some angles in the driveline. I am hopeful doing this will help me determine the cause and fix that issue.

-

How vibration free is your 70-71 240Z?

This video is good as well - much longer and somewhat entertaining actually: https://www.youtube.com/watch?v=YgNZfIR-8Ng

-

How vibration free is your 70-71 240Z?

Thanks for that info, Mark. So, it seems like I should focus my efforts on the driveshaft. While I had the driveshaft shortened and balanced by a reputable driveshaft shop, I am thinking I will need to have it checked. There are actually several driveshaft shops near me, I found out today. I also am unsure if the alignment of the transmission to the differential is off. I need to check left to right of each as well as vertical angles of the rear of the transmission and the front of the differential. Raising the engine a small amount from stock (via the new motor mounts) may be a factor. I am going to buy a digital inclinometer to help with figuring these angles out.

-

Choosing an SU Needle - If I have needle station info and real world AFR, can I use that to find the right needle?

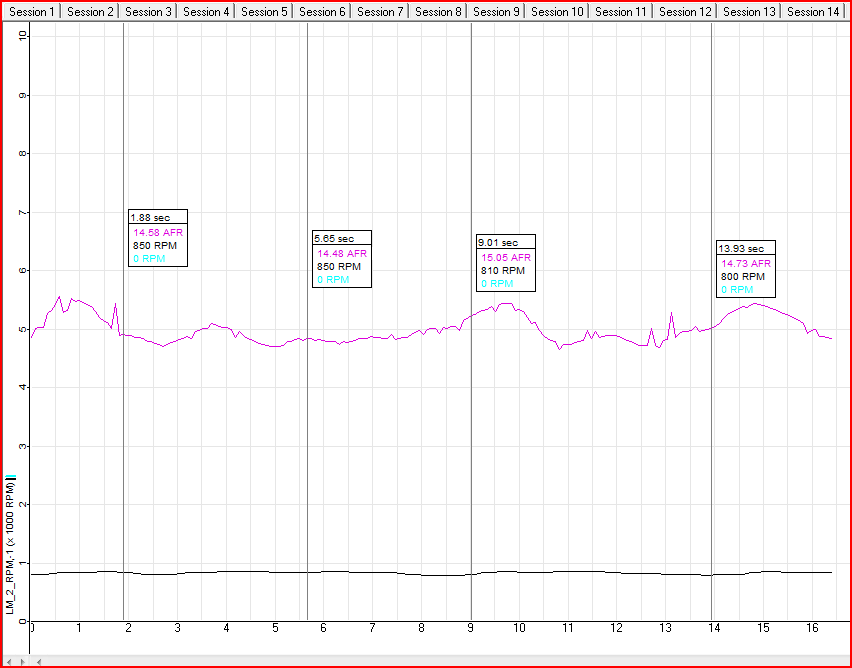

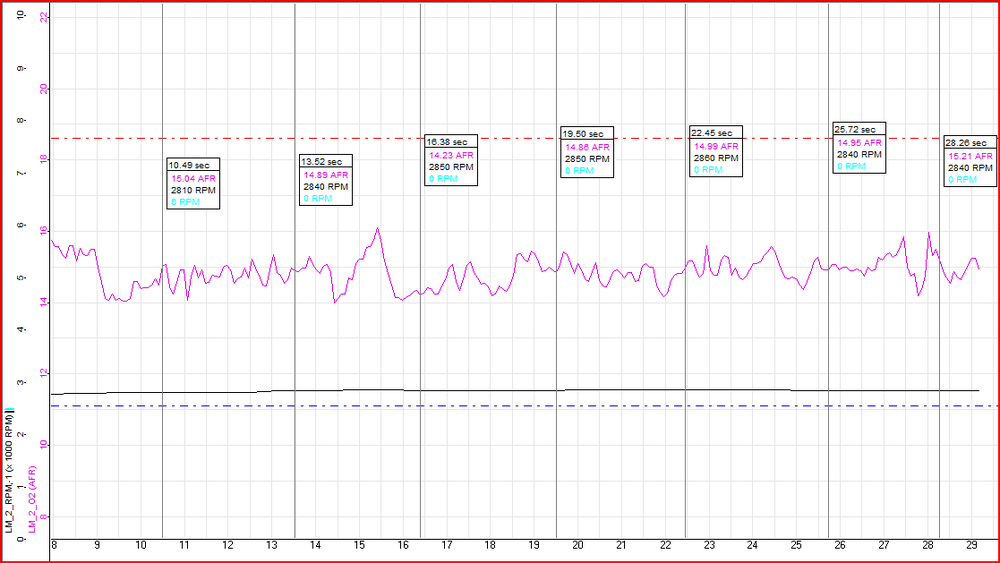

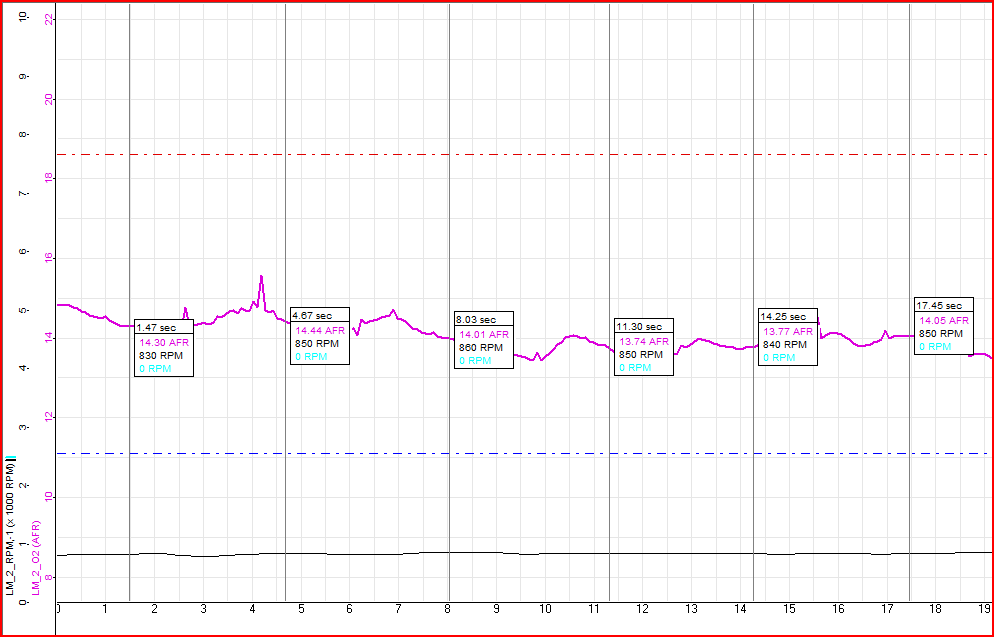

I put some easy miles on the car yesterday; I took it on the interstate for the first time. No full throttle application, I just did some cruising. I have completely eliminated all exhaust leaks I had at the joints. I have ensured that all the nuts and bolts relating to the intake manifold and header are tight and there are not leaks. While I was driving I took a couple more AFR recordings. With the SM needles, I am looking pretty darn good at idle - very near 14.7 to 1: My carburetor linkage is hanging a bit. When I drive normally, and stop for a traffic light, the idle is staying at about 1000. If I rapidly tap the gas pedal, the throttle plates drop a touch, and idle is steady at about 850. I have verified that both carb linkages are hanging... by what looks like something less than .010". When the linkage is hung and the car is idling at 1000, I can put my finger on the carburetor shaft linkage (each one) and force it to shut fully (move the linkage the last few thousandths to contact the idle screws). I think this is likely to go away when I get some more miles on the car. Anyway, during cruise, I am definitely lean with the SM needles - around 16.2: I don't notice any surging when this is happening. All seems well. However, if I depress the gas pedal anywhere from slightly to moderately, the AFR goes a bit more lean and I feel that hesitative state. I still plan to wait until I am at 500 miles before I attempt to do anything else. I am only 50 miles away from that point. Then I will do a leak down check, an oil change, and check valve lash. If the engine is fully broken in at that point, I will need to figure out what to do with either SU spring tuning, or needle tuning.

-

How vibration free is your 70-71 240Z?

Today, I was putting on some miles to be sure the engine is broken in fully on the Z I recently "finished" restoring. I have a vibration that seems to become noticeable around 70 mph. I have only owned two 240Zs, but I have experienced some driveline vibration with each of them. I was hoping not to have the issue with this one, but it is present. And it is bugging me. First, a simple question: Is it perhaps, normal... for a 240Z to have a driveline vibration? I mean, maybe with me driving modern cars, I just have lost touch with how these old cars really were? How do I describe it? Well, for one, the rear view mirror vibrates and blurs the image I see in the mirror a bit. That doesn't seem right. But, it isn't just the mirror. If I touch the center console, or the padded area of the transmission tunnel, I can feel the "hum" that is happening. And, I can feel it coming through the seat as well. The driveshaft has new OEM u-joints and was shortened and balanced by Carolina Driveline in SC. The rear axles have new, OEM u-joints and when they were installed, measurements verified they had the right amount of axial play. The rear differential has all new bearings and was assembled properly. The differential location is stock - it has not been shifted back as was done by the factory for the 1972 and later cars. I remember that the new engine mounts were thicker than the old ones by a bit. That may have raised the engine a touch. I also recall there being some slop in the transmission mount, which allows for a bit of side to side movement of the transmission. I think I will look at the propeller shaft angularity... to see if that looks off. I am interested to hear how much vibration... or how vibration free... is your Z?

-

Choosing an SU Needle - If I have needle station info and real world AFR, can I use that to find the right needle?

I have driven the car two times since the last post. Indeed, the AFR at idle is now higher - it is about 15.4 at 850 RPM. Cruise at 50 in fourth gear on flat road (2800 RPM) is about 15.8 AFR (much higher). While at full throttle in first and second gears, the AFR is about 13.1 to 13.2 (also much higher). No other changes were made. I just tightened the four nuts holding the carburetor bodies to the manifold, and each of the nuts holding the header and the lower half of the intake manifold to the engine and the 6 bolts holding the top of the intake manifold to the head. I also tightened the bolts that hold the intake balance tube to the intake manifold. I don't understand what I am seeing now. Perhaps tightening these, I have introduced a vacuum leak? What is odd though is that the engine seems to have more power. Oh... here is a thought: perhaps the engine is still breaking in! I only have 384 miles on it. Maybe as the cylinders seal a bit better, the combustion is more complete, and that is changing the AFR. I am going to put some more miles on it to get to about 500, and then do a leak down test and record the numbers. If the numbers confirm it is broken in, I will change out the break in oil. Then I will pick up with AFR testing.

-

Choosing an SU Needle - If I have needle station info and real world AFR, can I use that to find the right needle?

Just thinking through the option of adding a longer duration of time that the piston takes too drop - that would occur with higher weight oil. Probably wouldn't be the way to address the issue, because it would only add say another second or so (just guessing), before the piston would reach the same point of travel (and the needle reach the same point inside the nozzle) where it goes really lean. I found I was able to tighten all of the nuts holding the carbs to intake manifold as well as the intake manifold and header to the engine. Some I was able to tighten nearly a quarter of a turn. I fired the engine up after that, and I got a wildly different AFR at idle. So! It was raining and I didn't want to take the car out. I will revisit and see if I tightening up those things has perhaps eliminated an air/vacuum leak.

-

Bodywork Issues

Have a look at this post in this thread. https://www.classiczcars.com/forums/topic/55369-1971-hls30-14938-lily-build/?&page=79&_rid=2858#findComment-66409 Charles mentions that his hatch lifts up as a result of the interference he describes.

-

Choosing an SU Needle - If I have needle station info and real world AFR, can I use that to find the right needle?

I had it connected and it was working, but it malfunctioned twice (after the engine was warm), causing the engine to "idle" at like 2800 rpm. So, I took out the adjusting screw, which keeps it from operating on the linkage. Perhaps I will hook it back up again and troubleshoot the issue. And I noticed that the on blip, the AFR "nearly instantly" went rich. That is certainly good, as it shows the carb is working like it has an accel pump circuit. That tells me I could experiment with a higher weight oil than the 10W-30 I have in there now.

-

Choosing an SU Needle - If I have needle station info and real world AFR, can I use that to find the right needle?

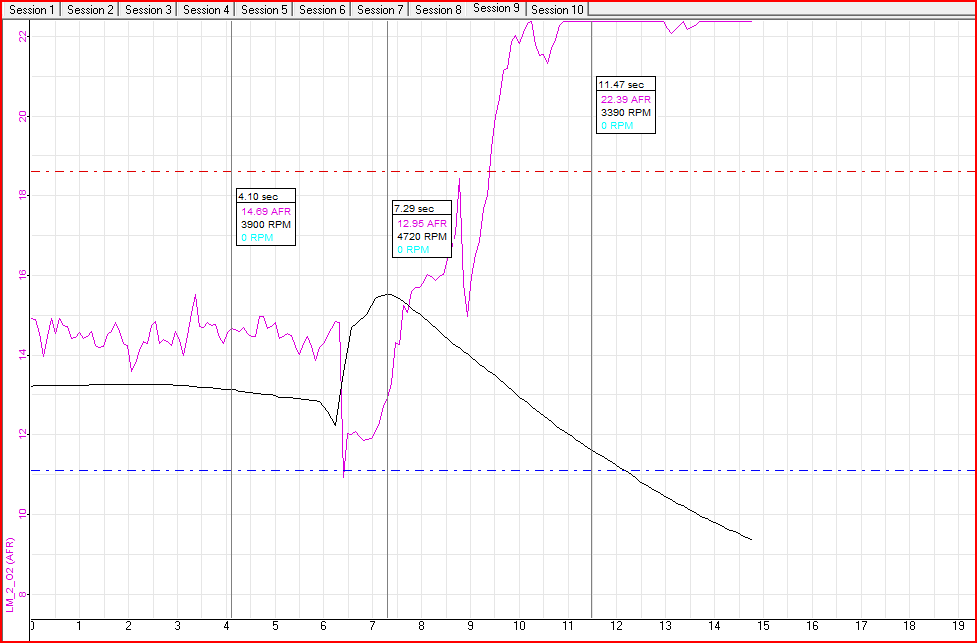

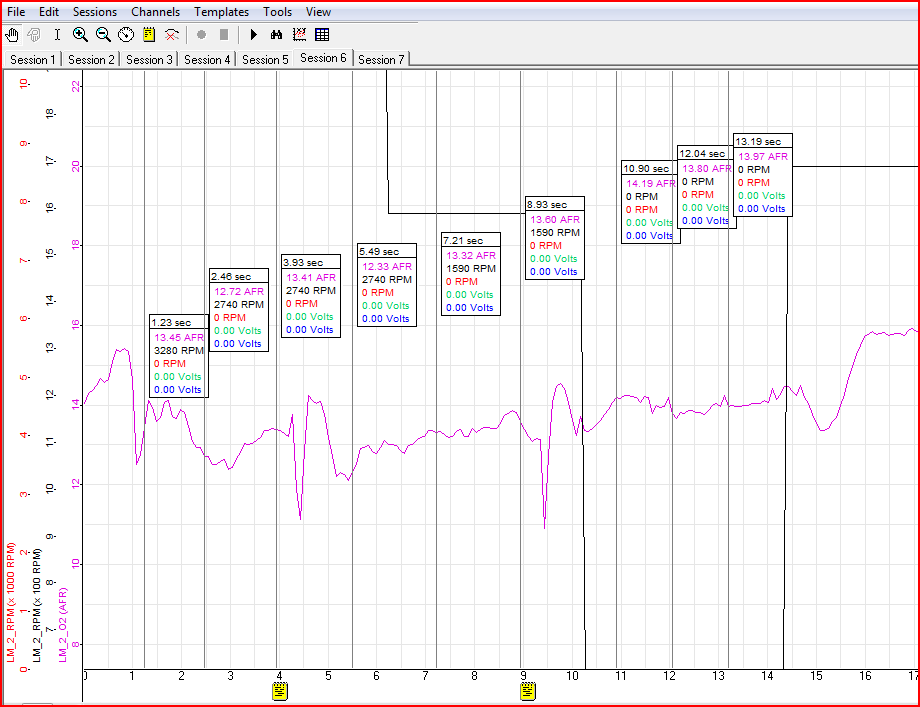

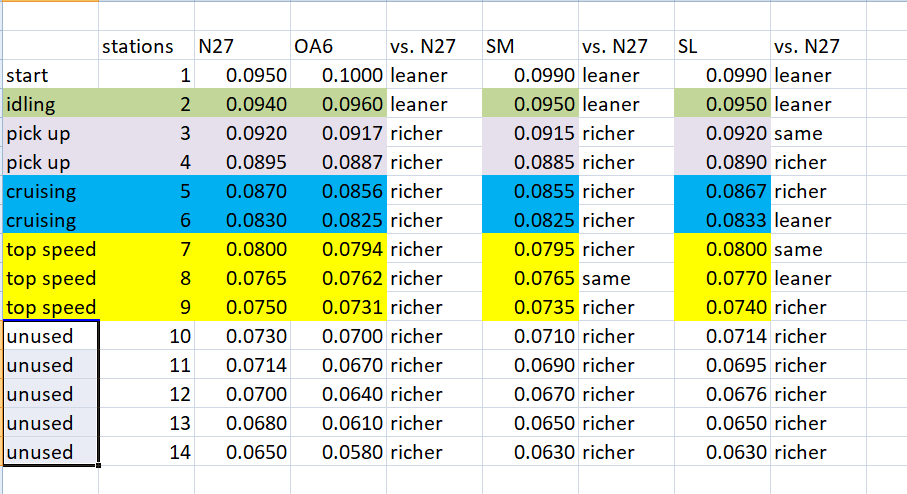

Thanks @Captain Obvious - little late is better than never I guess! But I did check the springs yesterday vs. a spare one I have and I checked the dampers. Both of the springs appear to be original and in good condition. They are the same free standing height as the spare one I have. I bought a carburetor rebuild kit from ZcarDepot a while back. The diameter of the brass barrel on the old dampers was not measurably different from the one of the new dampers that came with the kit. Interestingly, the barrel heights are shorter on the new dampers... and the distance they move on the stick is larger. And the new sticks don't have oil height marks. I choose to stay with the original dampers and springs. I changed the oil from straight 20 weight to 10W30 because I have that on hand and then went our for a few more AFR checking runs. Here is what I am looking at when letting off the throttle. This is cruising in 4th, then a rev match downshift to 3rd with throttle completely shut shortly thereafter for decel. From around 14.7 at cruise, when I blip the throttle to rev match, the mixture changes to around 12, but with the throttle plates shut entirely, after a second or so, the AFR starts to climb quickly, spiking north of 22. Unsure what that drop in AFR is at 9 seconds - I may have touched the throttle briefly. here is a lot of popping out of the exhaust during any overrun like the above. It seems odd that with the mixture looking pretty good under idle and cruise, and not far off under power that I am experiencing this. I will check for leaks at the carb manifold next, as maybe air is bypassing the carbs under high manifold vacuum conditions.

-

Choosing an SU Needle - If I have needle station info and real world AFR, can I use that to find the right needle?

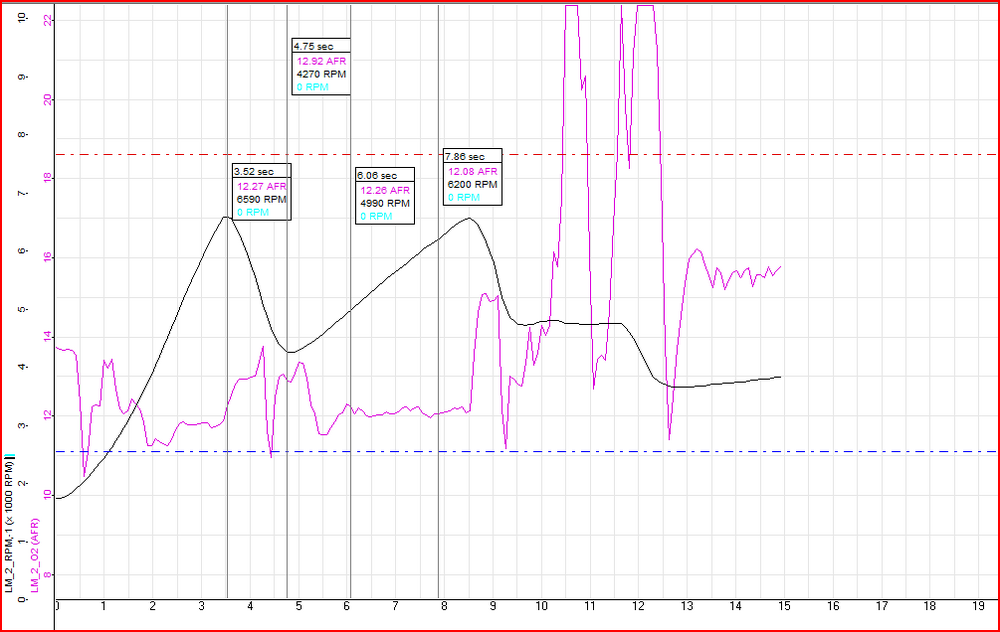

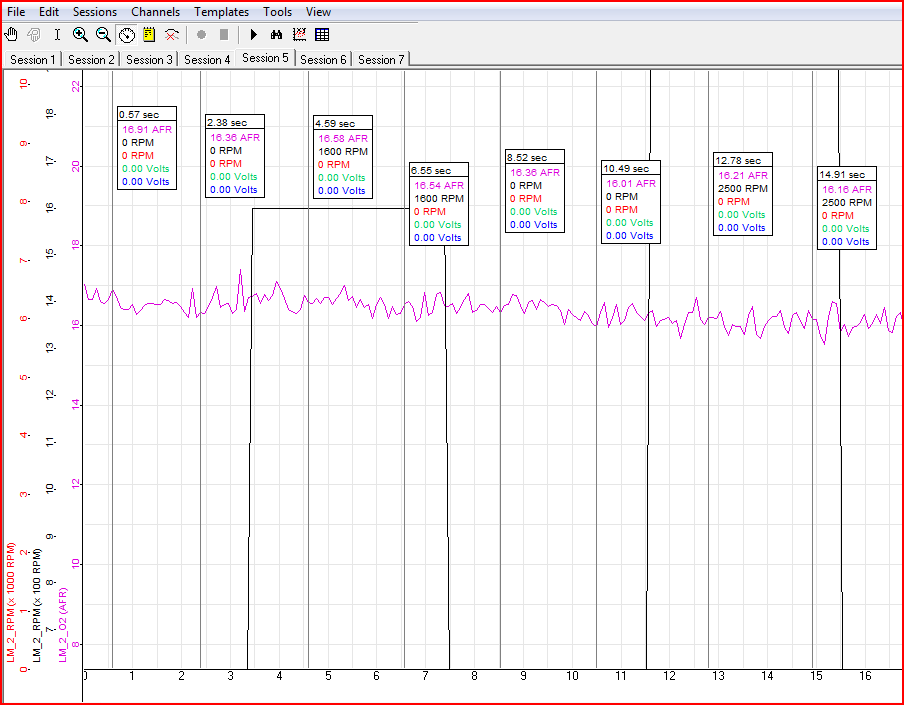

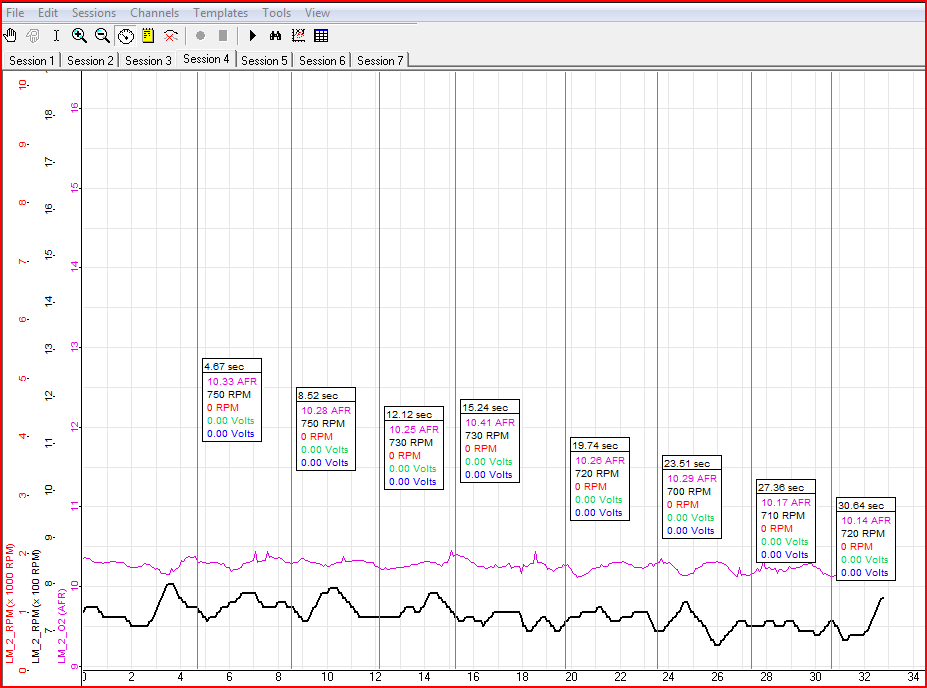

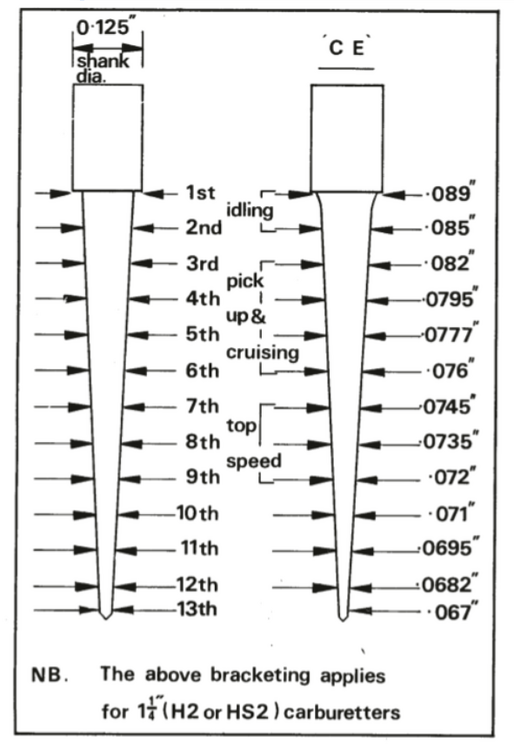

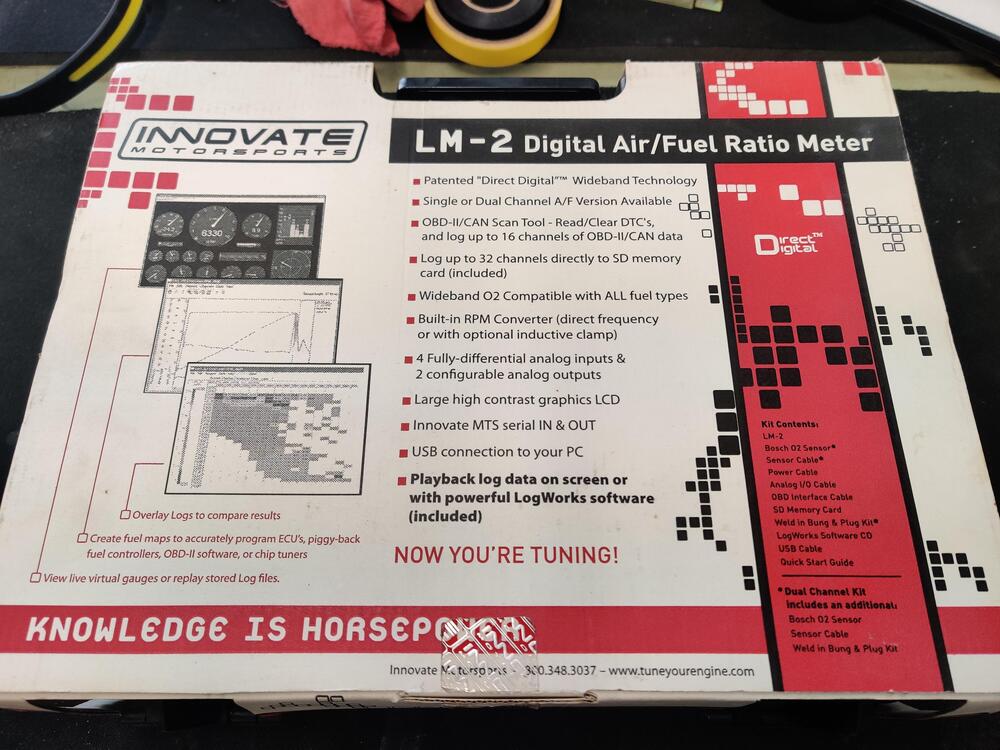

Since the very rich AFR at idle I am experiencing with the N27's is not acceptable, I decided to order some SM needles and give them a shot. A comparison: While the differences at each used station are "small", they are evidently quite large when tuning SU carburetors, as I found out watching How SU carburetors work parts 1 through 4 here: https://www.youtube.com/@ACDodd/videos Anyway, they were only $40 delivered, so not an expensive thing. I swapped those in last weekend and made a few more runs to collect AFR. Doing so, I saw some changes and made some new observations. First the plots: Idle: I am quite happy with that. 14.7 to 1 is stoichiometric. For idle speed, I think that would be ideal. But I think this is great. cruise: For the recording of cruising above, I was mostly on flat road holding the speed at an indicated 50 mph in third. My RPMs are now being recorded, but honestly, I don't know which to believe, my tach, or the LM2, as there is a notable difference off of idle. Generally, the LM2 is reading higher by as much as ~500 rpm. I plan to notate some speeds in gears and tach and LM2 rpm readings and compare with calculated info based on transmission and differential ratios and tire diameter to see which is more accurate. Again, for cruising, I like the AFRs I am seeing here. I do not notice any surging or anything out of usual when slightly lean by this much while cruising. It should be good for fuel economy. acceleration: Now, for acceleration, I am less pleased. The first steep rise is first gear. I think I pressed record just after the light turned green and applied full throttle in first, then shifted to second and applied full throttle, then shifted to third and applied full throttle - very briefly. My focus points are seconds 2-3 and 6 to 8 and a half. For those, I am in a steady state - full throttle - flat road. In first, the AFR is a bit under 12. In second, it looks like about 12 to 12.2. So, rich. What got really interesting is that when I shifted to third and again applied full throttle, the engine essential "stopped" as the AFR spiked up to north of 20. I suspect the float bowls went dry. I was able to repeat this a second time. So, I will need to investigate this further. Now that I have watched the video series mentioned above, I will plan out my next steps differently. I won't be messing with needles for now. I need to check the springs in the carburetor to see if they are original and in good condition. And I need to investigate my dampers. They may have too much wear. One of the indications that I have an issue with either the springs or the dampers is that (and this is with both the N27 and the SM needles), the AFR is going extreme lean on throttle off deceleration. It is worse with the SM needles - going north of 20. But it is bad with the N27s as well, going north of 18. Lots of popping out of the exhaust... Based on the info in the videos, that is either spring or damper.

-

Choosing an SU Needle - If I have needle station info and real world AFR, can I use that to find the right needle?

I installed the new exhaust clamps today. As is often the case, I had to modify them to fit the pipe that slips over the header collector. The clamps were for 2.5 inch diameter, and while the headers have 2.5 inch outlets, the merge pipe that slips over top of those has an OD of 2.665". The "T bolt" clamps that were supplied originally were not heavy duty enough to clamp the slip fit connection tight enough to eliminate leaks. These new ones are strong enough, but I had to use a die grinder to slot the holes for the bolt and trim a bit off of the aluminum spacer to achieve a larger overall installed diameter when on the pipe: One of them still leaks a tad, but the other seems air tight. I will mess with the one a bit more some other day. With that done, I went about the main task of the day, which was to get some baseline AFR readings. Stock N27 needles, new nozzles, remanufactured carbs, in sync, etc. Mixture screws are turned down 2.2 turns. Here is idle: Let's call it 10.2 - 10.4. Here is steady state cruise. I will note that at a steady cruise on a very slight incline road, the AFR is a bit leaner than steady steady cruise on a perfectly flat, or very slightly declining road. Also, my RPM are only being recorded properly at idle. Any revs, and the signal is getting lost. This run is basically cruising in third gear at something above 3000 RPM Let's call that 16.2 - 16.5. And finally, a near, if not full throttle pull in first, and second, and part of third: This This one is harder to read. Wish the RPM signal was recording accurately. That said, looking at the above and recalling from watching the AFRs while accelerating with near full throttle, I was surprised to see numbers in the 12's and 13's. I am near certain that the two drops in the AFR line above (I put yellow notes at 4 and 9 seconds are shifts from first to second, and second to third. So, "pulling" in second under near or full throttle (look at seconds 6 through 9), I am seeing 12.9 to 13.4? I think I will work on getting the RPM signal attenuated and then I need to make some more full throttle runs. Perhaps I should do a leak down as a check to see if the engine is fully broken in. I've got about 280 miles on it, and until today, hadn't given any full throttle. That's why I was surprised with those AFR readings - I had only been applying moderate throttle and when doing that I am definitely getting lean AFRs. Transitioning from cruise to part throttle acceleration, I am generally seeing 16.9 to 17.1.

-

Choosing an SU Needle - If I have needle station info and real world AFR, can I use that to find the right needle?

Thanks for the reply. I overlooked the RH, but it looks much like the OA6 - leaner than the N27 for the first two stations and richer at every other station. I'll add it to the rather narrow consideration set.

-

Choosing an SU Needle - If I have needle station info and real world AFR, can I use that to find the right needle?

Yes, that is the general concept I was thinking, if I know the percentage more fuel that I need, then I just need to do the calculation properly to back that into the increase in annular area needed to achieve that. https://en.wikipedia.org/wiki/Annulus_(mathematics) "a little lean" at cruise is desirable. That is, lean enough to reduce gas consumption, but not so lean as to cause any noticeable surging. 14.7 at cruise would be a good choice. Yesterday, I noticed that my exhaust joints from the header to the pipes are not sealing well - they leak. So, I need to resolve that before I can take new baseline AFR readings. I have some new exhaust clamps coming today that should solve the issue.

-

Choosing an SU Needle - If I have needle station info and real world AFR, can I use that to find the right needle?

You are probably right, Charles. I'll tell you what I find myself thinking about though. The open height of the pistons in the domes at cruise, for example, is likely very close if not identically the same with needles that are not radically different from each other (and with all other factors (oil, springs, nozzle heights, etc. the same). If cruise is stations 3, 4, 5, and 6, and I am getting an AFR of 16.0 at "cruise", then wouldn't I be able to run a calculation to determine what percentage increase in fuel flow I would need to achieve an AFR of 14.7 instead, for example? And, subsequently, could I not calculate the change needed to the annulus area, and thus back into the width of the needle that I would need at "cruise"? If the issue is which of the four stations is "cruise"... then that might be determinable, perhaps by recording operation of the pistons in a video (with markings or indicators for readability). Also, the needles do continuously taper. So, if I am seeing a consistently lean AFR through the entire range of "pickup" and "cruising" (e.g. 16 AFR for tip in, pick up and cruise) then I may need the same percentage of fuel increase across all those stations. Yah - nice video! I do plan on at least using the AFR info as guidance as to which general portion of the needle needs to change. I have spent some time reviewing specs for needles. Here is a small selection of the few I have found to not be obviously bad choices: From here, I plan to set the mixture screws at 2.2 turns out (per the factory manual spec). Then I will make some recordings with the LM-2 wideband. My RPM signal is not being capture accurately at the moment, so I will have to address that first. I think fixing that will assist with some of the repeatability that will be needed for testing. When I do that, AFRs will change from what I have seen thus far, as right now, the mixture screws are about 2.7 turns out. While I am seeing around 11 at idle, and 16s pretty much everywhere else (other than throttle lift off, which will cause AFR to hit 19-20), I may find that idle moves to 14 instead, and everything else jumps past 18. Who knows. But, I will attempt to get some AFRs with 2.2 out on the mixture screws and use those as my N27 "reference" AFRs. Once I have these, I will review the above needles again, comparing with the N27, and consider the change in "general direction" that will be necessary at each station. Regarding sucking the bowls down, I believe I would observe lean mixtures getting leaner as RPM's increase. In other words, during heavy throttle applications (I haven't gone full yet, but I have gone close) as the revs build, I would expect AFRs to go leaner. I don't have the data to show that is not happening (yet), but I will when I get the RPM signal working properly. From my driving experiences thus far, accelerating near full throttle through several gears in succession, can be repeated, with no notable increase in AFR at any point in time during the series of "pulls". Simply put, the AFRs are lean, but very consistently so. I will do a little run tomorrow, weather permitting, and see what pulling the choke lever up does to the AFR. I have done that a couple of times when the engine is a touch cold and the slight hesitation (from being lean) goes away.

-

Choosing an SU Needle - If I have needle station info and real world AFR, can I use that to find the right needle?

I have been driving my Z a bit with a wide band 02 installed. Generally speaking, the car is rich at idle and lean everywhere else. If I am not mistaken, the needles I have are the stock N-27. I cannot confirm because they have not markings. After reading the following post, I got to thinking... If I have the needle station measurements, and I can record my AFRs for each of the general categories of start, idling, pick up, cruising, and top speed, then might I be able to calculate the station measurements of the needle that my engine wants?

- Headlight upgrades

-

Restoration of BringaTrailer 240z - HLS30-35883

Thanks. If I recall correctly, the needles don't have any markings on them. Originally, I believe they had N-27 "silkscreened" on the portion that slips inside the piston, as were some replacements I was able to source new from a dealer in the 1990's. Adjusting the float level on the front carb to match the rear carb, my idle AFR went from around 10.5-10.8 to 11.0 to 11.3. I will proceed with something more than 2.5 turns on the mixture screws as an experiment to see how much is required to get more desirable AFRs during acceleration with load and steady state cruise. Anticipating that idle will be unacceptably rich when I attempt this. If so, I will likely look at other needle options.

-

Restoration of BringaTrailer 240z - HLS30-35883

I don't think so either, but am hoping :) I am using SAE 20 - this one, actually: https://www.acehardware.com/departments/automotive-rv-and-marine/fluids-and-lubrication/lubricants/10705 I carefully put it in and the level is registering on the high line of he SU "dip sticks". Since the engine is not stock, I am thinking the stock needles may not work properly. The engine is over-bored and has .030" cast pistons, and it has an E31 head. It has this Isky cam: Grind No L-475 Stage 1 Intake 26-64 Exhaust 64-26 V. Lift 0.475 V. Lash Cold 0.006/0.008 Advertised Duration 270 0.050 Duration 222 Intake valves are 44 mm SI stainless, exhaust are SI stainless in the stock size The exhaust system is not stock - I am using a Zstory header and exhaust pipes. The carburetors have been completely rebuilt (by Paltech, who I don't think is in business anymore). They are in sync/balanced. And, I have confirmed timing and correct distributor advance functionality. Now, I am off to change the float level...

-

Restoration of BringaTrailer 240z - HLS30-35883

I got the LM-2 hooked up today and made one run to log some air fuel ratios. The situation right now is basically idle: around 10.5 cruising at around 70 mph is about 16.5 to 16.8 giving it a decent amount of throttle to accelerate: above 17 Of note, I have the front carb fuel level set by the "wet set" method and the back carb set by using a 14-15 mm length of a nail and blowing on the inlet (air will not flow with the specified length nail between the roof of the float chamber cover and the float). Since it is rich at idle, I am going to redo the front carburetor float level to match how I set the rear one. I am hopeful that will lower the level in the front carb and consequently, lean out the ratio a bit at idle. Assuming I do get that result, I will then unscrew the mixture screws equal amounts to attempt to get lower AFR's at cruising and under throttle. If I recall correctly, they have been unscrewed exactly 2.5 turns as they sit now. My rpms signal is not recording well. I need to try a couple of things in the LM-2 manual to see if I can get that registering correctly.

-

Rear tie down hooks for originality: Yes or no?

The front right and the back right hooks are the same part. Starting here, I put a couple of posts that you may want to have a look at. https://www.classiczcars.com/forums/topic/63087-restoration-of-bringatrailer-240z-hls30-35883/?&page=50#ipsMenu_elcomment_659473_menu

-

Restoration of BringaTrailer 240z - HLS30-35883

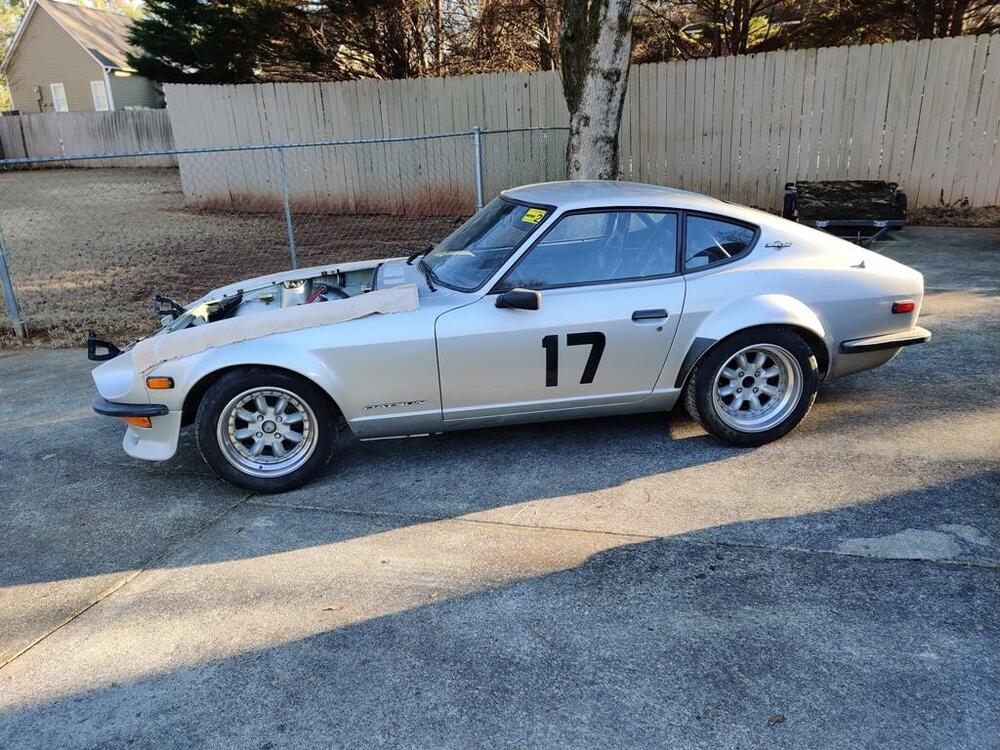

This past weekend, I moved all of my project cars around to facilitate getting started on the "track car" - my 240Z with a prod date of 12/70: I blew the motor up at Road Atlanta 9 years ago. It took many of those years to get a replacement, but I have that sitting in the corner of the shop. While I had the project cars out of the "shop", I organized some things and put a bunch of parts away in boxes and on shelves. Then I put them back in the garage. My order of attack will be to bring this 240Z back to life, then repair my wrecked 2004 Honda S2000, and then build the 1970 510. Unsure how long it will take, but going to guess 6 months or so on the Z. Hopefully less than a year on the S2000. And, I really don't know how long for the 510: Probably several years. But I still have some things to finish up with this restoration. I removed my wide band O2 sensor from the track car yesterday and will be installing that in the newly restored 240Z soon to see what I have going on for air/fuel ratios. I'll be able to record some data with this and the wide band O2:

-

Matching Rubberized Undercoating

(edit): Whoops, just noticed that what you are trying to do isn't match factory - so disregard. I was quite interested in this topic a while back. I think the best replica I have seen is what was used here (starting at about 6:25):

Subscriber

Subscriber