Everything posted by inline6

- Bumper guards

-

Bumper guards

What month and year are the guards from?

-

[SOLD] 14 X 6.5 Enkei 92 "copy" Wheels - Very Good Condition

Price drop: $250 for all (four wheels only), $300 with tires.

-

240z body parts for sale - Atlanta area

I have the following for sale - these parts lived in a dry climate and have been in storage for many years: Two 240z hoods. Both are OEM and in very good condition with no rust. If you would like more pictures, I can get them for you. Just getting this listing up fast because I could use the space. hood 1 $300: hood 2: $300 Two 240z tailgate/hatches. Not aware if there are any aftermarket versions of these - these are OEM. Both of these have the original Nissan glass as well. Tailgate/Hatch 1 (slight damage to rear edge) $150. This first one has horizontal defrost lines. I do not know if the defrost grid is functional. The lines look to be in good condition. The glass is in excellent condition. No significant rust anywhere. One piece of stainless trim has a mark: Tailgate/hatch 2 $250: This one is complete with original Nissan glass, stainless trim, and a white inner trim panel. This hatch came to me via the Denver area, and has no rust. I can get more pics. 240z fender - passenger side $250 - OEM part - straight, very little rust (only in the bottom corner): This part came to me from the Denver CO area - no accident damage. Does not come with the headlight housing which is currently attached to it in the pictures. That is also for sale however. Headlight housings - metal (left and right) - all mounting studs straight and intact with nice threads. $100 each: Again, happy to provide additional pictures.

-

Original 240z Exhaust - What's it worth?

I bought a 240z recently that was originally from AZ and was in storage for a long time. The car has an original Nissan exhaust system on it - exhaust manifold, front pipe, center section and rear. The original part numbers are embossed on the center resonator and the rear muffler (20050-E4150 and 20100-E4150 respectively). Both are in very good condition. 95% of the hardware is there also including the clamps, hangers, and chrome exhaust tip. Any ideas on what it's worth? I am going to restore the car, but not don't know if I will keep these parts on it.

-

Aftermarket - Replacement Door Panels Like OEM

Has anyone any experience with these door panels/cards I see on Ebay? They look decent...

-

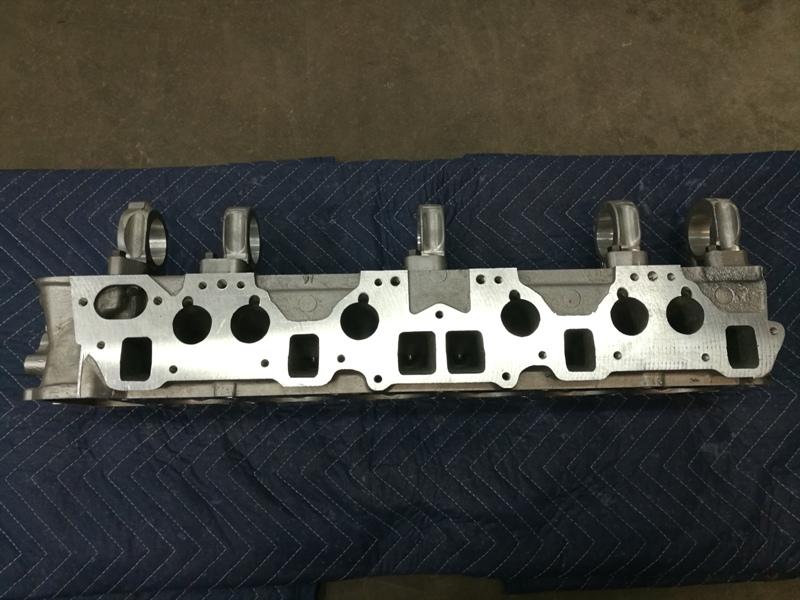

[SOLD] NOS P90A head for sale $700

Head is sold. Thanks.

-

[SOLD] NOS P90A head for sale $700

That's the way it came to me as a New Old Stock NOS head, yes. I am expecting payment from someone who wants it. So, it is likely sold.

-

[SOLD] NOS P90A head for sale $700

New Old Stock P90A cylinder head. Excellent condition. $700 plus reg Fed EX shipping to your zip code. See pics:

-

[SOLD] 14 X 6.5 Enkei 92 "copy" Wheels - Very Good Condition

$330 for wheels only - $400 with tires on the wheels. These wheels are in really good condition. Round and none are curbed. The dirt/brake dust cleans off easily with a rag and some WD40. Full width from edge rim to edge of rim is right at 7 inches. Measuring inside bead to bead, I get 6.5 inches. Back spacing is dead on 4 inches. I got these with a car I purchased and the owner said he picked up these wheels from the local Z club president - in CO. Wheel lug holes have quality inserts with tapered seats. Even though these are copies of the Enkei 92, they look to be quite good quality. Will polish up nicely without a lot of effort, or clean them and run them as is. Note, one center cap is slightly different writing. Tires have some age on them but are in good condition with decent tread left. Two tires are Yokohoma AVS, and two are Nitto Radial HP If you don't want the tires, I will dismount them. Willing to ship the wheels only - will not ship with tires.

-

"NEW" 240z Interpart "Lift Louvre" - for rear hatch glass

Located in Atlanta. This part has been sitting in a box for many years - obviously. Fits 240z. In excellent condition with rubber contacts to protect glass in good shape. No mounting hardware included (evidently lost). See pics. Hardware could be made, or ideally, you may have hardware but your louver may be in really bad shape after years of service. $80 plus Fed Ex standard shipping cost. Garrett

-

Adding turbo to non-turbo ZX motor?

All the same, we get notified by email of new posts to these old threads. And in this case, I'm still alive to see it! Thanks mel marabante. I think a lot of people just default to the ZX turbo motors because they were already turbo. I don't think that is necessarily the smart way to go. If you are going to run the stock efi, then maybe. Others have the experience here - not me. I have an F54 flat top now and decided to stay NA as I'm not ready to drop the cash or time on all the custom parts that I'd go with if I went turbo. I mean, I'd want to go aftermarket efi, custom intake, custom stainless exhaust, aftermarket injectors, etc. The works! Instead, I'm putting together a tripple 44 mikuni, big cam motor for now. I'd be willing to bet I won't be happy when all is said and done and I'll be pursuing the turbo route I was thinking about in 2004!

-

Need cyl head work - who do you recommend?

OZ connection, understood. For all I know the porting I'm doing could be a big mistake or done incorrectly, but I'm changing the car's purpose. I have several other cars now and my Z has become almost exclusively a track time car. In the last year or so, I've done 3 track events and driven it on the street once. The cam that is going in is pretty radical. From posts on Hybridz.org, it seems that several believe my 10.1 compression won't be adequate. We shall see. I am also changing from the stock SU's and stock manifold to a long Cannon manifold and tripple 44 Mikuni's. The porting has to match the cam and the carb changes... So, before and after of just the porting isn't really important. All the work that had been done to the head previously has remained untouched. Basically, it was just new guides, seats, and valves with some smoothing of the bowls under the seats... I had previously matched the intake ports to the stock intake manifold, with porting limited to about an inch into the ports. Now, I have added some combustion chamber work to reduce the restriction around the restricted flow areas of the valves against the combustion chamber walls, enlarged the stock ports to 1.545" (while moving the openings up as much as possible - staying away from the bottom of the ports). I've also ported the manifold extensively... No flow bench and not a whole lot of info out there on what exactly to do - understandably I guess. We'll just have to see how well (or not well) it works. Diseazed, I'll send you the pm.

-

Need cyl head work - who do you recommend?

I'm in central VA, in case that makes it more convenient (but am happy to ship the head), and I am looking for an engine builder/shop to do a general check of valve and guide wear and a to perform a quality valve job. The head was originally redone by the guy that did most of Malvern Racing's machine shop work. It has Manley stainless valves (1mm larger intake) and hardened seats already. I've spent a bunch of time over the winter modifying the combustion chambers and porting it and a tripple manifold in preparation for putting in a high lift/duration cam and tripple mikuni's. So, the work I'm looking to have done is likely just a valve job and possibly the cam installation. I am looking for first class work. Who are the go to shops for Nissan L-series these days?

-

Who else is SNOWED IN?

Yep, me too. My beater Honda Accord is my "snow" vehicle and it won't move with this much on the ground. Not used to getting more than a few inches at a time around here.

-

Nissan Motorsports square port header gasket NLA

Anyone know where to get a good quality paper gasket instead of the hooker piece? I need one for my head because of the porting that has been done - as John C mentions. Is the MSA one any good? Garrett

-

Mikuni 44 Accel Pump Stroke... Wrong spec in manual?

I read the post(s) about stumbling with the long runner Cannon manifold. I am in the process of switching over from SU's to Mikuni 44's on the Cannon and I know I am not going to be happy with a stumble :mad: I am curious... Why would the Mikuni service manual specify such an incorrect specification? I hear what you say about the pilot jet and what you experienced. In a futile attempt to think through this logically, I can't understand why that would help. There are two things going on with the pump. The pump nozzle regulates the duration of fuel injection as does changing the length of stroke on the pump rod. According to the manual, the larger the nozzle bore, the shorter the duration of the fuel injection. And the longer the stroke, the longer the duration of fuel injection. Seems logical that by playing with the two, you could come up with longer/shorter duration fat or skinny streams of fuel injection (you evidently had the same logic or you wouldn't have tried what you did). And if these carbs are set up with 3mm of stroke instead of 7.5, then won't that greatly shorten the fuel stream injected - a potential cause of the stumble? Maybe what is needed is a really long duration, skinny stream of fuel... That is longer stroke, smaller pump? Also, according to the service manual, the pilot (fuel) jet is functional at low and medium speeds, or in another place in the manual, only up to 20% throttle opening. People have said that they get a stumble when at say 2-3k RPM and they punch it. Again, according to the manual, a lean condition is created because fuel being heavier than air, when the throttle plates open, the flow of fuel will lag behind the flow of air. And, once you kick the throttle plates open all the way, the pilot system should be out of the picture... Not sure why what makes sense on paper doesn't work in real life. I plan to buy a narrow or maybe even wide band O2 sensor and try to go about this as scientifically as possible. Did you use one when you were making changes? By the way, Dave from Malvern was a friend. I grew up in Charlottesville. I bought a hot rod 510 in college that he helped me with. He had me install a 490/290 Nissan comp cam in the L-20B 2.3L which also had 44's. Changes he had me do to the carbs? 34 chokes were too small for that displacement he said. Install 40mm chokes. Also, he said I needed larger pilots and pump jets. Pilots ended up being 57.5 and pumps went from 35's to 50's.

-

L-28 dynojet

I don't have before and after runs with this exhaust. I used to run the same header and two separate pipes that were 1 and 3/4" in diameter along with 4 glass packs. In fact, that system was the complete Clifford Research exhaust which was the old Datsun Competition Department's exhaust set up for the street. There is a picture of it in the "How to Hotrod and Race Your Datsun" which I scanned and include here Years ago, I fabbed a straight pipe section which I put in place of the glasspacks while I was at the track. For the first session, I left the glasspacks on. During the remaining sessions, I switched to the straight pipes. In addition to a lot more noise, I noted the engine speed I could achieve on the back straight was several hundred RPM higher with the straight pipes. To me, that meant the street exhaust could be improved upon. That is why I went with two, 2" pipes when the old glasspacks wore out. It doesn't sound as nice, but the bigger pipes breathe better. The car revs out quicker in third and fourth and hits higher RPMs in fourth just like when I had the straight pipes on. So, if my HP is a bit high, I guess it could be the exhaust. I think it could be mild porting in the exhaust ports too. I'm told a little work there makes a big difference. But then again, that port work was there before all the stuff about exhausts I mentioned above.

-

Mikuni 44 Accel Pump Stroke... Wrong spec in manual?

I have two brand new 44's and two older ones that were on my 510 years ago. Looking at the Mikuni 44PHH manual and the Honsowetz book 'How to Modify your Datsun/Nissan Engine' (page 113), both call for 7.5 mm of stroke at the accelerator pump lever. Measuring the new Mikunis, which I assume were assembled correctly, as well as the old ones, I am coming up with only 3-3.5 mm of stroke for each of the four carbs. All of them have the cotter pin in the middle hole. All four have 2 thick washers stacked on the rod above the lever and the spring. Seems like taking those thick washers out and putting just one thin one on either side of the pump lever (like the manual shows) would be in order. Then adjust the pump rod length as necessary. Then again, maybe the 7.5mm spec is incorrect. Any thoughts on whether having these things set up for 3-3.5 mm is right?

-

L-28 dynojet

Graph of my L-28 dyno runs... power is at the wheels. I've seen some posts about 'how much horsepower should I have?' Perhaps my runs are a useful reference point given that my basic engine set up is a fairly common combination. Engine is: Stock L-28 (F54) with flat top pistons. (NA 280ZX short block) E-88 head with very little removed from head gasket surface - just to true... Intake port matched to stock intake manifold, very minor porting on exhaust ports. Manley stainless valves 1mm bigger intake (1.73'' I believe). Stock exhaust size. Stock valve guides. Stock cam, stock SU's (with SM needles), stock air cleaner, stock air filter Crane HI6 ignition Clifford Research 6-3-2 header with true dual 2" exhaust and 4 magnaflow mufflers. Two 4" round in the driveshaft tunnel and two small ovals in the back. Difference in the two runs is simply removing the air cleaner cover and filter.

-

Looking at Cam specs... Is this streetable?

About to pay a bunch for a cam from Kinetic Sunbelt (in GA). They came back to me with specs which are below. I've run a 490/290 in my 510 years ago (daily driver in college) which I liked... I've read some posts and tried to decipher what cam is really too radical. My car has an F-54 L-28 with flat tops, about 10 to 1 compression with E88 head (1 mm bigger intake valves). Switching from SU's with SM needles to a set of tripple 44phh Mikunis when I do the cam upgrade. So, is this cam going to be too radical? Can I still drive it to and from the track? It pretty much just sees autocross and track duty these days, but I don't trailer it. Intake Seat duration 320 degrees .050" duration 290 degrees Valve lift with zero lash .565" Hot valve lash .015" Net valve lift .550" Exhaust Seat duration 315 degrees .050" duration 274.8 degrees Valve lift with zero lash = .565" Hot lash = .015" Net valve lift =.550"

-

Z is getting a face lift

Hey Dreco, I watched your video at myspace. Very cool. What are you running for exhaust? G

-

fender flares

I guess I'm just not convinced. On the rear flares, I used fiberglass bondo and covered the flare mounting flange (where you blend) and about 4 inches onto the quarter panel. The rears did much better, but you can still see where the rivet holes were in the right light at the right angle as slight convex recesses (but no visible seams). There was obviously some movement in the materials after sanding and painting. I did not use fiberglass cloth like Barrie, and I think that is clearly a good way to go. I think creating a lot more surface area over the seam helps secure the flare and hide the seam's edge if there is a bit of movement later. I'm not an expert, so take the advice or ignore it if you wish. Here in VA we see temperature extremes of about 5F to 99F. Using rivets can't hurt in my opinion, and I'd hate to see someone spend upwards of $1000 on paint only to suffer the same problem I had. G

-

fender flares

Here are some photos of the flaring process on my car. May take a while to load: http://members.tripod.com/trueweb/Zcar I wouldn't recommend the E6000 epoxy that Motorsport Auto recommends for bonding the flares to the body unless using lots of mechanical fasteners as well (bolts, rivets, etc.). I think the different expansion rates of steel and fiberglass with regard to temperature changes caused problems on my car. The fiberglass flares separated after I had the car painted (they stayed attached, but the seam became visible about 4 months later during the first warm days of spring). I used aluminum rivets and the epoxy, but when I did the blending, I ground the rivet heads off (was told the epoxy would be strong enough by itself) during the start of the blending process, and then used bondo to finish. I did this because of less bondo and a better looking transition from the body to the flare. In retrospect, I recommend using lots of rivets (maybe 1 every inch) and leaving the rivet heads on when you blend.

-

Low idle after hard stop ???? 240Z

Hi Lee and Gav, My head was rebuilt ~40k miles ago and the bottom end only has about 75k on it. This motor is in great condition. I have the same situation on start up Lee. My motor is a F54 L-28 with an E-88 head. I only have to pull the starting circuit out 1/2 way, crank for about 6 seconds and it fires right up. I have to shut them all the way within 10 seconds though or it starts running really rough. Amazingly, I can drive like normal after about a minute with the chokes in all the way even if it is pretty cold out. I have had different needles before that provided different behavior. I am currently running the SM needles and not the N-27's that came from the factory. The N-27's needed to have choke while driving until warm. All this varies depending on you initial mixture setting of course. Anyway, it is interesting that a few others have the same problem. I am thinking of lowering the fuel level in the bowls a little bit to see if that helps. Garrett

Subscriber

Subscriber