Everything posted by inline6

-

Low idle after hard stop ???? 240Z

Hi, I have an annoying problem. Whenever I come to a really hard stop, the engine idle drops to about 400 rpm for 4 or 5 seconds and then bounces up to normal idling speed (650-700). While it is doing this it idles like the mixture is rich. I have the stock 71 SU's, floats are perfectly adjusted to the high side of spec (14mm clearence instead of 15). Brake booster seems to be functioning properly. Anybody have any ideas? I have had the problem for a couple of years, but can't relate it back to anything I've changed. Seems like it has to be fuel related. I unhooked the fuel chamber vent lines to air filter, but no change. Is it just the fuel sloshing to the front of the fuel chamber, allowing the float to drop and bring in a little too much fuel temporarily until the car has stopped? If this is the case, I can see that the fuel level rising too far would cause an overflow situation at the nozzle, causing an extreme rich condition until the motor sucks up the excess fuel. The longer I am at threashold braking, the longer it seems the car takes to return to normal idle after stopping. But if this is it, then I would expect others to have experienced it. Anybody????

-

Guess I just can't play in the Hose Wars

Hey MDBrandy, Check you PM's. I got a tip for you but you have to look before the end of the auction. Garrett

-

Crane HI-6 ignition work with factory tach?

Hi, Searched the archives and found some info with regard to using a tach adapter with the Hi-6 so that the tach will work. Can anyone confirm that this will work? Can anyone confirm that it doesn't work without an adaptor? I recently put an L-28 with about 10.2:1 compression ratio in the car and I am experiencing a little bit of misfire at higher RPM's. I am thinking the Euro distributor with points and 30 year old stock coil need to be upgraded and will fix this, but see no reason to spend a bag of money replacing gauges in the process. If that is the case, I'll drop down to the XR-3000 and be done with it. Garrett

-

Rebuilding ZX 5 speed

I finished rebuilding and installing the transmission. Here is a fair amount of info that will help you and save you some of the trouble I had. Again, this was the 83 280ZX Nissan (not Borg Warner) box. The most striking thing I learned: The synchros aren't what takes a beating when you crunch gears! Each gear has a part that is manufactured separately and then press fit to the gear itself. It has straight cut gears and is what the gear sleeve meshes with to secure the car in gear. The synchro helps the sleeve slide onto this part of each gear more easily. This piece, which takes the brunt of the wear is NOT REPLACEABLE. You have to buy new gears. (2nd was $214.00 from the dealer with 20% off) Given this, if your box is crunching gears horribly and it is not a problem outside of the gearbox, don't expect a cure all by rebuilding with new synchros. Even with all new bearings and needle bearings, 3rd gear has a high pitched whine to it. I suspect that is a characteristic of the tranny. It is not loud, but present I think in all of them. Don't expect to get rid of it. The tranny, in general, is very quiet now however. There are several regular bearings and some needle type bearings. I replaced them all, but the needle bearings were probably fine. There are some "bushings" (made of steel) that the needle bearings ride on. These look like wear items in the exploded view diagrams, but in fact don't seem to wear. Same with the washers next to the mainshaft nut and countershaft nut. So here is what to replace in my opinion: Countershaft bearings seemed to be worn most Mainshaft bearings if you want to be thorough. My tranny easily had 150K+ miles but, I could not detect the difference between old and new when checking play synchros as necessary. I replaced them all, but they showed little wear. mainshaft and countershaft nuts oil seals and front gasket Special Tools: Factory Shop Manual! shop press 1 small 3 finger gear puller 1 large 3 finger gear puller pipes of various diam. to use as drifts to install bearings: (1) 7" long 1.5" min ID (1) 7" long 1.0" min ID (1) 16" long 1.063" min ID (1) 8" long 1.375" min ID pipe to use in making special tool to hold guts of tranny in shop press: (2) 4" long .8" min ID (you need a welder to do some tack welds to make this tool) several plates (.250" thick would be best) for making a "tool" to hold tranny guts in vise (shown in factory manual) and for the tool hold guts of tranny in shop press (also in manual) bearing separater (used in press to get behind bearing when removing) vise Autozone has a tool rental program. Basically, you buy the tools (used) for list price and when you are done, return them and get a full refund. Finally, there are two hog rings on the reverse idler gear that are beasts. I broke two sets of hog ring pliers and ended up mangling them and having to buy new ones. Get some serious hog ring pliers to do battle with these guys. Summary: Not hard at all with the right tools. Making the tools was the hard part. Second gear probably takes the most abuse in general. Examine that one closely compared to the others to gage amount of wear.

-

Rebuilding ZX 5 speed

Thanks for the compliments Steve. I've got a whole website in my head that I would love to get public, but I'm not an html person. A friend put together my website for me several years ago. I've got a lot of other stuff that I have learned along the way, as many Z owners have no doubt, but getting it public sure would save a lot of $, time and aggravation. My 83 ZX transmission is nearly back together. I ran into a problem with the hog rings on the reverse idler gear. They are so thick and beefy, that even the toughest set of hog ring pliers I bought at Sears won't get them off. I damaged both of them getting them off and had to order new ones. So, I am waiting on parts. I made a host of special tools (drifts of the right diameter and length, and another one that allows me to use a standard gear puller to reach one of the gears really far down on the mainshaft) that are like the ones in the ZX factory service manual. Since I have a second ZX tranny to rebuild for my 510, they will come in handy again some day. Garrett

-

Rebuilding ZX 5 speed

I can get copies of the pages for rebuilding the T5 for you. I started out asking if anyone could do that for me and didn't get any response here, so now that I bought the book, I am glad to help someone else out that is in the same situation. The tool, however, won't work for the T5. I'll double check, but I don't think it is used at all with that tranny. Mine is the Nissan box. You want to send me a pm with your address, so I can mail the pages? Garrett

-

Rebuilding ZX 5 speed

Hi, an update: I got a used 83 factory workshop manual off of ebay. It has excellent info on both the T5 and the nissan 5 speeds. So far, I have taken the front and rear housings off, made a tool (like the factory tool shown) to hold the gear assembly in a vise (to make it easy to work on), measure existing gear clearences (all within factory spec) and removed the shifter rods, forks, and detent balls. I am going to see about borrowing some tools (puller, bearing separator) from Autozone tonight. Garrett

-

Head Gasket TO Suit E88 F54 Combo.

Good luck finding a burrette. After I had my engine together, someone recommended that you can buy syringes from Wal Mart. So I didn't get to measure the chamber cc of my head. N42 is a better head to go with to start, but my E88 already had a fair amount of work (larger, hardened seats, larger intake valves, some porting, etc), so there was my incentive for using that head. BTW here is a useful page with engine combo info: http://www.zhome.com/ZCMnL/tech/128combo.html And a compression calculator: http://www.turbofast.com.au/TFcomp.html I have the F54/E88 running now and comparing it to my 77 L28 short block, I'd say I picked up a couple of horses. No dyno results, :cross-eye but the car is clearly reving to 6k in 3rd quicker and feels a bit quicker by seat of pants. Both blocks are in good condition, so it wasn't like the old one is worn out. Carb mixture (original round top SU's with SM needles) only needed a tiny change. Same exhaust and everything else. The big change was the timing. I was running insane advance with the previous combo-- something like 25 or 27 degrees BTDC initial (Euro distributor with points still). With the new combo, I am running right around 20 degrees BTDC (manual calls for 17 for that distributor, btw). Any more than that and I get some detonation. I used to run on 89 octane. Now I run the best I have access to which is 93. Not fair that you guys in Australia can get 98!

-

Need 280ZX Factory Manual

Looking to see if someone will provide me with the transmission chapter? I would like to rebuild my transmission. Can you make copies and fax the pages to me, or sell me the book for cheap? I'm bidding on one on eBay, but don't know if I'll win it. My transmission is manual 1981-83 Nissan (not T5).

-

Rebuilding ZX 5 speed

Hi, After reading through my 240Z factory workshop manual, I realize that rebuilding my 83 ZX (not Borg Warner) transmission is going to be a large challenge if I don't get the factory info for that one. Does anyone have a factory workshop manual for the ZX? I would really like to have that info before I give this a try. In my 240Z manual, there are specific instructions for disassembly, and the available shim sizes, clearences, etc. Transmissions are a new venture for me. If you have the factory manual info, can you copy and fax / scan and email it to me? If so, let me know. Garrett

-

Discontinued 240z Relay

Two Nissan dealers here have tried the superceeded number and they say it is discontinued and no longer available. I forgot to mention that the number indeed superceeds to the number you mention. Also, Motorsport Auto in California doesn't have any. It is not a part that breaks often evidently as they say the last one they ordered was in 2001. I'd like a new one, but if no one has one then I guess I'll grab a used one from a salvage yard-- hopefully.

-

Discontinued 240z Relay

Hi, It looks like a very important relay, 25230-E4100, is discontinued and no longer available. I have a 71 Z. This relay is attached via machine screws through the passenger side kick panel and is just next to the flasher relay. Anybody got an extra one? Mine is sticking and when I turn the ignition key from the accessory position to two positions to the left, it is energizing the starter circuit. I took the cover off the relay and when I turn the key back one position (to off) and then physically separate the contacts in the relay, then click back to the first position (now you can pull the key out) then the starter circuit is no longer energized. Nissan description is "Relay for Heat Glass". Seems to me that it is more like "relay for power to whole car". Garrett

-

Nice day for a pic

Handles pretty well considering it has never actually been fine tuned. It has a bunch of cool parts though Ground control coil overs, tokico 5 setting adj-- 240z front in the rear, short version up front. 250lb front, 275lb rear Eibach springs. All four struts shortened. Adjustable camber plate up front only. Just put in the new short block. 83 F54 with flat tops and same E88 head. Should be around 10:1. Picked up a few more horsies.

-

Best sounding 240/280 exhaust

It sure would be nice to get some mp3's up so we could hear the different combinations. I am sure it would help a bunch of us save money and get it right the first time. Still looking for the right combo... inline6

-

still play in new ball joints ?

I chased my shimmy problem for years and then found that my new ball joints did the same thing I think you are describing. I jacked the front (either side) of the car under the ball joint (or outer end of the lower control arm) to keep the load as if the car was on the ground, but allow the wheel free movement. then grabbed the wheel and was shocked at the amount of movement in and out and front to back. When I jacked the front of the car off of the ground like done normally, everything felt tight and I couldn't perceive the play. I literally replaced every bushing and rod end in the front end, prior to that, but didn't replace the ball joints because they were already new when I bought the car. Replacing them with new OEM nissan ones was the final solution. The shimmy finally was gone after I did that.

-

What is the second oil sender on F54 block

Thanks ZVoiture. I put compressed air on it and it didn't go anywhere--- it is in the car, so I can see it very well. Well, that saves me a lot of trouble. I don't have to order anything to plug the hole! Thanks!

-

What is the second oil sender on F54 block

Funny, mine is not a turbo engine. It is an 83 though. Perhaps the latest 83's had knock sensors. I am thinking it taps into an oil gallery... I'm going to go blow compressed air in it and see if it goes anywhere. I should be able to hear I hope...

-

What is the second oil sender on F54 block

The sender switch goes in a raised boss area directly on the block about 2 inches behind the oil filter. It is directly in line with the top of the oil filter, not quite as high up on the block as I indicated earlier. Anyone know what it is? Does it control the fan motor that blows air through the valve cover splitter onto the intake side of the engine? Seems kind of strange to use oil to trigger that fan, so I don't think that is it.

-

What is the second oil sender on F54 block

There are two oil senders on the right side of my 83 280ZX block that I am putting in my 240. The one part I threw away, a short sender switch with a fuel injector type (2 electrical pins) cnnnector is all that is keeping me from starting it up. It goes behind the oil filter (the other one is the canister that goes in front of the filter) and towards the top of the short block. Seems like it would be a oil temperture sender, but I can't find it anywhere on the microfiche at carfiche.com. What the heck is it? What is the nissan part #. I would get a plug, because I don't need the switch but the hole appears to be some funky pipe thread pitch (spec).

-

Broken head bolt

Another thing the machine shop could do is drill out the bolt. Basically by using a mill or precision equipment, the machine shop should be able to locate the exact center, and the drill out the center of the bolt so that just the thread of the bolt remains. Then remove the thread with a pick and or compressed air etc. What a pain, I'm going to clean those holes and put a drop of oil on the threads before I put the head on my new motor. I didn't realize that this was a common problem.

-

Need a new roof for my Z

Hi, I saw a couple of posts in this thread about drilling spot welds to replace the roof panel. That is what I did because my car had a sunroof. This page takes a long time to load but I have some good pictures and some write up of the process. I also put lead back on the roof joint to quarter panel like the factory. Structural integrity of the car was not compromised by doing it this way. http://members.tripod.com/trueweb/Zcar Let me know if you have questions.

-

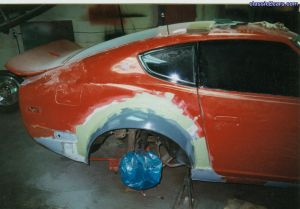

240Z flare work

What did you use to bond the fiberglass to steel? I used E6000 epoxy but have had separation issues.

-

Top Down Cooling?

Hi, I remember reading about the 1996 corvette LT1 motor getting some innovative improvements. One of which was reverse cooling. Instead of running the coolant into the engine block and then the heads and out, GM reversed flow and the coolant came to the heads first then the block. The main benefit was that it allowed them to bump compression to 10.4 to 1 for more power. Here is a link to some of the info: http://corvetteactioncenter.com/specs/1996/96technology.html Anyway, I am about to take an E-88 head that I had rebuilt (L-28 intake valves, hardened seats) back when I first fixed up my 240Z, and put it on a low miles F54 L-28 block with flat top pistons. I am going to cc the chambers on the head and rerun the calculation, but with the figures I have now, I show 10.1 to 1 Compression Ratio. Might be ok with 93 octane, but might not. An engineering friend of mine wants to take a look at what is involved in adding a belt tensioner bearing and converting the L series V belt to a ribbed belt like on more modern motors. I am thinking we can just wind the belt to reverse the flow of the water pump. Could just be a pipe dream as more would be involved like changing the propeller on the stock pump. Anyway, the idea intrigues me and we'll take a look and see if it is worth doing. Kind of trick if we can do it... Garrett

-

electric water pump

Conferred with an engineering friend of mine and he agrees with you HLS30. For dragsters, which is what these were originally built for, they are fine, as they are running off of battery power- a completely separate power source (ie no alternator). For street, using the crankshaft to turn the alternator to charge the battery, which runs the electric water pump, doesn't make sense. Just run the pump directly off of the crankshaft.

-

electric water pump

Hi, I found out about this the other day reading a back issue of SportZ magazine. I wonder if the polarity can be reversed to achieve top down cooling? I know that topic has come up before as a way of running higher compression without detonation problems. Of course the wheel would have to cut reverse as well. Garrett

Subscriber

Subscriber