Everything posted by gwri8

-

5sp Trans Chatter

What was the Mobile One product you used? One of the main reasons for Redline MT-90 is the compatibility for the brass synchronizers.

-

rear main sealant

I haven't ever used any sealant for the main seals, a little grease maybe when you tap them in, but not anything extra. Then again, my rear seal leaks a little, not much.

-

Always check the details

This one is just a cooper, not the S. The S model with 172hp ( I believe) has got to be a blast! But It's really a tight little car, and like Mike mentioned, fun to drive also. It fits's my daughter's personality so I went for it. I was hesitant about the mini from what I had heard and read about timing chain failure. This one had experienced that engine failure at 74,000mi and had an engine transplant just last July. I saw some of the bills for it that were left in the car and I'm pretty sure the previous owner just puckered up and abandoned ship. Then ran away from the experience as fast as they could . At any rate, it's in my driveway now. I've only had to do the regular/minimal stuff to get it up to par. If I ever have to pull the engine, it looks small enough I think I could do it with just a couple of beers!

-

WANTED numerous parts for new restoration

Here's a few places to start; http://www.datsunzparts.com (Charlie is a nice guy to deal with) http://baddogparts.com/index.php?main_page=index&cPath=2_4&zenid=9860c8d58b850892cb5e7ec5e9aa8af5 (good quality stuff) https://tabcoparts.com/amfinder/ http://www.rustrepair.com/PANELS/240-260-280Z-70-PATCH-PANELS.HTM Have fun!

-

In tank Fuel line repair suggestions

I wish chemicals and air had worked but the blockage was so far down I don't believe they could reach, at least none of the others did. My patience had worn off anyway so I went for the Nuclear option . I do like the idea of compression fittings or flare nuts. Sometimes my brain is broke and I start to over think simple solutions. That's why this is a great group of folks here. Y'all help keep me in line. Thanks!

-

In tank Fuel line repair suggestions

I've got a spare fuel tank from a '77. I've had it for a while and been meaning to restore it. It was pretty ugly from sitting for who knows how long but salvageable. Last summer I had it hot tanked to get rid of the crud inside and after being in the hot tank for 3-4 days, I was getting ready to POR 15 the inside. It turns out that both the return and feed lines inside the tank were clogged. I tried running different gauge wires down the lines with no success. CLR, Acid couldn't get in far enough to get to the blockage. Air compressor didn't work either. I had to put the project on hold. Now I'm back at it. I cut a hole in the top of the tank for easier access to the lines. I figured the best way to get to the blockage was to cut the lines, which I did. Success! They were clogged all the way down by the baffle tube. Got them free flowing again. My question is how best to repair the cut lines. As you can see from the pictures, My thinking is to put a sleeve of slightly larger fuel line over the slice in the lines. What would be the best way to attach/adhere the sleeves? Brazing will be tricky in the confined quarters of the tank. Would something like a JB weld or something similar work in that situation? I would think there would be some pressure there. Of course the tank will be re-cleaned and lined when I get these fixed. I've put a sleeve on the bottom return line to show what I'm trying to convey.

-

Always check the details

Nope, but I did just get a used Mini Cooper for my daughter…. So I'm kinda expecting it.

-

Always check the details

Mike might have to "bend" the rules a little for that to happen….

-

78 280Z N47 cylinder head

Just by looking at the picture, It's a N47. But who knows what you would get if you actually ordered one?

-

Always check the details

Well Steve, the last time I looked for anything like that was……Never! However, it does open the door for an interesting X-mas gift for someone. Not even the crack of dawn is safe anymore. 'Tis the season for waterproofing!

-

Always check the details

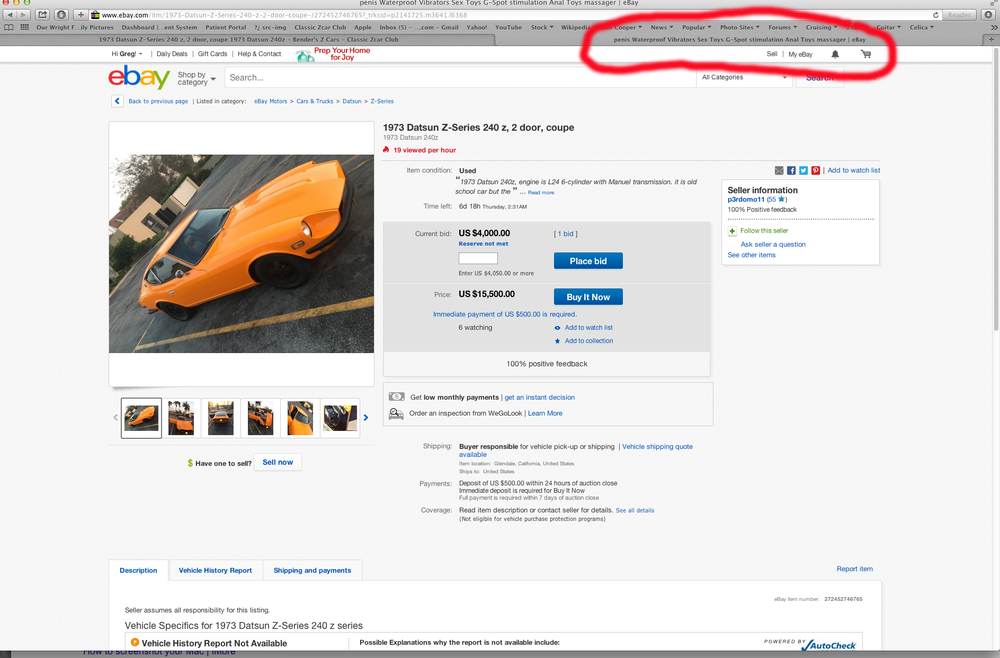

So, I'm browsing through Classic Z Cars this morning and bender had found a 73' on ebay. I'm looking at it thinking "nice car!" but not for me. I go to close the tab and I notice the title of the page. Talk about an Omen……..

-

78 280Z N47 cylinder head

You can download the Tom Monroe book "How to Rebuild Your Nissan/Datsun OHC Engine: Covers L-Series Engines 4-Cylinder 1968-1978, 6-Cylinder 1970-1984" here: http://www.nwdatsuns.com/dtech/How_to_Rebuild_Your_Nissan_&_Datsun_OHC_Engine.pdf But I find a hard copy more useful.

-

78 280Z N47 cylinder head

When I took my N47 to the the machine shop I left everything intact. He Discovered a couple of bent valves and was able to regrind some also. Just make sure to keep everything together in the order that you took it off, like rocker arms, lash pads, etc with cyl#1, cyl#2 etc.

-

Under Hood Inspect. Light Lens Cover

Just in case y'all forgot. Pricey, yes, when available. http://www.240zrubberparts.com/apps/webstore/products/show/4519997

-

280z oil leak

The cheapest fix I know of is to tighten/re-torque your pan. That is always a good thing to do anyway. If the leak isn't very bad I wouldn't worry too much about it though. Replacing a rear seals (I think there are 3) means pulling the tranny and oil pan, or pulling the engine, either way that's a lot of effort for a few drops of oil. It's all part of the fun of Z ownership IMO.

-

Anyone Else Obsessed With The Walking Dead?

The season opener this fall was…..Brutal. And yes I'm still watching.

-

N47 Head Removal Problem

Update: Got the head back, It was warped and had a couple of bent valves in #3 and 4. All the exhaust valves had to be reground also. Now shaved with a couple of new valves. As I was adjusting the valves before I put it on, I noticed something odd. Two adjustments were waaaay off (new valves) and another would not adjust at all….. So I call the machinist and asked if he had kept everything in order during disassembly/reassembly. He said no . He looked at me like I had slapped him in the face with a fish when I brought it back. My fault for not making that point clear when I dropped it off. The result is, he moved the lash pads around and shortened the new valves. At least hey adjust normally now. So I get the head torqued back on and buttoned everything down. All is looking good at this point. I took the time with the head in the shop to refresh the engine and bay a little. Cleaned the plugs and replaced the Cold start and Thermotime connecters. In addition, I replaced the '77 fuel rail with one from a '78 or '79 (not sure) from unknown heritage (used) to reduce the amount of fuel line hoses. I made sure it was not blocked using carb cleaner and an air tank. Which leads me to new issues. When It started the engine it was running really rough at low idle. I tried to adjust the timing via distributer but it had no effect. Then I noticed my fuel pressure gauge was at 50 psi. It was 30 psi with the old rail/FPR. I pulled the #'s 3 and 6 plug and they were both black. I needed to walk away for a little while. So my my thinking is, Is there that much difference between a 77 and 78 FPR? Maybe It's bad. Maybe I reconnected something wrong? Opinions welcome…. New fuel rail pic.

-

Classic car insurance

Thanks for the lead Cliff. I was considering Haggerty but they were being pretty sticky about excluding my children from driving the Z. My son, away at college ,and my daughter who hates my car and can't drive a manual. No big deal really but it just kind of bothers me a little. I'll have to check Infinity and see what they can offer.

-

N47 Head Removal Problem

Question: Is it wise to use Anti-seize on the head bolts and exhaust studs? I'm wondering if it holds up under high heat. I would like to avoid snapped bolts in the future.

-

Black Dragon Closing

I just placed my 3rd order. I'm about to enter myself into rehab.

-

N47 Head Removal Problem

Hmmmmm, I wonder if that's what was on it that made it so difficult to remove? I'll ask the machinist about that permatex gasket spray when I pick up the head.

-

N47 Head Removal Problem

That is a Helicoil. I discovered it the first time I changed spark plugs and it came out with the plug. I about crapped when that happened because I had never seen one before. I've since used Thread lock to help hold it in.

-

N47 Head Removal Problem

No, not corrosion/rot because it comes off. I'll guess that maybe it's varnish? I have run some CRC one tank on occasion and maybe that was some carbon or whatever that was peeling off? I can't say for sure because the head is in the shop. Looks like something got soaked and wasn't all the way off yet.

-

N47 Head Removal Problem

I wasn't expecting OEM from Datsun Spirit but I'm glad they sent them. The reason I ordered from them was that they wanted the specific block and head #'s for the appropriate part. I appreciated that Datsun Spirit would take that step. None of the other vendors I checked were that specific for information. The leak was about 2 inches wide right below the right angle cylinder head water outlet to the back corner.

-

N47 Head Removal Problem

Snapped Head bolts are out! Soaked them in PB Blaster for a few days while the head is at the machine shop and today i heated the bolts only, not the block, with a propane torch. Gave them a good tap with a hammer and put a vise grip on the nub sticking out of the block. It took a little while but with some tapping on the vise grip with a medium hammer they finally broke loose. No more snappage. Now just waiting to hear from the machine shop. I asked them to check head level and give the valves/seats and seals a good inspection.