-

Posts

1,210 -

Joined

-

Last visited

-

Days Won

11

Content Type

Profiles

Knowledge Base

Zcar Wiki

Forums

Gallery

Events

Downloads

Store

Blogs

Collections

Classifieds

Everything posted by Chickenman

-

If you already have a Pertronix ignitor already installed, ( or any other type of ignition electronic module ) , and your Tach works. It should work with the HI-6S as well. Crane does a better job with electronic Tach compatibility than the MSD. MSD-6A is a CD box as well. Hi-6S is a long duration inductive box, Tach output does not have to be converted from 450 Volts primary output like on a CDI box.

-

Multiple sparks to Redline sounds like marketing hype to me. Just not enough time to do it at higher rpms. Especially with an induction spark. Now maybe if you count two separate sparks at 6,000 rpm. But there is n o point. Multiple sparks were really intended for CDI boxes because of there short spark duration. Laen mixtures at low RPM's may not light of the mixture. Multiple sparks are the solution, but even CDI can only do that up to approx 3,000 RPM and 20 degrees of crank angle. If you're looking for a nice Induction Box with great reliability, check out the Crane Hi-6S Inductive box. Multi-spark ( to 3,000 RPM, ) Digital Rev limiter, RISC processor, proportional Boost retard, Starter retard, Stage Limiter and at a reasonable cost. Part number 6000-6300 You can still pickup these on E-Bay as NOS. Crane sold off their Ignition division. S&D Cycle took over, then they sold it to FAST EFI. Fast is now selling the " Crane " Ignitions again... but where they are made is a mystery. For that reason a lot of tuners prefer NOS Crane Fireball ignitions, as those were all " Made in the USA " : http://www.ebay.com/sch/i.html?_from=R40&_sacat=0&_nkw=Crane+6000-6300&_sop=15 If you want a warranty, here is a link to Summit with the new Fast produced 6000-6300 Inductive box. https://www.summitracing.com/int/parts/fst-6000-6300/overview/ Crane Hi-6S and Fast Hi-6S ( 6000-6300 ) specs; http:// http://www.cranecams.com/uploads/instructions/9000-6320_.pdf Edit: The 600-6300 is designed to be used with an OEM style electronic module. So if you have a Pertronix module in your Dizzy, 123 Ignition or a Matchbox dizzy, these will trigger off the module. They will not trigger off a Hall or Magnetic sensor alone. Points will work though... as will the ancient 260Z and 280Z Trignition boxes. Basically they just need a Pull to Ground circuit.

-

Throw a bottle of Redline Water Wetter in as well. The stuff really works. Have been using it for years on my Hillclimb cars ( as have other competitors ). Even worked in British Double Decker buses that had over heating issues. BDD's used to puke their coolant all over the ground a a particular stop just after a long steep hill. Redline Water Wetter dropped the temps just enough to prevent after boil. Shop was presently surprised, as they had spent thousands of dollars on upgraded radiators , extra cooling fans etc and the BDD's still had this after boil problem at this one particular stop. I Drove for Grayline Tours in Vancouver for many years. Loved that job.

-

Why would you run a 190F thermostat in Houston? All that does is make the engine more detonation prone. As Braap has mentioned in his articles, actual water temps at the rear of the cylinder head run about 20F higher than the temp at thermostat housing. 170F is the " Tropical Zone " thermostat recommended by Nissan and Houston would definitely fall into that range. On another note, Dyno pulls also show L-series like to run cool. 160F stat seems to give the best HP and Torque. It's all in the ignition timing and detonation control. N42 and N47 heads being more prone to detonation, are best run with no more than a 180F thermostat. 160F - 170F in hotter climates. IMHO of course...

-

Well, the factory systme does run through a relay. So you can just wire in a simple SPST switch to the factory relay. I didn't know if you were doing a custom wiring job or what.

-

The fuel pump should always run through a high amperage ( 40 amp ) continuous duty relay. The relay itself shouldn't pull much amperage. A 10 to 20 amp switch should be fine wired through the relay. 5 amps fuse is enough on the switch side. A 25 amp fuse should be good enough on the fuel pump side.... for the stock fuel pump Here is an article testing various aftermarket Hi Performance fuel pumps. Amperage draws are included. Note amperage draw was tested at 13.2 volts. If voltage at fuel pump is less than this figure, amperage draw goes up. Make sure the fuel pump supply wire is of adequate size ( 12 gauge minimum ). Most factory wiring is not large enough for aftermarket pumps. Note that the Walpro 255 was not tested. It tends to draw more amps than other models, so plan accordingly. Edit: Forgot to include the link to the article. http://realstreetperformance.com/Fuel-Pump-Comparison-Test.html

-

^ For seals. Go to Rock Auto. Buy 1 ( one SK-4 kit ) Dirt cheap and the RA info is wrong. Says 1 pkg contains 2 seals. 1 small tip seal and 1 large body seal. But the SK-4 package actually contains a full set of 12 seals. 6 small tip seals and 6 large body seals.

-

Hmmm....want to build me one? Expect a PM soonish.

- 9 replies

-

- pwer steeringo

- steering

-

(and 1 more)

Tagged with:

-

SilverMine Motors has a new setup that looks very complter. Nice parts is that steering column is a bolt in. I gather this is the one OP was talking about for $900. http://www.silverminemotors.com/datsun/datsun-240z/power-steering-kit-electric I'm probably going to order this for my 280Z. But holding off for now as Canadian Dollar has tanked.

- 9 replies

-

- pwer steeringo

- steering

-

(and 1 more)

Tagged with:

-

Weber selection and initial jet tuning

Chickenman replied to blodi's topic in Triple Mikuni and Webers

Oh... I figured they came with the Race Engine due to the first picture of carb jetting on the VC. Accelerator pump jets and the pump spring tension may still have to be changed to match particular engine builds. New does not necessarily mean " Good to go ". Carbs come with " Generic" settings. Tweaking after install, to suite your particular engine characteristics is often required. You may need to go to the stiffer pump springs and 55 pump jets. That will give a sharp hard shot to fill the low speed lean spot. And do physically check pump operation. Sometimes machining swarf will block passages. happens more these days with " Global " economy. Another question. New carbs typically come jetted for street use and the chokes installed from the factory. Did you change the factory jets and chokes from what they came with? The picture of the Race engine carb specs and previous replies seem to imply that??? What were all of the original jettings and specs, and what, if anything did you change ? ( I haven't read your complete build thread as I've been up since 4:00 AM with insomnia. I don't know your engine specs. Fading now,,, going back to bed... ) BTW, do adjust timing as suggested. It doe make a big difference to IR carbs. If you have a larger camshaft you can even start off with a Static timing of 17 to 20 degrees. -

Weber selection and initial jet tuning

Chickenman replied to blodi's topic in Triple Mikuni and Webers

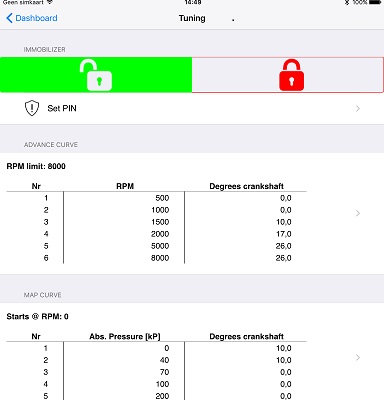

Here is the MAP programming image from 123. You can see where you can turn off Vacuum advance at low RPM's where you have large pulsations in the Intake runner. Then switch it on at a higher rpm once things have smoothed out. ( 2,300 to 2,500 plus rpm is usually good, ) . Note. Mechanical advance curve shown is just for viewing. It's not a very good curve and is wasting set points. I would make a Triple carb tune as follows.something like: Static timing of 15 degrees Additive RPM timing: All degrees are in Crank degrees All values are automatically interpolated on a curve. 1: 650 RPM = +2 Degrees ( This is an Anti-Stall feature ) 2: 1,000 RPM = +0 Degrees Crank ) 3: 1,400 RPM = +5 Degrees 4: 2,300 RPM = +10 Degrees 5: 3,500 RPM = +21 Degrees ( 15 static + 20 dizzy = 36 Total Crank. High Torque range ) 6: 6,000 RPM = +19 Degrees ( 15 static + 19 dizzy = 34 High RPM retard ) Pictures of 123 Demo Ignition curves: -

Weber selection and initial jet tuning

Chickenman replied to blodi's topic in Triple Mikuni and Webers

Independant runner carbs also require a Unique distributor advance curve. They need a lot of static advance at idle. 15 to 20 degrees depending on Camshaft is normal. Total mechanical advance is the same as the SU's, so you usually have to Weld-up the advance slots or limit total mechanical advance somehow. Vacuum advance really improves cruise milage, but it's hard to run a Vacuum advance with Triples on the street due to the strong Independant runner pulsations. Some manifolds have a balance tube built in... much like the balance tube on the SU's. The purpose is the same. to act as an accumulator and dampen the Intake pulses ( or " Combine " them ) to get a usable Vacuum signal for the Vacuum advance. These manifolds are rare, because most of the Triple or Twin ( 4 cylinder ) IR runner manifolds were meant for racing. However a modern solution to that problem is the 123 Ignition with programmable Ignition curves. that can be used to emulate a Vacuum advance at cruise RPM with IR manifolds IR manifold pulsations are wicked at idle, but they smooth out at cruise RPM So you can get a stable MAP reading. That enables you to run extra advance ( Vacuum advance ) via the built-in MAP sensor of the 123 ignition. It's not cheap though... http://www.123ignition.nl/product.phtml?id=221 -

Weber selection and initial jet tuning

Chickenman replied to blodi's topic in Triple Mikuni and Webers

Have the Carbs been rebuilt after you bought them? Did you check for Accelerator pump operation with the carbs off the car. I put some solvent in the bowls and then give them a quick test off the car... in a safe area of course and with a Fire Extinguisher handy. Often the accelerator pump passage gets gummed up with Varnish or crystals. Excellent video on how Weber pump circuits work and shows all the components. Component check is good, as sometimes Race Carbs have some strange Modifications made to them. https://www.youtube.com/watch?v=VLct6_XWOQE To fix a flat spot in transition, that is due to a calibration error ( Not plugged passages etc ) you want to lean towards a larger pump jet and a stiffer spring. This gives a sharp hard shot of fuel needed for street use. The spring tension plays a bigger part than most people realise. What number are your accelerator pump discharge jets and are they clean? That tiny aluminium washer on the bottom is important. -

On my modded 1971 240Z ( Cam M445 Shadbolt, 2.5" exhaust, ported and polished E31 head ) I ran E88 needles if my memory is correct. . Again those were perfect at the Top end but too rich at idle and low range with the Cam and Mods I had. So what I did is install the needles dropped .020" from the flush setting. This leaned the low end , but kept the Top end. Taper changes fairly rapidly at fat end, but the taper is slow at thin end. I just used a set of Vernier calipers set to .020" and butted the needles's shoulder up against that. Then tightened the set-screw. Mixture came out perfect.

-

Double irony. I live in Coquitlam.... Sorry again.

-

N27 doesn't show up in SU charts because the Datsun carbs are not SU's. They are a copy of the SU design. However, as you mention... someone somewhere has to have measured them. Ironically, I did just that back in the late 70's when I was making some custom needles for my 240Z race car. And i just mailed my last set of N27's today to a fellow in Hong Kong. Could have miced them for you if I saw this post a day ago... Sorry.

-

1976 280z Can anyone sell me a Thermostat Housing

Chickenman replied to SeKcGamer's topic in Help Me !!

When you do find a replacement. replace the top bolts with short studs. No more problems with seized bolts. The studs are " standard hardware " items from any Japanese car parts dept. You just gotta find a Partsman that doesn't have to ask you... what you and model is that for. That can be the tricky part. -

Getting the urge to upgrade in size

Chickenman replied to Zedyone_kenobi's topic in Triple Mikuni and Webers

This is the setup I used to run to achieve 420 hp on a daily driven 1986 Camaro. Could pull 25 mpg on Highway and set record times at Hillclimb. Aircare ( emissions testing ) came out as clean as specs for an FI engine. Fairly mild cam, good HP figures and broad Torque band. Engine went to 7,200 at Hillclimbs. https://www.facebook.com/TMPCarbs/ https://www.youtube.com/watch?v=5tKBwAruqXU -

Getting the urge to upgrade in size

Chickenman replied to Zedyone_kenobi's topic in Triple Mikuni and Webers

You should be able to run stoich or even 15 to 1 at 3,000 rpm cruise with those carbs and proper tuning. Literally, a well tuned set of Webers can almost equal fuel injection curves. Keep tuning. Maybe invest in a AFR gauge to mount permanently in car. Gotta get the emulsion tubes bang on though... -

No, I was lucky. Mine was more of an immediate failure. No misfires. From what I could tell the worm gear cracked at the keyway ( from vibrations ) spun on crank and engine stopped with 5 feet of flame shooting out of tailpipe. Spindle gear was damaged, but not nearly as bad as your's. Plus the bypass valve in oil filter block was removed and plugged, so all oil was filtered in one pass. Edit: We did end up replacing crank though. Found no evidence of damage to bearings but I still pulled the entire engine apart and cleaned all oil passages. Pissed me off though, because it was a $1,200 knife edged Tilton crank. That was $1,200 in 1980 dollars... With the amount of damage to that gear, I think I'd play it safe and pull EVERYTHING apart. Check and clean all oil galleries in block and head. Pull the oil pump apart. If you start finding any chips in oil galleries or bearings, throw out the oil cooler and oil cooler hoses. Oil coolers cannot be cleaned of all metal chips unless they are very carefully cleaned in an Ultrasonic blaster. Oil lines will get chips embedded in hose lining and cannot be completely removed by flushing with solvent or other means. You will always have some chips remaining, and they will come loose at the most inappropriate times. Now aluminium gears eating themselves up is not too bad. It's relatively soft and may get ground to a fine particulate. But you still have to pull everything apart and check. Valve train parts like Tappets and are the absolute worst for engine damage. Those are very hard chips, and usually shatter into many, many small pieces. You blow up valve train parts and you have to do major forensics to engine. Usually takes out everything... and I mean everything. Including dry sump pumps. Oil coolers and all the oil cooler lines are trash and even the Dry sump reservoir has to come out for cleaning.

-

And secure the Crank Bolt with High Strength Red Loctite or Stud Lock. Same with Flywheel bolts ( alternator bolts, driveshaft bolts, caliper mounting bolts and just about every danged thing on the car!! ) . Red loctite is a Racers best friend. Although Red- Green may argue....

-

I'm betting the loose bolt ended up bending the crank snout. Mine took a about 3 thirty minute races, and then the spindle gear sheared and the worm gear cracked . Engine stopped mighty quick. If stock L28 bottom end and used for enduros's I'd drop rpm to about 6,500 if possible. Especially if still using factory balancing. 7,000 RPM on an L28 can give a lot of secondary vibrations. Old syaing that is very true : RPM's = $$$

-

That's how I bent my crank. Crank bolt came loose. Didn't fall out. Just became loose. Engine builder ( not me ) did not check how far the bolt went in. Front damper was a Tilton torsional damper and was supposed to use a longer bolt because the center hub was thicker. He used a stock bolt and it worked loose.

-

One thing to remember is that factory oil filter systems are a bypass system. It does not filter all of the oil in a single pass. If you have removed and plugged the bypass valve in the oil filter mounting pad, then yes, it is a full pass filter. But if bypass valve is still in the OF mounting pad, then some unfiltered oil is always bypassing the filter. . Normal contaminants eventually get filtered and are small enough ( and soft enough ) not to damage the bearings or anything else. But the factory bypass system will not save the bearings from mechanical engine damage and the resulting metal chips/shavings,... FWIW. . Edit: Filter does NOT have to be plugged for the bypass valve to open. It will always be open somewhat under racing conditions. Thta's why engine builders plug them.

-

^ Very true.