Everything posted by Chickenman

-

Does this damper/pully look familiar?

3 groove 280ZX front damper. The PS pulley has been unbolted from the front.

-

1976 280z Stuttering

The kinked hose in the picture above is for water heating of the Auxiliary Air Control valve. Basically your fast idle valve. The kinked hose will not have any effect on the problems you were experiencing. Not liking those gear type hose clamps on the fuel injection hose though. Those can tear the rubber. Get proper fuel injection clamps that are fully banded and protect the hose.

-

CV conversion issues

I have friends who are machinists . They can whip up adapters for me. End result is a custom made product with closer tolerances than what we are seeing on the Market. The junkyard half shafts are just to scrounge the good Audi/VW Cv's at an affordable price. . You keep the used CV's and boots and toss the actual shafts. Used OEM CV's are better than new " China/Taiwan... who knows where" made junk Quality axles are one of the key ingredients to making " clunk " free half shafts. Just as important as the CV's. $70 used CV's ( 4 ) + $350 custom half-shafts + $250 adapters = $670 or so. That's how mosts of the Formula SAE cars are done as well.

-

CV conversion issues

I'd just get the splined half shafts manufactured to specification. There are various shops that can do the job. Mark Williams , Driveshaft Specialties , The Drive Shaft shop, Moser Engineering , etc. They all make custom length splined shafts to fit CV's.... some are better than others. I know from personal experience that Mark Williams are very, very good. Some of the others... not so much. Not much difference on a street car. But a 900 HP Road Racing Corvette separates the boys from the men. You can get a Custom pair of half shafts made for $350 and up. I do know that one of our local fabricators ( Andy Pearson at Specialty Engineering ) makes custom half-shafts in house. His driveshafts have been going strong on Keith Law's Turbo 510 ( 280 RWHP ) for well over 10 years. Keith is one of the few locals guys that has not had any issues with his CV's that I know of. Pretty sure Andy uses the OEM Audi/VW/Porsche CV's. Might be worth while giving them a call.

-

CV conversion issues

Personally, If I was going to get some CV's for my Datsun 280Z, I would go to an Auto Wrecker and pull the axles from an later model Audi or VW. Pick A Part in Chilliwack has CV axles for $34.95 CDN each. And they have a few Audi's in the yard right now. ( Ton's of VW's and Passats ). I was out there this afternoon. \ Edit: Thought I was posting this to the 510 Realm thread ...

-

CV conversion issues

255,000 KM on the ORIGINAL CV's on my Audi A4 AWD. Prop shaft has CV's as well. Oh... and they all have gaskets between the CV and the mating flange. FWIW. If you split a boot on OEM Audi/VW's the honest shops tell you to just clean the original CV's and replace boot and grease. Don't buy an aftermarket rebuilt axle and CV assembly because they are never as good as the originals. Some shops at VW/Vortex have had customers run over a year with a split boot on Audi's. No ill effects. My right outer boot was was split for about 6 months ( That I know of ) of constant work driving in Winter. Took it apart in the spring and it was as good as gold.. Not a spec of wear. That was in Mar of 2008 at 158,679 KM. Car now has over 255,000KM on it. Pretty normal for Audi/VW CV's to go 300,000 + KM with no issues. You don't have to grease them as a part of scheduled maintenance.

-

Front Wheel Bearings (Avoiding Made in Mainland China)

Blue... Canadian Tire for parts... really? I buy Garden hose and BBQ supplies from them, But wheel bearings? Shame on you. Any local bearing supplier should be able to get Timken, NTN or SKF. PS, all kidding aside, Canadian Titers Professional grade of Mastercraft tools are pretty good.

-

alternator amps for 240z stock wiring ?

Was this WW1 or WW2 ?

-

alternator amps for 240z stock wiring ?

Well... Quite few of our Local 510 guys have been running SS V/Regs for over 15 years with zero problems. AC Delco or " Made in USA " Standard Blue Streak Better Voltage regulation than the mechanical ones as well. The AC Delco's that I recommended are good quality. Specialty Engineering, one of the premier Datsun engine builders on the West Coast, will install nothing but SS regulators on 510's... if the customer wants to retain the Vintage look for concours. He switches out the short SS V/Reg cover with a re-plated Mechanical cover and the concours judges are none the wiser. Looks like a mechanical V/reg on the outside. All SS on the inside. Andy's been doing this for over 20 years with virtually no comebacks. Problem is...there are very, very few quality brands of mechanical V/regs these days. Mechanical V/Regs haven't been used since the Mid to late 70's for a reason. Nissan was late to switch over to SS internal regulated alternators. My 1973 Camaro came stock with a SS internal V/reg. That's 44 years ago....

-

alternator amps for 240z stock wiring ?

Try and find a Solid State external regulator if you go that route. They are usually a lot more dependable that the Mechanical style and up the Voltage a bit. Stand Blue Streak used to make some decent SS External Regulators. And Beck Arnley is good in a SS as well. Problem is always the cheap Off shore junk that is made these day... Edit. Rock Auto has a Solid State external V/reg ( E661 ) for $41.89. AC Delco is usually pretty darned good. https://www.rockauto.com/en/catalog/nissan,1973,240z,2.4l+l6,1209170,electrical,voltage+regulator,4884 You can tell if the V/Reg is SS by the height of the case. The SS V/regs are about 1/3 the height of the mechanical ones.

-

alternator amps for 240z stock wiring ?

Just an FYI: USA and Canadian 240Z from 09/71 got a 50 amp alternator. ( 23100-P0102 and 23100-P4501 ). USA 260Z models received the 50 Amp model as well ( 23100-P4501 ) Canadian models from 08/72 got stronger 60 AMP alternators. Both the 73 240z and 74 260Z alternators were upgraded for Cold Area climate. ( 23100-N3302 and 23100- N3303 ). 60 Amp alternator became standard equipment on all Production models in NA from 08/77 ( 23100-P3006 ) Source: http://www.carpartsmanual.com/datsun/Z-1969-1978/electrical/alternator/12v-50a

-

alternator amps for 240z stock wiring ?

Do yourself a favor and make the upgrade to a 60 Amp internal regulator model. Use the MSA adapter or something similar. Unless it's a Concurs car, there is no reason to use a external regulator these days. And the quality of what you can get is usually suspect. Times change. BTW, I wouldn't hesitate to go to a 70 or 80 amp. Wiring doesn't really matter. A circuit only draws what it needs. Problem is the factory alternators were undersized to begin with.

- headliner

-

Ignition drops voltage while cranking/starting

That's not a good way to do it. The ignition switch cannot handle a lot of amperage. Fuel pumps can draw significant amperage, especially when used in a returnless system and when they get older. The factory wiring also uses too small a gauge of wiring to the F/Pump and that also increases current draw and Voltage drop. 40 year old wires don't help either if they are still stock. The addition of the extra Fuel Pump amperage draw, plus all the normal devices connected to switched ignition, could be enough to burn the contact points in the ignition switch. Connect the Fuel pump through a proper relay. A Bosch 30 or 40 amp relay is better than the factory EFI F/Pump relay Use 12 gauge wire minimum to the Fuel pump from the relay. Both on power and ground side The MSD is also sensitive to voltage drop on the small +12V ignition feed. That's why I recommended isolating the small +12v switched power lead and running it though a Relay to the battery.

-

Ignition drops voltage while cranking/starting

MSD boxes are infamous for out right failing and having intermittent problems. The older model 6AL's and 7Al's are particularly bad. Might be an idea to disconnect the MSD from the Ignition switch power though and temporarily wire the small red wire ( +12v switched) directly to the Battery positive terminal. Use a small switch and a fused line. Large red wire should of course be connected directly to the Positive battery cable with a 20 amp fuse or Circuit breaker. It's best to run the switched +12v wire from it's own separate relay. They can be sensitive to voltage drop from loads on the ignition switch. MSD shorting internally could cause the voltage drop to 0.

-

Ignition drops voltage while cranking/starting

MSD??? It's possible the Red Box has struck again...

-

Cooling issue from hell

The fact that the new Thermal clutch fan is NOT engaging, at what you figure is 200 to 210 degrees is an indication that the engine may not be running as hot as you think. At this point, I think I would buy a decent Mechanical temperature gauge and temporarily plumb it into the system so that you can get some factual data while actually driving. Factory electrical Temp gauges can be notoriously inaccurate as already mentioned. Certainly a conundrum...

-

Cooling issue from hell

Just as a reference point. I have a 1976 280Z NA. 3 core custom Copper Rad. New 180 F Nissan Stat, New OEM Nissan W/pump. Factory 8 Blade Fan and Shroud ( 280Z AC fan ). New Thermo-clutch ( Hayden ) Redline Water Wetter. Temp Gauge normally sits in middle of the " E " in Temp. Stop and go traffic. On the Hwy it will drop to the left end of the " E " ( 60 to 70 F ambient ). With AC on, stop and go traffic at 90 to 95 ambient, gauge went up to left hand leg of the " M ". That's pretty darned good. BTW, just got back from a 600 mile Cruise through the Cascade mountains and Okanogan desert region. Car ran as cool as a Cucumber even though it was stinking hot outside and AC was going full blast all the time. I should add that this is on a freshly rebuilt block and head that had been cleaned a High pressure Steam cabinet. There was absolutely no rust or scale in any internal water passages. So that has to be taken into account. FWIW.

-

Cooling issue from hell

^ Yes, same old story with " Global Market " parts. Even Stant aren't what they used to be. OEM Nissan thermostats are the only ones I will now use. Same on my GM's and Audi. Stant ( and other aftermarket ) hysterious is way off. IE: Slow to respond to opening and closing temp differentials. . I also found that the Stant " Hole opening " size was substantially smaller than OEM Nissan. Changing to a factory Nissan thermostat would be the quickest and cheapest thing to try. Edit: Notice you stated that you had a new OEM Thermostat. Is that an OEM Nissan Thermostat? Of course the factory gauges are often inaccurate as well, So get a Digital thermometer as others have mentioned. A fan shroud will certainly help maintain cooling at idle. At idle the Fan does turn, but not at full speed. This makes operating without a shroud much less efficient.

-

Anti Rattle Springs on Stock frong brakes?

They do fit the stock application. Can't remember how the little boogers fit though. The flat spring steel clip ( 4 of them ) fit over each pads and are retained by the Pad locating pin. That's all we used to run as that provides 90% of the anti-rattle damping.

-

Rear bushings

Missing my 12 Ton Hydraulic press. Didn't need it very often... but when you did, it was a life saver!! Had to sell it when Dad passed away and we had to sell the family home. That was my workshop for decades. Kind of hard to set up a shop in a 2 bedroom apartment... although I've made a good attempt.

-

Electric Vacuum Pump for Brakes?

14 inches isn't bad... That's what SHE said!!!

-

78 280z flooding when starting

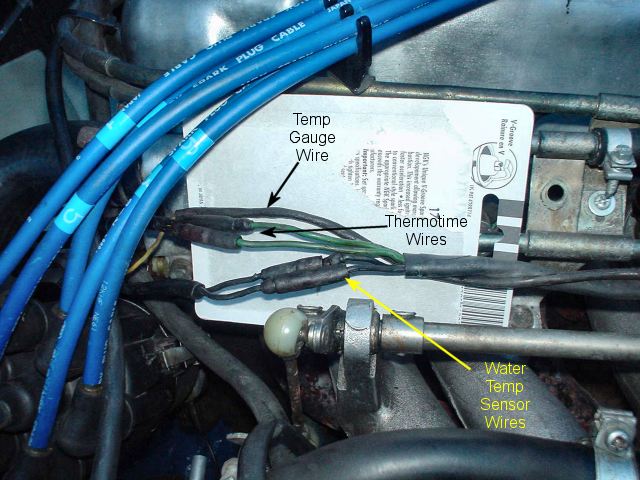

A couple of things that OP may want to look at. 40 year old EFI systems are very sensitive to corrosion or electrical resistance in the wiring harness. Particularly the ECU CTS. Buy some Deoxit spray or Weicon Electrical Contact spray. Weicon is a German company and makes a great line of Industrial products. Carefully inspect all terminals and connections for corrosion. Spray the terminals with the Electrical Contact cleaner, wait 10 minutes and inspect. Weicon usually leaves the terminals looking like brand new. However, heavy corrosions may need a second application. Go through every single electrical connection for every single EFI component. Injectors, all sensors, AFM connections, TPS ( you can also spray the Contact cleaner directly on the TPS contacts. ) and the main ECU plug. It is amazing the improvement this can make. With really stubborn corrosion you may have to get in and pick away with Jewellers screwdrivers or a Dental pick. After a proper cleaning you can take some Dielectric grease and coat the terminals with it to prevent moisture from getting back in. One other thing . It is really easy to get the terminals for the Thermal Time Switch and the ECU CTS mixed up. They are 4 bullet connectors. One pair is Black and the other pair is Dark Green. But after 40 years the Dark green turns Black!!. Peel back some of the insulation tape to reveal the true colors of these four wires. Missing them up will cause the car to run Pig Rich. The following picture should help identify the proper way to connect these :

-

Electric Vacuum Pump for Brakes?

There are also auxiliary Vacuum canisters that are available for Muscle Cars with big cams and low idle vacuum. These are plumbed in parallel with the factory Booster and increase the overall Booster volume. That may be easier than changing boosters them selves. More capacity allows vacuum assist to be maximised ( volume wise ) under cruise and decel. Even changing gears will build some vacuum. Available at Summit and Jeg's. https://www.summitracing.com/int/search/department/brake-systems?N=4294947838&SortBy=BestKeywordMatch&SortOrder=Ascending&keyword=Vacuum Canister&retaillocation=int Edit: This will not reduce pedal effort, but can correct issues when you run out of assist due to insufficient Booster volume. A problem that can occur early Z's and the smaller diameter Brake booster, when used for Track Days or Road Racing. On the D-Production 240Z that I Road Raced in the late 70's, we switched over to a non-assisted Braking system and eliminated the Brake Booster entirely. This was allowed by our racing organization under Safety modifications ( ICSCC ) . On certain tracks with heavy braking ( WestWood was a prime example ) you could use up all of the booster volume under braking for a hairpin that followed a long downhill straight. Then it was a flat out climb with no braking to the next corner, Some cars could not build enough vacuum volume in the booster when changing gears. When you arrived at the next corner you found the pedal was a solid brick and you had no or little assist. Definitely a scary moment. We eliminated the booster entirely. Had a billet adapter made to take its's place and used a Custom made adjustable length. pushrod . We used the same pushrod mounting location on the brake pedal. This gave a very solid feel to the brakes that required a fair amount of leg strength, but were very easy to modulate. I really liked a firm hard pedal. There were a few C-Production Porsche 911's that got a Nasty surprise if they tried to out brake our D-Prod Z at any Circuit ( Particularly WestWood ) . Of course we employed other tricks as well.....

- Upgrading a 280Z EFI to Spitronics Mercury 2 ECU