Everything posted by Chickenman

-

Death Wobble in Steering Wheel

And make sure that the steering coupler is tight secure. Especially if it is still the original " Rag " joint. One place where Poly is good.

-

Death Wobble in Steering Wheel

One other thing to check on the wheels. Make sure that the center hub centric is not machined too small. The wheel will not sit flush with the wheel hub. It can be installed kocked at a slight angle. This won't show up on a balancing machine ( when checking for wheel runout ) as balancing machines use tapered arbors.

-

Triple Weber throttle connector hitting mounting point on carb??

Use an Allen head bolt.

-

brake proportioning valve

PM sent...

-

brake proportioning valve

It is. But It's all about weight transfer and balance. Grip levels are the same for front and rear Wet or Dry. It affects all four tires at the same time. The weight transfer off of the rear tires ( and to the front ) is less in the rain . Less negative G forces under braking in the Wet ( obviously ) = less weight tranfer to front tire = rear brakes have more of a percentage of weight on them = more rear brake bias availble. Part of the " Traction Circle " equation.

-

brake proportioning valve

Well... considering that we just had 7 freakin' months of bloody rain here. You may have a point...

-

brake proportioning valve

You gut the insides because you cannot have two hydraulic proportioning valves in series. Creates problems with long pedal travgel. You could plumb the WilWood prop valve in place of the factory valve. Depends where the factory valve is located. Meant to say " Coupler " not a Tee. Sorry.

-

brake proportioning valve

Not really. That can create problems in the Dry. You get more weight transfer to the front under dry Road conditions. That requires less braking force from the rear brakes. From us PNW Road Racers who always race in the Wet, you actually crank in more rear brake bias ( Wet ) because you don't get as much weight transfer to the front.. Setting the brake bias up for maximum braking in the wet, can cause the rears to lock before the fronts when it's dry. That's a good way to spin out. An in-Cockpit knob for Race cars alleviates the problem somewhat. But for a street car with the proportioning valve in the engine bay, it's best to set up Brake bias in the dry. Hill climbs also allow more rear brake bias as you're going uphill and the rear wheels have more weight on them under braking than when on a flat road.. or a downhill. I'd typically have to add a full turn of rear brake to my Camaro when I ran Hillclimbs as compared to Autocross or track days. And I liked a LOT of rear brake. Modern race cars such as F1, Indy Car and WEC have brake bias controls on the steering wheel. and the drivers will adjust them constantly for different types of corners ( Road racing ). You can often see the driver twiddling with knobs or buttons before a corner and see the Dash flash up numbers like 63.2, 63.0 etc. That's the brake Bias percentage.

-

This Old Cam

Take a picture of the face of the back of the Cam. There may be some numbers scribed in there to identify the grind number.

-

brake proportioning valve

Richard. Regarding the WilWood proportioning valve. It will work fine on drum brakes as well as Rear discs. I've used them on many Autocross and Road Race cars to adjust corner Turn-in. You could gut the insides of the rear Datsun proportioning valve to turn it into a simple Tee fitting. That would be the easiest. Or buy a Metric Tee fitting. Then plumb the WilWood valve into the rear brake line that comes off the Master cylinder. You didn't mention if the WilWood in cockpit adjustment on your Roundy Round cars was a Hydraulic valve or a balance bar system. Doesn't really matter. On a street car it's not something your are often changing. The hydraulic adjuster will be fine in the engine bay. Make a few braking runs on a deserted back Road and adjust the balance to where you want. You can get a LOT more rear brake than what the factory system uses as a default.

-

Aftermarket ECU Megasquirt Install

As I recall, the ZX Pintle caps are much longer than the 1.8T caps. The ZX pintle caps will disrupt the spray pattern of the 1.8T injectors. Edit: This is an image I found on the Web of 280ZX injectors. The pintle cap is quite long. If the pintle caps you put on the Bosch 1.8T injectors look like these, the spray pattern will be severely disrupted. How bad exactly, I don't know... But the spray pattern is going to hit the walls of the pintle cap and that can't be good. 280ZX Injector picture:

-

Aftermarket ECU Megasquirt Install

Not really. The VW/Audi 1.8T injectors are a use a flat disc ditribition plate. This has twin laser etched holes to give a very wide spray pattern The pintle caps are special for these injectors. They have a very wide Bevel or countersink on them to allow for the spray pattern to " Fan out" with out hittiting the sides of the Pintle cap. Changing to a different style of Pintle cap may cause the spary to be disrupted. Here is a picture of the Bosch 1.8T pintle caps. Note the wide countersink on the base ( Brown pintle cap ) compared to a Narrow spray Bosch pintle cap: 1.8T Pintle cap: It's hard to see in this picture. But the Blue Bosch pintle caps are designed for a narrow spray pattern Note the subtle difference.

-

Aftermarket ECU Megasquirt Install

Yeah, I'd definately recommend High Impedance injectors with any MS conversion. Eliminates the whole PW Current limiting difficulties. Funny thing is I had four Bosch Audi injectors sitting here on my shelf and didn't even think about using them. The spray Pattern on the VW/Audi injectors is rather unique, as the 1.8T engine has 3 Intake runners per cylinder ( 5 valve ). And it's a very wide spray. The regular single cone spray pattern of Bosch injectors made for Ford engines would actually be a bit better spray pattern than the VW/Audi ones. You get a bit more ( Edit: maybe a lot more ) wall wetting with the VW/Audi injectors than what is desirable for our Intake runners. But they will work. How well is the question??? Here is a picture of both small port and large port VW/Audi Intake ports. You can see how wide the ports are and how the injector spray has to " fan out " to cover the port area. The AEB runners on the bottom are HUGE!! And her is a picture of the head side showing the three runners as they split after the port face:

-

Aftermarket ECU Megasquirt Install

What heat range are those Plugs Steve? I can't see from the picture. If those are the plugs that we ran during the setup the other day, I wouldn't say that they are lean. Unless they are new plugs, the soot on the shell is probably due to the initial startup and idle tuning. Injected engines run much cleaner than carbed engines in regards to plug coloring. Especially at idle. Injected engines don't tend to foul plugs at idle, even with big cams and wildly fluctuating MAP values. Careful with the timing. I was a a bit more aggressive on this Tune based on your feedback and also that it's a NA engine, which I'm pretty comfortable with. You're at 36 degrees total mechanical now with an E88 head. That's pushing it on these engines. Smaller combustion chambers need less spark advance than open chamber heads. Even though the E88 head is less sensitive to detonation than an N42 or N47, the smaller chamber size and more efficient chamber design does not mean more timing is necessarily better. You are getting into that range of pinging on pump gas. 93 or 94 Octane " might " handle a degree or possibly 2 more... but I think that's really pushing it. For 91 Octane I wouldn't raise it any at all. Just my .02c. Yeah, the TS Auto-Tune is OK... but it's not as accurate as it could be. As I mentioned before, don't trust it 100%. Sometimes it goes a bit too far. When you really get down to " Fine Tuning " a Load Cell Dyno and Manual Tuning of the VE cells is the only way to go.

-

Aftermarket ECU Megasquirt Install

- Crane Hi-6s + Pertronix + tach adapter?

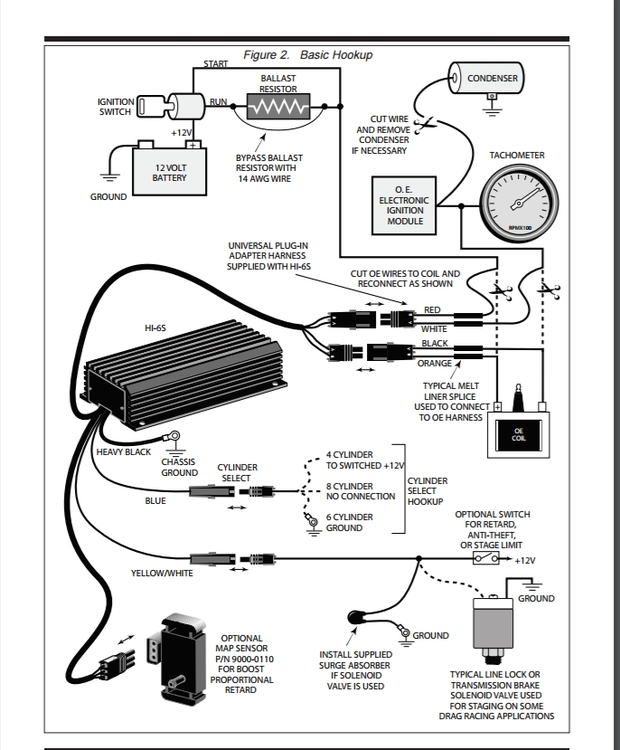

Just curious. Did end up using the white wire from the Crane adapter Harness hooked up through the Tach Adapter? That seems to be the same hook up as the Pertronix/ MSD diagram???- Crane Hi-6s + Pertronix + tach adapter?

Awesome!!! Good detective work. I'm sure that will help others out who may end up with the same issue.- Crane Hi-6s + Pertronix + tach adapter?

The Crane Hi-6S is an Inductive box with advanced dwell and Multispark features. You don't really need the Multi-Spark feature on an inductive box. The spark duration is already very long. CDI boxes are different as the spark duration is so short. But Multi Spark on an inductive box is really just overkill. You can turn off the Multi-Spark feature with the rotary switches Then you should be able to connect the tach wire from the Factory Datsun harness to the coil negative post. Or connect the TM-02 Trigger input to the coil negative terminal. Give that a try and see how it works. Do you have a link to the old Crane Tach adapter instructions? That would help us follow along...- Stroker 3.1

If you have the room, a Ford Taurus 1987 to 1993 single fan is a favorite of the 4X4 crowd and Turbo guys. They pull a TON of air. Dirt cheap at the Auto wreckers as well. Here is a link to just one of the many articles on Taurus fans: https://www.jalopyjournal.com/forum/threads/ford-taurus-cooling-fan-wow.486504/ Many OEM fans pull a lot more CFM than aftermarket fans. They have to last a long time and handle extreme conditions. Bone yard is dirt cheap as well.- Crane XR 3000 and the Z Tach

What year is your Z? Early 240Z cars have a Current sensing Tach and thye don't play nice with aftermarket Ignition systems. . Several options available depending on what year your car is.- 1 reply

-

- electrical

- engine

- gauges

- ignition

-

Tagged with:

- Stroker 3.1

Nothing like the sound of Triple 44's at full song!!. Unless it's a set of Jenvey ITB's with modern Fuel Injection!!!- Identify those brakes

Those look like mid 80's Maxima calipers ( 90% sure on that. A popular swap ) . Doesn't really matter, as they are Tokico calipers and Tokico is an OEM manufacturer of Nissan brake parts. All of the Datsun calipers around the 80's and 90's had the same Banjo bolt thread size. Silvermine motors will make the SS brake hoses to fit. Just tell them your year and Model of Car. $75 a pair. I have a 1976 280Z and I have their custom made brake hoses for Maxima rear calipers sitting in front of me. Look to be exactly what you need . All fittings are included, including new crush washers, Banjo bolts and even retaining clips. Silvermine Motors sells all individual parts for their brake kits. http://www.silverminemotors.com/datsun/datsun-280z/brake-kit-individual-parts Here's the link to the custom made SS brake hoses: http://www.silverminemotors.com/datsun/datsun-280z/brake-kit-individual-parts/steel-braided-lines- Electric Servos Instead Of Vacuum Driven HVAC

Following. Although I have my Vacuum system working 99% right now. Still a little problem with heat control sensitivity, but I think that's because I have a seized or leaking Automatic water valve. I wonder if that can be updated? Hmmmm.....- 1976 280z Stuttering

- Wilwood caliper angle.

That's just fine. No need to remove for bleeding. With multi-piston calipers, lightly tap the caliper with a Plastic tipped hammer while bleeding. This releases any air bubbles that may be hiding in little nooks and crannies of internal passages. - Crane Hi-6s + Pertronix + tach adapter?

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.