-

Posts

1,210 -

Joined

-

Last visited

-

Days Won

11

Content Type

Profiles

Knowledge Base

Zcar Wiki

Forums

Gallery

Events

Downloads

Store

Blogs

Collections

Classifieds

Everything posted by Chickenman

-

FSM calls for crank run out limit of less than .0020" ... but that's measured in middle of crank. The runout on the snout can be more critical, because of the length that is unsupported and the leverage involved. I'd prefer to see it around .0010" on a race motor. Measured at end of snout. A good crank shop should be able to straighten a bent snout fairly easily. Just make sure they know it's a Race engine and that " Good Enough " is NOT acceptable.

-

I blew a spindle gear like this once ( and the worm gear ). Turned out to be a slightly bent crank snout. Check the radial runout on the crank snout. Check at very end of snout. Will destroy the spindle gear in short order. FSM should have specs or a good machine shop. Endurance racing will really amplify any vibration/harmonics issues. Is this a stroker engine by any chance? What size is the engine, has it been balanced and what RPM range are you using? What are you using for a front damper? Front damper design can really affect spindle and worm gear life. Secondary vibrations in a inline 6 can get very high. A good vibration damper is critical to crank and component life on an Inline 6. Never use an aluminium or solid billet steel pulley on the front of the crank. Check the TC bushing to make sure it hasn't elongated. Can cause spindle shaft whip. Are you running a Crank fire ignition by any chance and have eliminated the Dizzy? Dizzy lower bushing gives support to top of spindle shaft and helps to limit shaft whip. If Dizzy eliminated, top of spindle shaft should be machined for an upper bearing. It should not be left unsupported. That will cause spindle shaft whip for sure and destroy the gears. Other possible causes are excessive oil pressure. . What oil and weight are you running? Low levels of Zddp in oil could also cause this issue, but I'm leaning more towards a vibration or bent crank issue.

-

Were the plug leads ever checked with an Ohm Meter? Could be a couple of plug leads have a higher resistance than they should? Regarding higher voltages required by Gold Palladium plugs. I recall reading something about that years ago. Palladium is not that great of an electrical conductor. So, even though fine wire, they do require more spark energy to fire. Was on some forced induction forums. GP plugs were an answer back in the 1990's to extend spark plug life over Copper core/Nickel tip plugs. Iridium has come down in price since the early 2000's and offers increased melting temperatures and reduced spark firing voltage over Gold/Palladium plugs. The other proble with GP plugs is that the GP was actaully a " Chip " that was fused on to the center electrode and side electrode. These were very brittle and had a tendency to break off if the engine pinged or detonated slightly. On a Turbo car these very sharp and hard " chips " would then damage the exhaust turbine as they blew out of the combustion chamber. Iridium plugs are constructed differently and they do not have the same problem with " Chips " breaking off.

-

But a Pertronix is not an MSD style syste. The MSD is a Capacitor Discharge box. ( At least the ones that Drag Racers would be familiar with ). The Pertronix is an inductive box. And not a particularly strong one at that unfortunately. MSD does make an Inductive box. The 5 series, but no serious Drag Racer would use one of those. It does however, put out a stronger spark than Pertronix. Don't believe all the hype about voltages. 40KV may sound great, but a plug may need only 20kv to Arc Over and initiate the spark kernel. One the kernel is established, it is amperage or current that maintains the spark. Current output or Amperage is more important than Voltage. Think of a Garden hose and a Fire Hose. Get hit with 100 psi ( PSI = Voltage ) from a 5/8" ( Amperage ) Garden hose. Now get hit with 100 PSI ( Voltage ) from a 3" ( amperage ) Fire Hose. It's gonna knock you on your arse. Same thing with Voltage and Amperage in a Coil. Modern Ignition designs are all switching to High Amperage and have since the late 90's. Unfortunately the Pertronix is not one of those systems. A quick fix is to Combine the Pertronix with an Auxilary box like a Crane Hi-6S. This is piggy back system ( Needs a module to trigger it ) that will take the output signal from the Pertronix and up it to a long duration, multi-spark Inductive system with a very sophisticated Rev control. Crane units are generally more reliable than MSD. the added bonus is because the electronics in the Crane Box take the amperage draw from the coil, your Pertronix module now see millamps of darw. The Crane box is much heavier duty and has very reliable protection circuits. Modern OEM inductive systems can easily fire .045" to .060" plug gaps. Those are recommended new plug gaps. The Pertronix, gets iffy around .040" , as you've found out. Crane inductive boxes, MSD inductive boxes and Nissan OEM 12-80 Match box modules can easily handle .040" to .045" on NA motors. MSD CDI boxes and Crane CDI boxes... heck, you can snip the side electrode of at the base and thye won't acre. They will happily fire away with no side electrode at all. ( Or jump to another internal dizzy cap terminal if you have a bad plug or plug wire. See comment below ) I did not mention the Crane Hi-6 CDI box , because frankly it is over kill in a standard Nissan dizzy. You need a larger diameter cap than what Nizzan supplies for the huge spark it puts out. An 82-84 Turbo dizzy cap is just getting large enough to handle a CDI box like MSD 6-AL or Crane Hi-6

-

I've been using Crane Hi-6 CDI boxes and there coils since about 1998. Pretty familiar with the products. Crane recommends the PS20 or PS40 coil for the XR700. I think that the PS91 compatibility with the XR700 was be old info as well. later coil recommendation catalogs do not mention the Crane XR700 as being compatible with PS91 coil even with a ballst resistor. The PS91 is also a CDI coil; http://www.cranecams.com/404-405.pdf Edit: More info on PS91 and Ps92 coil. XR3000 box recommended as minimum required for a PS91. ( XR3000 is much more heavy duty than XR700 ). And a PS92 Race Coils much stronger than a PS91. Word to the wise. Either of these coils can stop your heart and kill you. Never check spark gap quality with your hands. Always use a spark gap test tool. Seriously folks. I got laid out on the ground and thrown 3 feet from car when I got zapped from a Crane Hi-6 CDI box and an PS92 race coil . Fortunately current went down the right side of my body, as I always handle HT leads with my right hand only.

-

Ummm... I don't think an XR700 box can handle the amperage that a PS92 coil draws. A PS91 which pulls less amps might even be iffy with an XR700. I'll have to check my Crane technical documents. PS92 coil is a High Output race coil is only rated for Crane Hi-6 CDI boxes and higher. Even an MSD 6AL is not recommended to be combined with a PS92 or LX92 coil. The 92 coils are CDI coils and are not meant to be used with an Inductive box like the XR700. Edit: Yeah, you can't use a PS92 on an XR700. It will burn it out. Even NSD requires a MSD 7 series or higher for a PS92 coil. Ther's mor info than just this link available. But a PS92 will burn out an XR700 pretty quickly. PS91 you can get away with on an XR700, but it does need a Ballast resistor attached. http://www.cranecams.com/uploads/instructions/9000-1091_.pdf

-

Not necessarily.... ( ECU bad ). Keep testing and eliminating issues one at a time. Let us know what ZH's method shows up.

-

Not sure how you tested, but a test test light can sometimes fool you. Injectors always have a constant 12 volts. If you probe the hot side of injector harness, test light should light up with engine cranking over. However, that does not tell you if you are getting an injector pulse because it is the ground side that is switched on and off. NOID lights are a cheap and effective way of testing for injector pulse. NOID lights just test up to the harness end. You can still have a physically dead or stuck injector. Obviously if you probe the hot side of the injector terminal, crank the engine over and test light does not light up... then you know you are not getting any power at all to the injector harness and you need to find out why. ZH's method will also work You could use ZH's method to test each injector 1 at a time to make sure they all work. 6 injectors clicking at same time can sometimes confuse you, so I like to connect and test them one at a time in the relevant terminals.

-

Go to Napa, Autozone or even WalMart. Pick yourself up a Noid light or two. You can buy whole kits for under $20 on E-Bay. I buy universal ones at Princess Auto for $1.99 each. Plug into the end of the injector terminal and they will tell flash with injector pulse. Makes it easy for testing for stuck or dead injectors. Picture below is what I pay $1.99 for at Princess Auto: http://www.ebay.com/itm/WILMAR-BOSCH-PFI-NOID-LIGHT-W85102-/282404897015?hash=item41c0a4c0f7:g:r48AAOSwax5Y0XZb

-

Getting the urge to upgrade in size

Chickenman replied to Zedyone_kenobi's topic in Triple Mikuni and Webers

^ Yep. Totally true. Stronger booster signal overall on the 45's compared to the 40's with the same Choke size. Passini has very good info and charts. -

When you have things apart. Inspect the oil pump. Make sure that nothing has damaged the oil pump rotors and possibly jammed the teeth for an instant. That could make the spindle gear spin or damage the worm gear /key on the crank. Rare...but worth checking.

-

Obviously that will work to.. LOL. Weird that it was running Ok then you first fired it up. I just looked at my BNIB turbo spindle, and it is not pinned. Just pressed on, Probably to a splined shaft. So I guess it could spin , although that is rare. Only other thing that could change the gear timing like that is a sheared key on the crank for the worm drive gear on the crankshaft. I did have one of those gears split on me during a race and it slipped on the crank.

-

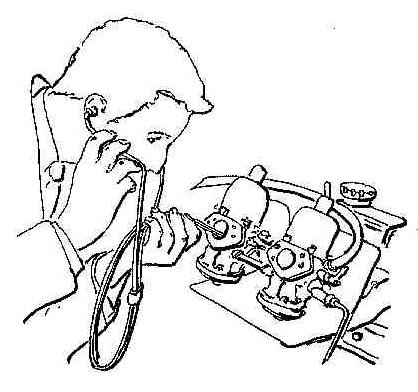

1: Distributor shaft is definitely in wrong position. 2: Something looks weird with your timing Mark and pulley. What engine is this? What pulley is on engine? That timing tab is not factory. Even the factory timing tabs and pulleys vary. The pulleys and timing marks were not all the same for various years of L-series engines. The mark on the crank pulley can be misleading if the engine is built up from mix-n-match parts. 3: You absolutely sure you're at TDC? See #2 Did you check with a positive stop method. Don't go by pulley. Outer ring could have slipped, or that Timing pointer is not right. I notice that the alternator is on the opposite side of the engine than normal. Pull all the plugs and slowly rotate crankshaft to TDC by hand. Put your finger in the #1 hole until you feel compression. When the piston gets close to the top, put a long thin screwdriver in #1 hole , You should be able to feel the piston come up, pause and then head back down. Obviously when it pauses that is TDC. see where your timing pointer points to on the damper pulley. I think the marks are out. 4: Check firing order. 1-5-3-6-2-4 . Rotor rotates counter clockwise Picture of Distributor shaft in correct position:

-

I remember seeing that thread and was looking for it. Do you have the link?

-

Delete. Double post.

-

Delete. Just found out OP has a 280Z. My Information not relevant.

-

I don'y know what I Luv more. Your cars or your garage. Jealous!!

-

This is on your 1976 280Z correct? Does the car have factory AC? The hose going into the Firewall controls is the main vacuum source for the Vacuum operated heater controls. A lovely Rudi Goldberg collection of Vacuum selector valve and Vacuum pots that makes all the Climate controls work. Have a good long look at the FSM, It's available online. The white Plastic Tee is not stock and has been added by someone. Take some pictures of heater control panel and levers and also up by the passenger side strut. There should be an Vaccuum accumulator tank there and one ( or Two ) elctro Vacuum switches. Setup varies oif car originally came equipped with AC.

- 1 reply

-

- 1

-

-

Delete. Double Post

-

Do not use the 30R6. This is a low pressure fuel hose and it is not designed to be used with Fuel Injection systems. While the pressure rating may seem enough, that is the BURST pressure... which is not the same as working pressure. Working pressure is the pressure that the hose has to withstand in constant use over it's lifetime. 30R76 only has to meet a working pressure of 50 psi. Even used as a non pressure tank feed, 30R6 is an old standard and causing issues. 30R6 is causing a lot of issues in North America with the new formulation of fuels. Damage from Ethanol and excessive permeability being the major problem. New fuels require at least the 30R9. Note. Since you live in Germany the European specs may be different part number. I find it hard to believe you can't find appropriate specification hose in Germany. European standards are usually higher than North America. Here's ane article from Pelican Parts forum. It usually has a pretty good reputation, as they have a lot of Porsche and BMW club racers who contribute. http://forums.pelicanparts.com/porsche-911-technical-forum/671288-sae30r6-kx-fuel-line.html And here is a link to SAE documentation on the standards. http://www.volksbolts.com/faq/SAEJ30.pdf

-

Wow... that's just not good. Strangely I have a " dead " feeling just off center with my 1976 280Z New Poly Rack bushings, Poly steering shaft coupler ( old ) and 225/50 x 16 Conti Tires. Very heavy steering an car just doesn't respond to initial movement of steering wheel, then it takes a big bite. Very disconcerting. I've had the front end checked a couple of times but nothing has been found. I'm going to replace the Lower Control arm bushes and Lower Ball joints just for good measure. It actually feels like the rack is moving just like Daves car. But it shouldn't with the Poly bushings... at least I would think it wouldn't. If memory serves me correct, the 240Z bushings were a lot thinner. Perhaps the 280Z rack bushes just have too much material and deflect too much with wide sticky tires. Even with Poly bushinsg? I'm going to have to put it up on an Alignment rack and load up the front end while turning the steering wheel. Something is not right.

-

" Revs up fairly smoothly and pistons move like they should " ... contradicts the subject line and main premise that the engine is only running on one carb. That tends to lead us all on a wild goose chase?? Sounds like it's actually running on both carbs, but not properly. Synch them again and check that the pistons are free. Remove both oil dampers. With engine off, lift each piston to the top position and then let it drop. It should move freely with no sticking and should drop freely and stop with a solid " clunk ". If there is any binding, remove the Piston cover and make sure jet is centered in jet holder. Check needle to see if it is bent or has score marks. After making any necessary adjustments. Replace the Piston cover and lightly tighten screws. Do the lift and drop test. If any binding, slightly reposition dome cover. There is some assembly variance built in. Make sure dampers are filled to the correct level with lightweight oil ( I prefer ATF ) and reinstall dampers. Re-synch carbs. Edit; Be sure to check for any vacuum leaks around intake manifold. Loose Intake manifold bolts, split hoses etc. A Vacuum leak will put the carb synch out of whack.

-

Edit: Dang Capitano Obvious beat me to it while I was downloading fancy pictures. I concur with CO. What happens when you Rev the engine rapidly? Does the rear piston lift and the engine respond halfway decent? You may just have the front and rear carbs really out of balance. Throttle blade wise. Rear throttle blade closed at idle...= no airflow = no fuel draw = no idle difference when piston lifted manually. happens all the time on Triples and happens on SU's as well. Do you have a Carb balancing tool?

-

Bushes are probably oil soaked and gone mushy. That's a technical Term LOL. Rack Bushings are one place that Poly Bushings are good.

-

Something strange with that link. Takes me to videos of a Slot car Track.