-

Posts

1,210 -

Joined

-

Last visited

-

Days Won

11

Content Type

Profiles

Knowledge Base

Zcar Wiki

Forums

Gallery

Events

Downloads

Store

Blogs

Collections

Classifieds

Everything posted by Chickenman

-

As a temporary measure after a Tank clean it may work. But the Atlantic Z article doesn't say that. You should definitely run a Pre-Filter all the Time. But it should be a filter that suits the Task. In tank filters come with a Filter sock. As mentioned those work well. They are a coarse filter and relatively non-restrictive. Being 80 to 120 Microns in size. Just because you aren't having a problem now, doesn't mean you won't down the Road. On a mildly driven car with a relatively stock fuel pump you may get away with it. But on a Turbo car with a high volume fuel pump it WILL cause a problem. Fuel Filter on clients car was only about 6 months old and it was clean. The Walbro 255 pump volume and suction and simply collapsed the filter Media. That's alo why I included the Tech article from Aeromotive. You need a non-restrictive coarse filter before the pump to catch the big trash. But the Fram G3 style is the wrong choice for a pre-filter.... especially on a Vehicle with a high flow fuel system. It is designed as a pressure filter, not a suction filter. It is designed for low fuel pressures and volumes on carburetors, . It is not a high volume fuel filter. The G3 is anywhere from 15 to 20 Microns depending on whose specs you read . And it wasn't easy finding those specs I can tell you. I finally managed to finally find them in an Industrial Trades catalog . Can't remember if I saved the PDF though. As I mentioned. I also have a Fran G3 on my NA 280Z. It's got a pretty potent engine. I've always noticed that the EFI Fuel pump ( Airtex Ceramic Turbine ) gets noticeably noisier on a low fuel tank and especially at high ambient temps. The high ambient temps and louder F/Pump are the hidden clue. Higher fuel temps promote more fuel cavitation at the pump. A Ceramic Turbine pump should be very quiet. My fuel pump is nothing special. But on a Big Turbo EFI car you have to look at the Big picture. Every component is important. Think of sucking a thick Milkshake through a thin straw. Yes you will finish your Milkshake. But not very easily and your Cheeks may ache a bit. Same thing with your F/Pump. By using a restrictive filter ahead of the pump you are making it work harder than it should. Eventually that will wear the pump out faster.... and could cause other issues.

-

One of my customers E-Mailed me after I told him to remove the Fram G3 " pre-filter ". The cellulose filter media had completely collapsed and wa plugging the outlet Nipple. Car suddenly went Lean and Walpro Fuel pump got REALLY noisy. He installed a 100 Micron Aeromotive pre- filter and problem was solved. Fuel pressure came back and FP was quiet.

-

Yes, I Remote Tune a fair number of L28 Turbo cars. I've had about 6 customers have issue with the Fram G3 restricting flow. Don't feel bad . I fell for that article as well. I have a Fram G3 on my 280Z NA motor. And the Fuel pump gets noisy as hell when fuel gets low or the ambient temps get hot. I'll be switching to a proper EFI SS 100 Micron filter in the future. Probably an Aeromotive. Holley also makes a nice one as well. The Holley one is available with 3/8" NPT, so you can run hose nipples or AN fittings as you wish. https://www.summitracing.com/int/parts/hly-162-553/overview/?retaillocation=int

-

Do not add the Fram G3 fuel filter between the Tank and Fuel pump. Worst danged piece of advice on the Internet. Atlantic Z should take that article down. The Fram G3 is a fine filter for use on the pressure side of Fuel pumps and only for carburetors. It filters medium is between 15 to 20 Microns. A pre-filter for an EFI pump has to be fairly coarse. 100 Microns in size is good, and it has to be non-restrictive. The Fram G3 or similar filters will restrict a Fuel pump inlet and can damage the pump through " Supercavitation: " I will attach a file from Aeromotive explaining EFI Pre-Filters. Stock Nissan pump is a Roller vane style. They are relatively insensitive to small debris. Pros: They will chew and spit out must debris like a mini Garburator. Cons: They are nosy and not very efficient. Gerotor pumps like a Walpro or Bosch 044 are a lot more efficient and pump more pressure and Volume. They will tolerate less Debris, so a pre-filter before the pump is advised. Ceramic Turbine pumps are used on many OEM cars. They are very quiet, will push very high pressures and adequate volume for stock cars. But they will not tolerate ANY debris and a Pre-filter is necessary. Most are in Tank pumps and the Nylon sock on the end is used as a Pre-Filter this is usually 80 to 120 Micros in filtering size. Fuel pressure. If you have an adjustable FPR, the stock FP is 37.5 PSI at idle on 280Z and ZX. That is with engine idling and Vacuum reference hose removed from FPR while setting pressure. Reattach vacuum hose and pressure should drop about 8 - 9 PSI on your Gauge. I see Dave WM is replying as I'm typing.... TB_101_InletFilter02.pdf

-

As far as Fuel pressure. Do you still have stock injectors and EFI system?

-

Fuel pressure damper. Leave it in place. Helps absorb " Water Hammer " from the injectors when they open and close. Like in an old hose when you shut a water tap off too quick and the pipes go Bang. Same principle.

-

Problem with trying to diagnose something like this is that we aren't there. How much " wiggle is too much ". Without actually feeling things in our grubby little hands it becomes a perception issue.

-

The 14mm bolt idea would be a good check. Does seem to be a machining issue on the inner Tie Rods.

-

It may be an idea to contact Rare Parts Inc directly and see if they are aware of this issue. They could have have a Batch of parts that were machined wrong.

-

Z-Boy-MN : Are you buying or exchanging the Inner Tie Rod ends from the same source every time ? If so you may be getting the same aftermarket manufacturer parts every time. Do the inner toe rods come in a box with any type of manufacturer name on them? The problem seems to be the inner Tie rod end being too small. But you could have a Clearance " Stacking " problem. You could try ordering a new Right outer Tie Rod end from Rock Auto. Bech Arnley is usually really good. Most of the time OEM Japanese parts. Moog Premium part is also good. You are only looking at $22 to $24. RA is also very good with returns. https://www.rockauto.com/en/catalog/nissan,1972,240z,2.4l+l6,1209169,steering,tie+rod+end,7428 TT3 outer Tie Rod ends aren't going to help if the Inner tie rod threads are undersized. Which at 13.65imm t sounds like it is. I'd be trying to find a source for a different supplier of new Nissan Tie rod end. Or even A good used one. Nissan part number for Rt Inner tie-rod is 48511-E8725. Interesting that I found a mention from TT3 that the only manufacturer of Inner Tie Rod ends is Rare Parts Inc in North Carolina. And they only make the RIGHT hand side. If the Z-Car Depot is suppling new parts from this Manufacturer... then you could have your answer. https://technotoytuning.com/nissan/240z/outer-tie-rods-datsun-240z-260z-and-280z Now..I don't know how true the above statement is ( About Rare Parts inc ) I'm betting if you look hard enough you can find a NOS OEM right inner Tie Rod end or a good used one.

-

Lower radiator hose came off while returning home

Chickenman replied to Johnny wick's topic in Engine & Drivetrain

CTIE. -

Got that right!!

-

I could be completely wrong... memories getting old. Ball joints did have two different thread sizes. Early ones were smaller. It could be a manufacturing error as already mentioned. Offshore parts are infamous for poor quality control. But steering rod thread fit should not be sloppy at all. Loose thread fit means less thread engagement and danger of fatener component. There is a heck of a lot of load on Tie Rod threads. You do not want them loose. The Jam nut is not for structural integrity. It is just to prevent the inner Tire Rod end from unscrewing. If one side fits tightly and the other side is sloppy... then you have an issue. Period. If you run Track days or Autocross, big hot sticky tires will load the steering linkage parts to the maximum. They must be 100% perfect. I'm with Captain Obvious. Personally, I would not accept this situation. Something is not right. Ever watch Mayday? The Airplane disaster show. One had a British Air episode where the front windshield blew out while in flight. Captain was sucked half way out of the windshield opening., before Engineer grabbed his legs. Cause was a windshield replacement the night before. Mechanic mistakenly replaced the 9 mm bolts with 8mm bolts. They fit... but were " loose " . Fortunately the flight crew managed to land the plane safely despite a Catastrophic decompression at 14,000 ft. And even more amazing was that the Captain survived. But the outcome could have been tragic. Food for thought. Bottom line. Fasteners of any kind are not meant to fit " sloppy". And certainly not in high stress areas such as steering linkage. Just my .02c...

-

Hang on a second. I've got alarm bells ringing in my head. I seem to recall that there was an early and a late style of Tire rod assembly. The early ones had a smaller diameter inner and outer Tie rod assembly. It was a running factory change beef up the steering components. I have to check a couple of things.......

-

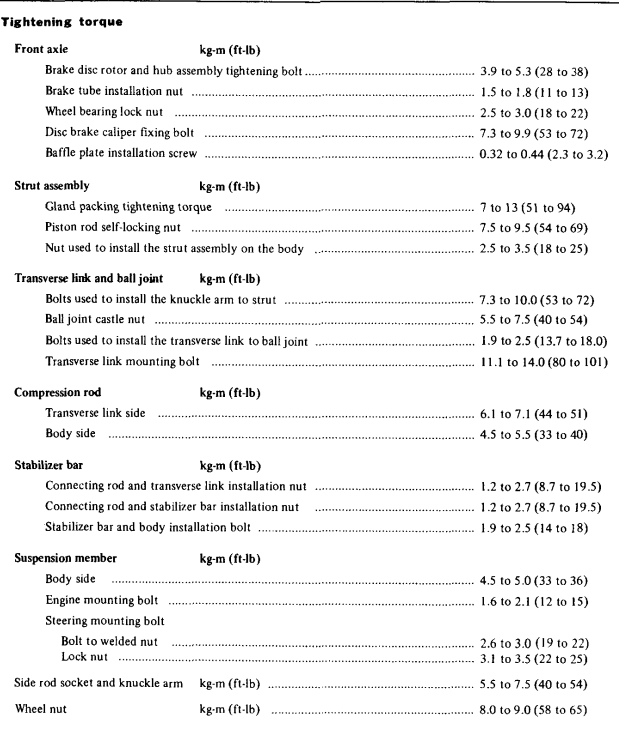

Factory specs for Ball Joint to Transverse Link ( LCA ) is 13.7 to 18.0 Ft Lbs. It's only an 8 mm bolt!! Maybe you were looking at the spec for steering arm bolts... which are 53 to 72 Ft/lbs?? I believe those are a 12mm bolt. 50 - 72 ft/lbs makes sense on those. Not on the Ball Joint mounting bolts though.

-

Yes another Brake Upgrade Thread Vented front + drums

Chickenman replied to PrincePaul's topic in Wheels & Brakes

For rear shoes, go with some of the Carbon Racing shoes. Carbo Tech makes some good ones. The MSA Carbon shoes may be good. I personally haven't tried them. Back in the 70's we could get some pretty good semi metallic shoes or Velve-Touch sintered Metallic. I use Nissan " Green Stuff " on my race 240's. Great shoes, but a bit hard for the street. Most of the Retail available brake shoes for our cars are junk these days. -

Yes another Brake Upgrade Thread Vented front + drums

Chickenman replied to PrincePaul's topic in Wheels & Brakes

One thing that is very important with calculating piston area. With Fixed caliper you only Calculate one side of the Piston volume ( if switching from floating Calipers ) . This is VERY important when comparing Piston values between sliding calipers and Fixed calipers. It is very important to stay as close to the Piston Area of the original design ( front and rear ) otherwise you will end up with balance issues and possibly pedal travel issue. Here is a handy Piston Area calculator. IMPORTANT. For floating calipers multiply the resulting value by 2 with this particular calculator. https://brakepower.com/help_abc_27_PAC_t.htm Edit. WilWood also has a handy chart. http://www.wilwood.com/TechTip/TechCaliperTip.aspx -

Sound dampening and plush/pile carpet...why?

Chickenman replied to riverstonefly's topic in Interior

The other thing is that the Z car has an open hatch area. You get a lot of road and differential noise amplified by that big Tin Drum in the back. Commonly called a spare Tire well. And the glass hatch reflects any noise forward. I have carpeting and underlay already ( Custom carpets for 280Z ) but I still get an annoying diff whine at certain speeds. Hoping that some DynaMat will reduce the whine somewhat. It seems to be an inherent trait of the R200... but I suspect I may have a pinion bearing getting a bit noisy. Was supposed to tackle the diff this winter.... but it was too danged cold!! I had the same situation on my Third Gen Camaro. Rear hatch glass reflected a lot of diff and road noise. Dynamat in the spare tire well area really cut the noise down. -

^ What ECU are you using?

-

What makes you think this was " No Good "

-

^ If I recall correctly, that is how the Nissan Comp 23mm rear bar mounted on my 09/70 240Z as well. Combined with the 22 mm Nissan Comp Bars, Nissan Comp Race springs and 3.9 gears, it made for a very quick Autocross car. I ran on Goodyear slicks in Mod Class.

-

Hmmm... you know the Thermo Time switch and the engine CTS split into bullet connectors about 12" from the sensors. You can get the bullet connectors plugged in wrong. Then the Thermo Time switch is hooked into the CLT sensor pins on the ECU. Car will run Pig Rich . Edit: Oooops... already been covered. You may want to Triple check that. Posts #46 thru #48. Tricked me up on once my 1976 280Z and car ran Pig Rich. BTW, picture in Post #48 is from my 1976 Federal model 280Z... after I sorted out the crossed Bullet connectors.

-

^ That's some nice info about CarboTech. Thanks for sharing. I'm, running Z32 calipers up front and have a spare set of used pads. May send the backing plates off to CarboTech to get some Track pads made. How much does this usually cost?

-

If you subscribe to engineering magazines like Racecar Engineering and Race Engine Tech, they often have articles on Cooling system design. Circle Track Racing also has very good articles. The testing has already been done. You just have to find the articles. BTW... the stamped steel designs always fall to the bottom of the tests. It's not a real surprise is it? Look how complex Compressor wheels are on a Turbo. W/Pumps are the exact same thing. Only thye move a Liquid, not air. Same principles apply though. W/Pump design gets very, very critical. It is surprising how the smallest detail can affect pump efficiency. All of your Top Racing w/pimps use CNC designed impellers and Volutes these days. Equal flow, block pressure and Anti Cavitation are all areas that must be addressed. Impellor to Volute clearances are very critical. The lack of the back plate of those Stamped " Paddle wheels " greatly affects their efficiency. http://www.hotrod.com/articles/ctrp-0404-water-pump/

-

Doctor gave me one of these the last time I had a Medical.. If your aim isn't straight.....