Everything posted by Chickenman

-

Auto Trans Oil Change?

I had a local Drag Racer who was having troubles with blowing up TH 400's. A local Tranny shop who were supposedly experts at building Drag Transmissions. had been building them. I had one of my Autocross TH400's up for sale ( just switched car to manual tranny ) and it was filled with all sorts of hard core Trans-Go race parts. He wasn't running an auxiliary cooler or a trans temp gauge. I told him to put both in and immediately switch to Synthetics. He put temp gauge in the pan first and ran an event that weekend. He called me the following Monday. He was seeing over 350F ( in the Tranny Pan ) after his burn out and staging on the Transbrake!!! Needless to say he was putting a big arse cooler and fan in ASAP.. Fortunately he had installed the Amsoil Synthetic transmission fluid as I had recommended. About three years later, I ran into him at the local Strip. The same TH400 that I sold him was still going strong. Only thing he did was install fresh Synthetic Fluid ( Amsoil ) and a new filter at the beginning of the season. After the second season on the transmission he stopped pulling the pan to inspect it for any wear every couple of races, as the fluid and pan were spotless every time. Clean fluid, cool fluid... and a decent build = no headaches

-

Auto Trans Oil Change?

If you do go Drag Racing ( or any other competition ) don't forget to upgrade with an big Auxilary transmission cooler. For Drag cars the burnout and holding on a footbrake or Trans brake to buid boots creates a TON of heat more than the factory cooler can handle. For Drag racing and using an Air to Oil cooler, put an electric fan on the cooler, as you need some airflow through the fins during burnout and staging. A n Ice box with Water cooling is sometimes paired with a Water to Air Intercooler and a Water to Oil transmission cooler. An auxiliary air to air cooler is also a big help even on a stock street car with an Auto. Factory coolers are often too small.

-

Auto Trans Oil Change?

Australia is a big source for Jatco 3N71B racing parts. Ozzy's luv rotaries and the 3N71B from the first Gen RX7 is very populra in Drag Rcaing. http://www.keas.com.au/products.php You could also contact RB30X at Australian Z Car. I belive that he has developed some kits. http://www.viczcar.com/forum/topic/5097-shift-kits-for-auto-zeds/

-

Auto Trans Oil Change?

You can also upgrade to a locking convertor model in either 3 speed or 4 speed. ( L3N71B and L4N71B ) Bear in mind that for high HP drag racing use, the non-locking 3N71B may be a better choice. Lock up convertors can be more troublesome on high HP Turbo applications. The clutch plates in the convertor usually doesn't have enough surface area. ( You don't want to be Boosting 10 lbs or more with the stock convertor locked ) . And they are more complicated. http://community.ratsun.net/topic/36901-automatic-transmission-upgrade/

-

Auto Trans Oil Change?

Funny thing with Auto's. I ran modified Camaro's in Autocross for years. In what would be equivalent to SCCA Prepared clas ( Really soft Goodyear slicks ) . I originally ran am Auto then switched to an 4 speed stick. Car was faster with the Auto. Geared to run 60 MPH in first gear ( 3.3 rear end Ratio and 7,000 RPM ) . Auto trans was modified extensively with many parts from Trans-Go including full manual shifting at any speed and RPM. 3,000 RPM Stall. Torque convertor. Torque convertor gave better Torque multiplication out of corners and was smoother to drive. Only put in the 4 speed when I started doing Hillclimbs and track day events. As far as HD parts go. Look for online Auto Matic Parts suppliers such as ATS. send them an E-Mail. You may even have some suppliers available locally. There are normally HD parts available for all types of transmissions. HD clutch plates and bands made out of vbetter material should be fairly easy to get. Shift kits may be available or you can make modifications on your own if you have the knowledge. Most shift kits involve raising pressures with internal springs and changing shift points with the governor. Band apply pressure can be adjusted with springs or by increasing Accumulator piston Apply area with special pistons. TransGo is a really good supplier for modified parts. They may have something for Jatco's. You will probably have to call them by phone though. Jatco parts may not be listed in their catalogs. I'm pretty sure there is a publication by ATSG Technical or HP Books on how to rebuild and modify Jatco transmissions. I've seen it at a local speed shop. I'll try and find some links for you later, but I've got to run tight now.

-

Auto Trans Oil Change?

There is some truth in the Tale of not switching to Synthetics in an old engine that has had regular oil in it for decades. And that is when people abuse the engine and do not perform regular oil changes. Then you get horrible amounts of sludge building up Modern oils ( Synthetic or Dino ) have pretty powerful detergents. Often these detergents will dissolve this old sludge and it can end up clogging the oil pickup. Or with oil pan gaskets, the only thing holding the brittle old gaskets together is the sludge. But if your engine is all sludged up like that... well what type of oils you use is the least of your problems. If you have sludge ( engine ) or varnish ( Auto trans ) build up , really the proper way to fix the problem is to disassemble and clean everything properly. Otherwise you are sitting on a Ticking time bomb. Those early Jatco 3 speed Auto's are also fairly easy to rebuild. Simpler than an engine IMHO.

-

Auto Trans Oil Change?

IMHO, there should be no issues at all switching to a full synthetic after years of regular petroleum oil. . Again, most of this was old wives tales from way back . When Synthetics first started appearing in the early to mid 70's, they did have some issues with seal leakage. Mainly because of lack of normal petroleum products that would cause the seals to swell. 40 years later and that is no longer a real issue. Synthetic formulations have changed and now include seal swellers. Even the seal technology has changed so it is more compatible with Synthetics. . If you are buying new seals ( O-rings whatever ) from the aftermarket or even Nissan, the materials are different. If you have 40 year old seals in the engine... or Transmission... well it might be an idea to pull it apart and freshen it up. Auto tannies can take a lot of abuse. But once they start eating them selves alive, it a very fast downward spiral of destruction. If you are really concerned about old brittle seals. Throw in 1 bottle of non-synthetic Tranny fluid to mix with the Synthetic. That should provide more than enough Seal swelling agents. Although as I mentioned, New synthetic formulations have had over 40 years to solve that problem. Personally, I've used full synthetics ( Amsoil, Red line, Motul, Shell Rotella T6, Mobile 1 ) in a variety of Vintage cars for over 35 years, and have never has any leakage issue or any other problems at all. That's with engines, manual transmissions, Auto Transmissions ( Amsoil ATF ) . Power Steering and Diffs. Have I left anything out? I used Amsoil products pretty much exclusively until the Mid 2000's when I started to use Rotella T6 on some of my Turbo cars. Amsoil was just getting a bit too pricey.

-

Relay Mounting Locations - Firewall? under dashboard

Blue Sea marine products also make some nice Fuse blocks. Their ST Blade series in 6 or 12 circuit with Negative Bus and cover are very nice. Screw on terminals for Marine specs. Reasonable price as well. https://www.bluesea.com/products/category/16/61/Fuse_Blocks/ST_Blade Pictures of 12 circuit PDC with Negative Bus and cover. 6 circuit PDC is also available.

-

Relay Mounting Locations - Firewall? under dashboard

Here is a nice source for Building Custom Relay and Fuse combo's in the Mini ISO 280 standard. https://www.kinnettickreations.com/fuse-and-relay-solutions 48 position Relay/Fuse mini PDC box $40.00: https://www.kinnettickreations.com/product-page/48-position-pdc Custom pre-assembled and wired Relay/Fuse mini PDC box with six 20 Amp relays and 12 fuses.$120.00 : https://www.kinnettickreations.com/product-page/48-position-pdc

-

Idle vacuum w/ aftermarket cams

Ah... but that lovely Lope from a well Tuned L- 6 with a big(ish ) cam and some decent CR just can't be beat.

-

Idle vacuum w/ aftermarket cams

Lobe separation angle greatly affects idle quality. EFI engines often use wider LSA to get a smoother idle. Usually by a couple of degrees. Smaller, higher revving engines will make more Mid-range Torque with tighter LSA's. L-series typically work well with LSA in the 108 to 109 range, with something like a 270 to 280 advertised duration. Race Cams are often ground on 106 LSA . My Datsun 1200 Race grinds were on a very tight 103 LSA. Meanwhile 700 CI Pro Stock motors run LSA's of around 117 to 118 degrees.

-

Idle vacuum w/ aftermarket cams

Depends on your definition of Race cam I guess. In his books a 270 to 280 duration cam must be a Race Cam. But it will be next to impossible to get 14" with a a Colt 542 and your CR . The 108 Lobe separation is one of the reasons why it makes such good Power... but that will adversely affect idle quality. The tighter the load separation angle, the more mid-range Torque you will get, but at the expense of idle quality and idle vacuum. You might get 12" with 9.5 compression or higher... but it's doubtful. That Cam will really come alive with more CR. You can raise low end advance to help out... but there is a limit to that. I already had it pretty aggressive at 18 BTDC on Tune #3. Then we raised it to 20 during the test run. That was to take care of the Cam overlap . From tune #5 I see you raised it to 21 BTDC. That's getting a bit high... but still workable. I wouldn't go much higher though, or you could run into some issues with knock just of idle transition. I used to run a Digressive Timing on my Hillclimb Camaro. 24 Degrees at idle ( 1,000 RPM ) then immediately dropping to about 16 degrees just off idle and then the Curve built normally to 3,000 RPM. Even at 26 BTDC all I ever saw was 12" of Vacuum on a Chevy 350 with 10.5 CR. Cam was and isky 280 with 224 degrees at .050" and .485 lift. LSA of 108 degrees. Which is surprisingly similar specs to a Colt 542 grind. I ran 1.6 Ratio rocker arms which gave me .517" lift at the Valve. But higher ratio rocker Arms on a SBC have very little effect on the Cam Timing. BTW, the idle speed on your car should be around 1,000 RPM with that camshaft. Will help idle vacuum, but more importantly the higher lift and more aggressive profile of the Cam puts more loading at the Cam to rocker interface. And it gets worse with stronger springs..You need more oil from the spray bars or cam oiling holes to keep those surfaces well lubricated. Helps with Camshaft life.

-

Idle vacuum w/ aftermarket cams

That's probably all you are going to get with that Camshaft and that low of compression. I pull about 12 inches with a similar cam but 10.3 CR. That Cam really needs 9.5 CR or a bit more to work properly. You need to pop over and pick up your USB cable. and so we can finish Road Tuning.. Have a few more Tweaks with AE tuning to try.

-

Auto Trans Oil Change?

^ Old Internet Wives tales. Change the oil and Filter. It's one of the first things I do when I buy any used car with an Automatic Transmission. Two things Auto Trans missions like. Clean oil and cool oil. Auto trans oil is no different than engine oil. Auto trans oil cannot last 40 years and still be good. BTW, I'd go for a complete flush and replace the Filter and out in a good Synthetic fluid. Amsoil Dexron ATF has saved me two Automatic transmissions that were incorrectly assembled by so called " Experts". .

-

MegaSquirt Tuning

Just a note on engine temps. 180 degrees is fine on a Datsun L-series motor. Regarding thermostats. I'd recommend that you buy a factory Nissan thermostat. They are still available from Nissan dealers. Many of the aftermarket stats have sloppy tolerances with opening and closing temps. Even the premium Stants. Also, the factory thermostats have a 30% larger flow area than the Stant recommended model. I think can see an Aluminium rad and dual fans??? If they are a decent size and the fan(s) pull enough air ....engine Temps shouldn't be an issue. Only issue is if fan setup does not pull enough CFM. You can go either expensive with Spal fans... or inexpensive with Ford Taurus Fans or Volvo fans. A favorite of the forced induction crowd.

-

MegaSquirt Tuning

PM sent. Got a couple of local tunes sorted and can probably help this fellow out.

-

Need Help Burning A Flash ROM

Must be a German car with a Bosch ECU. ME5.X ? The 44 Pin programmers are available. Just harder to find. BTW. I have about 6 of those chips sitting in my desk drawer vright now. Trying to replec the No Flashable Eprom on my Audi ME5.3 ECU with a flashable one. Gave up some time ago when I bought my 280Z. the guys at Nefmoto.com may be able to help you.

- What size are the brass bullet terminals?

-

L series engine oil dipsticks

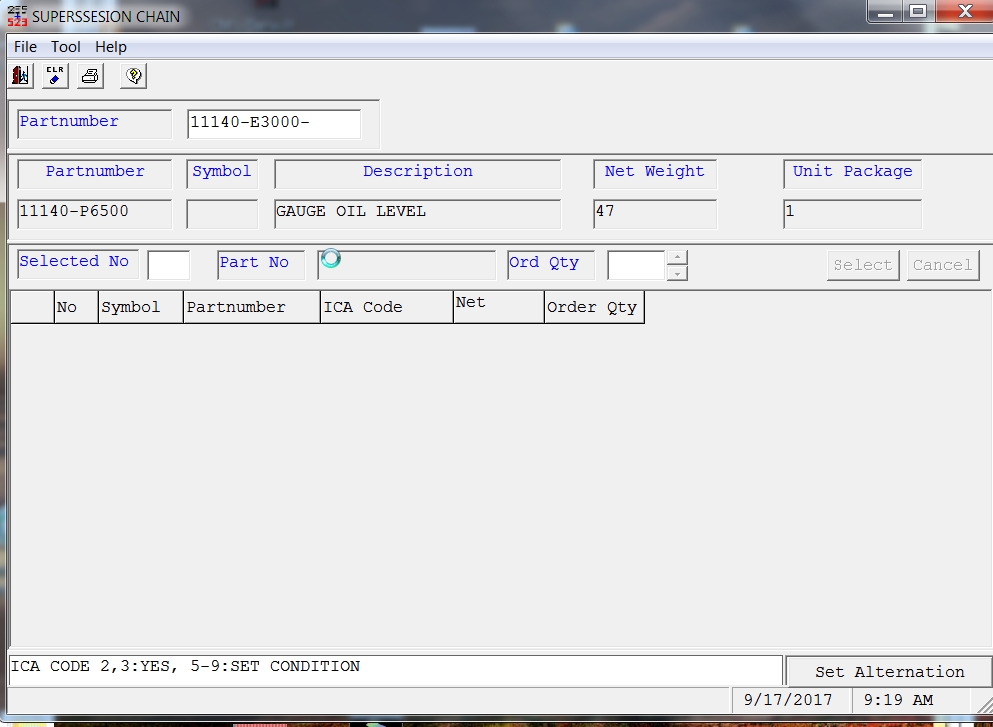

Here you go. Question answered. 11140-E3000 supersedes to 11140-P6500 ( 11140-P6500 supersedes to 11140-P6502): Back to watching this mornings F1 race!!

-

L series engine oil dipsticks

That's the most likely answer. My E-Fast is down right now so there are a couple of things I can't check right now. Edit: Ok. So I just did a side by side comparison of the E3002 Dipstick ( Z ) and the P6502 dipstick ( ZX ) I measured from the rubber shoulder seat to the high mark on each dipstick. The high matk is what you should be comparing. NOT the overall length. The E3002 measures 7.375 " to the high mark. The P6502 measures 7.00 " to the high mark. What that means overall.... not a hell of a lot IMHO. F54 block on my car, so P6502 is definately correct Also considering that I ordered a new 11140-E3002 dipstick, and it was superseded to a 11140-P6502 ( This is in Canada ) .

-

Replacing Rear Shocks -- Spindle Pin Questions (of course)

Lots of never seize on the new spindle pins and they will slide out easily the next time. Next time will probably be about 20 years...

-

L series engine oil dipsticks

Measure form the bottom of the stopper to the " Full " line mark. That is the only measurement you have to be concerned about.. Dipsticks should also have the last 5 digits of the Part number stamped on it. I believe you will find that measurement is all the same. The Nissan Parts catalogs list all 240Z to 280Z blocks as having the same dipstick. 11140-E3002. . I ordered a new dipstick for my 1976 280z Z motor. It was superseded to a newer number with a nice Plastic insulated handle. I'll look at the stamping numbers tomorrow.

-

Head Gasket Oil Leak

Stone is a brand that I've never heard of before, so I can't really tell you if it's good or bad. You should always match the head gasket to the block and head visually before installing. Any gasket should be checked for that matter. L28's were the models that had different shaped upper block surfaces throughout their manufacturing years, and there were different versions of head gasket available. Installing the wrong head gasket would leave certain water passages on the block uncovered and they would naturally leak... ( Like a sieve ). Nissan eventually superseded ( revised ) the gasket so that one Part Number worked on both types of L28 block. Problem is that some of the aftermarket manufacturers still had two different Part numbers.

-

Head Gasket Oil Leak

Remove all the head bolts. Apply a proper thread lubricant to the threads ( ARP and Clevite make thread lubricant ). Also put some lubricant between the head bolt and the head bolt washer. Installing the head bolts dry will not allow the bolts to stretch properly. You will get a false ( High ) Torque reading on your gauge. I trust you were using new head bolts the first time? If so you can re-torque them again. Especially as they were not stretched to their Plasticity value. If you were trying to re-use old head bolts. Get some new ones. BTW, what Head Gasket were you using? Some aftermarket ones have incorrect water passage positioning.

-

280zx 5 speed going into 75 280z

With diaphragm clutches, the pedal effort goes up as the disc wears. So a lighter feel is probably normal.