Everything posted by heyitsrama

-

Is the Zcar Depot dead?

I've been able to talk to Healey and Max from ZCarDepot, they were pretty helpful. It was a couple years ago, not sure if they still work there.

-

Zx 5 speed rebuild

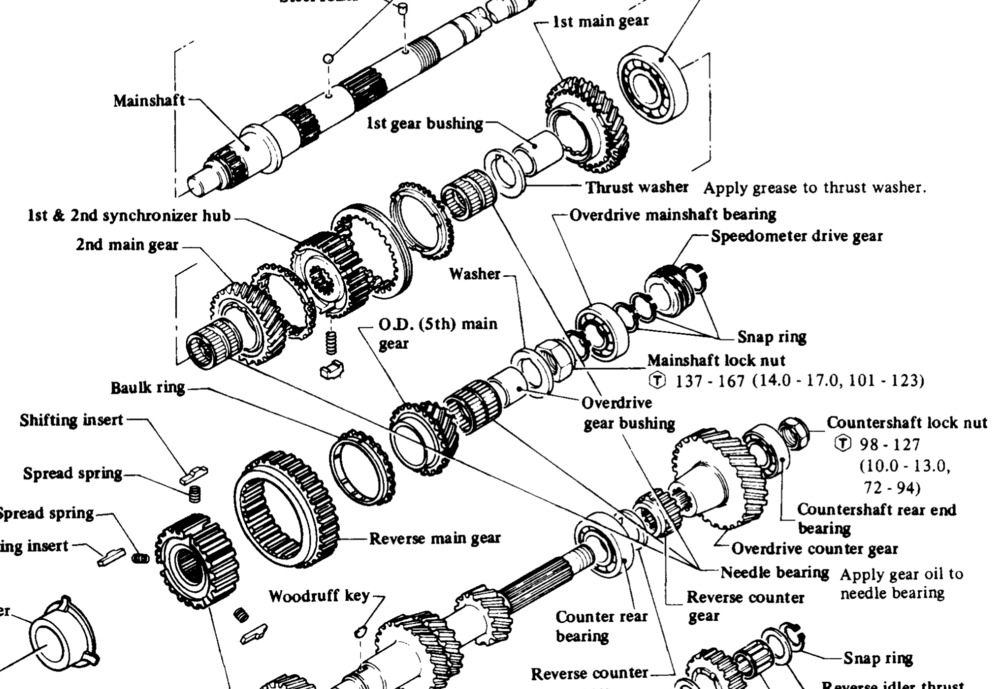

@Patcon Which internal clearance are you referencing? Here are a couple of them: 1. baulk ring to glear clearance ( page - MT-11) 2. gear end play (page - MT-11) 3. front counter shaft bearing (page MT-7) 280zx-manualtransmission.pdf

-

240z Front Brake Calipers - how to read markings on castings... and what is the bridge bolt torque?

I’d say from 30-45ft lbs. make sure you orient them to the correct side when you go to install it. the blasting looks great, zinc plate?

-

Bad noises somewhere in my drive train

What gear ratio did you end up with? OSG diff? Where are the pics?! 😇

-

My parts hauler

That's pretty cool, I like the EX-cab. How does it run?

-

Shifter Rattle

So I assembled the front/tail housing over the assembly (with sealant) and started researching how to check the clearance between the front counter bearing and the housing. Its hard for me to get a precise measurement on the bearing, When I measure the top (between the front mainshaft bearing) its 3.20-3.7mm depending on the spot I measure it, on other areas its between 3.12-3.2mm... I might be able to use the old shim (0.4mm) but I might have messed up.... I noticed this post by @Dave WM I failed to consider the dimples on the thrust washer when i assembled the 1/2 gears, so its a 50% chance that I assembled it correctly... I don't like it. I'm probably going to pull it apart again to double check the orientation, I assume these dimples are to allow oiling on the bearing, and I'd rather do it now then again.... Is disassembly a destructive operation on the bearings? I read that you don't want to create a load on the outer race of the bearings. The disassembly process seems is stressing the bearings (esp when you have to beat the mainshaft/counter shafts out...) I don't mind doing the work over again, its probably going to go way faster this time.

-

Caliper rebuild service

I rebuilt mine at home, I think I got a rebuild seal kit from rockauto. Works great… Clean up the calipers with purple power, throw on some paint if you want. Man I wish I had a media blaster at home. 😞 Power Brake exchange out of San Jose might be able to rebuild it, they rebuilt my brake booster, great service.

-

Existing FS5W71B Bearing/Seal Size Inventory?

Ohh I just did this, I would use Eurodats part list for OEM part numbers, or on the right side it has the bearing number (e.g. 6305 c3) and order high quality bearings from an online distributor. I bought a bk104 bearing from Transmission Parts Distributors it had one wrong size bearing, it gave me a larger bearing for the fs5w71c. All of the bearings in this kit were from Nachi, they were very smooth.

-

Shifter Rattle

I was at my desk this morning, and it looks like the older 1980 gearboxes have a tighter tolerance than the “close ratio” 81-83 boxes. I’m not sure what gearbox this is anymore, it had a RHD main shaft, but a CR tail housing…. It’s a mix. I think I’m happy with the end play at the moment, everything seems to be in “spec” @Dave WM thanks for your YouTube videos BTW, I’ve been using them as a reference. @EuroDat I’ve been really happy with the MT-90, I’m got some fresh stuff for this rebuild. But to be honest the old stuff is so clean I’ll probably use it in my beater. On a side note, I thought about safety wiring these roll pins, to avoid any “lost shifters” at the track. I don’t know how I feel about the “looseness” of the wire, and it wearing down the aluminum shifter forks…. Am I just thinking too much about it? I’m not 100% on the shifter fork orientation for 1/2 gear. I saw an old photo that @Patcon posted and I think it’s right… no image in my phone or in the manual… It looks pretty good, the housings are washed up. Hopefully I can get it buttoned up tonight, and installed tomorrow after work.

-

Shifter Rattle

@EuroDat I torqued the main nut to 110ft-lbs the clearance is around 0.25mm on the 5th gear. That’s 0.05 tighter than OEM spec.

-

Shifter Rattle

I was on my thinking throne earlier today and remembered this tool from Autozone to change out tie rods. It has a die for both 1-1/2, and 38.4mm. Worked great, didn’t have to make anything custom.

-

Shifter Rattle

I reused the old "overdrive gear bushing" but used new needle bearings in between. If the old one was "too short" in length, it could cause this issue right?

-

Shifter Rattle

@Dave WM@EuroDat I'm most done with the rebuild, I'm trying to measure the endplay 5th gear after torquing the mainshaft nut (RHT). The OEM manual specifies the endplay at 0.30-0.35mm. It seems like I can only achieve this amount of end play if I "loosely" tighten the nut to the shaft. If I actually attempt to tighten down the nut (no torque wrench at the moment, just by feel) the end play goes super tight and out of spec.... Any insight? Shoot for 110ft-lbs, and call it a day regardless of the endplay?

-

4 Speed Bell Housing swap to 5 Speed Case : FS5W71B : Reverse Switch Modification

https://www.allstategear.com/FS5W71-Extension-Housing-Bushing-p/nis-62.htm https://sales.omegamachine.com/Nissan_FS5W71C_Extension_Housing_Bushing_p/71411.htm I had to order one for my gearbox rebuild, the shipping is $25 bucks so get that wallet out.

-

280 front struts

I welded another pipe to the top of the gland nut, then used a pipe wrench on the welded pipe, the heat from welding helped. The gland nut does not have much surface area to put the torque down... New struts should have new gland nuts.

-

72 Z Bumper rubber refresh recommendations

I've had good results with https://www.amazon.com/TriNova-Plastic-Trim-Restorer-Motorcycles/dp/B01AAZ1OAE/ref=sr_1_12?crid=U5ZAYVORXUE7&keywords=black+trim+restorer&qid=1656873126&sprefix=black+trim+restore%2Caps%2C134&sr=8-12 It lasts a couple months in the California sun on our Honda CRV trim, but eventually it does "dry up" again. If you are garaging the car it will probably last a while.

-

Scarab Parts Car (Craiglist)

Apologies for the misleading title. I did not fully look into the ad, I saw scarab in the text, and figured I’ll post it in case someone had a need for it.

-

Scarab Parts Car (Craiglist)

https://santabarbara.craigslist.org/pts/d/santa-barbara-1974-datsun-260z-parts-car/7500420356.html Looks like a project, but decent price.

-

Shifter Rattle

I was able to place an order with jp-carparts for the 23T reverse idler 32282-E9000 ($45) shipping was 37$ so I added some rollerbearings as they are more expensive from within the USA (2x cost). It's going to take a month as its a built to order part..... good thing i pulled that L28ET from the junkyard.....

-

Most dreaded of jobs finally on the horizon ? the fuel tank !

I'm assuming you have another car while the Z is down... Get a good amount of fuel hose, attach one side to the fuel pump and pump it into a jerrycan, then pour that into the other car. I use a big ol cement mixing tub to wash parts out. https://www.homedepot.com/p/Black-Large-Concrete-Mixing-Tub-A-42/318924309 It works pretty well, i guess you could also pour the fuel into this, but its gonna smell... and be a fire hazard.

-

Most dreaded of jobs finally on the horizon ? the fuel tank !

There’s some nice threads on this forum that talk about alternative hoses that you can get from any auto parts store. The stupid expensive one does some a 180* turn, I just used some metal 90* elbows in its place. I’d give you more threads but I gotta get back to yard work. 😞

-

Shifter Rattle

Super confused about the main nut being right hand threaded... this is a close ratio gearbox (borg warner style syncros, no-dust-shield over the drive shaft, one exhaust hanger on the housing). I destroyed a bit of the nut to get it off, but I was expecting to be able to find a replacement, looks like they are all NLA... I think I'm the only person that has been inside the gearbox, no random color sealant, only one spot on each nut where they were striked in to keep them from spinning...

-

Shifter Rattle

Alright, I got most of the gearbox apart today, I found out that the main shaft nut is actually right hand threaded, not left like I wrote above (good thing I did not order it yet). Most of the bearings feel OK, with the exception of the counter-shaft rear end bearing, it's a bit rough. It's a bit hard to find that reverse idler gear (23Teeth), I'm emailing jp-carparts to see if they have anything. I don't know if i need to replace the reverse main gear, it looks discolored, and MOST of the teeth are ok (6-7 have chips) This "aftermarket" replacement looks to be half the cost of what jp-carparts shows for 32245-E9801... Not sure of the quality (how many factories really made these gears?) Is throwing money at an OEM part in this case a waste? https://www.transmissionpartsdistributors.com/fs5w71c-fs5w71e-fs5w71g-fs5w71h-transmission-5th-reverse-gear-slider-36t-fits-81-92-nissan-cars-trucks-nis-36/

-

Electric fans

I would consider replacing the fan clutch with an OE replacement. I've heard of people attempting repairs and using the same oils that are used in some electronic / gas powered model cars.... 😕 Here is a link to an AtlanticZ PDF that talks about rebuilding the OEM clutch unit. FAN 280zx Datsun rebuild fan clutch.pdf It was from @240260280 in this thread In that thread they talk about a silicon oil, but i dont see a reference to any weights (cst). Here is another supplier https://www.amainhobbies.com/mugen-seiki-silicone-differential-oil-50ml-1000cst-mugb0324/p453219 New fan clutch can be had for $30 bucks probably. 😇

-

Electric fans

I ran electric fans/shroud on my car and I had issues with the thermostat that would control the electrical fans. I got off the track one time and the dang fans were not on. I saw @ around 4:30 these dudes are using a stock fan. I figured if it was good enough for them I’ll switch… and I’ve never had to think about the fans again. Good temps on the track now too.