Everything posted by ConVerTT

- 240z - fabbing new front rails

- 240z - fabbing new front rails

-

Parts for Sale: 1973 240z L24 with 4 speed MT, SU Carbs, 6-1 header, E88 heads

View Advert 1973 240z L24 with 4 speed MT, SU Carbs, 6-1 header, E88 heads I've had this drivetrain sitting in my garage since I drove it in ... (in 2014 LOL). It's an L24 from a 73 240z. It turns over easily by hand. Notables: 4 speed MT, early SU carbs, 6-1 Header, E88 heads. I think I probably have the matching air filter box here somewhere as well. Can anyone use any of this before it goes to Kijiji? Just let me know. Located in Calgary. Advertiser ConVerTT Date 07/15/2022 Price $12,345 Category Parts for Sale

-

240ZBUILTBYME 1971 240z HS-001063 Project Georgia

Been there Ryan... My thoughts - cut it out and replace it while you are still on the jig. Check out my old thread - start from the bottom of page 5... Look at the bright side...your metal fab skills are about to go through the roof 😉 https://www.classiczcars.com/forums/topic/61483-240z-fabbing-new-front-rails/?&page=5#comments

-

240ZBUILTBYME 1971 240z HS-001063 Project Georgia

Nice work Ryan! Way to stick with it! So i would cut out all the rust on the jig, fix the floor and rockers and then go to the rotisserie personally. The jig holds everything straight. I did each rocker and the front rails separately, but I am certain I could have cut more away at once. The floors basically attach to the trans tunnel and the inner rocker. I had patched my inner rockers but once I got it on the jig I actually cut it all the way out and replaced it. The frame didn't budge. Same thing when I did the front rails. Have fun!!!!

- 240ZBUILTBYME 1971 240z HS-001063 Project Georgia

-

240z gets jiggy

Fantastic - glad to help ...

- 240z - fabbing new front rails

- 1976 280Z Restoration Project

-

280Z Vented Hood on 240Z - Advice Please

The non-vented hood is of course correct on an original 240z. But if the car is a going to be a resto-mod, then do whichever you prefer. I have both hoods for my 72 project. I haven't decided either - I might paint them both before deciding ....

- 1976 280Z Restoration Project

- 1976 280Z Restoration Project

- 1976 280Z Restoration Project

-

240z gets jiggy

Haha - Thanks! No I am just an amateur. I basically bought the same unit as the guy who showed me how to weld. It's a Miller 141 - relatively cheap, 120 V but best to run on a 20A circuit, MIGs sheet metal through 3/16 plate (would be fine on 1/4" too). Uses 0.024 or 0.030 wires.

- 240z - fabbing new front rails

-

Relationship solution

A lot of truths in this thread ?

- 240z - fabbing new front rails

-

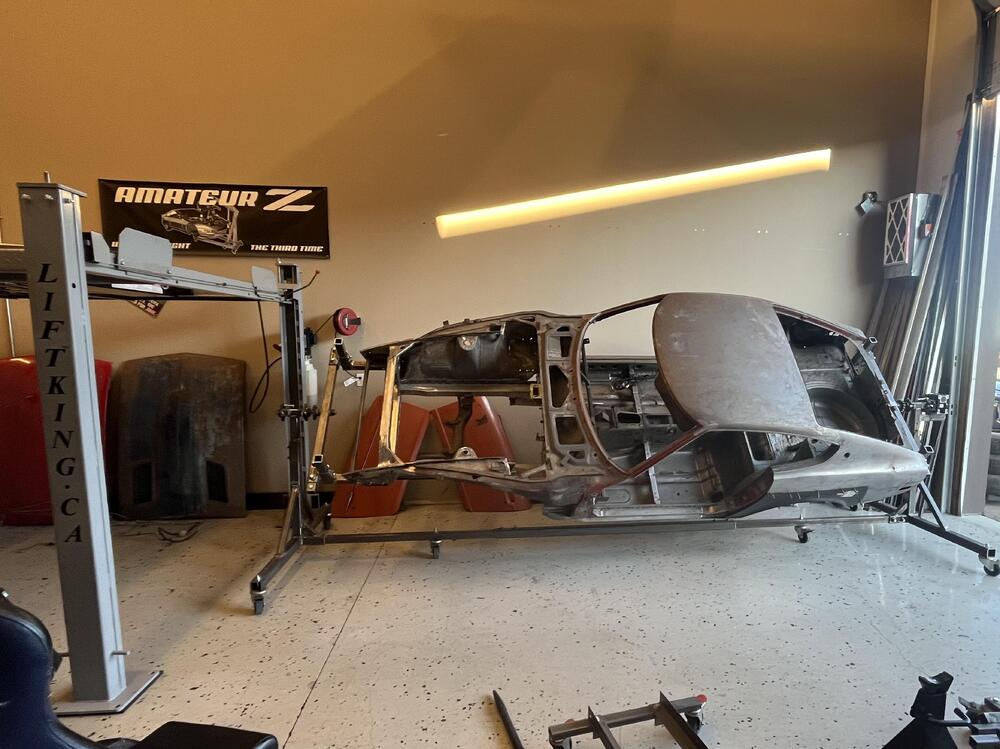

240z - fabbing new front rails

So I repositioned the car a bit on the rotisserie to get better balance. It was fine side to side, but I could feel the weight increase as I rolled it to the vertical position - meaning that it was bottom heavy. Or the center of gravity of the shell was too low relative to the rotating axis. So I moved the car up about 2". For reference: The mounting bolts are 3 inches below the axis of rotation in the front and 5 inches below the axis of rotation in the back. The car is still very slightly bottom heavy (on purpose - safer) but she rolls over well by hand (with one hand) or with the worm gear.... so I probably spent around $350 on steel, $200 on the worm gear, bearings, drive shaft and pinion gears, $50 on bolts and hardware, and I already had the casters laying around - maybe $60 or so. So around $650 in round numbers not including shop supplies... Let the games begin ???

-

What's Wrong with this Picture?

me neither I guess ??

-

What's Wrong with this Picture?

Doh ?♂️?♂️?♂️

-

What's Wrong with this Picture?

Arms are backwards? Channel should face upwards. My question would be are they just upside down or are they reversed right-left?

-

What's Wrong with this Picture?

Haha! ??? So is that on the white car or the red one ?

-

240z - fabbing new front rails

I am thinking that careful pressure washing can't hurt..... I am thinking of making a tow bracket out of leftover square tube and then just rolling the whole rotisserie right outside with my truck. Then just carefully pressure wash the bad areas and dry it with the leaf blower. Roll it back it and then media blast with glass bead... (The tow hitch is really to use the truck to push it back up the grade into the garage. I am sure it will roll out just fine ?)

- 240z - fabbing new front rails

-

1971 240Z Driver Build Advice Requested PLEASE

I've been down this same road. Bought three cars from an estate sale. The "best" car turned out to be the "worst" car once they were naked LOL. But I agree with you - if you can keep both, start stripping the white car to see what's there. I hope it all works out -keep us posted....