Everything posted by ConVerTT

-

So long Eastwood.com...

Woohoo! time out: does not show this on their website ....

-

HLS30-09579 selling for pretty cheap on eBay

I looked ....

-

S30 vs Z32 for first project car?

Not my personal favourite, but good value there

-

S30 vs Z32 for first project car?

-

Complete roof R&R

So, after sleeping on it, I agree again. I would keep “peeling” from the top down until I found some solid metal to use as a base to start building back up (or until the entire roof disappears).

-

Complete roof R&R

I agree with Patcon here. Peel the roof skin and see what you have first. Before cutting into or attempting to remove the pillars. At that point you are no worse off than you are today, and everything is still lined up. Consider putting it on a jig beforehand. re: windshield - yes fitment is a concern. So when reattaching the roof position it with Cleco fasteners or sheet metal screws and make sure it is properly aligned and the windshield fits before welding it in.

-

Complete roof R&R

What is the replacement lead filler?

-

Complete roof R&R

I am going to need to replace a massive sunroof, but I am not planning on cutting the a-pillars. At @zKars suggestion I am going to cut a patch from a donor roof and epoxy it in. A guy in Sweden did it years back. Posted a bunch of pics and vids but I don’t know if they are still around. Aside: inspired me to build a jig. Google “Project Hugo 240z” or “Projekt Hugo” What happenned to yours? Here is mine. (Please ignore the mess made by the PO ...fortunately I have spares)

-

Restoration of my 72 240Z

Very nice!

-

I want to buy a cheap 240z-280z!

Agreed - it is much cleaner than the shell I am working on for sure.

-

I want to buy a cheap 240z-280z!

To be clear - that is all I got for $800 Cad - just the shell, windshield and tail lights...and a white hoodliner. I do have a few spares though ....

-

I want to buy a cheap 240z-280z!

Calgary

-

I want to buy a cheap 240z-280z!

Spring 2018

-

I want to buy a cheap 240z-280z!

-

240z - fabbing new front rails

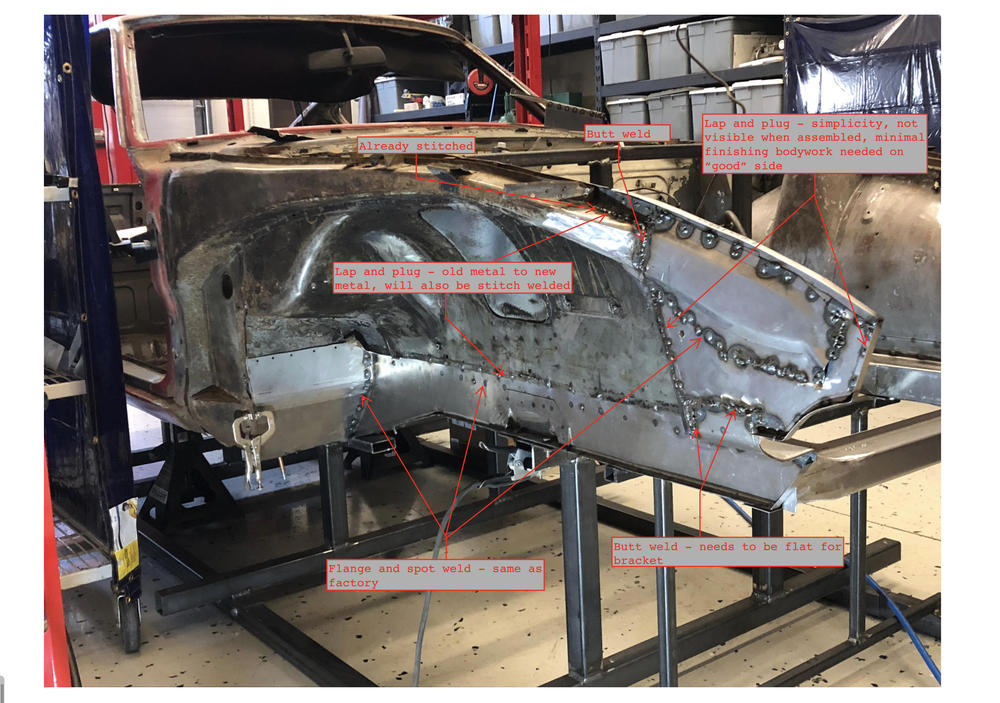

So ... there are a lot of opinions on butts, versus laps/flanges and plugs versus stitches. I use all of them depending on the circumstance. For example: I will almost always lap, plug stitch when attaching “Important” old metal to new metal (like floors to transmission tunnel, or frame rails to the inner fender patch). I used almost every type on the Franken Fender ....

- 240z - fabbing new front rails

- 240z - fabbing new front rails

- 240z - fabbing new front rails

- 240z - fabbing new front rails

- 240z - fabbing new front rails

- 240z - fabbing new front rails

-

240z - fabbing new front rails

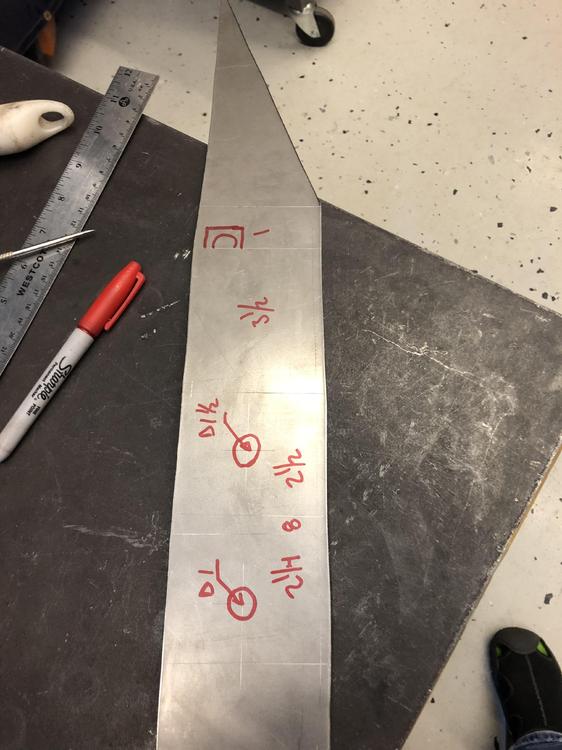

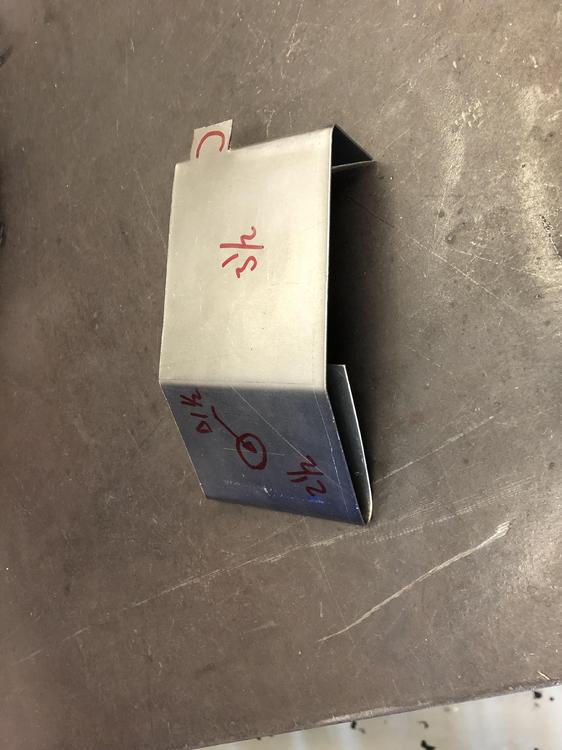

Ahhhh - that looks a little better now.... Still some cleanup to do but heading in the right direction .... so I decided to spend some time on the rad support.... I re-did the lower support. This version is a single piece with only two small weld in patches. I think it will be a little cleaner than my first attempt last week .... Interestingly the factory rad support is made of 13 different pieces of sheet metal and then welded together. Not an easy piece to make. I roughed out three more pieces today ... Upper gusset braces ... And the upper cross piece ... Only 9 pieces to go ???♂️....

- 1976 280Z Restoration Project

-

Unique 1977 280z

Man - I love the colour, and the bumper delete is not bad actually. It’s fixable ?

-

Moving forward with my buddy's 73

Paint looks great!