Everything posted by ConVerTT

- 240z - fabbing new front rails

- 240z - fabbing new front rails

- Parts for Sale: Datsun FS5W71B Close Ratio 5 Speed Transmission

- Parts for Sale: Datsun FS5W71B Close Ratio 5 Speed Transmission

-

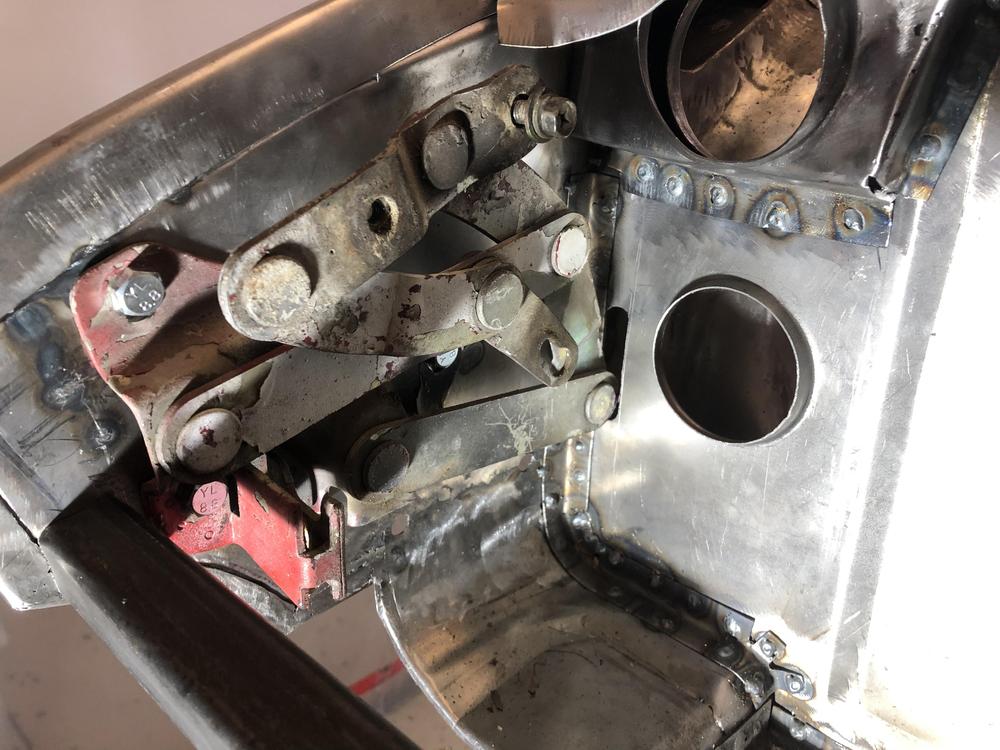

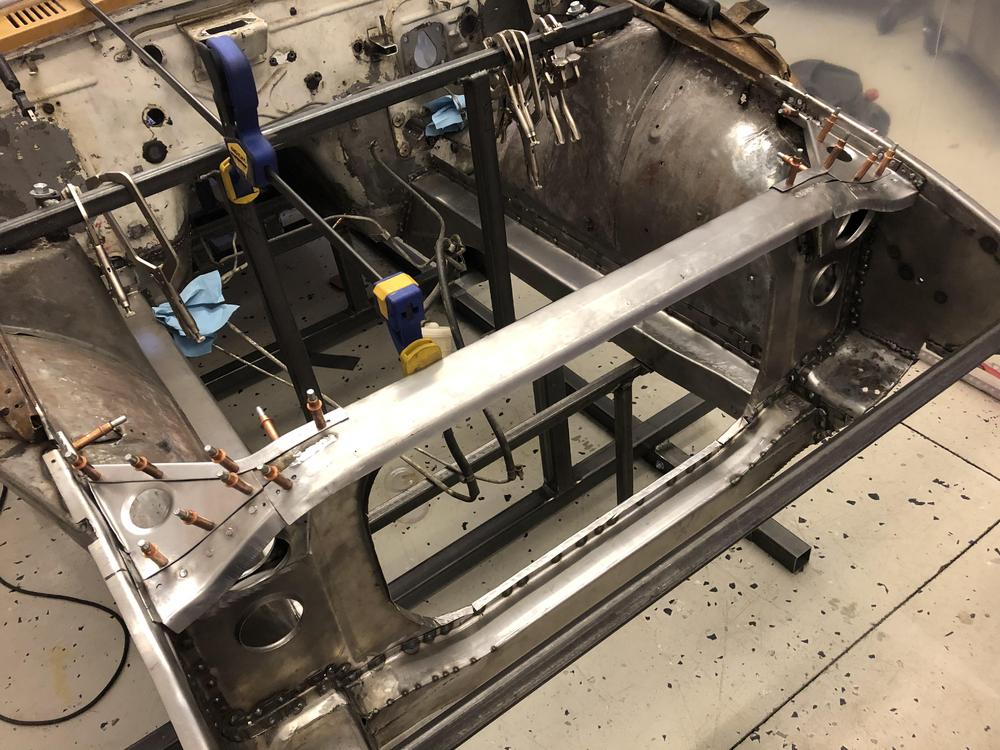

240z - fabbing new front rails

Very! In theory everything should be unloaded so that there is nothing to release but ... I've been pretty careful to try to minimize any tension/compression in the metal while welding the rails and the rockers...but there has been a lot of heat and thermal stress. A key piece of work will be to inspect all the spot welds (to make sure none popped) when it is on the rotisserie. Then seam weld everything (Maybe back on the jig)

- Parts for Sale: Datsun FS5W71B Close Ratio 5 Speed Transmission

- 240z - fabbing new front rails

- 240z - fabbing new front rails

-

Starting my Wall Sculpture

Nice work!

- 240z - fabbing new front rails

- 240z - fabbing new front rails

- 240z - fabbing new front rails

- 240z - fabbing new front rails

- 1976 280Z Restoration Project

- 240z - fabbing new front rails

- 240z - fabbing new front rails

- 1976 280Z Restoration Project

-

240z - fabbing new front rails

And moved on to putting the final touches on the radiator support.... I welded the new rad support in some time ago but I wasn't happy with the upper brace ends so I cut them out and started over .... Went with dimples instead of beads, (for no particular reason?) Still need to some fitting, trimming and hammer/dolly work, but I am happier with the direction this is going ....

- 240z - fabbing new front rails

-

My two swiss S30Z Fairlady Restoration build thread

Footrest is cool! I have never seen one of those!

-

Thinking about installing an BMW M6 engine in my Z

Looks great. Not happy to hear about the Silvermine kit - I was just looking at it a few nights back ...

-

Mint '71 240Z - More Fun Coming to BaT

Lol - but the Datsun will fire right up ??

- 240z - fabbing new front rails

- 240z - fabbing new front rails

- 1976 280Z Restoration Project