Everything posted by dutchzcarguy

-

280zx 1979 2+2 slick roof restauration

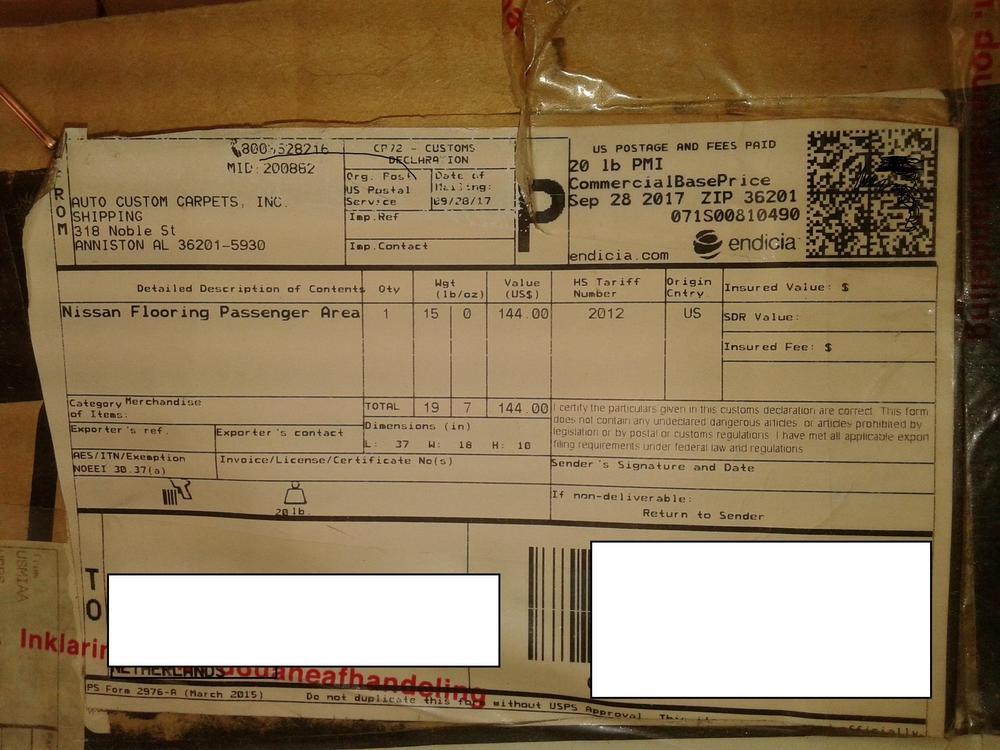

I looked at the invoice and the sticker pic just a few posts back but no.. Can't figure it out yet.. on the invoice it says: 1 unit EA description is : 2012 nissan flooring passenger A I can't find that number 2012 anywhere in the shop listings.. I'm sure i bought a 2+2 complete set for the car, it surprised me they do all the carpets exept the (very simple square) trunk cover! (you know, that peace that hangs on a single hook ) I was just a little bit kidding, about getting angry.. Much to soon for that.. i think i get/hear a solution today or so.

-

Matching Original Paint Code

Hello, Yours is a 280z 1978? I'm still not sure what color my 280zx 1979 is i thaught it's #510 sky blue metallic also but i can't find the paint color number on my car.. what do you guys think? see pic. Thanks in advance! Mart

-

280zx 1979 2+2 slick roof restauration

HAHAHAHA ? Not yet.. NOT yet!! Cliff!! L.O.L. Thanks for chipping in.. I'll wait for their answer on my explaination, Do you (OR ANYONE) know of any brand car that made a different size car for different continents.. I SURE DON'T …. As we say OVER HERE IN THE Netherlands: go fool the cat!! (dutch.. MAAK DAT DE KAT WIJS! )

- 280zx 1979 2+2 slick roof restauration

-

280zx 1979 2+2 slick roof restauration

Oh Man! It gets even funny-er! Look at my pictures! The new ones are laying on the OLD ONES!!!! !!!! in all the pic's!! People who follow my restaurations here at home... they are .. to say the least.. "surprised" that an american firm just tells me.. my car is altered the carpet is fine, my car is the problem! I'm not far from getting very angry now… ?

-

280zx 1979 2+2 slick roof restauration

Hahaha…. Today i got a funny mail from The USA.. from OC Carpets.com I ordered a set of 2+2 280zx blue carpets in sept. 2017 for my car but they don't fit! Here some pic's! So i sended them some pic's and explained that i was testfitting these last Friday.. Also sayd it's a euro version 280zx 1979 2+2.. i think they sended me a 2 seater carpet set but they said in a first reaction it was'nt.. It's made for a 2+2 and i would have A LONGER VERSION CAR!! ? HAHAHAHA… ??? i'm shure the US and EURO version 2+2 cars have the same length! SO i told them to give me a better solution than just to say my car is a special version! (I'm a special version maybe… i am 6 foot 4 ! ?) Are there more people here that ordered a carpet from them? i'm interested what your experience is with this company? I'm convinced they solve this problem.. if not i'll make a new topic here about the way they work and do business! With al the shippingcosts and the stupidly high taxes i payd over 400 euro for this set so i expect it to be fitting my car! TO BE CONTINUED!

-

Series-One Z sells for Record Breaking $310,00 USD

WOW.... yeah it can take some time.. in the 80's i once made me a plotter.. i made it including the full set of letters,numbers and all signs like #$%^&* and so on.. it took a lot of Hex coding then…. and that was on a commodore 64.. can you imagine… ?

-

Considering complete restore 1970 240z

Like Whee is restoring a 280z i'm restoring a 280zx.. and i do also a lot of work myself. just the fine bodywork i leave to a specialist, he's doing this for over 50 years now! so he is an older guy but very good at it. ( the shell is strait as an Arrow.. haha) I'm considering to do the paintwork myself also in a pro booth.. (then i don't have to pay a painter..) I have kept record of all the working hours (from everyone who worked on it) and i can tell you they are going in the direction of a Thousand hours.. Ones (25+) years ago i did a 240z that was rusted away and it did take over 3000 hours to restore .. but then i counted every hour, also when i was sitting behind a computer to look for parts or tech info and so on.. Also it was my first restore and you have to learn a lot. If one asks himself is it worth to restore a 240z? The answer should be:No.. unless it's a special model or has a interesting past.. or you'r just crazy about the model!! ?

-

Series-One Z sells for Record Breaking $310,00 USD

"We" ...europeans read 310 dollar.. that's a bit low aint it??? we work with the point in 310.000 not 310,000 so.. 310,00 is 310 dollar and zero cents... can i have 2 for that price? ? ( no.. i;m not going to ask for 10 Z's or so! i am not that greedy..)

-

HTP Quick Spot II spot welder - quick review

I see it's "made in italy" that explains a lot... i make a double left turn when i see "made in italy"…. ?

-

Series-One Z sells for Record Breaking $310,00 USD

Series-One Z sells for Record Breaking $310,00 USD Eh... where is that extra 0 gone… @Mike ?

-

Technical data of the car 280ZX

I've got an inlay sheet of paper in a 280zx folder with the tech. data.. but you can google it and print it out, thats the same..

-

Technical data of the car 280ZX

don't know what they want.. but the normal german papers that come with the car are more than sufficient to register a car.. Normally..

- 280zx 1979 2+2 slick roof restauration

-

280zx 1979 2+2 slick roof restauration

Yes! That could work for my '79 car.. Normally they are on a rubber band that is layd down in adhesive. ( one for lower side and one for upper side.. probably 2 different width's??) I don't know if the 1979 and later 1982 cars had the same width stainless strips on the front screen... If the strips of stainless fit on those clips, i would like to know where i can buy these? Should be 2 different sorts of clips (diff. width).

-

280zx 1979 2+2 slick roof restauration

So… these last 2 weeks busy with making the gaps perfect between the 10-11 parts a 280zx has in the front! My bodyshop guy is making them flawless.. Nothing to show for now.. in a few weeks i hope to get into the paintbooth with the 280zx.. For the windscreen rubber maybe the Carglass guys have some clips for me (???) to put the stainless strips on.. (round the windscreen so i can get them off when a screen is broken.) and not laying in the silicone or other gummy mess... PLEASE, if you have a good solution, tell me here! thanks!

-

Mint '71 240Z - More Fun Coming to BaT

Look in your navigation.. hihi... you where here in the south… you bought my perfect new in the box rear lights 240z.. now you remember.. ?

-

Mint '71 240Z - More Fun Coming to BaT

Now i have to buy me an alarm for my daily driver 240z type1...

-

New guy

THANKS GUYS !!!!!! This time the right pictures, thank you very much! I didn't know that there was a plug in the big hole! It's not completely round i see now.. could be that the EU model does not have the plug, iv'e had 3 280zx's but never seen those plugs.. (i think i put in a normal rubber plug like in the floor..) My bodyshop guy will be very glad with those pic's, thank you!

-

New guy

Sorry no.. Thats the wheel housing.. a pic of the (see my picture,) down right in the fender indent.. where the bumperflap is crewed down at the big round hole.. preferbly a pic at hight of fr.bumper and just at 90 degrees to see if i can see the dent sticking out of the bumper or is it covered by the bumper..

-

New guy

For as far i can see a Original 280zx 2 seater, i'm restoring my 3rd 280zx 2+2... know a bit about 280's ? Only the extra floor mat, the bumpstrips on the car and a few extra tie-raps in the engine compartment… are not so standard.. but overall a beautiful car.. Today i'm busy with the front bumper indentations in the front fenders.. I can't see those in your pic's, are there indentations behind the end flaps of the front bumper (on the sides, the ends of the bumper) ?? see the right-under corner of the fender.. Maybe you can make a (close up) picture of your front left bumper side for me, it would be very nice!

-

Another new Z owner

Bumpers guards… not needed.. i throw them away , much more cleaner car.. It was a tipical USA part.. europe and Japan don't have those (stupid (sorry) things that only make the car ugly and heavier.. just my opinion!

-

Shift lever boot

It was as far i know Always a vinyl boot with boot lace at the top.. Leather in a Z ? no way!! that came with the 300zx or so..

-

280ZX Frame Rails - Any Volunteers?

First.. sorry for my off- topic answer.. I'm restoring a 280zx 2+2.. but the framerails are in good condition.. also.. i don't think i can help seen the distance i'm on.. Over here the 280zx is a very rare car.. there were few sold overhere..

-

2021 Nissan Z: What We Know So Far

Ah... another giant annoyance!!! over here (The Netherlands..) the 370z costs over 100.000 euro!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!! Due to taxes taxes and taxes... that's nothing new here.. i drive a 300zxtt 1992 and i was told and i did the math and there are 50000 good old dutch guilders that dissapeared in the pockets of the government It costed 173300 guilders about 65000 dollars then?....