Everything posted by wheee!

- 1976 280Z Restoration Project

- 1976 280Z Restoration Project

- 240z - fabbing new front rails

- 240z - fabbing new front rails

- 240z - fabbing new front rails

- 240z - fabbing new front rails

- 240z - fabbing new front rails

- 240z - fabbing new front rails

- 240z - fabbing new front rails

- 240z - fabbing new front rails

-

76 280Z Throttle Body bolt spacing

- 76 280Z Throttle Body bolt spacing

- 240z - fabbing new front rails

- 1976 280Z Restoration Project

- 1976 280Z Restoration Project

- 1976 280Z Restoration Project

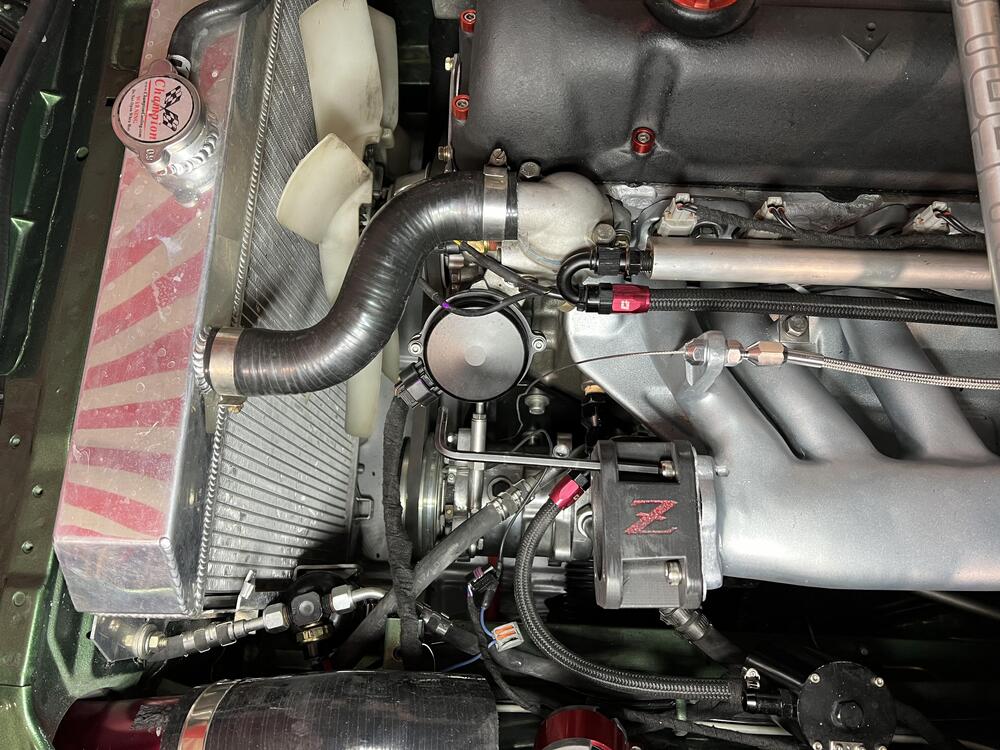

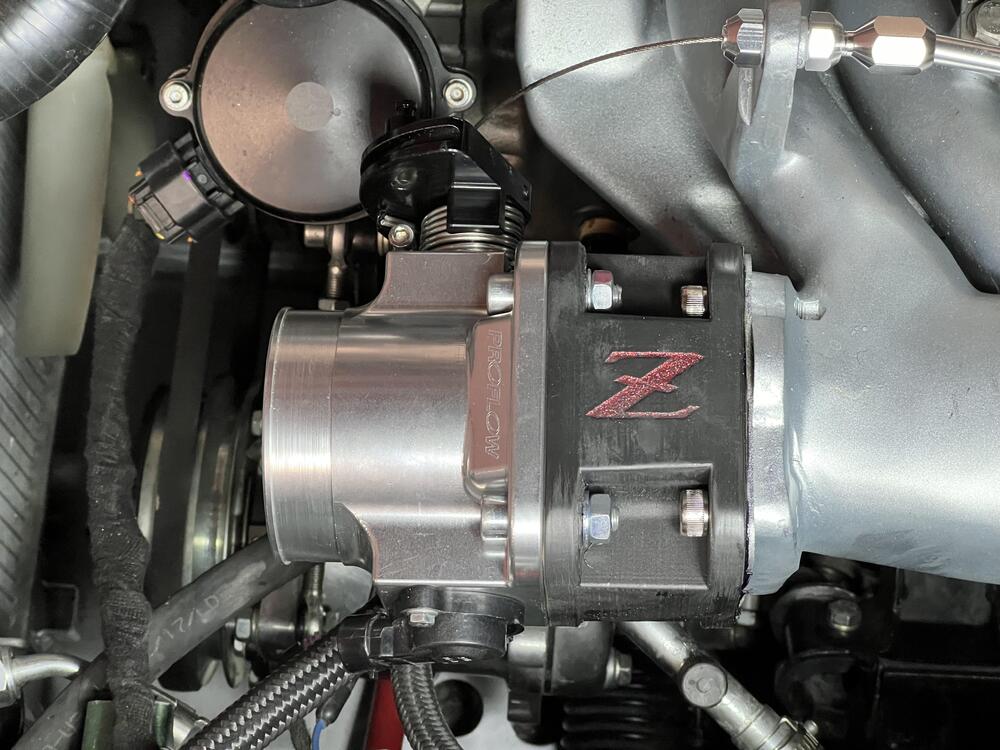

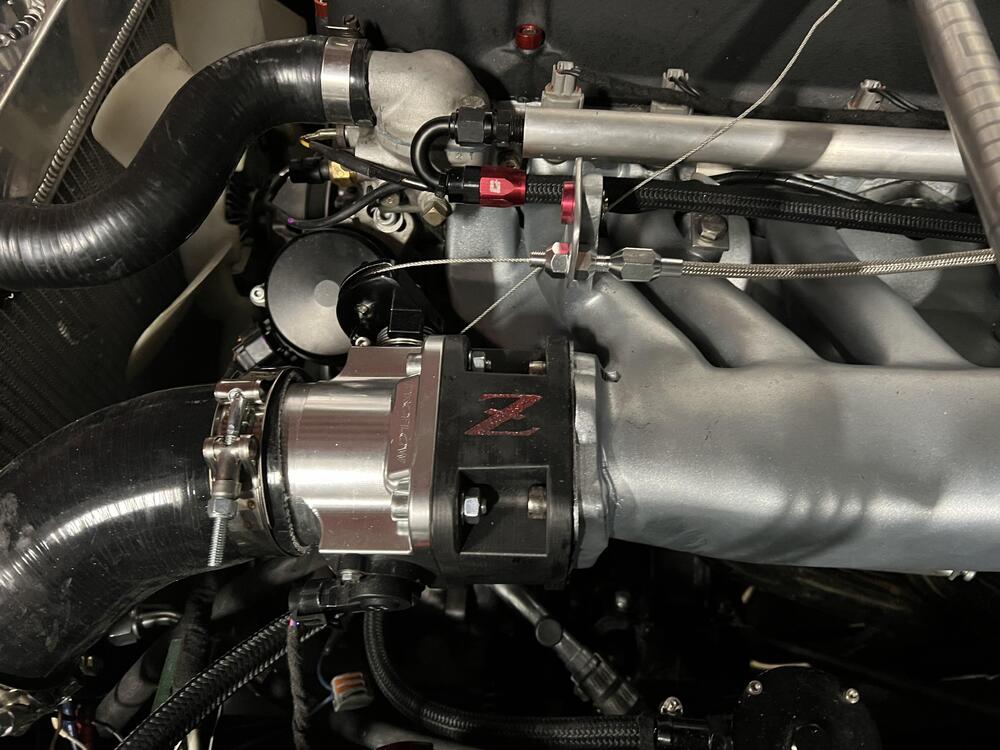

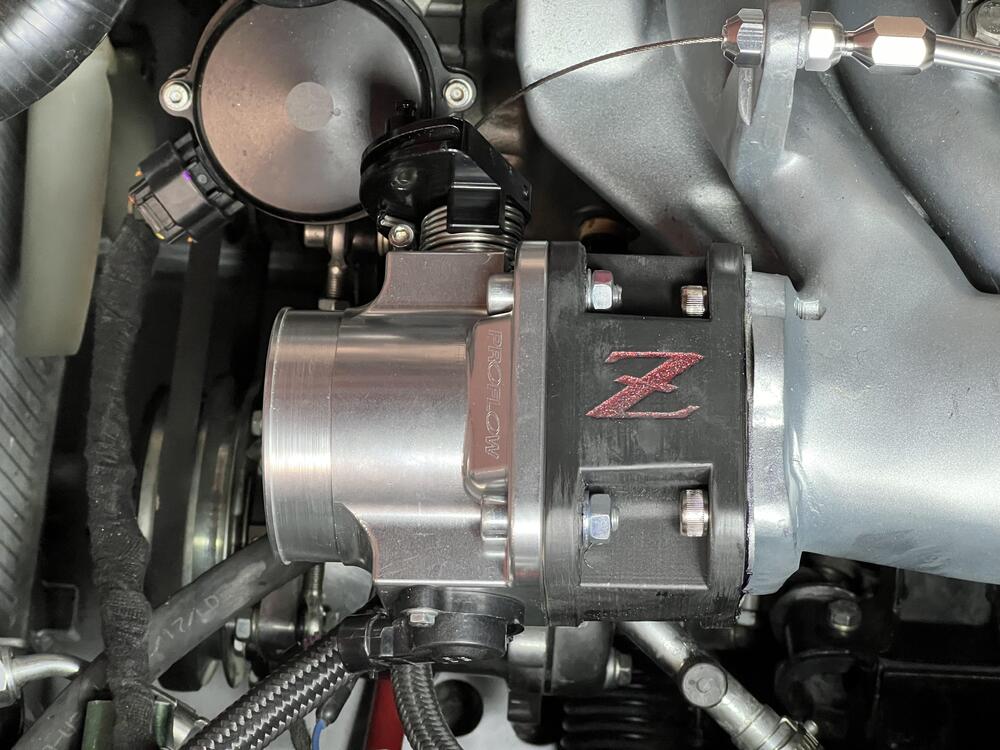

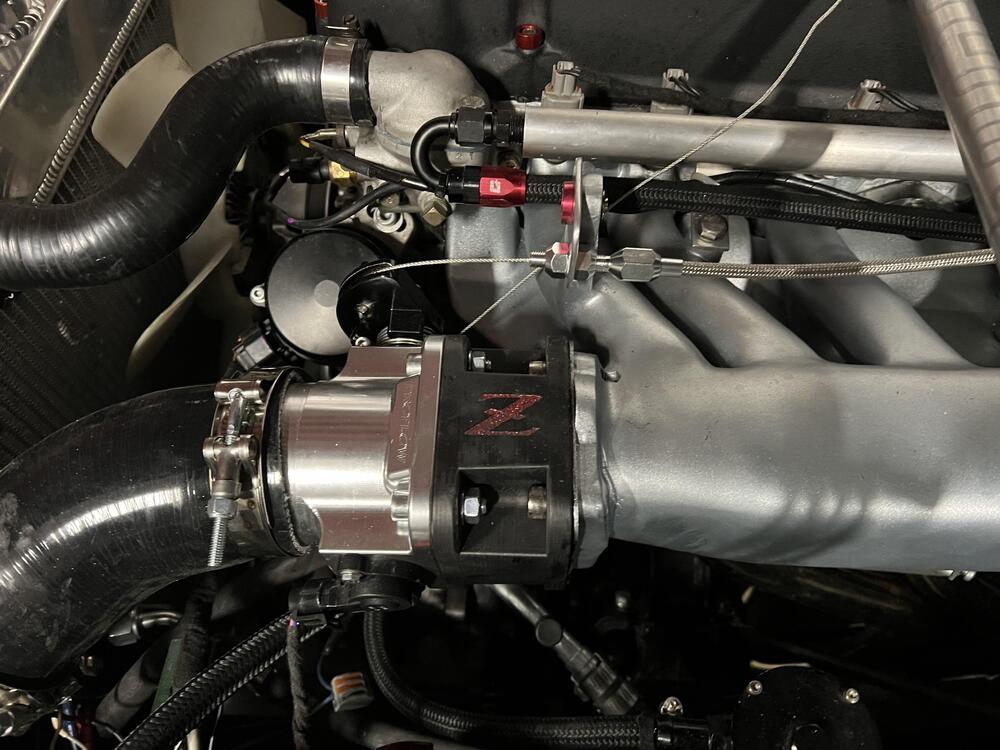

Completed the install with the CF infused adapter. Gave the Z a little sparkly red bling just because… 😉 The install went smooth. I replaced the existing throttle cable with a new one, which is always fun working on the under dash and gas peddle. Routed the cable overtop of the manifold versus under and built a nice throttle stop out of aluminum. Immediately noticed a performance improvement with the new throttle body! Steady idle, snappy returns, smooth revs… everything I was looking for! I have ordered the billet adapter to be cnc’d as the test piece is proven effective. Plumbed in the IAC line to the Bosch unit with some nice AN fittings too.- 1976 280Z Restoration Project

- 1976 280Z Restoration Project

- 1976 280Z Restoration Project

- 76 280Z Throttle Body bolt spacing

- 76 280Z Throttle Body bolt spacing

- 76 280Z Throttle Body bolt spacing

- 76 280Z Throttle Body bolt spacing

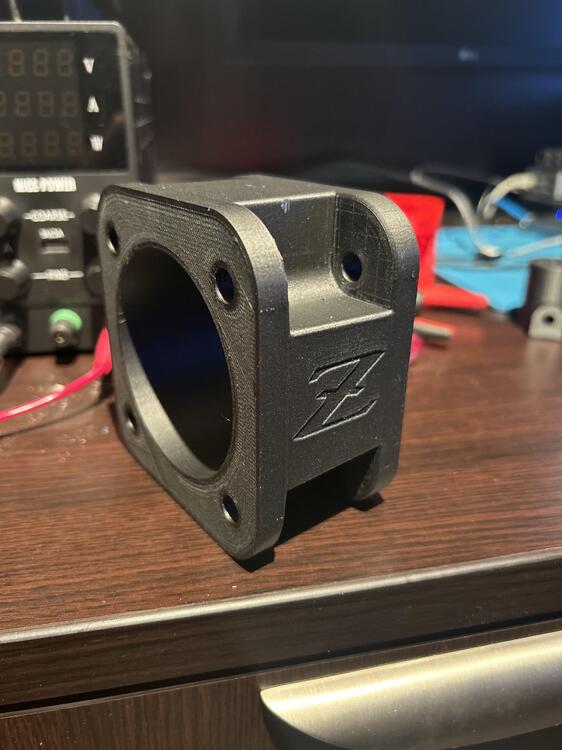

I have a friend 3D printing a double flange adapter that tapers down from 70 - 60mm with two different bolt spacing templates. 1/4” thick flanges and 1/8” tube wall. Might use this as a template for a billet aluminum prototype. Unless we can find a suitable 3D material for strength and heat resistance.- 76 280Z Throttle Body bolt spacing

- 76 280Z Throttle Body bolt spacing

I was also thinking of using an aluminum rod, threaded to fit the intake holes and sealed up then drilling and tapping new bolt holes in the intake to match the throttle body. Or - make a space that has a plate to fit the intake with 60mm spaced holes then a tube tapered from 60mm to 70mm with another plate with 65mm spaced holes. This would serve both purposes of matching the bolt holes and adjusting the flow diameter. The intake side is just bolt holes but the TB side would need to be threaded to hold the throttle body. I wonder if a 3D printed piece would be strong enough??

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.