Everything posted by Matthew Abate

-

Designing A/C System Using Other Cars Parts?

@Captain Obvious - Did you ever figure out your whole system? I am starting to think about this as well and wanted to follow up on what you chose for the various parts in your AC system. In particular, I was wondering what you chose for your condenser, as I see Z Car Source offers a bolt in one. I'm trying to figure out how it compares to the ones Vitage Air recommends,

-

1973 240z Custom Wiring From Scratch

Okay, so it’s the COIL that determines if the tach works correctly in the 240z. So why do I keep reading that the electronic ignition screws that up? Whatever! If my tach will work then I’ll keep it. The issue is that I don’t want to have to take it out once it’s in. Hard enough getting it out with the dash out. I can’t imagine pulling one from a complete car.

-

1973 240z Custom Wiring From Scratch

@siteunseen, you mean this, right? http://www.atlanticz.ca/zclub/techtips/distributor/index.html

-

1973 240z Custom Wiring From Scratch

Okay, I made some progress over the weekend. I pulled the gauges and ducts out of the dashboard last week, so I had access to all of the wiring, which is now out. I also purchased a Volt / Fuel gauge for a 1975-76 280z. These had the same condensed font as the 240z, so it should look like it’s supposed to be there. I’ll have to take note of this when I draw up the new wiring diagram. I also investigated getting a 280z tach, as we discussed previously. Originally I thought I would be able to put a ZX tach instrument into the tach housing because of a video I saw claiming this can be done, but he must have misspoken because the ZX instrument is pretty different and doesn’t just bolt in the way a 280z tach instrument does. I’m thinking about doing this because I went ahead and bought that 280zx distributor with the E12-80 module on it. I think the best course of action, although a little on the spendy side, is to find a good 280z tach and swap the instrument into my housing. This will be another place where I need to change the wiring diagram, particularly because of the 2200 ohm resistor required. So now on to cataloging this dashboard harness.

-

Parts Wanted: ISO 75/76 voltage / fuel gauge

View Advert ISO 75/76 voltage / fuel gauge I am looking for a working voltage and fuel gauge with the narrow font style matching 1975 and 1976 280Zs. See photo for style reference. Please PM me with a price if you have one. Advertiser Matthew Abate Date 07/24/2022 Price Category Parts Wanted Year 1975 Model 280z

-

1973 Rebuild

There sure are a lot of ifs in that write up. Given the state of disassembly of my car I’m wondering if there’s a way to eliminate some of them in advance. But if I’m understanding @Zed Head correctly I may be able to use my 240z tach with a 280zx distributor, which will same me a pile of cash, for sure. Would be nice to wire this up correctly so it’s nice and clean and doesn’t need to be opened up later.

-

1973 Rebuild

Okay, cool! Thank you. I passed this info along and we will see where it lands. In other news, I have the dash harness out and have been investigating the condition of the dash and all of the components. One thing I want to do is figure out the tach + ignition combination I want to go with. I am trying to make this electrical system as clean as possible from the get go, so if I can figure this out now it will be better. I am 90% sure I am going to go with an E12-80 ignition on a 280zx distributor. My engine is a ZX block and head, and even though it’s set up like a 1972 with SUs, that ignition feels right. So that means tach problems, since mine is a ‘73 tach. I watch a video on swapping a ZX tach instrument into a 240z tach housing, but upon further investigation I think the guy misspoke and actually used a 280z tach instrument in his mod. I know there can be issues with a 280z tach and an E12-80 ignition, so I want to look into this further. I see a clean 280z tach online that is complete, but I also see a few 280zx instruments that are in my budget. @SteveJ @Patcon @Captain Obvious, Based on your comments on other threads related to this I thought maybe you guys might know if the ZX instrument has the same bolt pattern and dimensions that the 280z and 240z instruments have. If so, this really simplifies my approach.

-

Windshield Polish

I know this is dead thread resurrection, but this is the best existing thread to ask this question and don't see the answer anywhere on the forum… Does anyone know if polishing the glass has any effect on the blue tint of the OEM glass? I don't know where that blue tint exists. Is it a film on one or both sides of the glass, or is it internal. Is the glass itself blue, or is there a layer of blue film sandwiched between two or more layers of glass? I am getting ready to try polishing a rear hatch glass on the outside and don't want to find that I have rubbed away the blue tint when I am finished.

-

1973 Rebuild

My dad wants to test run it before he ships it to me to be installed.

-

1973 Rebuild

Okay, with that sort of sorted and on the back burner I'm switching gears and have a noob question: How does one test run an L6 engine without a transmission attached? This is impossible since the starter mounts to the transmission and not the block, right? My transmissions are in New Jersey and my engine is in Arizona, so I can't just plug them together. Do I have to source a junk transmission or something so we can start it, or is there a secret trick to mounting the starter I am not aware of?

-

1973 Rebuild

I reached out to Z Car Depot about it and they pointed me to the OEM seal as well. It’s a Nissan part, so I am wondering if that is the best option. Pissed I have to drop another pile of cash on this. BTW, that seal is cheaper on Courtesy’s website than in their eBay auctions.

-

1973 Rebuild

It’s molded in the top corners for sure. The bottom ones have a curve but it’s not pronounced, so you could say they’re molded sort of. I don’t know how you would glue in the corners. It would require pressure keeping it against the hatch and the window should supply that. I guess you could glue it in without the window, fit the rest of the seal around the glass, and then complete the installation, but I am betting that would be REALLY tough to pull off. I think I’m going to have to leave this in for now and redo it later with a new seal. I need to get on to other things.

-

1973 Rebuild

Okay, I’ve pulled the window twice and am still having this problem with the top corners. Maybe this seal sucks. It has the right number that corresponds with the Precision seal, but it didn’t come in one of their green bags, so I’m not certain. It was part of a Z Car Depot kit and they aren’t great about fixing issues like this.

-

1973 Rebuild

Good call on the metal trim. I didn’t realize it needed to go in before the window was installed because the several videos I watched of people doing this didn’t do that. I got the seal from Z Car Depot a while ago and threw out the bag with the house trays on Friday, so I don’t know which one it is. I pulled the window out this morning and have a tube of silicone lubricant coming in the mail tomorrow. I’ll put the metal trim on first and try again when I’m better prepared.

-

1973 Rebuild

I installed my rear glass today and I have a problem. I can’t get the window to seat so that the two top corners are adequately covered by the weatherstripping. You can see above that there’s a sizable gap. This is the right side, which is the worse of the two. Am I stuck pulling the glass and doing this over again, or is there a trick I don’t know?

-

1973 Rebuild

Oh, I didn’t know you had one. I assume you didn’t have any of the quality control issues or the problem with the cap? Have you discussed it in any of your threads?

-

1973 Rebuild

Got a slightly off topic question for you guys… I have a line on a rebuilt E12-80 280ZX distributor. I am wondering if this is the right move, or if I should be looking at something else. The something else list right now includes the 123 Distributor, the Pertronix setup, the Crane HI-6s, and the Electromotive XDI (potentially NLA). I like the idea of the 280ZX distributor because it is the simplest option listed above. However, I don't see reliable sources for replacement ignition modules and I hear they tend to burn out. I don't really want to put something with a computer in the car, but if I do I want the best performance I can get, which I think would be something like the XDI or the HI-6s. This is all on my mind because it lightly impacts the wiring choices I make. If the E12-80 is the best choice I should grab it while I can. Thoughts?

-

1973 240z Custom Wiring From Scratch

Thanks! I am hopeful that I didn't make any errors. If I did it would most likely be with the measurements of the wire lengths, since I was super tired of working on this harness by the time I got to that step. I checked them a couple of times, so they should be right, but there are a lot more splices in this harness than there were in the body harness and they are mostly blue or yellow, so difficult to keep straight. I'm also bothered by the fact that someone cut 4 of the wires and I can't tell you how long they should be or what the connector should be. :/ ––– Also, I was wondering if anyone knows what gauges the OEM wires are. It looks like there are 3, maybe 4 sizes, which I have tried to indicate with (heavy) and (thick) next to the wire colors in the table.

-

1973 240z Custom Wiring From Scratch

I have another table for you, this time for the engine harness in automatic cars. For manual cars, you would not have the Seatbelt Relay, the Inhibitor Switch, the Thermo Relay, or the Thermo Switch. In a 1973 car with a manual transmission, you WOULD have the Throttle Opener Vacuum Relay for the flat top carburetors (not included in the table). Note that there are a few things I was unsure of in here, so they are marked with a pink background in the table cell. The wires that were cut have indeterminant lengths, so I measured how long they were to the point where they were cut. Where the harness I have differs from the FSM and wiring diagrams, I have marked the change in red. The things I am most curious / worried about are the missing black w/ yellow wire that should be coming out of the blue 10-pin connector and the missing green w/ black wire that should be coming out of the green 10-pin connector. 1973 240z Engine Harness (Automatic Transmission) Inventory Position Component Connector Color Connector Style Connector Image Direction # of Pins # of Wires Diagram Wire Color Sample Wire Color Min. Feet of Wire Needed 1 Instrument Harness A Blue 10-Prong F 10 9 Red w/ Black Red w/ Black 6 (to Yellow Splice C) Red w/ White Red w/ White (Heavy) [See Headlight LH] Green w/ Black Green w/ Black [See Horn Relay] Green w/ Red Green w/ Red [See Horn Relay] – – – Yellow w/ Green Yellow w/ Green [See Low Brake Fluid/Pressure Sensor] Red w/ Black Red w/ Black [See Reverse Light Switch on Trans] Black w/ Yellow – ? Red Red [See Fog Light RH] Blue w/ Yellow Blue w/ White [See Wiper Motor] Instrument Harness B Green 10-Prong F 10 8 Black Black [See Ground - ?] Black Black (Heavy) 2 (to Blue Splice A) Green w/ Black – ? – – – – – – Green w/ Black Green w/ Black [See Parking & T/S & Side Front RH] Green w/ Red Green w/ Red [See Parking & T/S & Side Front LH] Blue Black w/ Yellow [See Seat Belt Relay] Green Green [See Seat Belt Relay] Green Green [See Seat Belt Relay] Instrument Harness C White Black 10-Prong F 10 8 Blue w/ Yellow Blue w/ Yellow [See Wiper Motor] Red Red (Thick) [See Headlight RH] Green w/ Blue Green w/ Blue 5 (to Blue Splice F) Red w/ Blue Red w/ Blue [See Inspection Light] Red w/ Yellow Red w/ Yellow (Thick) [See Headlight LH] – – – – – – Black Black [See Water Tank] Blue Blue [See Wiper Motor] Yellow w/ Green Yellow w/ Green [See Intermittent Relay] Instrument Harness D Black White 10-Prong F 10 9 Blue w/ Red Blue w/ Red 2 (to Yellow Splice A) Yellow w/ Black Yellow w/ Black [See Oil Pressure Switch] Black w/ White Black w/ White 2 (to Orange Splice A) Black w/ White Black w/ White 4 (to Blue Splice C) Yellow w/ White Yellow w/ White [See Temperature Sending Sensor] – – – Green Green [See Hazard] White White [See Hazard] Black w/ White Black [See Ballast Resistor] Green w/ White Green w/ White [See Ballast Resistor] Instrument Harness E White 1 1 White w/ Red White w/ Red (Heavy) [See Alternator] Instrument Harness F White 1 1 White White (Heavy) 3 (to Green Splice A) Horn Relay Clear Spade F 1 1 Green w/ Black Green w/ Black 2 Clear Spade F 1 1 Green Green 7 (to Yellow Splice D) Clear Spade F 1 1 Green w/ Red Green w/ Red 2 Intermittent Relay White 4-Prong F 4 3 Yellow Yellow [See Wiper Motor] Green Black 4 (to Blue Splice B) Yellow w/ Green Yellow w/ Green 2 Hazard White 2-Prong (90 Degree) F 2 2 White White 2 Green Green 2 Yellow Splice A N/A N/A N/A N/A 2 2 Blue w/ Red N/A Red w/ Black 2 Seatbelt Relay (A/T) White 4-Prong F 6 6 Black w/ Yellow Black w/ Yellow [See Neutral Safety Switch] Black w/ Yellow Black w/ Yellow 6 (to Yellow Splice C) Black w/ Yellow Black w/ Yellow [See Inhibitor Switch] Black Black 1 (to Blue Splice A) Green Green 3 Green Green 3 Wiper Motor White 6-Prong F 6 5 Blue w/ White Blue w/ White 4 Blue Blue 4 Blue w/ Yellow Blue w/ Yellow 4 Yellow Yellow 4 Black Black 2 (to Blue Splice A) Blue w/ Red Blue w/ Red 2 (from Yellow Splice A) Ground - ? Missing 1 1 Black 4+ (from Blue Splice A) Water Tank Clear Spade F 1 1 Black w/ Yellow Black w/ Yellow 8 Black Spade M 1 1 Black Black 8 Low Brake Fluid/Pressure Sensor Clear Bullet (Large) F 1 1 Yellow w/ Green Yellow w/ Green 9 Yellow Splice B N/A N/A N/A N/A 2 2 Black w/ Yellow N/A Black w/ Yellow Orange Splice A N/A N/A N/A N/A 2 2 Black w/ White N/A Black w/ Yellow Blue Splice A N/A N/A N/A N/A 3 3 Black N/A Black Black (Heavy) 2 (to Blue Splice B) 3 Reverse Light Switch on Trans Clear Bullet M 1 1 Red w/ Black Red w/ Black 4 Clear Bullet M 1 1 Red Red w/ Black 3 (from Yellow Splice A) Neutral Safety Switch (for solenoid power) Clear Bullet F 1 1 Black w/ Yellow Black w/ Yellow 5 Clear Bullet F 1 1 Black w/ Yellow Black w/ Yellow 5 Blue Splice B N/A N/A N/A N/A 3 3 Black N/A Black (Heavy) Black (Heavy) 2 (to Blue Splice C) Blue Splice C N/A N/A N/A N/A 3 3 Black w/ White N/A Black w/ White Green Green Splice A N/A N/A N/A N/A 2 2 White (Heavy) N/A White 4 Starter Motor White 1-Prong M 1 1 White White (Heavy) 1 (from Green Splice A) Starter Ground Black Ring N/A 1 1 Black Black (Heavy) 2 (from Blue Splice B) Inhibitor Switch (A/T) Clear Spade F 1 1 Black w/ Yellow Black w/ Yellow 4 Blue Splice D N/A N/A N/A N/A 3 3 Black N/A Black (Heavy) Black (Heavy) 6 Oil Pressure Switch 1 Yellow w/ Black Yellow w/ Black 6 Alternator White 2-Prong F 2 2 White w/ Black White w/ Black 5 Yellow Yellow [See Voltage Regulator] Black Ring w/ Cap N/A 1 1 White w/ Red White w/ Red (Heavy) 5 Alternator Ground Black Ring N/A 1 1 Black Black (Heavy) 2 (from Blue Splice B) 7 Voltage Regulator White 6-Prong F 6 5 Yellow Yellow 2 White White 5 Black Black 5 White w/ Black White w/ Black 5 Black w/ White Black w/ White 5 Distributor Condenser Clear Bullet F 1 1 Black w/ White Black w/ White 5 5 Inspection Light Clear Bullet F 1 1 Red w/ Blue Red w/ Blue 7 Blue Splice E N/A N/A N/A N/A 2 2 Black N/A Black 2 (from Blue Splice D) Yellow Splice C N/A N/A N/A N/A 2 2 Red w/ Black N/A Red w/ Black Blue Splice F N/A N/A N/A N/A 2 2 Green w/ Blue N/A Green w/ Blue Yellow Splice D N/A N/A N/A N/A 2 2 Green N/A Green Orange Splice B N/A N/A N/A N/A 2 2 Red w/ White (Heavy N/A Red w/ Black (Thick) 8 Side Marker Lamp RH Clear Bullet F 1 1 Green w/ Blue Green w/ Blue 2 (from Blue Splice F) Clear Bullet M 1 1 Black Black 2 (from Blue Splice E) Parking & T/S & Side Front RH White 3-Prong F 3 5 Black Black 6 Black 6 Green w/ Blue Green w/ Blue 2 (from Blue Splice F) Green w/ Blue 2 (to Blue Splice G) Green w/ Black Green w/ Black 6 Head Light RH White 3-Prong M 3 3 Red Red (Thick) 6 Red w/ Black Red w/ Black 6 Red w/ White Red w/ Black 1 (from Yellow Splice C) Fog Light RH Clear Bullet M 1 1 Black Black 6 Clear Bullet F 1 2 Red Red [See Fog Light LH] 6 Horn RH Clear Spade F 1 1 Green Green 6 Blue Splice G N/A N/A N/A N/A 2 2 Green w/ Blue N/A Green w/ Blue Blue Splice H N/A N/A N/A N/A 2 2 Black N/A Black 9 Horn LH Clear Spade F 1 1 Green Green 8 Fog Light LH Clear Bullet M 1 1 Black Black 8 Clear Bullet F 1 1 Red Red 8 Parking & T/S & Side Front LH White 3-Prong F 3 3 Black Black 8 Green w/ Red Green w/ Red 8 Green w/ Blue Green w/ Blue 1 (from Blue Splice G) Head Light LH White 3-Prong M 3 3 Red w/ Yellow Red w/ Yellow 8 Red w/ White Red w/ White (Heavy) 8 Red w/ Black Red w/ Black 3 (to Yellow Splice C) Side Marker Lamp LH Clear Bullet F 1 1 Black Black 8 Clear Bullet M 1 1 Green w/ Blue Green w/ Blue 1 (from Blue Splice G) 10 Thermo Switch (A/T) - ? Missing 1 Black w/ Yellow 7+ (from Yellow Splice B) Thermo Relay (A/T) Missing 1 Black Black 9+ Missing 1 Green Green 9+ 11 Temperature Sending Sensor Clear Bullet F 1 1 Yellow w/ White Yellow w/ White 13 Distributor Clear Spade F 1 1 Black Black [See Coil] Coil Positive Clear Spade F 1 1 Black w/ White (w/ Shroud) Black w/ White (w/ Shroud) 12 (from Orange Splice A) Coil Negative Clear Spade F 1 1 Black Black 2 Balast Resistor Clear Spade F 1 1 Green w/ White Green w/ White 12 Clear Spade F 1 1 Black w/ White Black w/ White 12

-

1973 Rebuild

Question for the room: I’ve seen that the recommended sequence for assembling the interior of the car starts with the grommets in the firewall and then the rest of the firewall parts, but I imagine getting the tubes, wires, and other stuff that goes through those grommets is easier with them out, and I won’t be ready to put those thing in for a while. Is there a trick for doing this with the grommets installed and all of the insulation, boards, and stuff (not counting the dashboard) bolted to the firewall already? My interior was in cardboard boxes when I bought the car and I didn’t get a chance to take notes on the disassembly sequence, so this is a knot I have to unravel.

-

1973 Rebuild

I just opted for a glob of lithium grease between the pedal tube and the inner tube, as well as between the inner tube and the bolt. Keeping it off the threads was fun!

-

1973 Rebuild

While I’m working on the wiring I have also been reconditioning parts. Here’s the pedal box: New foot pads and brake switch. Otherwise just reconditioned original parts.

-

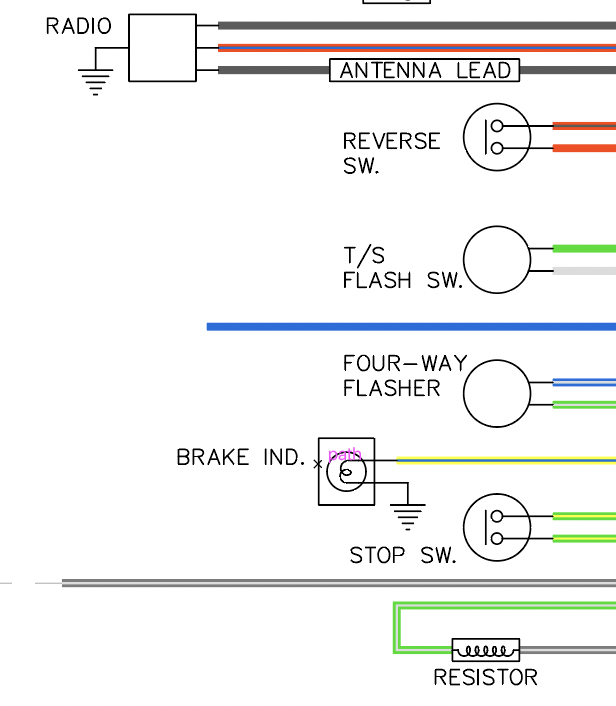

1973 240z Custom Wiring From Scratch

It's labeled "Brake ind." in the diagram and the wire shown is yellow with blue. It's also Yellow w/ Blue on pages BE-5 and BE-6 in the FSM diagram, conflicting with page BE-2.

-

1973 240z Custom Wiring From Scratch

I think I found the answer to the yellow w/ green wire question: apparently it's from a low brake fluid/pressure sensor to the e-brake light on the dash.

-

1973 240z Custom Wiring From Scratch

Thank you for getting in there and checking! I’ll take this back and start chasing the wires to see where things connect on the other end. Maybe that will clear it up.