Everything posted by fairladyz432

-

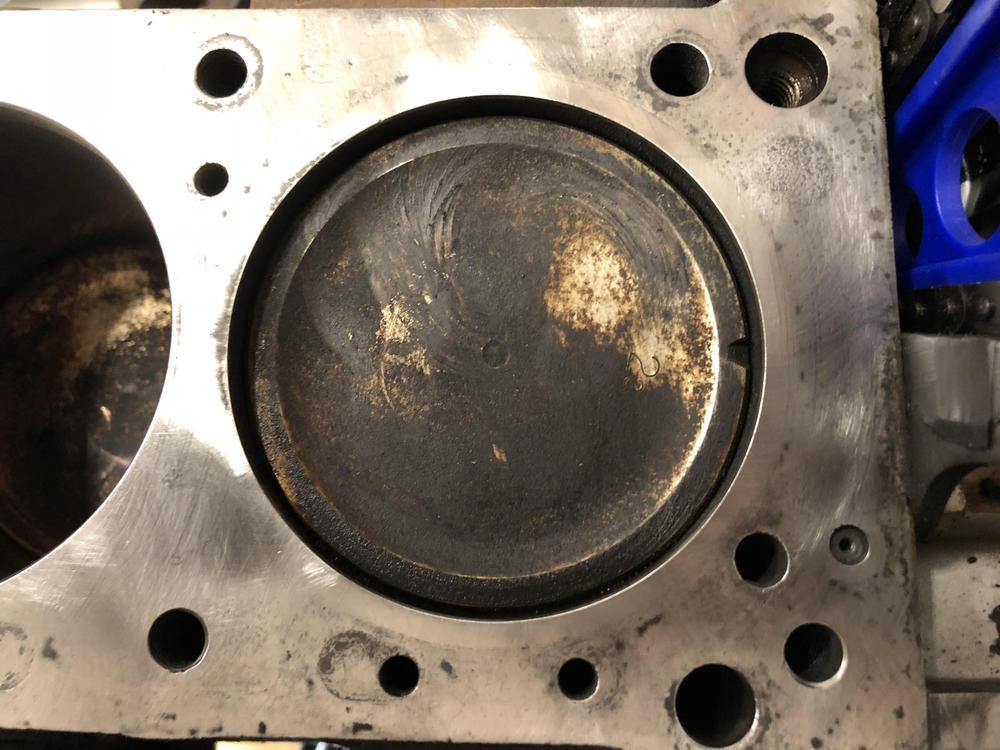

Head gasket engine block surface prep

I need some help figuring out whether or not my engine block is cleaned enough for the head to be reinstalled back on the engine block. I tried pretty much what i can to prep the surface of the engine block and just need some help with those who already went through this install. So far i got most of the old gasket gunk off but there are some spots here and there that still remain. I have some acetone ready to use in hopes of removing some of the left over material. Any suggestions would be much appreciated.

-

Solex 44 rebuild kits?

Thanks for the help gonna have to make sure they are direct fits.

-

Solex 44 rebuild kits?

Anyone know of a good place to purchase a rebuild kit for a triple solex 44phh (5 bolt)? My set is pretty clean just the gaskets and other usual seals need to be replaced.

-

280z fuel tank hose sizes question

checked lowes and dont have exact sizes but managed to squeeze 5/16 injection hose over a pre fuel pump filter so all i need to find is a reducer that will go from a 3/8 hose to 7/16 to the tank. THanks for help anyways.

-

280z fuel tank hose sizes question

My 1975 280z fuel tank feed hose needed to be replaced and i think the size according to a number of sources say its a 7/16 fuel hose for the feed side that goes to the fuel pump. However, im trying to figure out how to go from a 7/16 size fuel hose to a 5/16 fuel hose that goes to my new electric nismo carburetor fuel pump. Any ideas on how to convert that or is there a reducer of some sort? Tried looking at some barbed reducer ones but haven't gotten an exact match.

-

Cam upgrade?

hmm interesting, i would of thought the opposite. How much of a rpm limit do the stage 3 increase? i heard for stage 1 its about 6500 or so.

-

Cam upgrade?

I’m running a stage one cam and had to get new lash pads and made sure my valve seats were in spec which also ended up having to replace the oem valves to aftermarket ones that were more durable and to have everything in spec. It all depends if you want to shift all the power up top for a more race setup or street with a more low to mid range powerband. I’m installing triples as well but I’m running a l28. So I’d imagine a stage 3 cam on a l24 to be not so street friendly. That’s why I chose the stage 1 because since I have triples, power would be good up top but low to mid end would be good as well for a more balanced power band. I’ll have to see when I test out my new setup out. Maybe stage ii would be good too kind of a in between.

-

Rear wheel bearing install issue

Ahh glad I’m not the only one what a pain in the arse it was lol. Great close up pics definitely will help those in need out one day. The mechanic that worked on mine didn’t notice any damage in the slots where the bearing goes but I’m sure something close to that is what caused my issue. Possibly needed to go perfectly seated in order for it it to be tightened down on an old and worn hub.

-

Rear wheel bearing install issue

Just an update so might help some ppl out . I ended up taking it to a local shop and what they found was the seal was one of the issues when I installed it. It wasn’t sitting right and the actual inner bearing for some reason was not seated correctly. Not sure what I did wrong , possibly didn’t punch the inner bearing all the way in before I put the seal on not sure. But all is good now, thanks for all the help.

-

Rear wheel bearing install issue

The way I removed the old bearing was by using a slide hammer to yank out the stub axle and nothing was forced so pretty unlikely I damaged something by using a proper tool. As for the inner I just tapped it out with a pipe till it popped out nothing out of the ordinary. I’ll be posting pictures soon as I kind of took a breather on that particular job so I can i get the things I can finish quickly first as I’m really close to getting the whole project finished. This bearing was the last thing I thought I’d be having issues with. Thanks for help I’ll update soon

-

Rear wheel bearing install issue

Yep the stun axle is facing the right way. I’ll take a quick pic of how it’s installed. I just bought a caliper gauge that I will try to measure the races and see if they are within spec. The weird thing is that both driver and passenger bearingings bind or get stuck as I tighten the axle nut so don’t believe there’s anything wrong with the bearing housing themselves. Last thing I think that maybe incorrect are the inner bearings which I think will have to come out for inspection. Really lost at this point. Might even go as far as posting a video just so you all have a better idea what’s going on. Also the washer is for sure used with the axle nut.

-

Rear wheel bearing install issue

Might have to just get a new set of oem bearings and give that a try. Is there a difference which side the wheel flange goes or are they made to fit both driver and passenger side ? Are they marked at all?

-

Rear wheel bearing install issue

Ok what I did was I removed the new outer bearing and put back the old bearing. Same results if I tighten too much. Is the rear bearing similar to say the front bearing where the tighter you torque the nut the harder it is to turn? Right now, I have the rear just torqued enough for smooth rotation. The nut looks to be locked in where the old axle nut would be originally. Any more tightening it will begin to lock up. Also, are you supposed to torque down the axle nut when the wheels are on it does that not matter? Thinking if this doesn’t work I have no other option but to bring it in to a shop for inspection. Did everything I could for something that should be bolt on and go in my eyes.

-

Rear wheel bearing install issue

I do notice that there is a difference between the old bearing that fits fine and the new one that I installed. Clearly there’s a difference in thickness but not sure if that can make any difference?

-

Rear wheel bearing install issue

Hoping that this is the case as thats an easy fix if it is. Thanks! Im working on a 1975 280z coupe. Im beginning to think that the outer bearing isn't seated properly and needs to get hit in more with a drift all the way in. Im going to give it a try and take some pics of how it sits installed all together. From the looks of the diagram posted earlier it looks like the wheel flange sits all the way in towards the bearing housing and leaves no gap and shouldn't scrape if it is properly aligned/seated.

-

Rear wheel bearing install issue

This is what i got so far.. the outer bearing is exact same size as the original one that was on the car. The rubbing is occurring on the outboard side i can hear it kinda scrap as i try to spin the stub axle. I also can see the outboard side flange slowly creep toward the bearing housing as I tighten the axle nut and eventually rubs.

-

Rear wheel bearing install issue

Hoping that this is the case as thats an easy fix if it is. Thanks!

-

Rear wheel bearing install issue

Just a thought, the fsm says something about preload and adjust if necessary. Could i just possibly knock out the stub assembly (stub end ) back outwards with a drift so the wheel flange will get pushed out a little so it won't scrape the bearing housing after torquing down the axle nut?

-

Rear wheel bearing install issue

Awesome ill take a look at the bearing housing and see if they match up with the distance piece and do some measurements of all the pieces. I will update this thread on the results. thanks Yes, the collar is facing toward the wheel flange of the stub axle and the seal is facing outward toward wheel. Seated all the way back.

-

Rear wheel bearing install issue

oh and do you guys know where the distance piece mark letter would be located? Don't see a letter B marked anywhere.

-

Rear wheel bearing install issue

yeah i can actually see it, the stub axle would rub against the housing assembly and scrape as i turn the axle by hand. it gets tougher and tougher to spin freely the more i torque down the axle nut.. which is very odd. I bought oem nissan bearings and pressed in the outer bearing correctly and pretty straight forward. The inner bearing is seated as far as it can and where it should be. Might think theres a need for shims or something or possibly buy a new distance piece.

-

Rear wheel bearing install issue

Just took apart the stub axle and the distance piece are both labeled B on it so looks like they are the same pieces.

-

Rear wheel bearing install issue

Thanks for reply and Yes i have referred to manual. When setting preload on the bearing how do go about doing that? Are the distance pieces different for driver or passenger side? Maybe thats what im missing.

-

Rear wheel bearing install issue

Need some help with methods on how to torque down the the axle nut without causing the stub axle to bind against the drum assembly (making contact). When i tight to say 70 foot pounds of torque on the nut the stub axle and bearings spins freely without any binding but when im reaching up towards 100 or more, the outer stub axle with the sealed bearing will start touching metal to metal against the drum assembly and start to scrape when i spin the axle. Any steps im missing here? I tapped the inner bearing first to seat where it was suppose to and then tried to tighten the nut so the stub axle will naturally pull into the inner bearing but that just doesn't seem to work. What i was thinking is maybe the torque on the nut is just way to much? Any help will be great.

-

[SOLD] R200 w/MFactory LSD $1000 SOLD

messaged you about the lsd.