Everything posted by german240

-

240Z pulling to the right when braking

Calipers, hoses, brake MC, hard lines - all new, and they worked perfectly until last week. But will check it anyways ?

-

240Z pulling to the right when braking

Hey guys, my 240z pulls to the right if I brake really hard. The car is bolt and nut restored, means all brake system components (except brake booster) are brand new. I didn't notice this issue during the first 1000 miles, so I suspect something changed/failed recently. What I checked: Tire pressure, even wear Tension rod nuts (torqued them a little tighter) Rear left drum (no issue there) front left caliper and pads (even pad wear) The car drives straight as it should and the problem is really only noticeable with high brake pressures. Could it be an alignment issue? Or did I miss any other thing to check? Any help is highly appreciated ?

-

L28 Stroker Build - I need your advice :-)

1200 miles later, 3 oil changes, full load up to 6000rpm, everything is fine. The engine pulls really hard! Only issue so far is that the right engine mount already disintegrates (new aftermarket). I found that SM needles were not sufficient, it leaned out at WOT from 4000rpm on. I switched to RH needles which are slightly richer but leaner during idle. The engine is super responsive and torque, so far I can't justify buying triples! Timing set to 16° BTDC initial, regular fuel (US: 90 octane). It's a blast to drive. Thank you guys for your support!

-

240Z intake cooling delete

A little follow-up: The more I digged into this topic, the more I think this line must not be capped off. I just bypassed the intake without thermostat and everything works perfectly. No issues at all, temperature always right in the middle. Additionally, it warms up very quickly.

-

Ammeter X-file - after alternator upgrade

I have the same issue with the needle moving while the turn signal is flashing. Since my voltage system is working perfectly fine I guess this is like it is and nothing to be worried about ? Besides that, the needle is always close to middle or slightly right.

-

Removing Clock Arms

A good trick is to use a spoon or fork (whatever fits better) as a lever. Usually it pops right off (at least it was like this with my clock). ?

-

Ammeter X-file - after alternator upgrade

I did the same upgrade and my ammeter works fine ('72 240z).

-

Need fan clutch

Oh, I didn't know that there's a difference compared to the later fan clutches (as these are rebuildable).

-

Need fan clutch

Why don't you rebuild your fan clutch?

-

240Z intake cooling delete

@siteunseen Thank you, I've read some threads in the meantime. I think it could be deleted, however, during warm-up there would be no coolant flow through the head (thermostat closed). So the purpose of this line is, beside carb heating, to allow a little flow back to water pump. The only question is if the flow needs to be cut as soon as the engine is hot. I will keep it like this for a while and watch ?

-

240Z intake cooling delete

Hey guys, since I broke the intake manifold thermostat I bypassed the intake with a regular hose (red line). Would it be better to completely cap off the coolant flow by a plug at the thermostat housing and the 3-way connector at the engine passenger side? Thank you!

-

L28 Stroker Build - I need your advice :-)

I'm thinking more and more it is just a resonance during run down. I've heard that many BMW E30/E46 M3 owners experience a similar issue but there's no solution. I've switched to colder plugs, high octane gas, played around with ignition timing.. still rattling. My engine features completely different harmonics comparerd to stock (500g less weight per piston assembly!). Therefore, the engine mount stiffness might be not ideal now..

- L28 Stroker Build - I need your advice :-)

-

L28 Stroker Build - I need your advice :-)

Update! The engine is running ? Got A/F ratio dialed in pretty well (using a wideband probe). Timing set to 16° BTDC initial, around 35° maximum mechanical advance. Only issues I'm still fighting with: When shutting down the engine, it rattles/shakes a little. Is this something unusual? I don't have another Datsun engine to compare, so I don't know if it is supposed to be like this. Besides that, the front nozzle of the SU carb sticks sometimes after the choke has been applied. Cables are greased, so are all pivot points. Should I try to bend something?

-

Adjusting/recurving vacuum advance

Thank you! I knew I've read it somewhere, but couldn't find it ?

-

Adjusting/recurving vacuum advance

Hey guys, is there a how-to recurve the Datsun vacuum advance mechanism? What are typical target values? I got a remanufactured Cardone ZX dizzy and would like to play with it a little bit. As far as I understood, there are two screws: - Inner screw for maximum advance (CCW for more maximum advance?) - outer screw for vacuum setpoint to start advance (CCW or CW for sooner start of vacuum advance?)

-

Turn signal dash indicator reversed?!

@Villeman All solved! 1. Rear lights not working: Ground points (behind licences plate light and above fuel tank) were missing 2. Turn signal indicator dash bulbs were reversed ? Took me a while, but it was an easy fix ?

-

Turn signal dash indicator reversed?!

Hey guys, Finally, my late '71 Z is about to be finished. Only a few wiring issues are left - and I have no idea how to solve them. Current situation: I did the ZX alternator upgrade with harness plug instead of the old voltage regulator (seems to work fine). I did rebuild the combination switch (no issues during rebuild, I doubt I did something wrong). Issues: 1. Rear turn signals don't work 2. Front turn signals stay solid (Turn signal switch) 3. Dash turn signal indicators are reversed and solid (means left turn, right dash indicator turns on, left front turn light turns on) 4. Hazard switch turns on both front turn signals (flashing), no rears Fuses are fine, so are the bulbs. Could it all be low voltage related? Or is there a major issue? I remember when I first installed the charged (but weak) battery, the rear lights turned on barely visible. Thank you!

-

WTB 280ZX distributor E12-80

@EuroDat So I have to turn the inner adjustment pin clockwise in order to limit the vacuum advance travel, right?

-

WTB 280ZX distributor E12-80

@EuroDat: Did you ever try this? Does turning the screw clockwise increase or decrease the vacuum advance? I might have to do this as Cardone can't tell which advance they implemented. All years got the same parts number.

- L28 Stroker Build - I need your advice :-)

- L28 Stroker Build - I need your advice :-)

-

L28 Stroker Build - I need your advice :-)

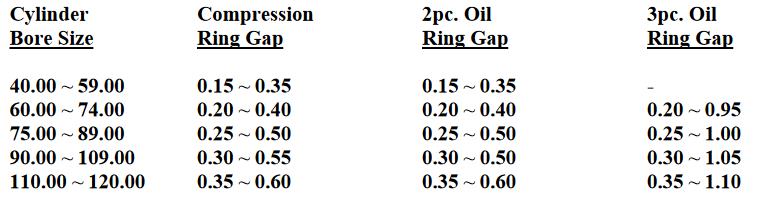

The question is: What are correct ring gap specs for this application? It is not a KA24E engine (where the pistons are from), nor a stock L28. NPR (Japan ring manufacturer) lists the following ring gaps: I'm still undecided @madkaw are you sure that the head bolts (got new OEM turbo bolts) are not a yield type?

- L28 Stroker Build - I need your advice :-)

-

L28 Stroker Build - I need your advice :-)

A friend of mine just checked his piston ring gaps. He got exactly the same rings+pistons, same bore (same engine shop), all gaps were within spec (on the tight side, though). It is very unlikely that my gaps would be any different... However, I might still tear it all down again. Let's see.