Everything posted by 240260280

-

Another great source for lash pads.

$0.02 Lash pads.

-

vin 181

I could have bought #48 for $19k when he put it up for sale.... it hurts! No money at the time otherwise life would be a little different. Q: Did you get that NOS water pump from the guy in PEI's Ebay auction?

-

Nice story: Resto for a dad

https://www.columbian.com/news/2018/jun/16/memorable-car-gets-a-tune-up/

-

vin 181

That is interesting Mike. Do you know when that shipment arrived in LA? I thought it was in January but Brock said he got his first Z after Sharp (Who got his in February). With respect to delays, a club member once owned #48. It had a 02/70 date so it must have had some significant issues for a 5 month delay. It is interesting that so many early cars keep popping up. A testament to how well they were built and how loved they were and are.

-

vin 181

My Vin 147 is 12/69 so it must have hung up in the factory if VIN181 is 11/69

-

Aluminum Valve Cover Cleaning

Eagle One Etching Wheel Cleaner may help: http://atlanticz.ca/zclub/techtips/wheelclean/index.html The only other ways I know are: 1. Vapour Blasting 2. Painting/Powder Coating 3. Sanding, polishing, and buffing

-

Has anyone found a source (and replaced) window squeegees?)

I need to replace the rubber squeegees in the door to glass mouldings. - Does anyone know a source for the rubber (no metal)?

-

1972 Float Adjustment ...

Also, if you think your car is running lean on acceleration, try putting an 80wt oil (thick) in the carb dampers to see how enriching the transition works. If you think your car is running rich on acceleration, try putting ATF (thin) in the carb dampers. 30wt oil is the recommended oil for your climate.

-

1972 Float Adjustment ...

Maybe your Z has a differential from an automatic? If you install a differential with 3.7 to 4.1 ratio, your 1st gear will pull better.

-

FI TO SU CARB CONVERSION

I just did it on a 77: 1. Get a 3 to 4 psi electric pump or install a mechanical pump on the head. Remove the high pressure EFI pump (you can use it but stepping the pressure from 50psi to 3psi is risky if it fails... you can open the return line orifice to reduce pressure in the system . If you install a low pressure electric pump, you can re-use the EFI pump wiring if you deal with the EFI fuel shut-off and EFI relays, I just installed a 4psi pump and wired it up in the engine bay. I did not re-use the EFI pump wiring. 2. Remove the EFI harness and EFI contraptions. 4. Get a manifold gasket that has the bolt holes for the carb manifold. 5. Plumb in Fuel Pressure Regulator (I used a Redline Weber regulator). 6. Plumb in a fuel filter (remove the high pressure one). 7. Relocate the mount for the shepherd's hook linkage (on firewall) and adjust the linkage as needed. 8. Install new manifold gasket and carbs.

-

Are these wheels of any interest?

FYI: Lots of Center Caps here: https://www.jegs.com/c/Wheels-Tires_Wheel-Center-Caps-and-Trim-Rings/10575/10002/-1

-

Are these wheels of any interest?

- [2018] What Did You Do To/with Your Z Today?

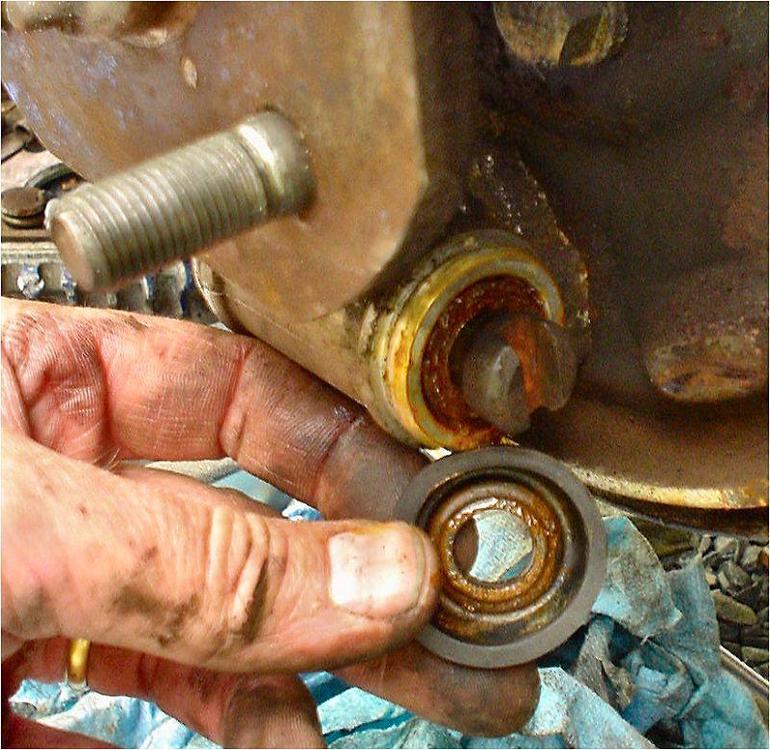

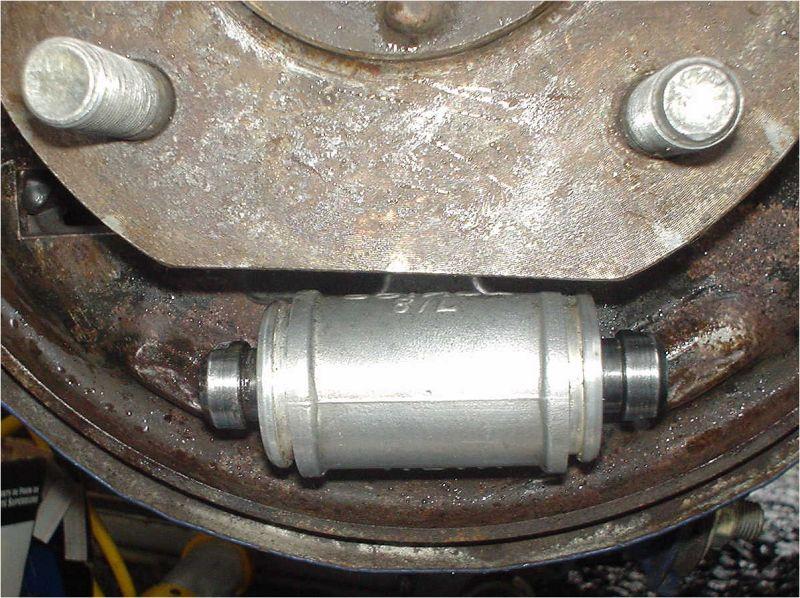

Mechanical: - Valves adjusted - Cam looks fine - Made new gaskets for oil bar Electrical: - Tail lights now work - Key now starts car - New alternator now charges battery On Deck: - about to practice Mig welding with C25 for first time.... holes in floor be warned!- 77-78 Rear Wheel Cylinder Brake Rebuilds

"L": Laughing all the way to the bank for selling polished turds. The manufacturers also save $$ by have no QA and by not testing products. It is an unfair advantage when competing against companies that do these normal checks... and let's not talk about no $$ for R&D "Rip-off And Duplicate" or not paying IP licensing fees .- 77-78 Rear Wheel Cylinder Brake Rebuilds

- [2018] What Did You Do To/with Your Z Today?

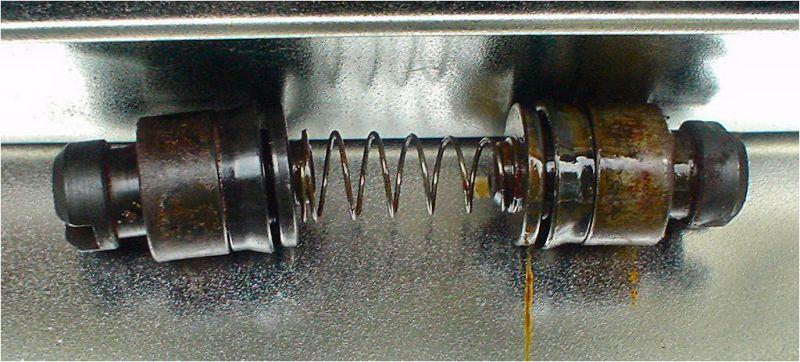

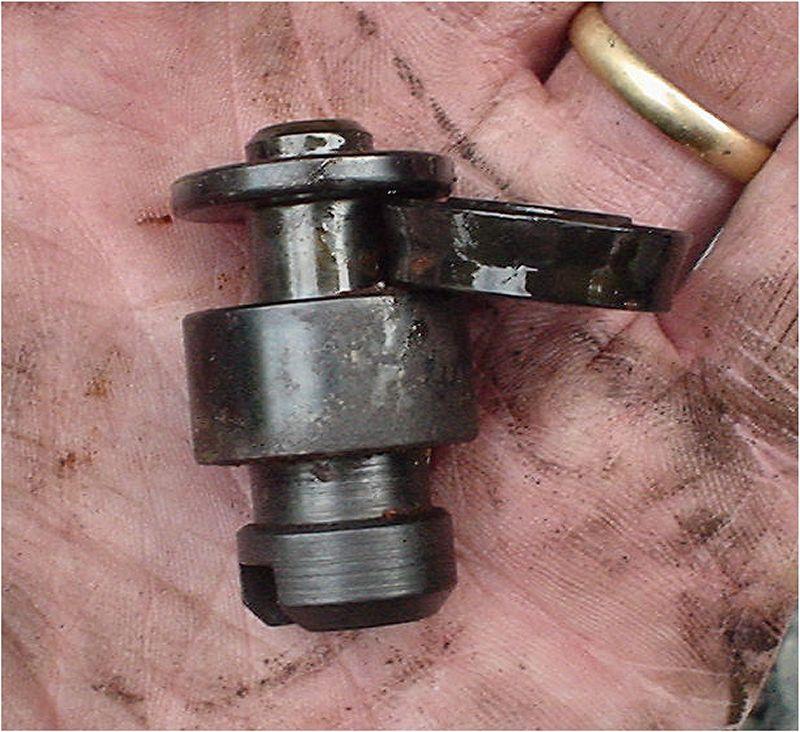

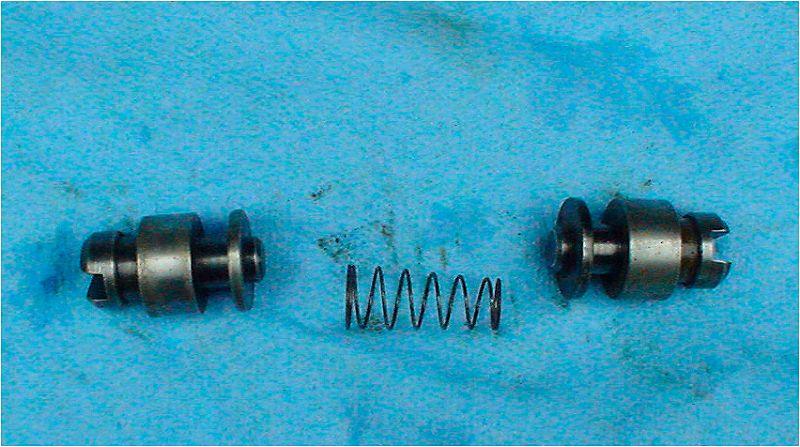

rebuilt 15/16 brake master cylinder installed: -- new rear brake hoses -- new calipers -- new brake booster -- new brake master -- new clutch master -- new clutch slave -- new clutch hose -- new hose clips Janet! I need you to help bleed the clutch! Waiting on front brake hoses to finish the brake job. All new hydraulics will be a treat. Blue always had a leaking booster so power brakes for a change will be nice. - brembo brake rotors weathered the 10 years in the elements nicely; just surface rust - Sumitomo S-12 calipers has rusted body and seized pistons - clutch slave had rusted pin and a slight leak - clutch master had a slight leak - brake master had the top caps rusted - rear drum brakes were great- 1972 Float Adjustment ...

Jalex we got your back. This is a very long process but you are in a very hot and humid area that most of us do not have to contend with. Please post a few pictures of your Z. I think it is beautiful!- We're bringin' back the Flat Tops!

I thought it was the extra pollution stuff on the 73 manifold that caused the complexity and problems which painted the flat tops with the same brush.- 1972 Float Adjustment ...

hi- How Do I hate Rebuilt Components? Brake Booster

Next up will be carbs and new linkage mods... then a single 55DCO with custom manifold.- How Do I hate Rebuilt Components? Brake Booster

Blue will not be embellished with stickers. It is a test mule ?- How Do I hate Rebuilt Components? Brake Booster

Just working on the outside. It held 15" vacuum for 15min so that is good for me. I just used the Duplicolor degreaser and some high-build primer followed with a satin black. It looks ok. Luckily the pits are not so bad on the shell. I also Zinc plated the push rod to reduce future rust.- How Do I hate Rebuilt Components? Brake Booster

I'm going to paint the shell this evening and thoroughly follow your lead and degrease it.- Weber selection and initial jet tuning

That is a bummer. I guess a new head is needed.- How Do I hate Rebuilt Components? Brake Booster

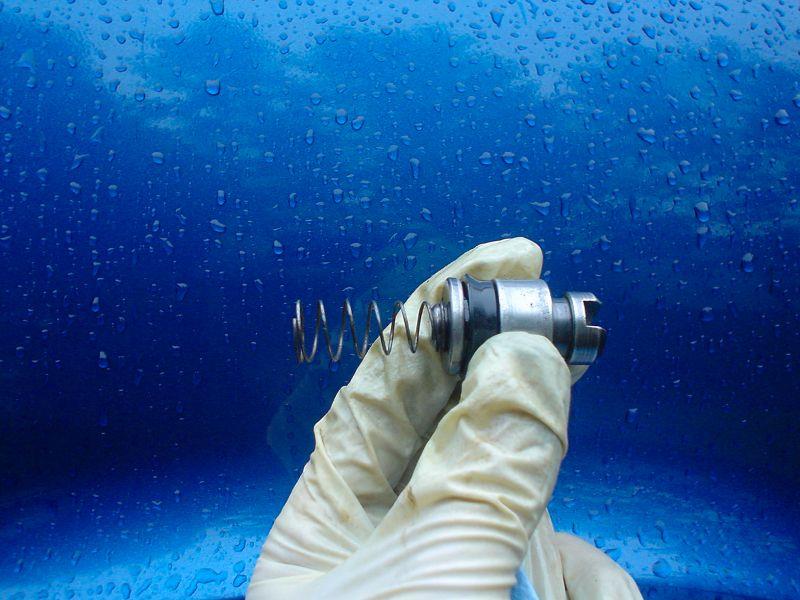

@Captain Obvious I just received a Cardone rebuilt booster like you and it had the same slathered silicon grease on the pitted push rod. I first experimented with a spare one (pittted) and chucked it in my drill press and gently sanded it from 120 grit all the way up to 800. I did not try to sand out the deep pits and they still show badly. I then spun the more pitted one (that came with the booster) but I hogged it at 50 grit until the pits were removed. I then finished it all the way up to 2500. It turned out very nice and worked very well at holding a vacuum even with the narrower shaft. Also in the collection below is an old one from a 240z that I tried to plug the pits with JB Weld then hand sanded. It worked just so-so. I'm not sure about the matt coloured one. I think someone may have zinc plated it. The rebuilt booster's seal works well with the hogged push rod. - [2018] What Did You Do To/with Your Z Today?

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.