Everything posted by 240260280

-

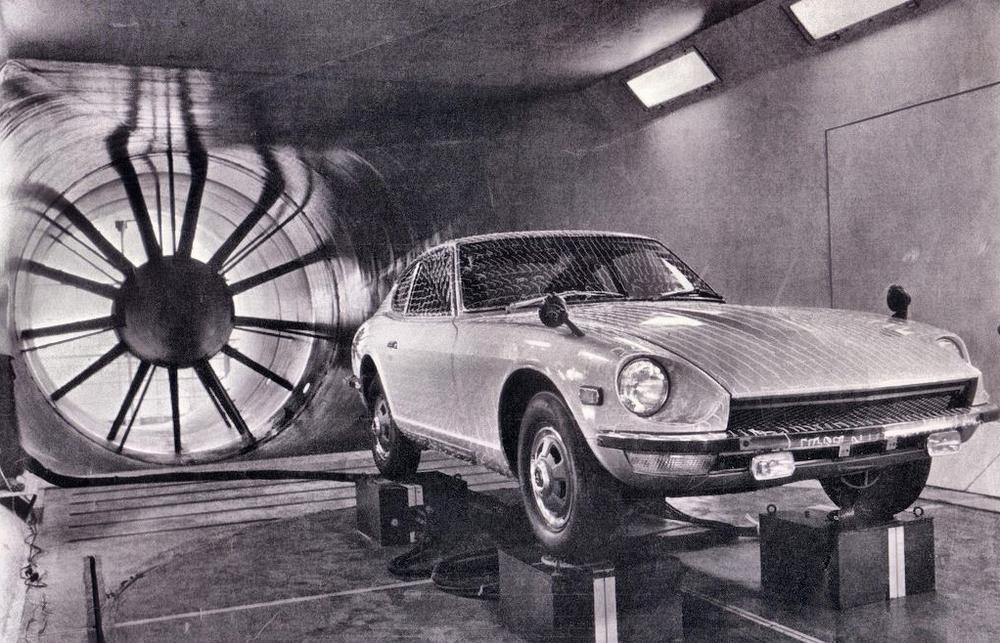

S30 aerodynamics

Have a look at this video: wind_tunnel_2.mp4

-

S30 aerodynamics

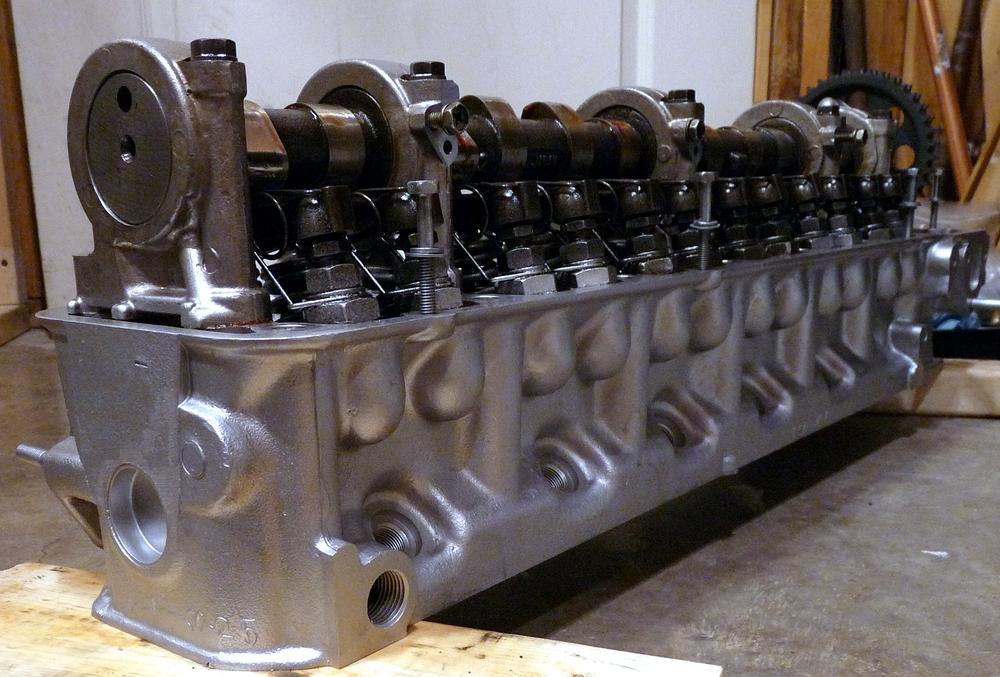

- Cleaned pistons and other parts

Thanks for checking. The rings are ITM and they have different shape from Grant. They have the word "TOP" labelled so they are difficult to install incorrectly. Also, I did not clock the 2nd and top rings for installation. I rotated them for the photo to show how clean the lands were.- Another unfinished project for sale in WA

PM sent- Another unfinished project for sale in WA

I'll be in Portland next week. Anyone around?- Calibrating Torque Wrench

Nice video for calibrating torque wrench. Additional info not in the video: you can calibrate the digital weight scale by hanging target weight on it and zeroing it at this target. you can verify the digital weight scale's accuracy by hanging known weights from it and noting deviation. Test in store with 20 lb weight when purchasing.- Imagine that!

https://www.reuters.com/article/us-autos-selfdriving-uber-settlement/uber-reaches-settlement-with-family-of-autonomous-vehicle-victim-idUSKBN1H5092- Should I be concerned?

They were incompetent from the start to make parts that do not fit and call them performance parts. I wonder what else is wrong with them.- Cleaned pistons and other parts

It is re-soldered, holes enlarged, and ends zinc plated (experiment). It is in great shape however, I'll take your advice and get a newer one..... just because it is you- Cleaned pistons and other parts

- Cleaned pistons and other parts

- Sold on LEDs

I also find that green radioactive glow of the painted markings soothing for some strange reason.- Sold on LEDs

- SUs and pumps

I do the same but with two steps: 1. Make sure the top of the float is parallel with the metal beam attached to its top. 2. With the lid off, upside down, and in front of your face, blow into the gas inlet while moving the float. It should block your breath when the metal beam is parallel to the top of the lid. If not, bend tang until you get it right,- Sold on LEDs

I guess I am old school. I just like to only see the markings on the instrument illuminated, not the face or the enclosure. Like this: Not this:- SUs and pumps

Some tips: - fuel rail only flows one way, as well as pump and most filters, make sure flow is correct through all. - you can quickly prime carbs by pouring fuel through fuel bowl vents to get it running quickly. - run outlet of fuel rail to container to verify fuel flow into container when cranking.- Imagine that!

https://www.bloomberg.com/news/articles/2018-03-25/china-seeks-its-own-brains-to-steer-30-million-autonomous-cars- Imagine that!

https://www.reuters.com/article/us-autos-selfdriving-uber-mobileye/mobileye-says-its-software-would-have-seen-pedestrian-in-uber-fatality-idUSKBN1H22LM- Stainless steel hard brake and fuel lines vs standard steel hard linesl

Beautiful work.- 1972 Float Adjustment ...

You could use this setting as a baseline for a few days and then give the jets a further 1/2 turn down to see if it runs better after you have a feel for the baseline.- Extrudabody EFI ITB throttle bodies for DCOEs

So 3 DCOE's w/o manifold for 3 ITB's?- DCOE Salt & Pepper Mills

Maybe they won't recognize this set: http://www.racechairs.com/rampipe_coffee_set_p/art40161.htm- DCOE Salt & Pepper Mills

You do realize that Janet will kill you in October if I bought those.- Fairlady Z - Date of manufacture

Join the Z Car Club of New England too. Great group! http://zccne.org/- 1972 Float Adjustment ...

I concur. Looks great! How does the problematic plug look? - Cleaned pistons and other parts

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.