Everything posted by 240260280

-

Caswell Plating

http://www.electroplatehomekit.com/zinc-kit-sizes.html

-

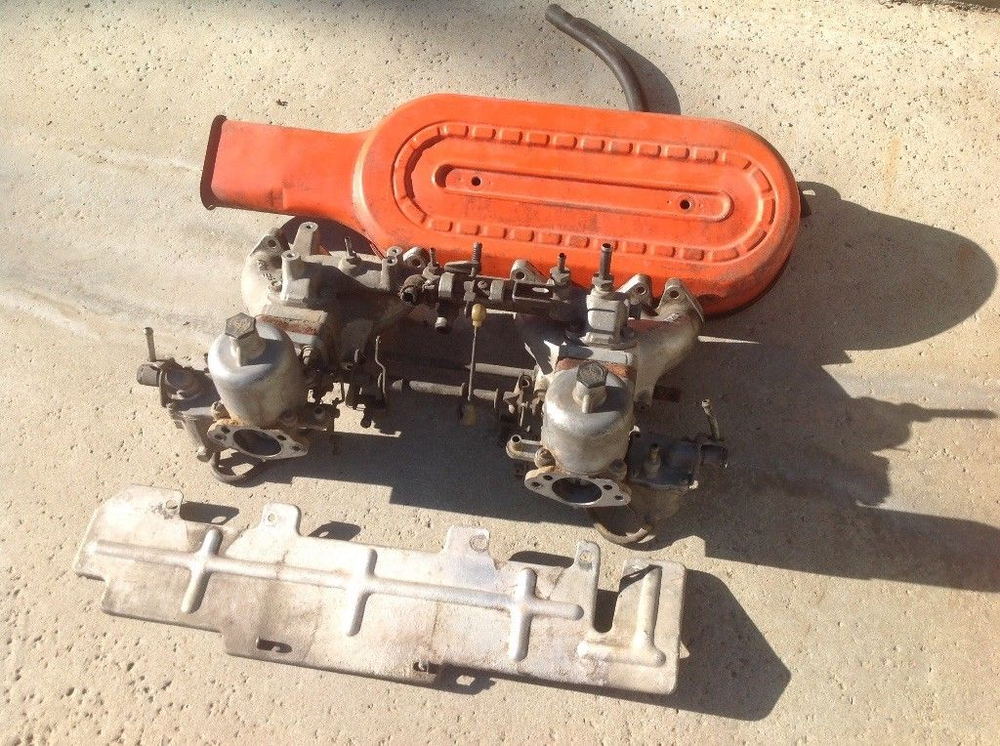

1969-Early filter housing and heat shield on Ebay

Early heat shield, early air filter housing, 4 screw carbs are later version as per MikeB's keen observation in post #2. https://www.ebay.com/itm/Datsun-240z-SU-Carburetor-4-screws-Series-1-NO-RESERVE/132514455721?hash=item1eda7a20a9:g:V0IAAOSw05tafN26&vxp=mtr

-

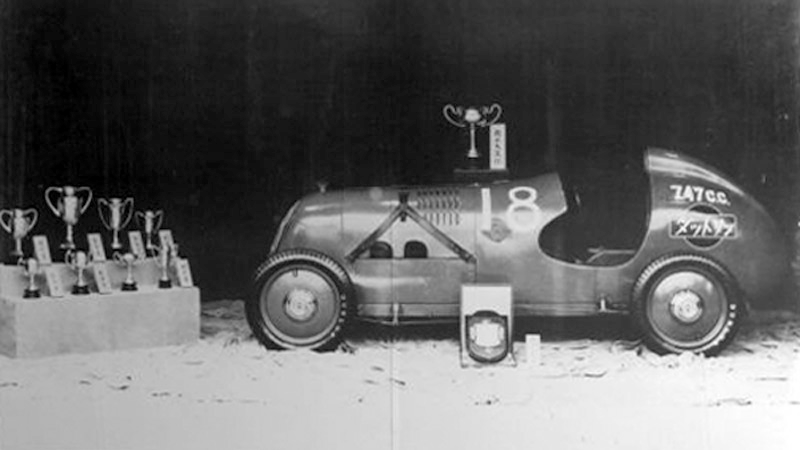

Interesting Historical Information Indicating Z was for US Market

More data related to Datsun/Nissan early sports car efforts in the 50's. It is interesting in that Mr. K is involved and so are the Americans in Occupied Japan. Here is what he says: "The years after the Second World War were difficult for Japan, and the idea of a sports car, let alone its production, was far from anyone's mind. I was, however, invited by the officers of the sports car club of the US occupation force in Japan to participate, and then to lead, the Sports Car Club of Japan. I soon realised the importance of the sports car to the automobile industry and remembered the intent of Ayukawa (the Chairman of Nissan in the pre-war years) of offering a sports car as Nissan's flagship. "By the time of the first Tokyo Motor Show in 1952, in my role as Nissan's Advertising Manager I arranged for a sports car body to be designed and manufactured by Yuichi Ohta. This body was to be attached to a Datsun truck chassis. This was the first sports model to be produced after the war by any Japanese company. Although this was largely my private project, Nissan agreed to build a production version, and this became officially named the Datsun Sports DC-3. One of the first production models is still proudly shown in the entrance hall of Nissan today."

-

Interesting Historical Information Indicating Z was for US Market

I'm tired of this. Just re-read the first few posts and consider the data and facts therein. You will find "Interesting Historical Information Indicating Z was for US Market".

-

Interesting Historical Information Indicating Z was for US Market

Heads in the sand boys...have a look at the big picture...not nit picking the little details that make no difference. Nissan focused on the USA market when making sports cars and the z was a continuation of this focus, as mentioned by many involved at the time and by the design changes made to accommodate the USA market.

- L28 280Z Car engine problems!!!

-

Interesting Historical Information Indicating Z was for US Market

That was one of the last photos of Goertz' association with Nissan at the 1964 Tokyo Motor Show in October. His employment ended then. The picture description is: " End of the line for Goertz at Nissan: Oct 1964 Tokyo Motor Show (CSP-311 Silva Coupe) Note earliest 240z sketches were ~ 1 year later. " The point is to highlight the time line and to highlight the point that he could not have been involved in the Z development.

-

Interesting Historical Information Indicating Z was for US Market

The sticking point is that all other sports car manufactures made cars for their domestic market and continued to do so, Nissan did not, they tried, it failed so they went for the USA market. The Z is a significant element in the evolution of this approach that started in 1960 with the SPL212.

-

Interesting Historical Information Indicating Z was for US Market

The point I am making is that Nissan, its executives, and its future executives witnessed the American automotive need during the occupation and when times changed they went for this market. Boots on the ground in the USA such as Katayama re-affirmed this. When sports cars gained traction in the USA, they went for it. I guess they could have gone after the UK market with their pre-war Austin experiences but they chose not to. They even had a hell of a time getting Z's into the UK for a car show nearly a year after they were released in North America. USA was a path of least resistance and opportunity.

-

I blame it on legalized pot

These people are volunteering to enable the govt to tax: 1. gas 2. miles traveled (even on vehicles not consuming gas) 3. electricity (needed by vehicles not consuming gas) Which opens the door for double taxing: 1. Miles traveled by electrics 2. Power to charge electrics I think the drugs are affecting people's judgement. Who would want this horrible tax, and who would volunteer for it? https://www.reuters.com/article/us-usa-trump-economy/trump-signals-open-to-mileage-tax-with-praise-of-oregon-program-idUSKCN1G527O

-

240z D Hubcap differences

JSM you may have maleware

-

240z D Hubcap differences

Yes but it only just occurred.

-

Interesting Historical Information Indicating Z was for US Market

Nah, you have to have grown up here to appreciate the car culture over here. Just like I watch Coronation Street and have been to Manchester a few times but haven't lived it.

-

240z D Hubcap differences

Site must be hacked I think. @Mike

-

Interesting Historical Information Indicating Z was for US Market

You guys just don't have the perspective that comes from growing up in the car culture over here. It helps understand why Nissan went after this market. Even if you just consider all of the trucks Nissan made for the USA presence in Japan after the war, then later their realization that all of these soldiers moved back to the USA with an understanding of Nissan trucks. Yokohama was a truck factory for the USA army before it was a Z factory for many of the same families. (See the photo below commemorating 100,000 trucks produced and on some of these on display at Oppama). Goertz was mentioned appropriately and with measure.

-

Interesting Historical Information Indicating Z was for US Market

You guys are just on the wrong side of the pond to understand.

-

Interesting Historical Information Indicating Z was for US Market

Goertz worked a little on the first Nissan sports coupe that preceded the Z. He deserves some credit for this fact but the point made above is that he was gone by the end of '64. Matsuo penned the first Z in late 1965 (below). The details of this design evolved along the path to production but it is clear he had it nailed from the start. All other Nissan production sports cars produced in the '60's were convertibles intended mostly for the US market. When the US safety regulations were changing, Nissan reacted, and the Z resulted from this (and other factors). There were many in Nissan/Prince forcing the direction of the Z between '65 and '69 but Matsuo persevered and his design in '65 carried through for the most part.

-

240z D Hubcap differences

-

Triple Mikuni thread

Annular Discharge Venturi or just a curved pipe with the exit at the venturi?

-

240z D Hubcap differences

Why is there a hyperlink in your quote content? (simply be). I hate the web and this automated crap...Artificial Stupidity "AS" as in arse.

-

240z D Hubcap differences

The location of the valve stem hole seems to correlate with the finger spacing. The fewer fingers seem to have hole aligned with spoke. Also one would think that fewer fingers would be earlier but here is a prototype from 67: The differences may simply be due to different suppliers.

-

Interesting Historical Information Indicating Z was for US Market

- L28 280Z Car engine problems!!!

-

Let's show vintage racing pictures. I'll start.

Bob Sharpe June 1965 Vinelands, NJ http://www.datsun.org/fairlady/bsr1965article.htm

-

Let's show vintage racing pictures. I'll start.

Looks like a hill at Lime Rock in the background. So it would be a view from inside the track looking out before turn 1.