Everything posted by 240260280

-

Ideas for getting better Microfiche pictures

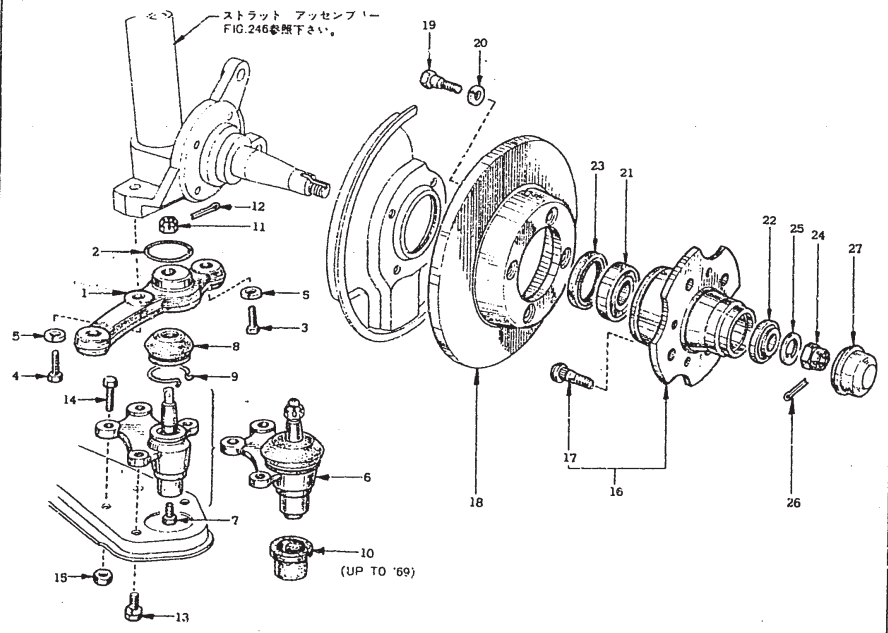

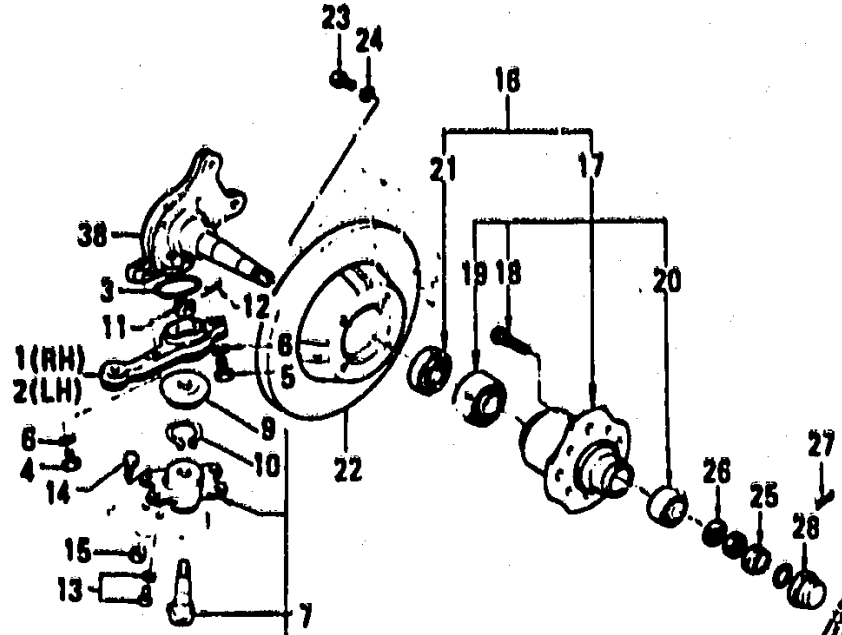

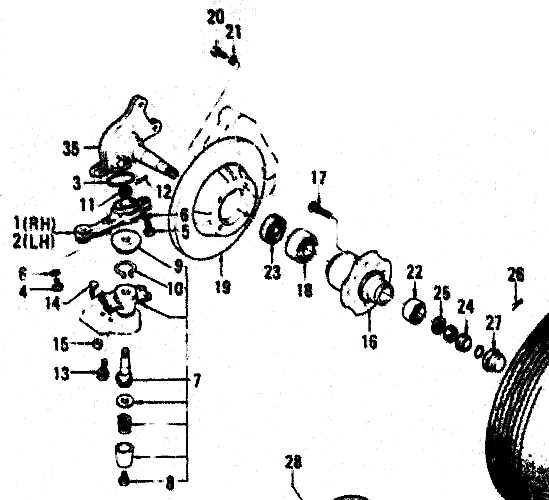

Lots of great photos in the FSM's. There are also printed parts manuals that have high quality drawings.

-

Datsun-240z Vs Fairlady-z432

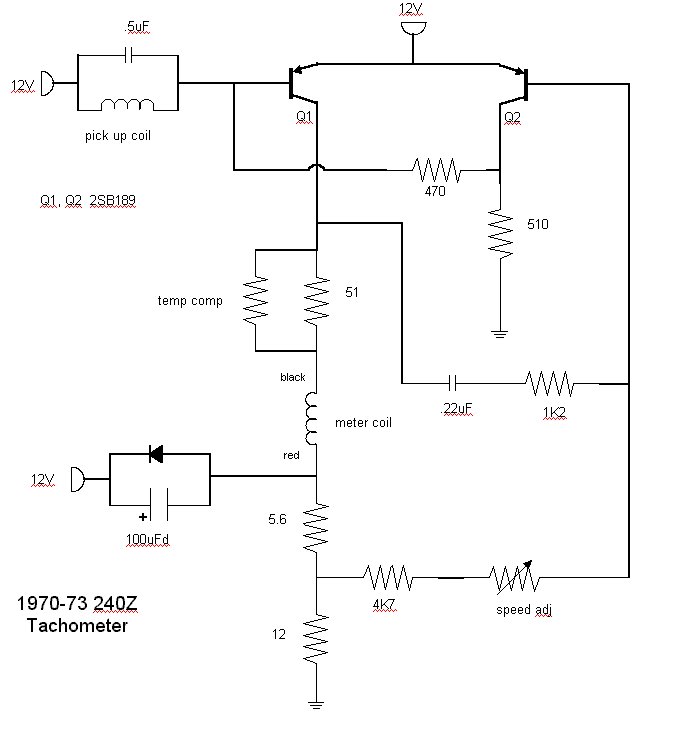

Hi Kats, For those of us in a hurry or with limited skills.... yes, it is easiest to match the electronic ignition with the correct electronic tach circuit board (3 wire voltage type) or to use the early points ignition with corresponding passive (4 wire induction type).... HOWEVER, this clever member of our board developed a circuit board to allow an early 4 wire points tach to work with electronic ignition modules: http://www.classiczcars.com/forums/topic/34295-converting-a-four-wire-tacho-current-driven-to-an-electronic-tacho/ Cool racing tachs above! I think racers typically put the sweet spot at 12 o'clock position for quick viewing.

-

Datsun-240z Vs Fairlady-z432

Hi Kats, I restored a 71 240z for a good friend. One of the project goals was performance so I installed a 280zx distributor with the small electronic ignition module on the side. To make this work, I had to change out the 240z tach's internal circuit board with a 280z circuit board, and also run a new wire from the coil negative terminal to the tach. FYI I have a nice 74 260z tach that I just tried to calibrate. Unfortunately my coil simulating signal was not strong enough to drive the tach. Later this winter I'll have another go at seeing if I can get a better driver circuit.

-

Ideas for getting better Microfiche pictures

-

240Z hatch support strut question

Mr. Matsuo specified 2 gas struts when designing the Z. Bean counters cut one... along with the rear disc brakes and under bumper grill.

-

Ideas for getting better Microfiche pictures

There are alternative pictures in the Fairlady parts manual too. (see the Nissan Parts Catalogue here: http://240260280.com/Docs/index.html) I have a project in the back ground to do this Jim. I'll ring you to discuss. I have lots of space on my 240260280.com website and planned to put drawings there. Here is an old effort before carpartsmanual I did way back in 2004: http://www.240260280.com/legacy/techtips/explodedviews/280z/index.html

-

Datsun-240z Vs Fairlady-z432

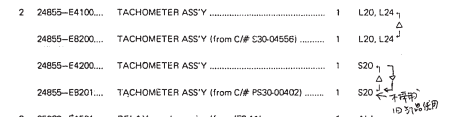

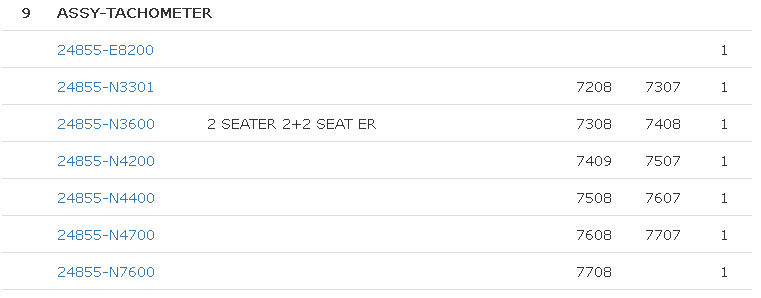

Hi Kats, I'm glad to help. #1 I checked the FSM's for North American Z's and the first electronic ignitions started in 1974 with the 260z. The start date would be 08/73. You can see the tach part numbers here: http://www.carpartsmanual.com/datsun/Z-1969-1978/electrical/meters. I checked the 260z schematic and the input to the tach is taken from the coil -neg terminal so it is voltage type tach. #2 I did not calibrate 280z meters yet but I have some spares and can try to see if I can adjust the sensitivity and scale to respond to the equivalent to 10,000 rpm (input = 500Hz). The 280z unit goes to 8,000 rpm which is driven by 400Hz so there is not a huge input difference.

-

Datsun-240z Vs Fairlady-z432

Flog the horse Enjoy this deeper dive: http://www.classiczcars.com/forums/topic/40718-tach-bounces-while-shifting/?tab=comments#comment-365973

-

Tach Bounces while Shifting

-

Datsun-240z Vs Fairlady-z432

Hi Kats, I swapped a 280z tach into a 240z housing in this thread. The 240z signal was picked up through induction at the tach. The 280z signal was a direct voltage. Here is the 280z primary connections.... looks very familiar You may be able to use 280z parts in the 432R tach

-

I like this tiger tool

- I don't know what this is

yes. If the hiss is coming from where a hose attaches, usually the hose has a leak or it is stretched and not sealing on the nipple.- #305 on Bring a Trailer

HLS30-00126 was the first blue on blue that I can see in the Z reg file. HLS30-00302 was the second blue on blue that I can see in the Z reg file so 305 maybe part of a blue batch.- I don't know what this is

You are at the right web site to help you on your journey!- I don't know what this is

Some helpful info here: http://atlanticz.ca/zclub/techtips/EFI&fuel.htm Try this one first: http://atlanticz.ca/zclub/techtips/efisystem/overview.html- I don't know what this is

The hose in your hand links the manifold air pressure to the regulator. It allows the correct fuel pressure to be maintained: When you are idling, the throttle body upstream is closed and there is a huge vacuum in the manifold that trys to suck extra fuel from the injector when it squirts. When you are driving with your foot on the gas pedal, the throttle valve is opened more and the vacuum in the manifold is much reduced and there is less suction trying to pull extra fuel. The FPR is controlled by the manifold vacuum it senses and it reduces the fuel pressure when the manifold vacuum is high and is sucking more fuel out. If you remove the hose or it is old and not sealing then you will hear hissing as it is a vacuum leak to the manifold. The engine is designed not to have these leaks. It is designed so that all air into the engine goes through the throttle valve.- I don't know what this is

It is a fuel pressure regulator.- Tool or materials to deep clean all the light bulb female sockets

Metallic Silver. Happy New Year!- Tool or materials to deep clean all the light bulb female sockets

1. Pull the assembly out 2. Disconnect wire from harness 3. Remove rubber seal around metal body 4. remove rust and treat metal. 5. paint metallic silver To refresh bulb socket, push the wire through from back then clean the centre contact. Push back in then clean sides with wire wheel or abrasive.- Interesting 1973 E88 240z head info

Looks nice. No corrosion evidence at water passages...that is a nice head!- [2018] What Did You Do To/with Your Z Today?

Whooohoo! 2018. I almost remotely controlled* my neglected 280z into the garage for its refresh but the Ridgeline developed an oil leak so it went in the garage... -15C outside. I'll have the truck fixed when the stores open on Tuesday then ol' Blue goes under the knife/welder. An experiment in rust. * walking beside it while pressing a remote starter and the transmission in 1st gear.- Tool or materials to deep clean all the light bulb female sockets

If the metal you are cleaning is solid then any brush will work. If the metal you are cleaning is plated, a correct chemical solution for saving the plate and a plastic brush is best. "Chemical solutions" would be metal polishes for brass, nickle, etc.- Caswell Plating

Physics: 1. Charged particles take the shortest path (thus the shadowing effect). 2. Charge intensity varies across non-uniform surfaces. 3. Charge is stronger at edges/points (related to #2 above). FYI: By using a rolling drum in a bath, the parts move randomly and the charge intensity on the part surfaces is always changing so there is less shadowing effect and less edge effect. A rectangular bath solution with a stationary part could be optimized by: 2 zinc plates running end to end and crossing in the middle bottom then running up the walls. The power supply output would connect to the middle of each side/plate (split it 4 ways). The part to be plated (if big and odd shaped like the throttle shaft) would need two or more wires connected to it and turned occasionally As Nix says, a circulation of the electrolytic will also redistribute the zinc ions so there are no pockets of depleted solution. An alternative to this would be to move the part in the bath. A string connected to a disc on a motor could lift the part up and down within the solution (or it could lift one side of the hanging rod). Some use an aquarium bubbler to mix the solution.- HLS30-07848

Could be corrosion through front cover behind water pump.- Interesting 1973 E88 240z head info

Thank @Lumens for sharing the TSB's. Glad to be the messenger. I look forward to meeting in October! - I don't know what this is

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.