Everything posted by 240260280

-

73/74 Flat top carb modification manual

http://240260280.com/Docs/index.html

-

Correct fasteners for Intake and Exhaust Manifolds

My Nov 69 has bolts too.

-

Thinking about installing an BMW M6 engine in my Z

Old school way to make 1500 HP on a 1.5 litre 4 cylinder: https://racingotaku.wordpress.com/2009/06/08/best-f1-engine/ BMW Too!

-

Thinking about installing an BMW M6 engine in my Z

Love the new engine!

-

Ah come on! Another one? Enough Already. Oh Fine.

Tres cool find. You Albertans sure can dig up old dinosaurs! I looked in FSM and now it finally pops out: I would like to offer to buy your old water pump if it is original (ol' smoothy) and you plan to replace it. Sanford.

-

Ah come on! Another one? Enough Already. Oh Fine.

Welcome to the grumpy old man club! You Hoser! You!!

-

Group 4 PAG (Replica Campagnolo 40802) Wheels

Is that the same Campagnolo that makes racing bike parts?

-

Picked up some brass rod..

Thanks as always master machinist CO. I had a quick look and young grasshopper will avoid the problem you mentioned https://www.youtube.com/watch?v=pAngKHIZgyA No collets yet but I foresee them in the future.

-

Picked up some brass rod..

CO I am a coward and will go the Dellorto Mikuni/Solex route at first. No angled holes at first. These will be true "E-Tubes" for "empirical" testing. Quick and dirty to understand the relation ships between hole locations and tube size. Once this is mapped then angled holes will be tested. I plan to make a drilling block that will have guide holes to consistently drill holes in the same location on all tubes. I may even try to make a Mikuni solution that fits in a Weber's jet well as a second phase. Some O rings may be all that is needed to keep the fuel in the tube. Have a look above at the tube on the right.

-

Picked up some brass rod..

I meant latte hero

-

Picked up some brass rod..

-

Mikuni FI Prototype?

If the Mikuni's never made it to production, SK Racing / OER make TBI units that may be similar: http://www.oer.co.jp/SportsInjection.html

-

Guitar folks, funniest thing.

Cliff, you may like this guy... cool name

-

Triple OER/SK carb issues, not balancing (SOLVED)

Glad you got them sorted. Measuring Air/Fuel ratios under different conditions will be the next step in optimizing.

-

Triple OER/SK carb issues, not balancing (SOLVED)

Popping/spitting out of any carb is usually a fuel delivery issue (not enough). Try to find the throat that is spitting then thoroughly check the jet values so they match the others and were not drilled or soldered in the past. Also check the orifices of the jets for blockage and or debris. Likewise check the passages in the carb for debris, including the progression holes and idle enrichment hole.

-

Triple OER/SK carb issues, not balancing (SOLVED)

Lumens nailed it! It is strange how spraying carb cleaner around these areas did not bring the problem to light earlier? btw our I6 engines are not prone to foaming gas as they are very well balanced at all rpms, so shock mounting carbs (fuel bowls) is not needed. However, road vibrations will shake the heck out of the needle valves and wear them out rather quickly thus the need for shock mounts.

-

Pros and cons of a triple Weber carb conversion

I would recommend SK Racing/ OER carbs over Weber. They have more useful advancements in the design yet they use the Weber jets and E-tubes that are available everywhere.

-

Pros and cons of a triple Weber carb conversion

If you use 28mm chokes in the Webers you will get huge low end torque.... very nice.

-

Triple OER/SK carb issues, not balancing (SOLVED)

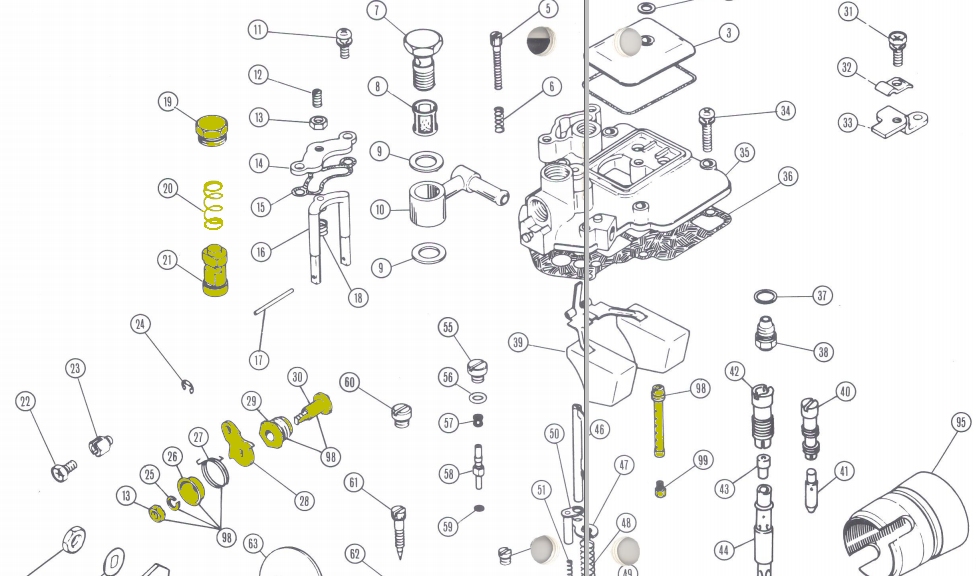

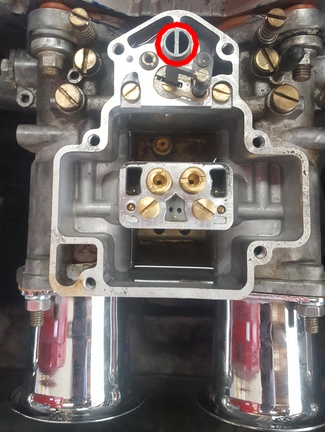

Duh.... I am dumb! The SK's have the cold start plunger up in the lid... so it is easy to take apart! Part #21 is the plunger. For quick and dirty check, you may be able to cover this port (below) with tape to block any leak to manifold at idle:

-

Triple OER/SK carb issues, not balancing (SOLVED)

Process of elimination. You need to remove carb lid and disassemble choke assembly to inspect thoroughly.

-

Triple OER/SK carb issues, not balancing (SOLVED)

btw the vacuum ports for tuning are not leaking or opened?

-

Triple OER/SK carb issues, not balancing (SOLVED)

OK then it is probably the rare case where the cold start circuit is not sealing on carb #2. Check it out.

-

Triple OER/SK carb issues, not balancing (SOLVED)

Maybe the throttle rod in carb #2 is twisted. Did you look in progression holes to see where throttle plates come to rest in the throat with the stop screws back off all the way? Compare all 6. Carb two is not closing enough.

-

Triple OER/SK carb issues, not balancing (SOLVED)

fuel flow check: Just hold the lid to your face and blow air through the fuel entrance in the lid. Open and close the needle valve by moving the float and you should hear the air stop and start when the valve opens and closes. Balancing: Too much vacuum on one carb at idle means it is doing all the work and the other two are not. You need to close the throttle valve stops on all to be the same before you start balancing. Also ensure the idle enrichment screws are all backed out by the same amount at start. Do not turn any enrichment screws until the air is first balanced. Here are the steps to follow: 1. Gently turn all 6 idle enrichment screws in until they stop then back each out 1 full turn (note: some recommend anywhere between 1.5 turns to 2.5turns however the SK Carb manual recommends between 3/4 to 1 full turn so 1 full turn should do) 2. Disconnect push rods from carb arms. 3. Turn back all 3 idle stop screws until each is not touching the idle stop. Then turn each in until it just kisses the stop, then give each an additional 2 turns to open the throttles a crack. 4. Start the engine and let it warm up for 10 min until it is nice and hot. (Don't worry about rpms unless they are too low). 5. Measure the air flow into each carb and adjust the idle stop screws until you get the air balanced AND such that you have lowered the rpms to between 650 and 850rpms. Hopefully this will get you in the ball park before you have to mess with the enrichment screws and linkage.

-

Triple OER/SK carb issues, not balancing (SOLVED)

How does the fuel level in carb 2 compare against the other two when you remove the lid. Also does the fuel needle valve work properly in #2? If it is not a fuel issue causing the lean cylinders then maybe it is valves.