Everything posted by 240260280

-

Does anyone have these for sale, or know where to find ?

https://zcardepot.com/products/engine-splash-pan-guard-240z#

-

Does anyone have these for sale, or know where to find ?

Splash Pan is often used.

-

price on a good condition interior tial light panel Series 1

The part is not rare like some of the 1969 parts but they are a little difficult to obtain. $200 to $300 seems fair as later ones are ~ $60 on ebay.

-

Do you read Playboy or race a Datsun? What sort of man are you?.

It must have made the BRE team angry after being portrayed that way.

-

Bright Links On Timing Chain - Line Up Every 11 Rotations

The Spinal Tap Chain.

-

Bright Links On Timing Chain - Line Up Every 11 Rotations

Bright ideas come from bright people! Thanks!

-

First Engine Start After One Year Of Restoration

The 78 has an electrical fuel pump that should be filled with fuel when running. All of the cranking for oil to flow will mostly have the fuel pump running... but the 78 seems to have a pump controlled by oil pressure so I would guess no oil pressure means no fuel pump running. Be aware of this.

-

Bad Spacer, BAD!

Give the man a lathe!

-

Picking up a 1977 280z 6 Hours Away. Tips?

Outer tie rod ends are easier than ball joints to replace. Just a nut at one end and a small ball joint at the other. Don't be intimidated. If you can change the suspension parts you can easily do the steering parts. The only trick is to match the length of the new rod with the old. Counting threads may be helpful if the rods are similar. FYI: The trick to doing a suspension is ensuring it is loaded with the car's weight before tightening to spec. To do this simply work on one corner and install all parts loosely loosely (with the car on jack stands) Note: do not fit sway bar endlink hardware yet. Then put a jack under the suspension corner you are working and jack until that part of the car lifts a few mm off the nearest jack stand. Then torque all nuts and bolts. The Tension/Compression rod must be snug but still free to swing up and down otherwise, if too tight, it will load your suspension. You should check this before connecting the free end to the control arm end. To do the sway bar, finish torquing both sides as per above then have the car on jack stands and put jacks under both front control arms/ball joint area to lift them up so that the endlinks can be fitted. Sway bar end links are hard to install with one side hanging.

-

First Engine Start After One Year Of Restoration

Change oil. Put fresh gas in tank. Remove Valve Cover. Pour oil over cam and rocker lobes. Disconnect 12v lead to coil. Crank engine while pouring oil on cam. Keep cranking until pumped oil comes out of cam lobe holes. Once you verify oil is pumping, you can then close valve cover, reconnect 12v to coil, and start car.

-

Do you read Playboy or race a Datsun? What sort of man are you?.

-

Bad Spacer, BAD!

https://globalnews.ca/news/3559236/humboldt-rcmp-fake-canadian-currency-blue-chinese-characters/

-

72 Fairlady Z never converted to US requirements

Alan, Were those the same rubber mats that came on the early exports?

-

72 Fairlady Z never converted to US requirements

Very Nice. I would guess $40k to $60k

-

72 Fairlady Z never converted to US requirements

There are actually many that were brought back. Prices are still high. https://www.classiczcars.com/forums/topic/58665-1972-fairlady-z-value/ https://www.classiczcars.com/forums/topic/62503-77-fairlady-z-on-craigslist/?tab=comments#comment-579787 https://bringatrailer.com/listing/1972-datsun-s30-fairlady-z-right-hand-drive-japan-only/ Please post pics and the rest of the gang here can help you out. There are also experts from UK an Japan here who have great knowledge. @HS30-H @kats@Mike B

-

72 Fairlady Z never converted to US requirements

bring a trailer or hemmings

-

Mikunis, but want a daily/recreational driver

Mikuni's are similar to Webers. This site might help you: http://240260280.com/Tech/Carbs/Weber/DCOE Theory Operation and Tuning.html

-

Mikunis, but want a daily/recreational driver

small venturi ~28mm to 30mm makes for a nice street setup

-

Fouling spark plugs su carbs

Lowering the nozzle adds more fuel. The next thing to check is fuel level in the bowls and correct needle valve functioning.

-

Fouling spark plugs su carbs

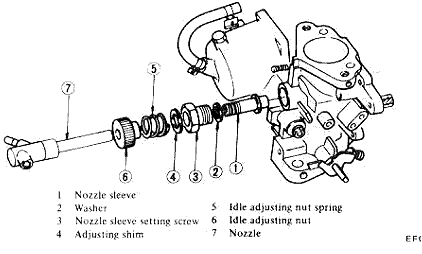

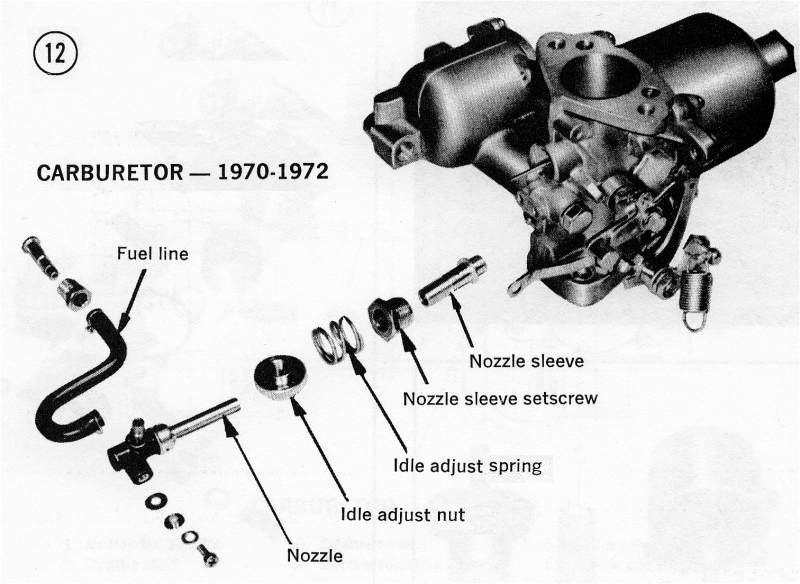

Great photos! Now it looks the same for front and rear. (needle tip showing amount is same) Try it. If the plugs need more colour, lower the nozzles 1/2 turn (3.5). If it runs too rich, raise the nozzles 1/2 turn (2.5).

-

Fouling spark plugs su carbs

to set both nozzle heights, turn Idle Adjusting Nut all the way up then turn it down 3 full turns.

-

Fouling spark plugs su carbs

the front nozzle needs to be lowered and the rear raised. Adjust nozzle height by turning Idle Adjust nut (6) (knurled knob)

-

Fouling spark plugs su carbs

- Fouling spark plugs su carbs

Disconnect choke cables and push Nozzle (7) in figure below, up from the bottom. They are probably stuck down. The outside of the brass nozzle's tube usually gets gummy and dirty over time and binds in the Nozzle Sleeve(1) You can remove the Nozzle and clean with carb cleaner and a scotchbrite pad but watch out for the screw and washers holding it to the lift arm (shown below): w- what's it worth?

- Fouling spark plugs su carbs

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.