Everything posted by 240260280

-

I hate Chinese "Metal"

Salt in the air from the Atlantic ocean (as fog and ocean spray), road salt, and daily winter temperature changes above and below freezing ensure all metal in this region gets a thorough thrashing of salty brine. It is easy to see the good metal from the bad metal. The Walker exhaust I put on my Rav is made from the same cheap crap and looks as bad as the rotor after a year! The original Toyota stuff lasts ~ 10 years or more. I would not buy a Korean car or Mazda here due to their accelerated rusting (compared to Honda and Toyota). Nissan and Subaru fall in between.

-

I hate Chinese "Metal"

Try not to cringe at the Premium Napa Metal from China. Yes it is a rotor...not the rusted hull of the titanic. Neat thing is that the rust makes the rotor thicker over time so it will always exceed the minimum wear thickness.

-

Steering Rack Disassembly and Refurb

Luv this thread!

-

Stainless steel headers, exhausts and JDM twin-pipe mufflers.

For a 1-5-3-6-2-4 sequence in our I6 engines, from an exhaust-cross-pulse & reversion perspective, are the front 3 and the back 3 collected together out of historical convenience of location? i.e. 123 go to one tube and 456 to the other? Another pattern of less convenience could be 135 going to one tube and 246 to another tube? Would something like a 2 to 3 to 1 be better? i.e. 15 to A, 36 to B, 24 to C then ABC to 1?

-

260z interlock TSB

I'll get it out this week.

-

Steering Rack Disassembly and Refurb

I agree. It looks like the concentric grooves were filled to maintain alignment and to prevent the aluminum mounting flange from sliding up and down the tube (left/right relative to cars direction).... not to prevent rotating.

- Triple webers DCOE 40

-

Triple webers DCOE 40

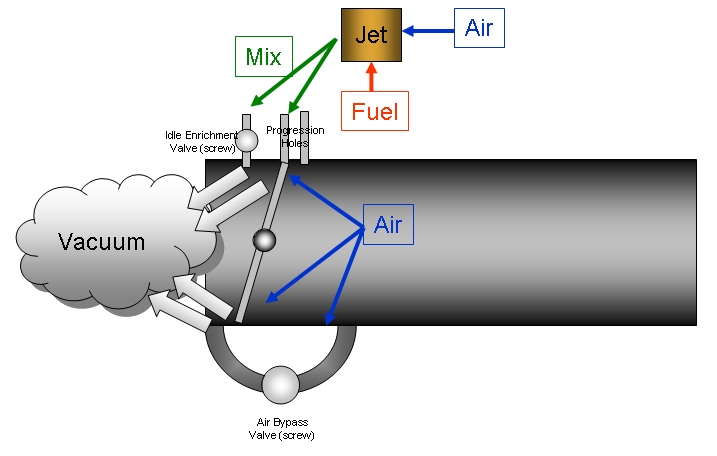

At idle, the only places for air to pass to the cylinders are: On Carbs: 1. Idle enrichment screws. If these are open too much or if the idle jets are too large (have too much air and fuel passing through large drillings) 2. Throttle plate air bypass (built into 40DCOE 151 and 45DCOE152 carbs). Early carbs like your 40DCOE 18's may have holes drilled in throttle plates. 3. Twisted throttle shafts (one plate closed but the other is partially open...usually on early carbs with brass rods). On Intake: 1. Poor sealing between carb and manifold (loose hardware where softmount grommets/thackery washers are located). 2. Poor sealing between head and manifold. 3. Air leak from brake booster. 4. Other (such as you PCV fitting). What are your idle jet sizes? For a next step, I would recommend that you check for all of the manifold leaks then if no leak is found: Keep push rods off and, with engine running, start turning in idle enrichment screws in to full stop then back out to 1/2 turn (gentle pressure at full stop is fine). For early DCOE's like yours, the taper on the idle enrichment is rather abrupt so a small turn lets a lot of air and fuel pass. Most early carbs work between 1/2 to 3/4 turn out. Yours at 3/4 are way out there. Read this if you want your head to hurt: http://240260280.com/Tech/Carbs/Weber/DCOE Theory Operation and Tuning.html :)

-

Triple webers DCOE 40

Thanks. Great info. Can you disconnect the push rods to make sure the throttle plates are at full stop? This could be the issue. Once you get the carbs air balanced and a nice idle, then you can attach the push rods to verify the same air flow( i.e. the push rods are not pushing at idle).

-

Triple webers DCOE 40

Can you write the full tipo and no for each carb like below? For your fast idle issue, set the timing at 15 degrees at idle, disconnect the push rod to each carb then start closing each throttle plate using the idle stop screw on each carb and see if you can get idle down. (this is a quick check). For next step: You will need to report idle jets and set idle enrichment screws our same amount then measure air flow in each throat. btw is your engine stock 2.4 with stock cam?

- Triple webers DCOE 40

-

Home Built Z 'Full video build'

Here is how the pros fake the gap. Bondo and parallel blade.

-

Steering Rack Disassembly and Refurb

Or drive it out then re-insert

-

Steering Rack Disassembly and Refurb

Fashion a small crowbar like piece of metal with flat blade end ground narrow to push pin.

-

Triple carb airboxes/heat shields

- Triple carb airboxes/heat shields

If you jet without an air filter, then add one that is restrictive, it will act like an old fashion choke and move the manifold vacuum further up the throat of the carb and cause richness. Make sure your filter flows freely and check a/f after adding.- New vinyl question

Yes, extra to be trimmed. Those pics are of initial fitting.- New vinyl question

- Triple OER/SK carb issues, not balancing (SOLVED)

AKA "soft mount": Rubber O ring insulators between the carb and manifold. The carbs are then secured with either bolts passing through rubber grommets or thackeray washers.- Datsun-240z Vs Fairlady-z432

I think a 3.364 gear would be great in a Z used for long trips (like going to Zcon in October).- Datsun-240z Vs Fairlady-z432

I think this is a little optimistic. Maybe the goal was to get 200kph at 12 o'clock position?- I hate Chinese "Metal"

But how hard is it to **** up a rotor.... the easiest thing to make on a car? It is made with one metal, on tools that have been around for hundreds of years, it has no moving parts, yet they turn it into a polished turd by making it look like a rotor but use the worst steel known to mankind. The only lesson I learned is that the crooks at Napa sell $15 to $70 rotors that are all the same Chinese $^!#. None are worth buying.- I hate Chinese "Metal"

Possibly but when you get things manufactured in China, you generally need to QA every item to ensure quality. Who can do this? It is usually statistical samples that are required to maintain quality.... and unless you have boots on the ground who can not be bought or tricked and can take truly random samples then you are screwed as the manufacturers will play the tricks to cheat. The first rule of doing business is to know that lying is OK. The second rule is that certifications, qualifications, and any quality document is either forged or a rubber stamp. When this crooked system hits your raw materials supply chain, you get steel screws in the first batch then white metal in all the rest until you complain.- I hate Chinese "Metal"

I think it is both but more China itself. I used Chinese kit when I worked for a Chinese company and the metal in their products made for the Chinese market and rest-of-world market was pure crap: stripped threads, no reinforcing, "soft" bolts, chromed EMF edge shielding that crumbled like snow when inserting a circuit pack. My friends in China only bought non-Chinese produced goods when possible.- Datsun-240z Vs Fairlady-z432

Kats, @moelk made very nice speedometer face plate reproductions on this thread: - Triple carb airboxes/heat shields

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.