Everything posted by 7tooZ

-

Optimal performing exhaust for street

-

Optimal performing exhaust for street

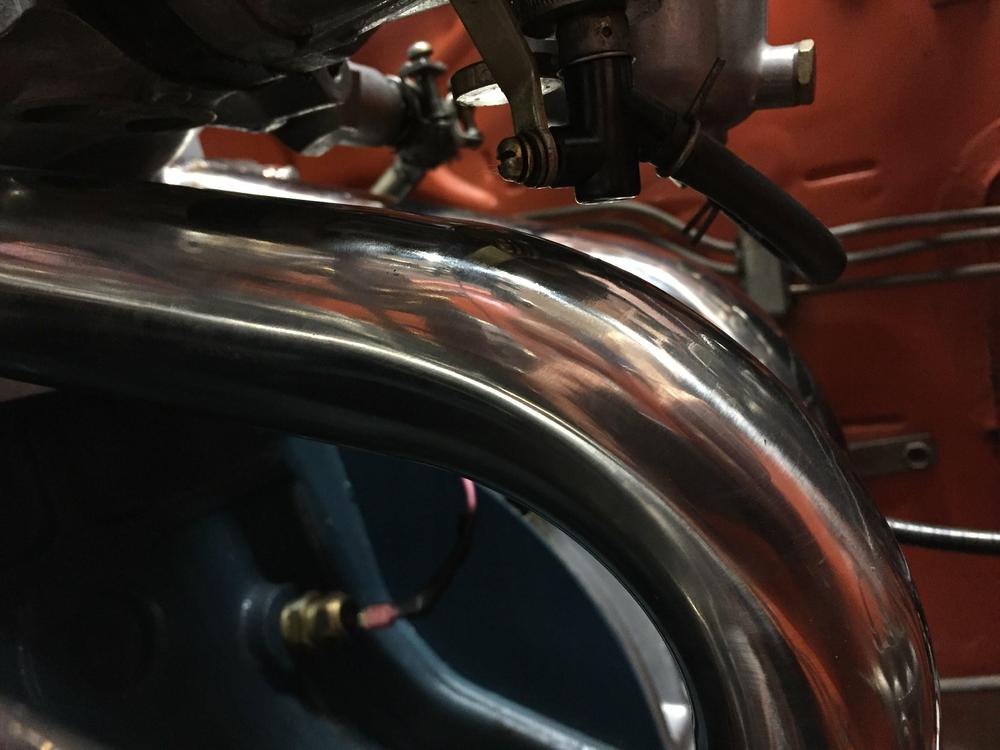

my short story is I purchased the full system with the JDM muffler. installed with no issues except the number six tube is so close to the Lower SU hose I never felt comfortable. Sean then sent me a Race header where the six tube is away from the SU. seemed okay until I installed it. The lower tube contacted the driver side frame. Tried everything I could to move things but nothing worked. Someone else here had the same issue. So I abandoned the header idea. Too much trouble for a basically stock engine. So I think I have the first dyno pull with a earlier exhaust. Stock exhaust manifold, stock down tube modified to a 2.25 in pipe a glass pak resonator and a Flowmaster muffler. My second pull is with Zstory full system using the Race/street header. This spring I plan to do another using my current system, stock manifold with a stock style down tube mated to the Zstory exhaust. I’ll be interested to see what difference there is. @S30Driver During my process I discovered my original down pipe flange was bad. I had a new one that had already been converted to 2 into 1, 2.5” Pipe. I bought clamps that matched Sean’s clamps installed it then had a local shop match the two together. They did all of the welding (very tidy). Here is photo after ceramic coating.

-

R200 Comparison

Just curious. Why are are you replacing your R180 ?

-

Parts for Sale: Z-story Stainless header $300

Sold

-

Parts for Sale: Z-story Stainless header $300

Sold

-

Optimal performing exhaust for street

Jeff i just noticed that I did not post those Dyno pulls. So I will go to work to find the earliest one as I have the later one saved on line. Also our club does a dyno day annually and I made a change that could be interesting. I have removed the Zstory header and replaced it with a ceramic coated stock manifold mated the the Zstory stainless system. We will be doing the dyno day in March of May at the same shop. In the meantime I will look for the earlier chart back to you soon. don.

- 240z in Portland

-

240z in Portland

Yah, i havent been able to locate the seller. I have someone who is interested.

-

240z in Portland

Do any of you Oregon members know this car or seller? https://www.classic.com/veh/1971-datsun-240z-series-i-hls3014396-n8vkGYp/ Looking for a contact number

-

center console 1971 question

Location of the three screw holes near the rear of the console will tell you a lot on which console came in that car. Has your car been converted to a five speed if so I have seen where the later console was used to allow for the change in the shifter location. a picture of the console you have and the screw hole location would help. D

-

Exhaust Manifold to Down-pipe Gasket

@Randalla I discovered that the flange on my original down pipe was no longer flat after fighting the same issue for a couple years. Using two gaskets helped for a while. Ultimately i purchased a new down pipe and had it mated to my new Zstory exhaust then ceramic coated it and the manifold. Problem solved. Good luck.

-

Parts Availability?

If you can avoid body or rust repair I think you will find owning and enjoy your car is reasonable. Shop time is always an expensive part of repairs. This forum offers repair manual online and many participants here are experts. Learning how to search the forum will help with most questions or just ask. You will probably get multiple responses. Pull up the members map and get to know the members near you and you may find hands on help. A 79 Fj is a classic

-

Parts Availability?

Welcome to the group. It has been my experience that finding parts is not necessarily hard as there are many available from after market suppliers. If you are planning a restoration to originality there some that hard to find but not impossible. You can find a few truly OEM parts at places like Ebay and other auction sites including Japan. Used parts are readily available from multiple sources. This site will be helpful in researching correct and quality parts. We will all be looking forward to seeing and hearing more about your car.

-

New member

Hey David is this post from you? Or @Rising_sun_racing either way I am pretty familiar with Ephrata since I grew up in Quincy. Ephrata was the first time I saw a 240z in person. Been taken by them ever since. @Rising_sun_racingthe battery is nothing special just a Optima red top. Thanks for compliment on the car. don

-

240z 1972

I live about 10 miles from him if I can be of help.

-

240z Door Mirrors OEM vs Replica

I agree from here it looks good. If you want one.

-

240Z GasTank vent hose??????

Yes back on the road. New clutch, bearing, turned flywheel, and new main seal. Replaced the vent hose, cleaned up the exhaust mounts and installed the ceramic coated exhaust down tube.

-

240Z GasTank vent hose??????

@CanTechZ Perfect that was exactly what I was looking for. Well done. That pretty much answers my second question about the critical size of the interior diameter of that vent hose. Carl Beck stated: “The Gas Tank has to be vented to allow air to escape as liquid gasoline is pumped in, otherwise an air pocket would form at the top of the tank and prevent the tank from filling completely. Note that the Filler Neck enters the tank well below the top of the tank. Air also has to be drawn into the tank as the fuel is pumped out to prevent a vacuum from forming in the tank.” So my thinking is that (approx) a 1/2” maybe the minimum size I.D. to allow the flow of fuel into the tank without shutting off the pump. The vacuum “forming in the tank”part I assume would require even less I.D. thanks everyone

-

240Z GasTank vent hose??????

Thanks David. I appreciate your help.

-

240Z GasTank vent hose??????

Have some on order, but looking more specific measurements. I spent a half day reading the past posts and other options for this issue. Anybody have a gas tank sitting on the floor and could get me accurate measurements.

-

240Z GasTank vent hose??????

Hmmm, I thought the O.D. Of the metal tube is 5/8”? Wouldn’t that make the inside say 5/16” or 1/2”? Hate to drop the tank just get a micrometer on the inside when someone has a tank out already. Assuming the I.D. Is 5/8” then if the vent line is reduced to say 1/2” would the restriction cause an issue when filling the tank or would it just require a slower flow at the gas pump?

-

240Z GasTank vent hose??????

Recently while I was reinstalling my exhaust I happened to notice my rear most vent hose (180 degree section) has collapsed. So After reading most of the prior posts I could locate, I have two basic questions: -what is the inside diameter of the upper rear vent tube on the tank? -is the inside diameter of the hose that connects to that tube “critical”? help is appreciated.

-

Which rear spoiler

@go z racer, go. Nice thanks for the pix.

-

Which rear spoiler

Nice view would you mind getting a front view and closeups

-

Which rear spoiler

I really like that one too. I have same front as yours thanks