Everything posted by Ed

-

240z MSA AC compressor coversion

Stephen, I've heard that if you have copper lines the R134a won't work as well as the R12. Have you heard anything like this? Ed

-

Finish my project--Mechanic needed

Too bad you don't live here or I live there. I'd love to take on your project.

-

I got my new beauty ('73 240Z)

Nice, a little bit of hammering a little bondo maybe some duct tape. She will be like new. Just kidding.

-

I need some parts. Anyone have these?

Do you have a MSA or VB catalog? Or do you want all used stuff?

- licence plate light

-

licence plate light

I'm finishing up the tail light finisher panel and the licence plate light assembly. I was wondering if they were all the same color? The tail light finisher panel is that dull grey (I forget the technical name) are they both the same?

-

Rear Sway Bar Installation Kit NLA - now what?

Eric, I installed a rear sway bar from a 74, 260Z on my 73. I used the factory brackets that are welded to the body. MSA has the bushings for it. Maybe look for a 74 bar and sell your Nismo one.

-

How to mount 70-72 bumpers on a 73?

On the inside of the fender in front of the radiator where the hood hinges are. Just below the hood hinges are two holes with nuts on the other side. This is where the early brackets go.

-

eBay beauty

Why can't people take five minutes to clean there car before picture time?

-

Who Needs Z Parts?

What color is the interior?

-

71 240Z Valve Problem

Something is wrong. Inspect the entire valve train. There should be plenty of slack when the adjuster is all the way down. Is the cam in the correct position to check that particular valve? Remove all the spark plugs, and try turning the engine over by hand (big socket on the crankshaft bolt). Pay attention to those #1-3 exhaust valves when it's there time to open. Is there any resistance? The valve should open and AND close freely. When both intake and exhaust cam lobes are pointing up for that particular valve is when you check clearance. Do not start the engine until you figure out what is wrong. You could be damaging it more every time.

-

Emblem ideas?

Maybe some polished aluminum or stainless buttons to fill the holes. Or some spikes like those used for a dog collar. Cell phone antenna, Nissan badge. 350 "Z" badge (just the "Z"). Once in a while on e-bay there will ba a Datsun "grill" badge. Me, I'd try filling the hole from the rear with some epoxy, then filling the front of the hole with some touch-up paint, sand smooth and polish.

-

Indy 500 Not Won By Danica Patrick!

I feel bad for the fans. I went in 2003 and it was not cheap. $150 for the ticket. $300 for the hotel. $80 for gas. $100 for food. $100 in souvenirs. A ticket refund would only scratch the surface. IMO they will be lucky if they sold as many tickets for next year, if there is a next year.

-

73 240z L28 4spd

Hi Rick, and welcome to the club! You will probably get different opinions on the engine but I think that most of the people here that needed to swap engines have gone to the L28. The L28 is more powerful. Bigger bore = more horsepower. Unless the entire car was kept original (including the carbs) the 73 isn't as popular as the early 70. Not to say it's the blacksheep of the 240's, IMO it is the most refined of the bunch. Not exactly sure what the problem with your car is. Give it a proper tune-up, from changing ALL the fluids to adjusting the valves. Timing, plugs, points, fuel filter and have the carbs adjusted. Once the engine is in tune and you still have the problem you mentioned you can start focusing on other parts that might be the culprit. If you don't have much experience working on Zed's I would suggest to buy yourself a shop manual first, Chiltons or Hayes from your local auto parts supplier. Do a little reading on tune up's then take it to a qualified & experienced mechanic. There are quite a few members in San Diego maybe they can help. If not I would recommend talking to the guys at "ZWhizz" they are in the book and have helped me on more than one occasion. Even though they say your not supposed to be in the shop area. Once your car goes behind the garage door take a little walk and watch what the mechanic does. You can learn a lot in just a few minutes. Good luck. Ed

-

- VIDEO - Heres a short video of my High Compr. MSnS turbo 280Z

I think I got whiplash from the in car cam. Nice!

-

Mechanic suggestions - Detroit?

Crack open your phone book and start asking if they have anyone familiar with the datsun 240z. If they say; "Datsun??? Just bring it in and we'll take a look". Keep on dialing. Good Luck.

-

D head bolts

Those same bolts were on my 73, driveshaft to diff.

-

Welding

I would have to agree with everyone's posts. I've been welding for 20 years (as a hobby) and I'm still learning. You can't just grab two pieces of metal put them together and start welding. There is a lot of preparation and fabrication. Choosing the correct welder for the job is also very important. Too strong and you will burn holes all day, to weak and your welds won't hold. And what does your finished product need to look like? If you really feel the need to tackle this job yourself buy some extra pieces of 18 guage sheet metal or use the pieces that you cut out of your car and practice, practice, practice. Your not any good unless you burn yourself a couple of times.

-

"Easy Out" bolt remover?

When you start to drill the broken bolt do as previously suggested and center punch the broken bolt. Accuracy is very important. Then start drilling first using a small bit 1/8, 9/64, or 5/32 will do. It is VERY important that you get the hole in the center and that you drill parallel with the bolt. After you have drilled out the center of the bolt spray some blaster in there. Then progressively increase the size of the drill bits (spraying blaster after every step) until you feel you are getting close to the threads. Now is the time to use the EZ out. Depending on the size of the last bit you used get the largest EZ out bit you can. DO NOT force the EZ out, they will break! Use some more heat if you have to but usually the heat generated from all the drilling will do. If you still can't get the bolt to budge then it's time to drill and tap ( If memory serves the bolt is a 8 X 1.25 so don't drill bigger than 9/32). The LAST thing you want is a broken EZ out on the frame. Don't forget your safety glasses.

-

Moron epidemic?

I bought some tie rod ends from VB about 6 months ago. They are repro's made in Taiwan or China and NOT Nissan.

-

drooool....

I don't think the clock works.

-

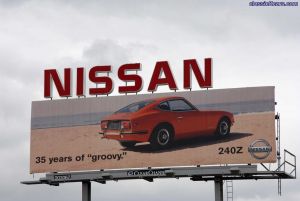

New Z Billboard

-

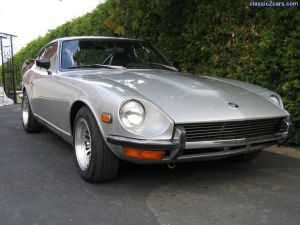

front_2

-

Cleaning tail light lens

The chrome strips were in decent shape. I polished them up a bit with some "never-dull" and repainted the black strip. Ed

-

Getting rid of my 72 parts car

On the e-brake handle, can I take a saw from the cabin area and cut the tube that is in the fenderwell area. Other wise it's going to take me a bit to get underneath to disconnect the linkage.