Everything posted by billgtp

-

Euro Balance Tune

I did the same on balance tube for my 71. Grind the lumps off and had it welded up

-

Fuel tank reproductions

Great product. I put one in my 71

-

Machine work on SU for roller bearings

He did tell me if I want new shafts he will make them out of stainless steel. But it was me that said no. I would like to see what the carbs do with just the new bearings. If I have a problem I will have him make shafts. He is not charging me a thing for doing this.

-

Machine work on SU for roller bearings

Throttle was milled from 10mm to 8mm. Its something they liked to do when he worked for electramotive. The picture , shining light up throttle shaft so you can see no light. So I feel the bearings are sealed for air leaks. I did move light around

-

Machine work on SU for roller bearings

- Machine work on SU for roller bearings

Carb. bodies returned today. picture of sealed needle bearing Bearings on throttle shaft. You can see the support with needle bearings Bearing in carb. body- Kyusha House Electronic Fuel Pump Bracket

I made own. Grannyknot is correct about $10 in materials- Machine work on SU for roller bearings

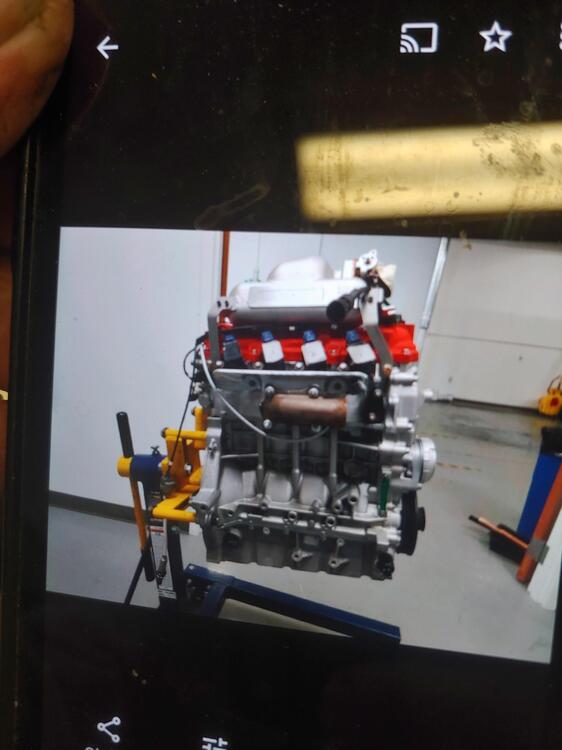

The engine is a Honda Fit for the Formula Ford. They just finished building it ran it on the dyno. No pictures of the car. They are just starting on bending the tubes to build the frame.- Machine work on SU for roller bearings

- Machine work on SU for roller bearings

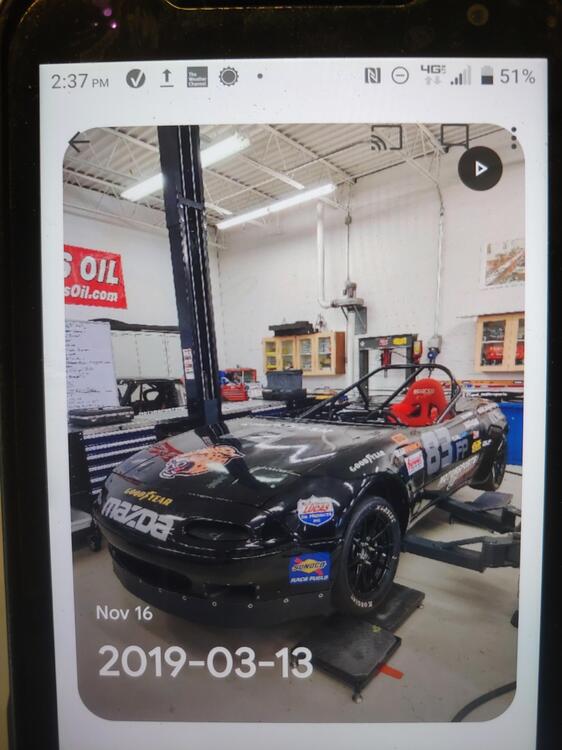

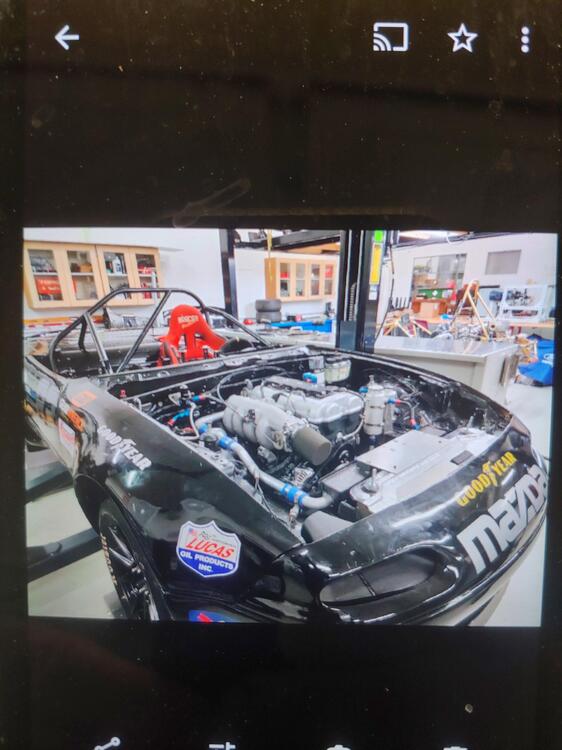

His been real busy. He teaches race car engineering and they have been building a Mazda miata and a formula ford for scca racing. The formula ford is their own design from the frame up. Soon as he does the shaft bores and install bearings I will post some pictures- Vintage air in 1971 240

The receiver drier I did not want it in engine compartment. I made mounts from aluminum rod, drilled and tap with 6mm tab. Something else Vintage air will make hard lines for you. There is a you tube video showing how to measure and bends you can make.- Vintage air in 1971 240

If you decide to use the hard lines from Vintage air do not use cheap tube benders purchase Imperial benders that are far better. I purchased mine from e bay at appox $40 (used). Another trick with using tube benders is to put a little grease on tool helps making a smooth bend. I was use dense foam between condenser and core support. This keeps all the air pulling though it and not from the sides. I do same with my radiator- Vintage air in 1971 240

More details?Just ask if you have a question. I purchased the Gen 11 mini basic kit, which does not come with a compressor or brackets. I purchased the under hood kit from auto a/c but dont do it. The only thing you can use is the ac compressor bracket. The condenser is why too small for r134. I will give some detail on the pictures I posted. All the hard lines are vintage pre made U Bent them lines. They come in lengths from 12 to 60 inches. If you look at the #6 high pressure line from receiver drier you see 2 joggles in it. I had to use the 60 inch line which was 4 inches too long, You cab get stainless lines and make your own. But the cost of the fittings and welding or solder them on did not look fun to me. The condenser is a 24 x 16 from Vintage air you want the largest you can mount (r134 likes big condenser) Also when you mount it do not put it in upside down like I have seen some people do. You have hot gas coming in at the top which as it travels down removes the heat becomes a liquid.- Vintage air in 1971 240

Almost done installing Vintage in my Z car. QZ16 has a good thread and it helped with some of my install. I had to use a bulkhead fitting because we had that side of firewall repaired due to a boom box or large speakers. A lot of holes, I also decide on using hardlines instead of rubber hoses. I like the look and less room. I installed the Vintage air controls into the original heat vent con- 1973 240z Custom Wiring From Scratch

- 1973 240z Custom Wiring From Scratch

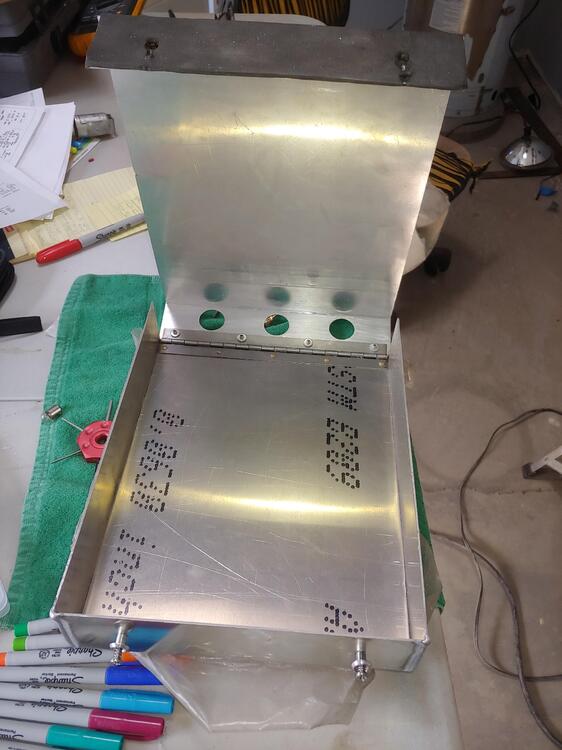

Won"t get into the pros and cons with electric fans. But for me its the only why to go. Did it on my 32 ford that I built. Matt on your relays I went though the same problem Spend all kinds of time at junk yards on the net looking for a relay box. Ended up having one made for me. You can go to any Hot Rod or custom car shop that does real fabrication work and they will build a box for you. Mine cost me $50 plus materials. I mounted it in front of the battery mount. Now my car had been hacked by POS where I even had to replace the right side if the firewall. First pic is relay box the lid has rubber seals on it to keep moisture out. It has a power relay to supply the relays above it. A ford enertia switch controls ground to fuel pump relay- Machine work on SU for roller bearings

As he explained to me this is to fit bore of carb so when he works on throttle shafts they are square with the carb throat. Butterfly and shaft will work smooth. He was a fabricator for cart race cars. Worked for electromotive, Dan Gurney, A J foyt knows a little more than I do. Also using 10mm length roller bearings for added support of throttle shaft instead of ball bearings.- The mystery of the secret Spare key box (in the frame)

Used to be real common. Hide a key- Machine work on SU for roller bearings

Next he will get a blank drill rod to line up throttle shaft bore. If you like I will post more pictures on his progress- Machine work on SU for roller bearings

I thought you guys would to see what my friend is doing to put bearings in the su bodies for the throttle shafts.First he made a fixture to hold body in a machine block on a mill- Engine rebuild smoking

I would do a cylinder leak down test before I take anything apart. At least this would give you idea of condition of lower end.- Machine work on SU carbs

The PO had fun with the air cleaner. He cut long slots all along the top and bottom of it. Thats what I was thinking the stacks but non where on the car when I saved out of a farm field.- Machine work on SU carbs

No. not machined on the exit- Machine work on SU carbs

Getting ready to clean carbs up and just notice the front of the carbs have been machined at angle to butter fly. I have never seen this done on SU carbs. Has anyone else seen this done?- Key buzzer and flasher relay

My car is 8/71 but I believe they used the same key warning buzzer up to early 260z. The wires to buzzer are yellow and red. Maybe these pictures will help you - Machine work on SU for roller bearings

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.