Everything posted by 240zadmire

-

1977 280z no power on fuel pump

Dug into my boxes (btw, boxes getting smaller and smaller... pretty happy about it) and found this. Look at the spring on the throttle body and notice there has to be something connect to that pin hole... low and behold, it supposes to bolt into one bold of the throttle bolt to the intake manifold. She now is so snappy. RPM goes right down when release the throttle or gas pedal. Need more clearance of the carpet but even with the obstructing of the new carpet, she is snappy. regards

-

1977 280z no power on fuel pump

one more thing forgot to mention should someone have similar issue is that the auxiliary next to the CSV also has bad electrical connection. Clean that as well. Placed order for the new connectors too. Lesson learned is that all new connectors work great. The ones I haven't replaced cause the issues. about the spring on the throttle, yeah. It is weak. I don't think there is a stronger spring out there. I might have to add another spring to the rod and pull it back and mount it to the throttle body. regards,

-

1977 280z no power on fuel pump

didn't know that is what Nissan did that. Apologies to previous owner. did read through the high idle section of the EFI bible. Follow instruction religiously. At least turn out the culprit was bad electrical connection at the 3 pins throttle body. Sand lightly about 30 strokes each pins... last instruction section page 61-68 or so to test voltage when key is in "On" position and notice some pins, the voltage is not the same as battery. Which lead to some resistant somewhere. Approximate 11.6 volts instead of 12.34 volts. Probable cause of this would be the dirty connectors somewhere. I will trace down later. When all instructions were completed, fire her up. Had to crank 3 times and she is up from a cool night. Pretty happy. The idle is approximate 2500 RPM or so and slowly drop down to 1500. Adjust the air intake from throttle body and able to bring her down to 1100 rpm and she is steady. No flickering on the RPM needle at all. I couldn't find the needle when using the strobe light. I must have painted the mark on the pulley. Will need to get under. one notice I see is that when rev her up, she is not return to idle immediately. She hovering around few hundreds where she peaks. Meaning if I rev her up to 2000rpm and release, she will come down to around 1500rpm or 1700rpm and stay. If I gently rev her up again and release, she goes down immediately to idle, which is 1100rpm. Just want to repeat my gratitude again for all the helps. Was beyond my expectations. any thoughts? regards

-

1977 280z no power on fuel pump

I think someone has similar problem here as well and suggest the EFI bible. Will look into it next. Let’s rest today, a successful day ?

-

1977 280z no power on fuel pump

Ladies and gentlemen, please sit down as I'm so ecstatic to share the news. I swapped the black and white connectors places for the main and fuel relays. White on left/top and black on the bottom/right. the kicker here is that common sense, in the USA, we're driving from the right side of the street. No one need to tell us. We intuitively just know that without paying any attention. So, as you've seen my previous posts about battery terminals and everyone is saying fusible link need to be on the positive side. Long story short, we commonly known that red color represent hot/positive and black is for cold/negative at least for battery. Guess what, for whatever reason, the previous owner either replace or got a spare one ... and swap it around. Black is positive and red is negative. I swapped the black and connects to the positive terminal and the starter and red to the engine block from the negative terminal. Took 2 cranks and she fires up right away. Boy, what a sensation I tell you. Better than a cold beer after working under the sun till your lips crack. Better !!!!. I've been working on this for 3 years and I had this car worked before. It probably too long ago and memory play tricks on me as I'm near the finish line. Plus the relay is a real killer as well as @Captain Obvious stated, perhaps try swap it and see. Well, swapping battery terminals and relays did the trick. I'm not out of the wood yet ? The idle is so violent. as soon as see starts, she climb to 2500-3000 RPM and fluctuate repeatedly. Like some one keep pressing/releasing the gas pedal. Any ideas I should look at is much appreciated. Thanks again for all of you helping me and continue so. Much appreciated. regards,

-

1977 280z no power on fuel pump

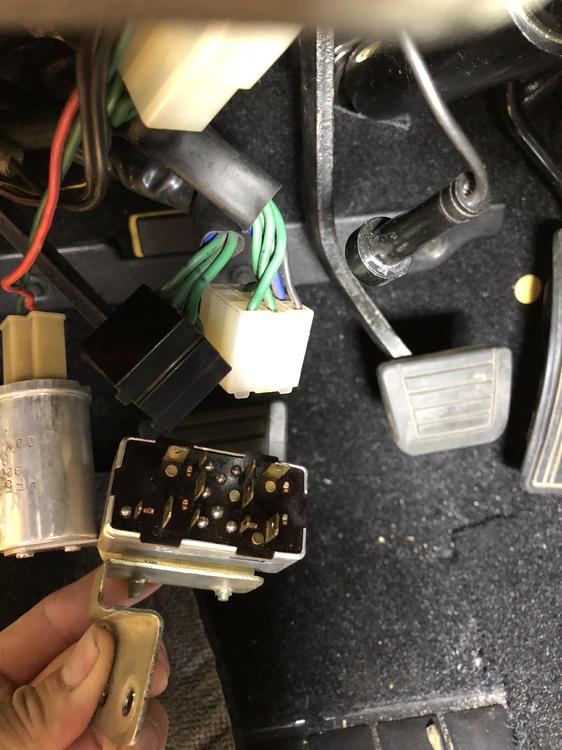

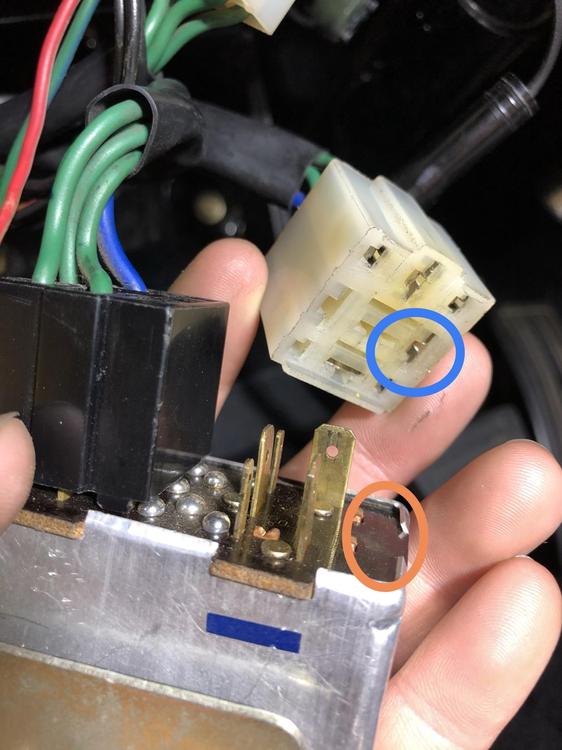

Hi all, There are only 2 possible ways to plug then white and black connectors. Leaving as is, is one way, the other is swap white with black. The face of the relay has number on it. Don’t know if you can see it but it is 88d on top left

-

1977 280z no power on fuel pump

-

1977 280z no power on fuel pump

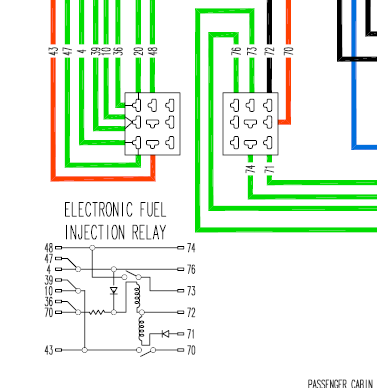

Have I gone mad? pin 70 goes nowhere. Please see picture. i decided to disconnect a pair of wire at the battery and only connect the fusible link from positive to the pin 70. But then again, pin 70 goes no where. Am I reverse connect something?

-

1977 280z no power on fuel pump

@wal280z in term of wires, it’s always setup like this. I forgot if all connection need to connect or not. But to answer your question, the wire I lift up come from positive terminal with a female out out. The wire cable come from negative is male connector that connect to a female connector that has black and white wires. It is very likely incorrect connection or one of the wire does not need to connect to anywhere. If that is the case I must have drop/lost the adapter when I strip down the car. Otherwise, the possible connection would’ve from the positive, the wire I lift directly connect to negative. Doesn’t make sense to me. Yes. The connector you circled. I found it and it is right near the combine power/fuel relay. i will check pin 70 again. Possible reverse power. stay tune regards and thanks for the new wire diagram/schema

-

1977 280z no power on fuel pump

Hi all, connect pin 70 directly to green/blue wire at the rear of passenger seat and leave the black wire intact, the pump spins. reconnect green/blue wire to its rightful place. Run power to pin 74 produce a small spark. I know, I was impatient to buy a test bulb/pen. Definitely a short circuit somewhere. traced the pin 74 leads to a connector of 6 pins with only 5 wires. It ultimately ends at wire connect to the pump at the rear of the passenger. I tried to see where is that mysterious 6 pins, 5 wires at the fuse box area on the passenger and could not find it. It has to be somewhere. the analog voltmeter is really handy. Must get one. regards

-

1977 280z no power on fuel pump

if you address to me offended by "written" by engineer? no sir. I'm thick skin! Shameless some might say ;). Isn't all engineers are like that? The pin 70 R/W is 11.4V. Battery is 12.3V. Some resistance somewhere? regards

-

1977 280z no power on fuel pump

I'm an engineer myself too. Not mechanical or electrical so I know exactly what you meant by "written" by engineer instead of tech writer ... I will follow both your suggestions of troubleshooting and find issue. Meanwhile, I'll hot wire the pump to see if the pump actually deliver fuel to the injector without cranking the engine up. stay tune. Learn a lot actually. regards

-

1977 280z no power on fuel pump

dumb question. will it cause more problems if I hot wire the fuel pump so that I can start the car? This will by pass all the safety of the intended relays/sensors.... of course, for the troubleshooting part to make sure continuous fuel and pressure will keep the car running. what do you think? regards

-

1977 280z no power on fuel pump

i do have the FSM and the schematic from https://www.atlanticz.ca/zclub/techtips/wiringdiagrams/F77ZCAR-WIRING1.pdf. I've been tracing wires and trying to make sense out of it. Below are what I replaced: - engine piston rings - valve seals - head gasket - timing chain - valve springs - fuel injectors' harness - spark plugs - spark wires - ignition coil - distributor cap - vacuum hoses - thermostat - radiator hoses - radiator fan clutch - dashboard bulbs. part of the tear down/rebuild, above those were replaced. I hope I didn't screw up too deep that there is no point of return. The plus side to this madness was that the suggestion to squirt starting fluid and see if engine work, and it did fire up right away. I was really, really relieve. I hope now it boil down to electrical issue somewhere that missing connection/bad grounding ... regards,

-

1977 280z no power on fuel pump

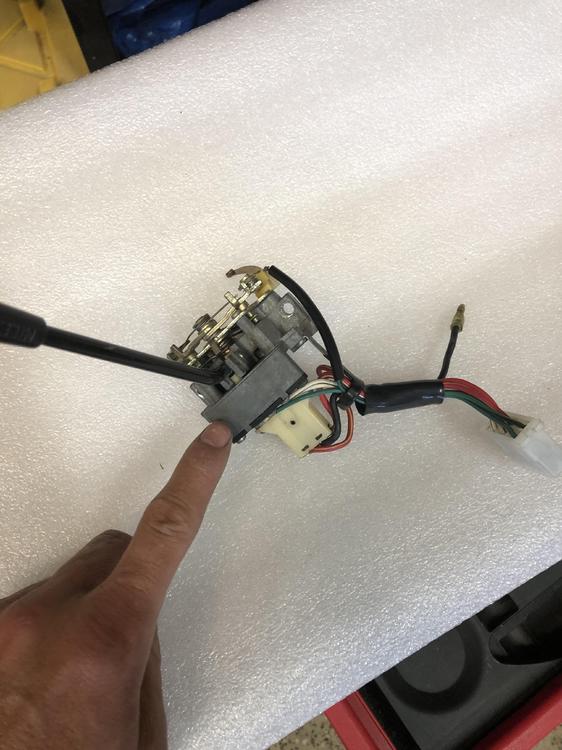

Hi all, The micro switch on the steering column on the signal side? Is it the one where my finger point to it or the plastic where 3 wires coming in/out? And the fusible link for the ignition at the positive terminal? Please see the attach photos also, I haven’t connect any light to the car yet such as signal, beam, rear. I did however replace all the small bulbs inside the dashboard since I took it out and might as well replace them all just in case any burn out later. I’ve replaced them all with LED. Few tiny wedge bulbs I left a lone as I couldn’t find suitable ones. since I don’t have signal lights connected, turning signal only get steady left/right. I think it is normal?! i will cleanup the micro switch later

-

1977 280z no power on fuel pump

Another finding, doesn’t look like oil pressure sending unit has continuity. I took it off the engine and one pin on a terminal and the other on the body and got 115 number. Usually if there is a continuity, i get a continuous beep. Check the resistant and I got 89 ohms. could that be it? regards

-

1977 280z no power on fuel pump

It’s a 7 pins AFM and the oil is one pin connector. regards

-

1977 280z no power on fuel pump

Hello all, put a few squirt of engine starting fluid, start the engine and it fires up right away. Please see the video. As soon as the fume is done, engine stops as expected. Please see the video. regards IMG_1301.MOV

-

1977 280z no power on fuel pump

Hi all, apologies if I miss state the current situation. - the car crank up - there sparks on each spark plug - direct wire connect to fuel pump, the pump spin - fusible links have continuity - starter works hence sparks on spark plugs - turn the key to on, a noise coming out from AFM connect voltmeter to fuel pump while turning the key to start got zero volt. That’s why I start from to trouble shoot why there is no power to the fuel pump. i will keep digging from the manual to find info. I’ll be honest, tracing wire diagrams and the symbols like relay is pretty tough for me. The answer is all there. It just doesn’t make much sense to me is all. I’ll keep looking but if you have more info, please help. @Zed Head I’m not offended that easy. If I don’t know, I don’t know. Remember you help me the other day with the brake could not hold pressure!? It’s only easy if someone point it out what you did wrong. It would take me days if not weeks to figure it out. But once you explained, made perfect sense and I thank you for that. I learned something. regards

-

1977 280z no power on fuel pump

@Dave WM History of the car was that it sat for 10+ years. Was running very before it sat there, previous owner stated. Bought and able to get it working and confirmed still very rough on idle. Replace all vacuum hoses and clean up all electric connectors where possible. Seem to fix it. However, after a drive when put back in neutral at stop light, high rpm stayed for at least 20 seconds before idle normal. long story short, few rust here and there, paint faded... pull the engine to fix the rust.... and we all know, one thing led to another, couple of years gone by, all rust spots fixed and paint inside out.... put the car back to where it rightfully... and now I’m trouble shooting it. must be some ground/wire broken somewhere. I don’t know. regards

-

1977 280z no power on fuel pump

@Zed Head and all, Just before I left for work, I did the below: I move the AFM flap all the way to the left and check pin 20. Set voltmeter to continuity test and got something like 572. Not sure what that mean. Look at the circuit diagrams, seem like CSV and Thermotimer are connected in parallel. I traced the circuit between the CSV and Thermotimer, one pin on CSV and the other on thermotimer and seem to have continuity. repeat the same steps for the other pin and also got the continuity. I did replace all the fuel injection connectors as they wore out. I was very careful about which pin for which side. I also did replace the connector for the thermotimer and the coolant temperature. I did not replace the CSV and Auxiliary connectors as I ran out of connector. I was very careful about the which wire goes to which. Hopefully I didn't screw up somewhere by connect positive to negative wires. I will check again when I get back home. Thank you all for the help. will keep everyone posted. regards

-

1977 280z no power on fuel pump

Hi car is early 1977 280z I recently put back the car after take it out for painting interior, engine bay. When turn ignition to on I hear no sound on the fuel pump. what I did: - connect direct power from battery to the 2 wire on the passenger side and hear fuel pump. Which means pump is good. Check continuity from the wire to the relay connector is good. - check the continuity base on the fuel injector bible on pin 20 against ground, no continuity. - ignition coil and spark plugs has electrical. funny thing is that both the pins of the cold start valve are positive. I connect positive pin from the voltmeter to battery and the negative to any pin has 12 volts. what did I do wrong? Some wire definitely messup thanks

-

1977 280z Brake pressure not hold

You sir or madam Zed Head, you’ve live up to your name. I’ve switch the calipers around so that the bleed screws upward. It works like a charm. I’ve struggle for couple of days and you made it seem so simple. Much much appreciated regards

-

1977 280z Brake pressure not hold

Hi Zed Head, The car is early 1977. I think the build date was July. you’re right the bleed screws are on the bottom and the big reservoir is for the front calipers. Makes perfect sense as gravity will pull the fluid down no matter how you bleed it. Only way can bleed successfully would have to hang the car bottom up to the ceiling or flip it upside down. I will switch calibers after kids are in bed and will update status thanks

-

1977 280z Brake pressure not hold

Hi, apologies for not being clear. the car was sitting for years. Before I disassemble to work on the car, it was working. However, a lot of dirt in the master cylinder. I took it apart and clean it with brake cleaning aerosol. I did not bench bleed it. I put back and bleed the master cylinder as it mounted on the car. i went ahead and bleed the other drums and disk as mentioned above. Brake very soft afterward and I notice moist on the low brake boost. Open it up and notice wetness there. I mean you feel the wet with your finger not dripping. Figure this is 40+ years old, time to get a new one. this time I bench bleed it before put in the car. For measure, I bleed the master cylinder again and go about other drum and disk as mentioned above. It is better but pressure not lock. and yes, even if I press the pedal all the way to the floor. Still not lock. 2 more info that I forgot. - I did rebuilt the front calipers and test the calipers before putting the pads in to make sure they work without leak. The rear ones are new. - if I pump the brake repeat couple of time fast, I notice the smaller reservoir toward the front of the engine shoot fluid up. It is not bubble but rather like you use your straw dip into water gently blow it. hope it help and hope you guys can help me