Everything posted by Racer X

-

240z video repaint indonesia

The finish systems in use today don't spray well through a suction (cup on bottom) type spray gun. The materials are high solids, low solvent, and work optimally in a gravity gun (cup on top). For sure, the cheap spray guns on eVilBay are junk. A good Devilbiss gun will get the job done, I bought mine at the local auto body paint and supply house. I do still use my old Devilbiss suction gun, for ordinary lacquer based primer, and metal etching primer, but haven't sprayed topcoat through it for over 25 years.

-

Z's on BAT and other places collection

Cars are bought, sold, registered and licensed based on their model year, not the date of manufacture.

-

Z's on BAT and other places collection

They are called hand stamps (or punches). They come in sets, numbers, letters, symbols, and in various fonts and sizes.

-

Z's on BAT and other places collection

You have a good hand for VIN poker. Three of a kind, lucky seven.

-

Z's on BAT and other places collection

You have a good hand for VIN poker. Three of a kind, lucky seven.

-

I thought I was done with Z cars

I have a friend in Rock Hill. She says it's fun to be a Gamecocks fan, 'cause she can chant, "Go Cocks!", repeatedly.

-

240z video repaint indonesia

I meant to mention the lack of proper PPE.

-

240z video repaint indonesia

It also looks like they didn't rebuild the engine or transmission either. And yes, the end result did look good, considering the shop. Reminds me of a video I saw of Vietnamese guys squatting in mud, remanufacturing grey market tractors. They were tearing engines, gearcases and hydraulic systems down, freshening them up, bolting them back together, spraying a new layer of paint, crating them up and shipping them to the US.

-

240z video repaint indonesia

They didn’t remove the fenders until late in the process for one. Cleaning up the backside should be the first thing, before repairing and prepping the exterior. Same for the engine bay, interior, and the underside of the chassis. The very first order of business after stripping the chassis should have been the floor repairs, and other rust mitigation. Then begin the bodywork and prep for refinish. I also noticed they didn’t disassemble the struts before repainting them. They also didn’t show if the gas tank was refurbished.

-

240z video repaint indonesia

There were a few things during the video that caused me to wonder about their methods and processes, but overall, they did a decent job, and with a result that should give the car another 30 to 40 years of life.

-

Z's on BAT and other places collection

Using up existing stock before moving to the updated parts.

-

Z's on BAT and other places collection

-

Z's on BAT and other places collection

-

Z's on BAT and other places collection

-

Z's on BAT and other places collection

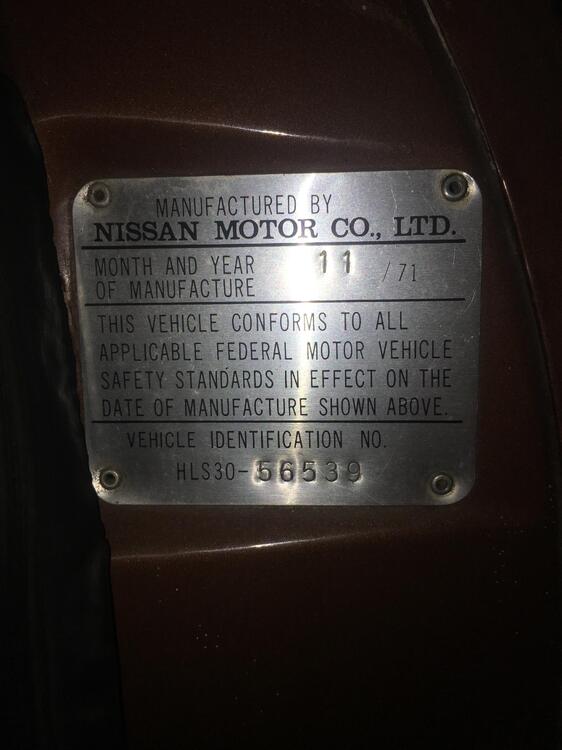

Model years for vehicles begin late the previous year. So a car manufactured in September, October, November or December of, say, 1970, usually is sold as a 1971 model year. Like this car. The door tag shows a 12/70 manufacturing date. It is a 1971 240Z. The seller is all wet. To further demonstrate, my 72 Z was manufactured in 11/71. That doesn’t make it a 71.

-

Parts Wanted: 280z Stub Axle and Companion Flange

If the vibration is coming from the rear and it is shaking so bad that it makes the front wheels shake, you have bigger problems than excessive runout at a rear hub. There is no such thing as too loose or too tight. Fasteners are either tight, at the correct torque, or they aren't. Checking runout of any rotating part is a simple process. Get a magnetic base dial indicator: Or: Although I would buy a high quality one from Starrett, or Sumitomo, cheap units are available on the web for around $20 to $30.

-

Parts Wanted: 280z Stub Axle and Companion Flange

From your description it is confusing about what is ‘bent’. Is this something you see? Can you post a picture of it? When not assembled, off the car, slide the companion flange onto the shaft. It should slide on all the way without resistance. The parts that fit inside the bearings is where there is an interference fit. Using anti seize on the splined portion is a good idea on assembly. It will aid disassembly later on. Finding a vibration can be difficult. As Mark mentioned, different parts of the drivetrain rotate at different speeds, and understanding this can help locate the source of the vibrations. You mentioned vibrations in the steering wheel. That suggests the vibrations are coming from the front of the car, not the rear. If you feel the vibrations in the seat, that suggests the vibrations are coming from the rear of the car. If you suspect the companion flange is bent, use a dial indicator and check for runout. It is an easy check, and the FSM should have a spec for it. Also check the runout on your wheels, halfshafts, driveshaft, differential pinion and output flanges. Be sure to closely examine the tires too, looking for damage, shifted belts or unusual bumps in the tread. Be sure the tires are properly inflated.

-

Oil pressure sending unit leaking

It is possible that the Teflon tape will insulate the sending unit from the engine, blocking the path to ground. Most auto parts stores carry small vials of an assortment of thread locking and thread sealing anerobic compounds for a couple of bucks.

-

Oil pressure sending unit leaking

That’s why I suggested the LocTite 542. A drop or two of an anerobic thread sealant will seal without interfering with the electric ground path.

-

Oil pressure sending unit leaking

The oil pressure tap on the engine block is a tapered pipe thread, originally JSP if memory serves me. It is very close to 1/8” pipe thread, and a 1/8” pipe fitting will work. Pipe threads seal by slight deformation of the threads as the fittings are tightened, so additional sealant is more insurance against a leak. Some Teflon thread paste will do, or you can use a hydraulic thread sealant such as LocTite 542. I’ve used it for years with no leaks, and there is still enough metal to metal contact to allow the sending unit to ground. Take the sending unit out, clean the threads on it, and the block. Examine the threads on both to ensure there is no damage or cracks, apply a few drops to the threads and assemble. Don’t overtighten, just snug enough to keep it from leaking.

-

Z's on BAT and other places collection

I guess if you have a Z that some actor drove once you can make a lot of money on it. https://bringatrailer.com/listing/1984-nissan-300zx-50/

-

280z starts but has a massive parasitic draw

So again, testing to sort out the trouble is the best way to find the root cause. Begin by ensuring all connections are clean and tight. A starter draw test can determine if the starter has a problem. Load testing the battery can determine if there is a problem with the battery. Load testing the charging system will pinpoint any charging system issues.

-

280z starts but has a massive parasitic draw

Why replace the alternator without testing the charging system, the starting system, and load test the battery? Simply guessing and throwing parts at a car is the worst way to go about troubleshooting. Test, prove what is malfunctioning, repair, then test again. That said, follow the testing procedures in the service manual. Find the problem and correct it. Most auto parts stores can test the alternator and the battery, to either confirm they are serviceable or not. Testing the voltage regulator should be covered in the service manual, and can be done with a voltmeter.

-

Harmonic Balancer Broken

I agree with the Captain regarding the history that leads to the removal of the damper, and about getting this damper rebuilt. The part that mates with the crankshaft is broken, and cannot be repaired. The parts are cast, then machined, and replacing the broken bits, and machining back to OEM condition would be a expensive and difficult job, if it could be done at all. Get another damper, and install it correctly. What does the crankshaft snout look like? It needs to be smooth and shiny, without any defects or damage, and the keyway should be in good condition, no burrs or irregularities. The damper should slide on easily without any force, and also be easily removed, without the need for tools.

-

R200 CLSD Whining...

So the noise on acceleration but not on coast is a symptom of incorrect pinion to ring gear engagement, or possibly (only possibly, a close examination of the bearings would confirm or eliminate the bearings) the bearings. Checking the wipe pattern will go a long way toward finding the cause. Find a local shop that specializes in differential work. There are a number of competent shops in the greater Vancouver area. Shipping a differential will be expensive, because of the weight.