Everything posted by Racer X

-

[2022] What Did You Do To/with Your Z Today?

Woah, Cliff! Ease up there. Don't want to wear it out all at once. 😂

-

Z's on BAT and other places collection

I’m always skeptical of cars from areas that salt the roads heavily in the winter. Rust is enough of a problem with Z cars and adding the de-icer makes things worse.

-

Most dreaded of jobs finally on the horizon ? the fuel tank !

You should be able to look through the opening the sending unit goes in. Use an inspection mirror and a flashlight.

-

Most dreaded of jobs finally on the horizon ? the fuel tank !

Yes, adding an additional filter upstream of the fuel pump would be a good idea. Can you see inside well enough to see if your tank has the screen like the one ETI4K has?

-

Most dreaded of jobs finally on the horizon ? the fuel tank !

In addition to Clint's reply, ETI4K posted his: In the fuel injected Zs the tanks had screens to reduce debris from getting pumped to the injectors. The holes in the injectors that the fuel sprays from are very small, and clog easily. Clean fuel is very important.

-

Most dreaded of jobs finally on the horizon ? the fuel tank !

Actually I think evap is a misnomer. The fuel tank has a very large inlet opening, and isn't thoroughly baffled. My guess is that the engineers used it to catch any fuel that would slosh up during cornering, catch it, and then let it drain back into the tank. It appears to be a complex solution that other vehicles don't seem to require.

-

Z's on BAT and other places collection

I just had another, closer look at the pictures. Besides the bodywork, I see he shows the rear brakes being converted to discs, then fully restored to OEM later. And while he has the hub apart he doesn't replace what look like original bearings. The engine is shown disassembled, but not machined. There are pictures of piston rings in a dirty cylinder, like one would do in a clean cylinder, after machine work is finished, to check end gaps. Similarly, the differential is shown opened, but not disassembled, cleaned, inspected, and reassembled with new bearings. Suspension and other bits look to have been cleaned, wire wheeled, and painted. Sure, better than nothing, but no substitute for media blasting. Clearly not a $45,000 car.

-

Most dreaded of jobs finally on the horizon ? the fuel tank !

It should be OK. Every evap tank I have ever had out of a Z has been clean and shiny. Wouldn’t hurt to have a look at it, do you have the inner trim panel removed?

-

Electrical Engineering Geek out. Coolest Switch Ever

It has 28 terminal connections. Hmmmm…… Does a Z even have 28 circuits? Sheesh, with that much connectivity, you could control every circuit in a Z with one switch! 😅

-

Z's on BAT and other places collection

Hagerty has been pestering me lately to increase the insured values of the Zs I have insured with them. I have the brown 72, and the red 71 (the race car) insured for $25,000 each. Hagerty is suggesting I go to $35,000 each.

-

15" Tire Recommendations for 2022

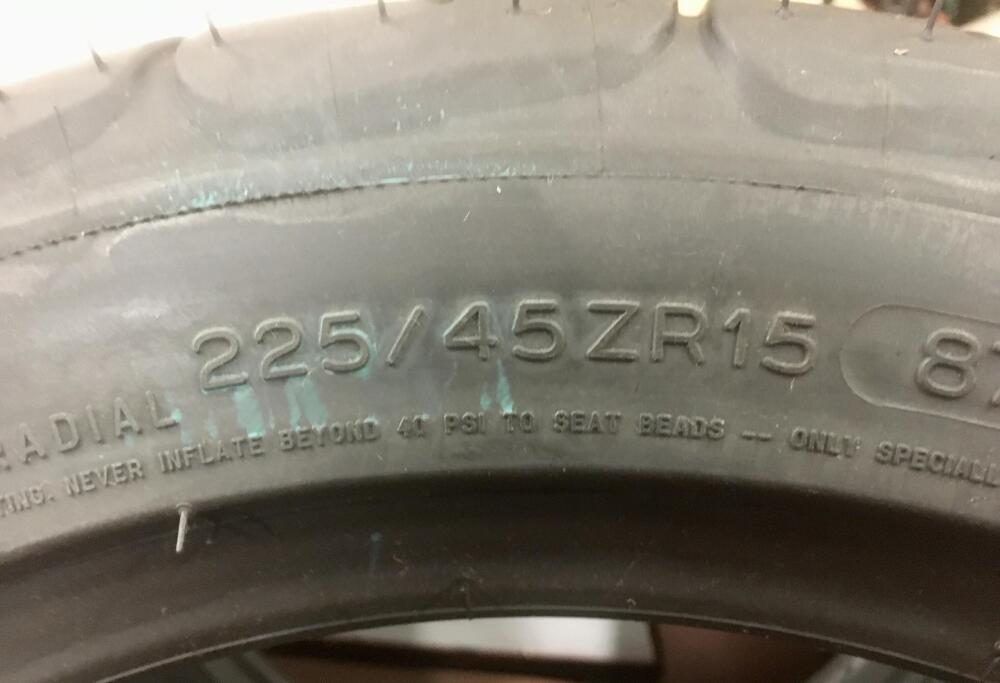

225/45ZR15. They are close to the same overall diameter as the Hoosier tires I run on the race Z, and about the same width.

-

15" Tire Recommendations for 2022

Are you asking me? 225-50 or 55, I think. 15x8 inch wheels. I’ll check when I get home. I run Hoosier Street TD, 225-55 bias ply on my race Z, on a 14x7 inch rim. Perfect fit.

-

15" Tire Recommendations for 2022

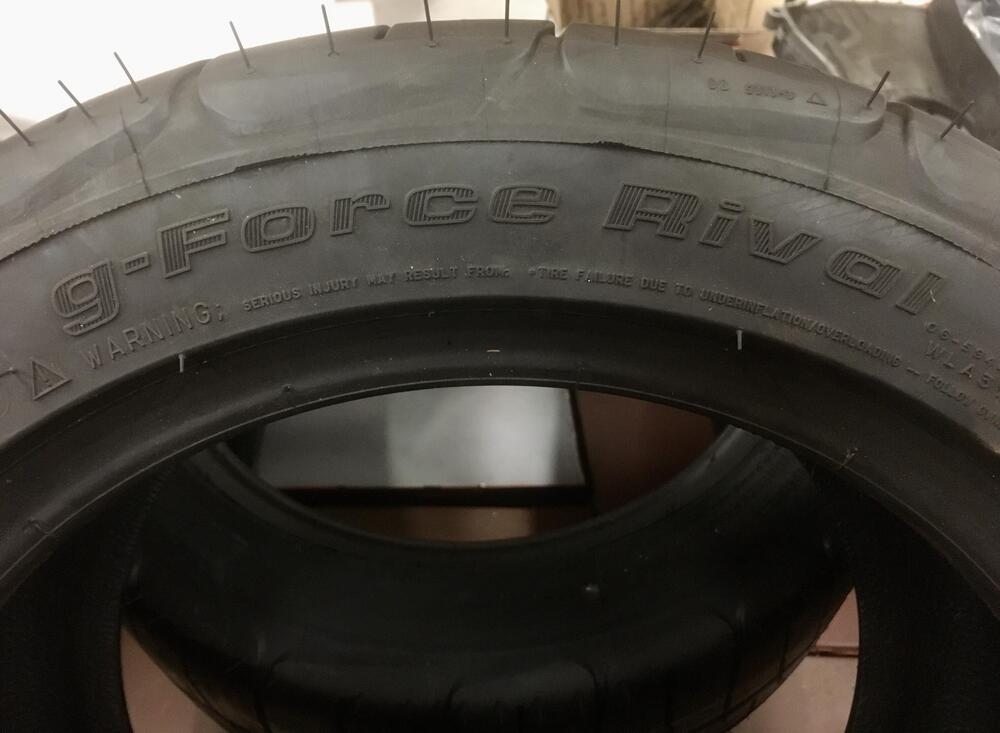

I don’t have them mounted yet, but I picked up a set of BF Goodrich tires recently for one of my Z cars. I also picked up a set of Konig Rewind wheels. I’m thinking it will be a perfect combination for my Z.

-

Z's on BAT and other places collection

I saw that too. Easy way to bend valves. I made a stand for L series cylinder heads. A simple affair, bolts to each end of the head and allows for the head to be positioned for chamber and port work, then assembly and initial valve adjustment.

-

Z's on BAT and other places collection

Yes, that is what he is talking about . They are there to cushion the door from hitting the jamb. And the Z currently at auction has one on the driver’s side, but the passenger side one is missing. Certainly a small oversight on the part of the seller, something which would require little effort and expense, but may keep more serious bidders away.

-

need help with broken hood latch cable

Yep, the only way is to reach up from underneath to push the latch to the released position. It will be easiest from the passenger side, as the exhaust will be in the way on the driver's side. A long prying driver, like this should get you there.

-

4th

Hope everyone had a nice holiday. Here is a little drawing I made around 1980, when I lived in a waterfront home on the Tulalip Indian Reservation. I hosted a party every year, charcoal grills cooking meat, lots of beer to drink, and fireworks. Lots of fireworks.

-

Let's show vintage racing pictures. I'll start.

Telegram. The original text message.

-

Oversize Pistons

I have seen it on torque converters, and driveshafts.

-

Oversize Pistons

When I was still working as a journeyman mechanic at the local electric utility I held ASE Auto and Truck Master certification, and was a certified Mobile Fluid Power technician (hydraulic systems). Can’t say that I have ever seen additional weight added to a flywheel for balancing. I have seem where material was removed, by drilling.

-

Oversize Pistons

An engine is an engine, cast iron, steel and aluminium. Doesn't matter if it was made in Japan, US, Europe, Mexico, Brazil, or China. The principles are the same. Sure, the rotating assembly can be balanced as a whole, or separately. But it is always better to balance those items I mentioned as a single unit. The damper is keyed to the crank, so no need to mark it for reassembly, the flywheel and clutch cover are not, so the must be marked for reassembly to the orientation they were in when the assembly was balanced. After the machining of the crank is done, the machinist I have used assembles the flywheel, clutch cover and damper to the crank, performs the balancing work, then disassembles it all. The piston and rod assemblies are balanced by bringing the weight of each assembly as close as is possible to eac of the others. It doesn't matter what language the manufacturer speaks, the materials and processes are the same.

-

Oversize Pistons

Why not the flywheel? The flywheel, crank and damper are usually balanced together, and having the clutch cover with pressure plate balanced at that time is something that should be done. The pistons will need to be fitted to the bores. When you use, say, twenty thousanths oversize pistons, the piston is measured and the cylinder bored and honed to fit that piston. Each one is fitted and marked for the bore it was fitted to. Then the connecting rods are checked for squareness and that the pin and journal bore centerlines are parallel, the pistons fitted to the rods, then the assemblies are weighed, and if needed, material is removed until everything is within a tolerance (I forget right now how close is considered the same). This is all very important stuff, especially for an L series six cylinder, as the crankshaft is quite long, and vulnerable to torsional twisting fatigue under load. Are you looking for cast pistons? Forged? Billet? Also, keep in mind, engines usually only have enough cylinder wall thickness to go two steps overbore. You've alread taken one cut. It is fresh. It is starting to sound like sorting this out by taking another cut is going to cost more than having pistons made, to fit the overbore you have now. Search the innerwebs for custom made pistons. JE is one I know of, although I have not used their services.

-

What is your (most) valuable "made it myself" PART! and most valuable lesson learned about Z-cars!

My toolbox has a full compliment of SAE and metric wrenches and sockets, from very small (I think the smallest is 5.5mm) to very large (2 1/2”, and a 4 foot pipe wrench. All my hammers are sized in ounces or pounds. Most of my machinist tools are in fractional inches, but I do have a couple of calipers that read in inches and millimeters. All of my torque wrenches are in inch pounds or foot pounds, if I need to torque something in metric (kilograms centimeters squared),? I do the conversion. I have two sets of taps and dies, inches and metric. None of my screwdrivers are metric. But I do have several Oklahoma Micrometers (crescent wrenches) that are inches on one side and millimeters on the other. I’ve been working on my 1995 F150 Eddie Bauer the last few weeks. Very aggravating that some fasteners are metric, others SAE.

-

Oversize Pistons

So in all of this there has been no mention of the rotating assembly, crank, rods, damper, flywheel. Are you not having the bearing journals checked, and machined as needed? Are you not having the rotating assembly balanced? All the fuss over cylinder boring and pistons is wasted if you aren't also having the other work done as well.

-

What is your (most) valuable "made it myself" PART! and most valuable lesson learned about Z-cars!

I went to work for Boeing eight years ago, as an aircraft structures mechanic. During the three month training period I was surprised that, as a world wide, multinational corporation, Boeing has stuck with inches and feet, 100%. Everything is built to the nearest 0.001”. Holes for rivets and bolts are drilled to decimal sizes in inches. Parts are located in inches. Locations on the airframe are given a by 3 point location system, in inches, from a point just ahead of the nose of the airplane aft to the tail for fore and aft, from the water line for up and down, and from the buttock line (centerline) for right and left, all in inches. Interesting to note that given a 777 commercial airliner has a wingspan around 200 feet, and is around 200 feet long (freighters are shorter than passenger planes), yet everything is located in inches. I was disappointed that engineering hadn’t embraced the metric system. Given that math is not one of my better skills, I thought that metric would be easier than fractional and decimal inches. *sigh* Oh well, it didn’t take long to get used to it, and now I’m very well versed in everything we do there. Everyday I machine the specialized aluminum alloys, titanium, and (only rarely) stainless steel. The hole sizes are small for the most part, nominal sizes of 0.125” for pilot holes and small rivets, up to 0.375” for larger rivets and bolts, which covers most of the fasteners used. Sure, there are larger fasteners, up to 1” and 1.5” for wing attachments (the titanium bolts that attach the wings to the fuselage cost several thousand dollars apiece). Holes for rivets are sized slightly larger than the rivet, which swells to the finished hole size when it is driven. Holes for most bolts (called “permanent straight shank fasteners) are sized slightly smaller than the bolt, which is forced into the hole (transition fit) using a rivet gun. The specifications call out for the hole sizes of various fasteners, with tolerances in the thousandths of an inch. Even the final assembly jigs and tooling are built in inches. The FAJ (final assembly jig) for each part of the build are massive steel structures set on concrete piers that go 30 feet into the factory floor. The FAJ for the 777 Wing Majors is 4 stories tall, and covers the area of a US football field, and 4 pairs of wings are built simultaneously. The forward and aft fuselage sections were also assembled inside massive FAJs, but the new 777-9 fuselage is now built on giant crawling cradles. The 767 freighters and KC-46 tankers are built in similar tooling, but the fuselage is still done in FAJs set on huge concrete piers. The 747 is also done with large FAJs, but those will be getting torn down soon, as the last airplanes are being manufactured this year, after more than 50 years. I started in 777 Wing Majors, then worked building the wing spars for 777. After a summer working on the flightline)also 777), I have been on the 767 Freighter/KC -46 tanker program in forward bodies (everything forward of the wings). I plan to retire at the end of the year. From the FAJ I work in on the 767/KC-46 program I can see the wing/body join and final assembly areas of the 747. The last pair of wings was loaded into the 747 wing/body join FAJ the other day. In another part of the factory the 747 spar FAJs have already been torn down after more than 50 years of manufacturing 747 wing spars. The 747 Wing Majors tool will be torn down soon to make room for the next chapter of Boeing in Everett, Washington, And as always, in inches.