-

Posts

605 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Knowledge Base

Zcar Wiki

Forums

Gallery

Events

Downloads

Store

Blogs

Collections

Classifieds

Everything posted by Jeff Berk

-

I'd (and others I would think) love to see a writeup on how you made it. I can access a fairly complete woodshop with a CNC. A fairly detailed step by step done a few installments at a time would be great. I'd have to find a donner wheel first since I don't want to sacrifice my current wheel in case something goes wrong.

-

What is your most valuable 'made-it-myself' tool?

Jeff Berk replied to Namerow's topic in Open Discussions

I also mounted a winch. In my case, I sometimes need to pull my car in and onto my 4-post lift. Pushing it up the lift ramps was too difficult so I attached a box hitch receiver at the other end of the lift. I have a small 12v winch that is welded to a hitch adapter. The winch can then be attached to the lift to pull my Z onto the lift. The winch can also attach to my Chevy Volt or my garden tractor with their box hitch receiver and run off their battery. I thought I was so original with my idea. I guess not. -

Gauge lights not working, only some.. not all...

Jeff Berk replied to Shawninvancouver's topic in Open Discussions

Add to that "Spray each contact you check with DeoxIT or other contact cleaner". Be careful since the circuit is energized and you might need to have some spare fuses on hand. -

I'm working on modifying my fuel delivery and need a reality check if anyone wants to comment. My current system has fuel going from no return to a return to try and control fuel pressure and prevent the fuel from becoming too hot while waiting in line between autocross runs. electric pump ==> mechanical pump (MP unable to keep up with the demand) ==> fuel pressure regulator (no return port) ==> "T" fitting ==> SU (4-screw) I was planning on switching to: electric pump ==> mechanical pump ==> fuel rail ==> SU carburetors front ==> SU carburetor rear ==> Fuel pressure regulator ==> return line ==> Fuel Tank fuel system.pdf

-

Gauge lights not working, only some.. not all...

Jeff Berk replied to Shawninvancouver's topic in Open Discussions

Siteunseen: I had to do likewise, then installed the relays to prevent further damage to the switch since the flip method only works one time. I'm assuming Shawn's switch is providing power since he didn't mention anything about headlights or parking lights. -

Gauge lights not working, only some.. not all...

Jeff Berk replied to Shawninvancouver's topic in Open Discussions

Your thoughts are correct; however, your wiring has undergone several iterations of tinkering. There is a potential that someone did a little rewiring. Or, you could be right that all the other bulbs burnt out. I'd like to see how far the power is getting first. How original are you trying to keep this car? I ask because you might consider replacing your bulbs with LEDs (which is not as easy as plug and play). -

Gauge lights not working, only some.. not all...

Jeff Berk replied to Shawninvancouver's topic in Open Discussions

Hi again... I don't expect all your dash lights to be dead at the same time. Lets look at your dash lights for now. 1) Turn the lights on and check if there is power to the hot wire going to the variable resistor (a.k.a. dimmer switch) to the bottom left of the dash. The plug should be a three contact with only the top/bottom contacts used (http://www.vintageconnections.com/Content/images/products/66/1.jpg) This will tell you if power is getting this far. 2) If you have power, try jumpering the harness wires at this connection to bypass the resistor. If the lights come on, you likely have a bad dimmer switch. If not, AND there was power to the switch, you'll have to start testing the connections at the bulbs sockets. That will at least give you an opportunity to see if the bulbs are burnt out. BTW: The URL for the connector picture is from Vintage Connections. That is likely the best place to purchase replacement connectors for your 260z. -

What is your most valuable 'made-it-myself' tool?

Jeff Berk replied to Namerow's topic in Open Discussions

Part of the reason for owning a Z and subscribing to this site is to learn something now and then. Fel-Pro does a good job of explaining the concept and included an example for a Subaru where the head bolts had to be tightened in two steps, loosened in two steps, and then tightened in two to three steps in order to get to the "yield zone". https://www.felpro.com/technical/tecblogs/proper-installation-use-t-t-y-bolts.html -

What is your most valuable 'made-it-myself' tool?

Jeff Berk replied to Namerow's topic in Open Discussions

OK, I have to ask... What is the purpose of a bolt stretch gauge? Please don't say to measure the stretch of a bolt. A little background please on this cool-looking tool. -

I just checked and the vacuum nipple is capped off. I tightened another vacuum connection (braided hose connected to the vacuum balance tube). I was able to keep the car running by using the fast idle adjustment screw. The engine is missing but I cannot isolate which cylinders are missing because its not missing consistently. I re-balanced the air flow between the carb's because I wanted to do something as long as it was running. I got the fuel pressure down to 3.5 to 3.75 using the pressure regulator. A previous owner removed the fuel rail and disconnected the return line so this is a "dead head" system. I'm going to try and put in a new fuel pressure regulator with a return once I get the car running and the cam shaft issue taken care of.

-

Its still running very rough. I suspect that maybe I knocked something out of whack with the carbs when I removed/reinstalled the intake manifold. Like I said above, It's going in to the mechanic for repair of the cam shaft so I'll have him look at the SUs. He knows them inside out. Thanks for the help.

-

As long as we are talking about fuel pressure and orifices, can I hijack this tread for a personal issue? My 260z has both mechanical and electric fuel pumps, no fuel rail, and the fuel return line was disconnected. I'm at 4.5 psi using an old Holley fuel pressure regulator who's adjuster is not working (internal spring worn out?). I'm using two round-top SUs. I'd like to lower the pressure to see if it correct a rich mixture situation. If I don't run the electric pump, the pressure drops to 3.5 psi but I periodically have the engine start to miss until I switch the electric pump back on. Any opinions on if I should just replace the fuel pressure regulator with a new non-return one or with a return type and reconnect the return line?

-

Thanks, I'll give that a try.

-

I need help getting my 260z with round-top SU’s running again. Symptoms: It cranks and pops but no start. Leading up to this, the engine would stumble. This was after I did some work on the car and I’m assuming caused the issue. In order of repairs, there’s the list: 1) Replaced the transmission. 2) Replaced the intake/exhaust manifold gasket. 3) Replaced the oil pan gasket. 4) Adjusted valves, discovering a damaged cam lobe. Spark plugs were coated with carbon, so I cleaned them with a propane torch. <this is when stumbling was first notice, but car not driven since before transmission was changed> 5) Removed rocker in contact with the damaged lobe for inspection and reinstalled. 6) Retorqued intake/exhaust manifolds and discovered several loose nuts. 7) I tested the vacuum that showed an average vacuum of 12 in Hg at 1300 rpm and 13.3 in Hg at 1570 rpm. 😎 I pulled the car out of the garage and turned it off. Later, I was unable to restart the car. 9) The spark plugs were removed and had gas on them. The fuel pressure gage showed 4.5 psi and I can hear the electric fuel pump running. 10) The Mallory Unilite (LED triggered) distributor’s ignition module tested out as working. 11) The Mallory 29440 coil is assumed to be working because a spark tester showed spark at cylinders 3 and 4. I didn’t test the other cylinders for spark. 12) Firing order was checked. 13) I don’t expect the timing has changed on its own, so I don’t want to mess with it. Also, for some reason, I have yet to find the timing mark on the harmonic balancer. The car is due the week after next to have the mechanic that installed the cam shaft repair the damaged cam shaft so worse comes to worse, I can have it towed in. Any idea what I should try next?

-

I have a regulator and assumed it was on all 260z's. I attached a fuel pressure gauge and was told to keep the fuel pressure below 4.5 psi. I guess what I'm saying is to check your pressure especially if you have an electric fuel pump and mechanical pump both running.

-

260z horn, signals, wipers not working

Jeff Berk replied to Shawninvancouver's topic in Open Discussions

It sounds like its likely a relay problem as Zed H pointed out. Did you get the relay open yet? Zed H: Any idea how a relay can get so corroded? How bad were the rest of the relays in that relay panel? -

260z horn, signals, wipers not working

Jeff Berk replied to Shawninvancouver's topic in Open Discussions

Here's a concise explanation of how a relay works if you need it. https://www.12voltplanet.co.uk/relay-guide.html I have a box of generic 12v relays to replace mine as they become faulty or for rewiring circuits (e.g. lights) that over tax the frail wiring of my Z. I saw you had a continuity light, do you also have an ohm meter? You may need it to check the fan on your heater. -

260z horn, signals, wipers not working

Jeff Berk replied to Shawninvancouver's topic in Open Discussions

The horn and wipers use the 10 amp fuse in position 10. You can look up the others in that table I posted. I've attached an Excel copy in case anyone wants it. This table is specific to the 260Z and has not been reviewed for accuracy. Wiring Cross Reference.xlsx -

260z horn, signals, wipers not working

Jeff Berk replied to Shawninvancouver's topic in Open Discussions

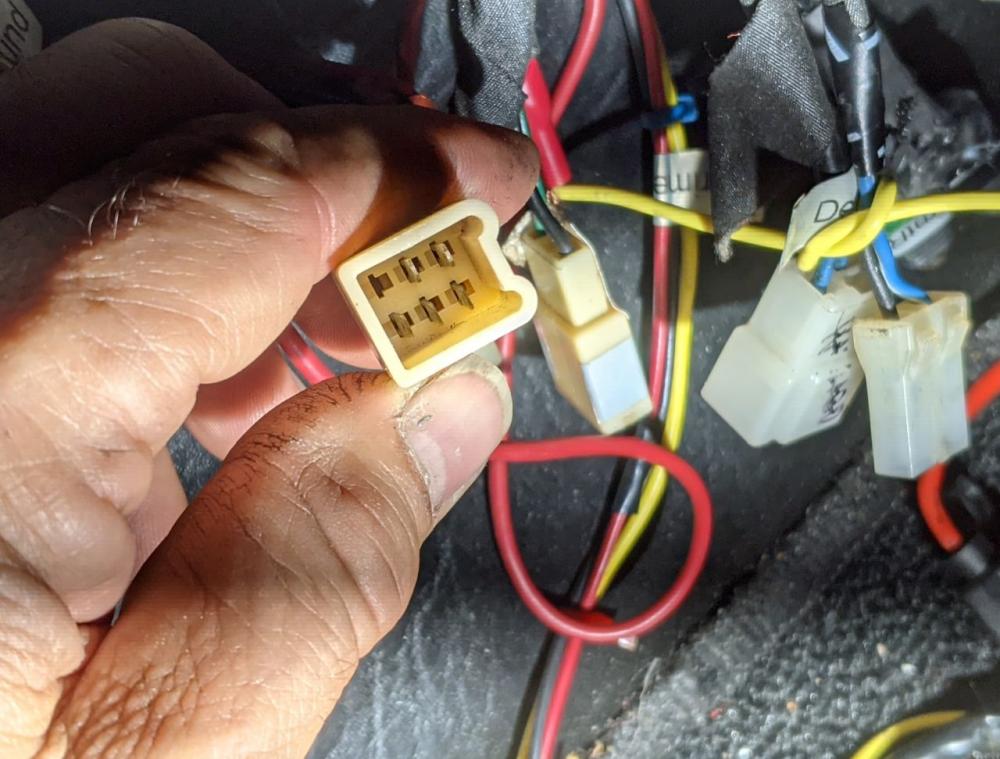

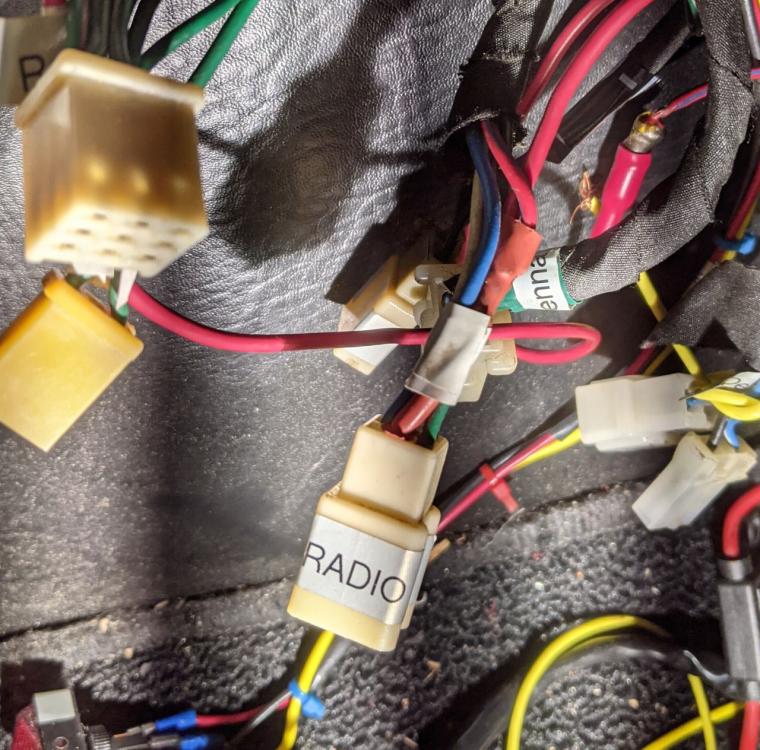

By chance, my center console and radio are out of the car so I can see my wires. I have a green/white female, and a red/blue male bullet, but they are not being used in my car. I capped off the male to be on the safe side. That multi-connector, if it's a 6-pin with 5 places used, looks a lot like my radio connector for the OEM radio (see photos). I noticed an in-line fuse in one of your photos so I think someone got creative with the electrical wiring on your car. When asking questions about where a wire gets plugged into, indicate the number of connectors and wire colors including the color of the stripe if there is one. Good luck. -

260z horn, signals, wipers not working

Jeff Berk replied to Shawninvancouver's topic in Open Discussions

I don't know if this helps or makes it more complicated, but here's a chart I started a few years ago. It's never been QC'ed so be forewarned. As an example on how to read this, the "Turn Signal" circuit is on page BE-11, involves junction connectors C-2, 3, 4, and 5, Fuse #3, which is 10 Amps, uses white, green and black wires (specifically white/red, green/red, green/black, black, and black/white). The way I've used this is to try and match up the colors, then go the the FSM page BE-xx to read the wiring diagram. Junction Fuse Wire Color (primary, secondary) System Page (BE-) Block Connectors No. Amp Red White Green Blue Yellow Black Head Light 10 1345 1 10 R, RB, RW W, WR Head Light 10 7 2 10 R, RB, RW, RY W, WR Turn Signal 11 2345 3 10 WR GR, GB B, BW Haz Warning 12 12346 11 10 WR GW BY Stop Lamp 13 26 11 10 W, WR B, BW Clearance & Tail Lmp 14 1256 5 20 W, WR GW B Reverse Lamp 15 3567 9 20 RB W, WR LB Meter Lights 16 246 5 20 RL W, WR GL, GW B Console Lights 17 12346 5 20 RL GW Interior Lamp 18 16 6 10 RL, RB W, WR B Glovebox & Cig Lighter Light 19 246 5 20 W, WR GL, GW B Map Light 20 46 6 10 RL W, WR B Tachometer 30 345 3 10 W, WR G LB B, BW Water Temp/Pressure Gauge 34 234 3 10 W, WR G YB, YW B, BW Amperage/Fuel Gauge 35 345 3 10 W, WR G Y B, BW Brake Warning 36 156 NA #N/A W, WR G, GY BW Heater Illumination 53 12346 5 20 RL W GR, GW B Heater 54 35 8 10 W, WR G L, LR, LW Heater 54 6 13 20 W, WR G L, LR, LW Heater (resistor) 54 NA #N/A B Horn 58 16 10 10 W, WR G, GB, GR Washer 64 3457 9 20 LR, LW Wipers 67 234567 10 10 W, WR L, LW, LY Y B Lighter 69 146 7 20 W, WR LW B Clock 70 146 6 10 RL W, WR B Window Defogger 74 3567 8 10 R W, WR LR, LW B Radio 78 357 8 10 W, WB, WR L, LR, LW B Theft Protection 81 146 6 10 RL W, WR B Choke Warning Light 85 357 3 10 W, WR G B, BW Interlock 99 7 14 10 W, WR B Ignition 102 35 4 10 WR BW, BY Interlock Relay 103 457 NA #N/A WR L, LR BR, BW, BY Neutral Switch Warning 105 457 NA #N/A LgB BY B Engine Revolution Sensor 106 6 14 10 W, WR B Emergency Switch 108 45 NA #N/A WR L Y, YB B, BW, BY Battery (Power Inlet) 106 14 10 W, WR B Junction Blocks Green C-1 Blue C-2 Black C-3 Brown C-4 Green C-5 White C-6 Black C-7 -

260z horn, signals, wipers not working

Jeff Berk replied to Shawninvancouver's topic in Open Discussions

The second picture shows a 3-contact connector with only the top and bottom connectors used, both wires are green. If so, that might be the map light above the vents. For the other connector in the 2nd picture, how many contact positions, how many are actually used, and what are the wire colors? -

260z horn, signals, wipers not working

Jeff Berk replied to Shawninvancouver's topic in Open Discussions

In the first picture, that looks like a green/white and red/blue into a T 2 conductor connector female for the heater control's light. I also have a similar connector but with green/white and red that is not plugged in right now. -

260z horn, signals, wipers not working

Jeff Berk replied to Shawninvancouver's topic in Open Discussions

I just pulled out my spare from the garage. Mine only had one screw. Getting it out is not half as fun as getting it back in. -

260z horn, signals, wipers not working

Jeff Berk replied to Shawninvancouver's topic in Open Discussions

ZH, correct me if I'm wrong, but I think the relay panel can be unbolted. This might make it easier to get to the relay. Remember these relays are old so they can wear out. Once you figure out the terminals, (i.e. which one does what) you can substitute a modern relay.

Subscriber

Subscriber