-

Posts

605 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Knowledge Base

Zcar Wiki

Forums

Gallery

Events

Downloads

Store

Blogs

Collections

Classifieds

Everything posted by Jeff Berk

-

I like that DYI rotisserie. Your design or did you find plans for it?

-

LOST RED PRIMADONNA Z FOUND AFTER 36 YEARS IN HIDING!

Jeff Berk replied to yojack1's topic in Open Discussions

I never heard of these. I'm not sure if I like it, but it is part of Z history. https://forums.hybridz.org/topic/53266-the-primadonna-z-story-56k/- 2 replies

-

- 240z

- jack atkinson

-

(and 1 more)

Tagged with:

-

wide ratio FS5W71B slipping out of 3rd & 4th

Jeff Berk replied to Jeff Berk's topic in Engine & Drivetrain

Soaking it with parts cleaner didn't work, A bearing puller/splitter didn't work, Heat didn't work... A 4-inch vice and two pipe wrenches with all my weight on one of them did the trick. The shafts started moving independently and eventually I was able to pull them apart. Zkars, you were absolutely right about the needle bearings. I snapped the tips of two teeth (one shown in the top left of the photograph). I'm assuming I can live with it. If not, I could see if I can find someone to weld some metal onto it. Thanks guys! -

wide ratio FS5W71B slipping out of 3rd & 4th

Jeff Berk replied to Jeff Berk's topic in Engine & Drivetrain

I had tried using the bearing splitter/puller clamped just behind the gear marked with the black arrow. It didn't move and I was concerned about damaging the teeth on the gear so I stopped. And yes, the front part appears to be seized to the rest of the shaft. I might try soaking it in degreaser for a while to see if it's just seized due to grit. -

wide ratio FS5W71B slipping out of 3rd & 4th

Jeff Berk replied to Jeff Berk's topic in Engine & Drivetrain

Well that 1st transmission was practice and I'm on to my 2nd unit I purchased hoping it was in better shape. I found a few issues but none that the rebuilding kit shouldn't take care of. My question now is how to get this gear cluster apart. On my first transmission, the shaft split into two sections between the black and orange arrow, this one will not budge. From what I can see in the diagram, there should be a snap ring between these two components so until I pull them apart, I'm not going to get any further. Any pointers on how to split it here without doing any damage? -

My fuel pressure was close to 5psi at the 4-screw SU's. My mechanic told me to just adjust the pressure regulator screw. I have an aftermarket regulator so I don't know if the original one also works that way. This was a good idea for how to mount an extinguisher. https://www.amazon.com/Bracketeer-Extinguisher-Bracket-Universal-Vehicles/dp/B015G3QXMY I ended up just making my own based on this design for the passenger seat. I've had a couple of wire melt downs when I first purchased the 260z. Sorry about the mess, my Z is a work in progress.

-

I ended up purchasing a CHANNELLOCK 929 because it has a lock on it. My old Craftsman won't hold the rings open far or secure enough, OEM #25014 won't hold the interchangeable tips securely, and the OEM #25356 interchangeable tip holder broke off. The 929's are 3-4 times expensive so I have my fingers crossed.

-

Some of the apprehension is gone since I've mostly torn my first one down so I know what to expect. I just picked up an inexpensive parts washer (Performance Tool W54043 ) because this one has lots of dried oil on it. I have to find a GOOD pair of snap ring pliers. Maybe a pair that locks would work.

-

Well that transmission had an issue. I couldn't get the shaft to spin by hand let alone a drill. I decided to buy it anyway after the seller agreed to accept $200 for it figuring once I tear it down, I can figure out what the problem is and hopefully fix it. The seller insisted that it was working fine when he pulled it out of the donner car last month. He also will switch it out with another one he has if this one doesn't work. Unfortunately, I cannot pull the tail piece off more than an inch or so and for now the front section is stuck to the adaptor plate. UPDATE: I GOT THE TAIL OFF! UPDATE 2: I GOT THE FRONT OFF The main shaft bearings are a little loose so I'll get to use the rebuilding kit.

-

Thanks for the pointers. I like the idea of using a drill to spin the transmission. That and checking for metal flake in the fluid seems like a good plan.

-

If you've been following my thread on a FS5W71B with a slipping 3rd/4th, I've disassembled and found numerous worn parts that cannot be replaced. To quote zKars "Holy crap, those teeth are in bad shape. ..You are out of luck as to finding a replacement. Time to look for a new transmission I think. " I found a used transmission on Facebook/market 3 hours away: https://www.facebook.com/marketplace/item/428839345022192/?referralSurface=messenger_lightspeed_banner&referralCode=messenger_banner Is there anything I can do to check it out before I pay for it?

-

wide ratio FS5W71B slipping out of 3rd & 4th

Jeff Berk replied to Jeff Berk's topic in Engine & Drivetrain

referring to the above photographs, the 3/4th fork pad thicknesses (top, center, bottom) are 4.11, 5.09, and 4.00mm. The center pad has a slight stepped appearance on one side. The 1/2 for pad thicknesses (top, center, bottom) are 4.55, 4.33, and 4.98mm I'm measuring the pad thickness as shown in the photograph. -

wide ratio FS5W71B slipping out of 3rd & 4th

Jeff Berk replied to Jeff Berk's topic in Engine & Drivetrain

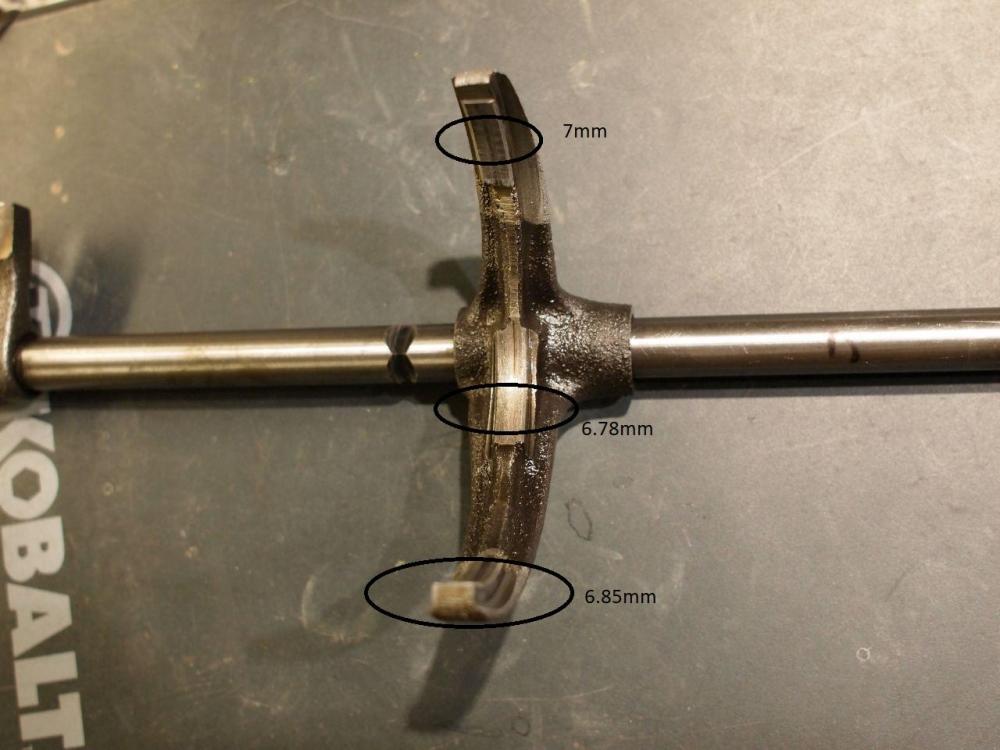

The fork was tight on the shaft (roll pin intact). I've attached closeups of the 1/2 fork (marked "T") and 3/4 fork (marked "C") with measurements. I'm not sure if there is any path forward if the 3/4 fork needs to be replaced because it appears to be NLA. The measurements are widths. I'll send the thickness shortly. An additional question... The rebuilding kit only came with one set of needle bearings but the transmission has several of them. Should I purchase additional needle bearings and replace them all? -

wide ratio FS5W71B slipping out of 3rd & 4th

Jeff Berk replied to Jeff Berk's topic in Engine & Drivetrain

OK, I'm good with the nut issue and I just about have the whole thing taken apart. I could use an opinion on the condition of the 3rd/4th fork condition. -

wide ratio FS5W71B slipping out of 3rd & 4th

Jeff Berk replied to Jeff Berk's topic in Engine & Drivetrain

I might just do that. $60 for a nut seems a bit steep. If I still had access to the maker space machine shop I'd try and make some but they're closed until further notice due to C-19. I actually found some M27X1.5 staking nuts but nothing M27X1.0. -

wide ratio FS5W71B slipping out of 3rd & 4th

Jeff Berk replied to Jeff Berk's topic in Engine & Drivetrain

Can anyone suggest a source for main and counter shaft staked nuts, with RIGHT HAND threading? I must have one of the earlier FS5W71B's. If they are NLA, can I substitute something else? -

https://www.yeggi.com/q/240z/ Good source for printer files. I've printed the plastic clip for retaining the chrome bezel on the door pull of Datsun 260Z and 280Z, 1974-78 and part of a cold air intake.

-

I've got several parts on my '74 thanks to my son's printer.

-

wide ratio FS5W71B slipping out of 3rd & 4th

Jeff Berk replied to Jeff Berk's topic in Engine & Drivetrain

Thank you Mayolives! There are many tips in there that will help. I'm on hold waiting for a bearing puller/splitter to arrive. I'm also mounting three dowel rods on my work bench to sting components on in order so that I can put everything back in the proper sequence and direction. It was suggested that I engrave an F on components on the side facing the front. I might do that as well. I'm assuming roll pins should be replaced with new ones but snap rings are fine to reuse. Correct? -

wide ratio FS5W71B slipping out of 3rd & 4th

Jeff Berk replied to Jeff Berk's topic in Engine & Drivetrain

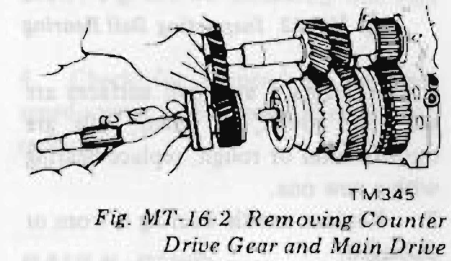

If you look at MT-16-2 below, there is a little play in the main shaft at the point where it's shown as being separated from the rest of the shaft. I'm assuming that's normal. I can see the bearings in the adaptor plate and it appears to be in good condition with no play in the shaft as I try and wiggle the shaft. Could the worn synchros be causing the slipping out of gear? I thought it would just be a problem getting into gear. It looks like I might be able to do the rebuild myself as long as I don't need a press. If it gets too rough, I have a local mechanic that has worked on these transmissions I can fall back on. -

wide ratio FS5W71B slipping out of 3rd & 4th

Jeff Berk replied to Jeff Berk's topic in Engine & Drivetrain

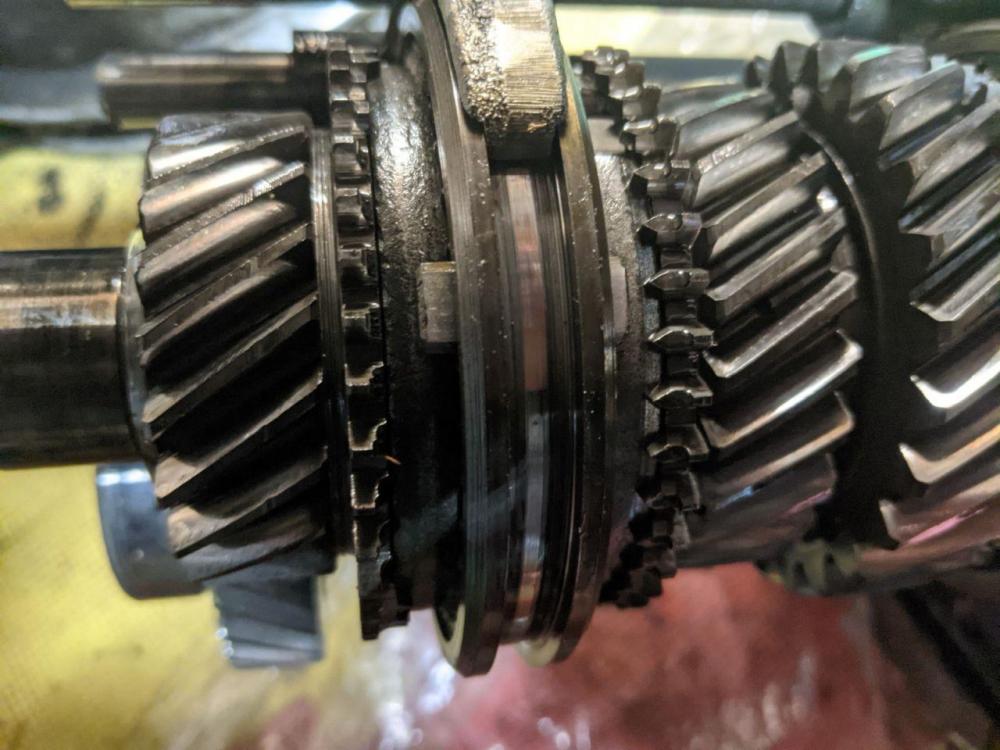

OK, I pulled off the front transmission case. Keep in mind that that I have not done this before so I'm not 100% sure what I'm looking for. What seems to jump right out is that the baulking rings seem to have some teeth chipped off. My problem, however, was that I'm slipping out of 3rd and 4th gear. -

wide ratio FS5W71B slipping out of 3rd & 4th

Jeff Berk replied to Jeff Berk's topic in Engine & Drivetrain

Thanks all, got it off. I'll take a stab at the front half of the transmission case tomorrow. -

wide ratio FS5W71B slipping out of 3rd & 4th

Jeff Berk replied to Jeff Berk's topic in Engine & Drivetrain

Zed... The dust shield has a small gap between it and the body of the transmission tail piece. I've tried prying with a screw driver and twisting with a pipe wrench. Before I get too aggressive, I just wanted to make sure I wasn't missing anything. I'll try and wiggle it with a dead blow hammer and prying. I'm assuming that the dust sleeve and seal need to be removed to pull off the tail end of the transmission. I'm sure it's a wide ratio based on it having two bolt tabs at its tail end and I don't see what looks like a reverse lockout mechanism. Jeff -

wide ratio FS5W71B slipping out of 3rd & 4th

Jeff Berk replied to Jeff Berk's topic in Engine & Drivetrain

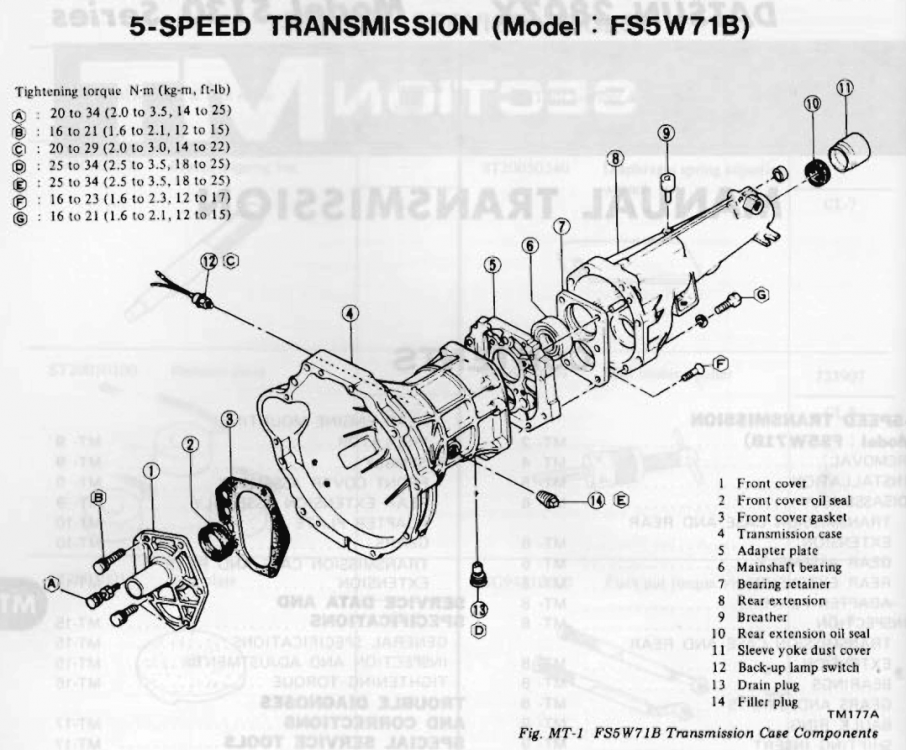

I'm getting around to disassembling by 5-speed to search for the cause of the slipping out of 3rd and 4th and I'm already stuck. I removed the stopper guide pin, return spring plunger, return spring plug, and plunger. I need to remove the tail end of the transmission and removed the six bolts that pass through the adapter plate and now I'm stuck. Do I need to remove the dust cover sleeve (No. 11) and seal (No. 10) to pull the tail section off? If so, is the dust cover sleeve screwed on? After their removal, just hammer and twist left to pull the tail end, right? -

I purchased a garage door high lift kit from DDM Garage Doors. https://ddmgaragedoors.com/diy-instructions/garage-door-high-lift-conversion.php The installation wasn't too rough although if you've never had to install or adjust torsion springs before, it could get a little unnerving. You also will have to buy a jack shaft, wall mount opener or just learn to raise and lower the door by hand which is what I do. I had also looked into two post lifts but they have some issues like being a permanent installation by having to be bolted to the floor, requiring a thicker concrete floor than normally found in residential garages, and I feel safer with the car supported for long term storage by four posts, each with it's own lock. BTW: All the photographs appear to show clean garages and at least two really cool cars. I'm jealous.

Subscriber

Subscriber