-

Posts

605 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Knowledge Base

Zcar Wiki

Forums

Gallery

Events

Downloads

Store

Blogs

Collections

Classifieds

Everything posted by Jeff Berk

-

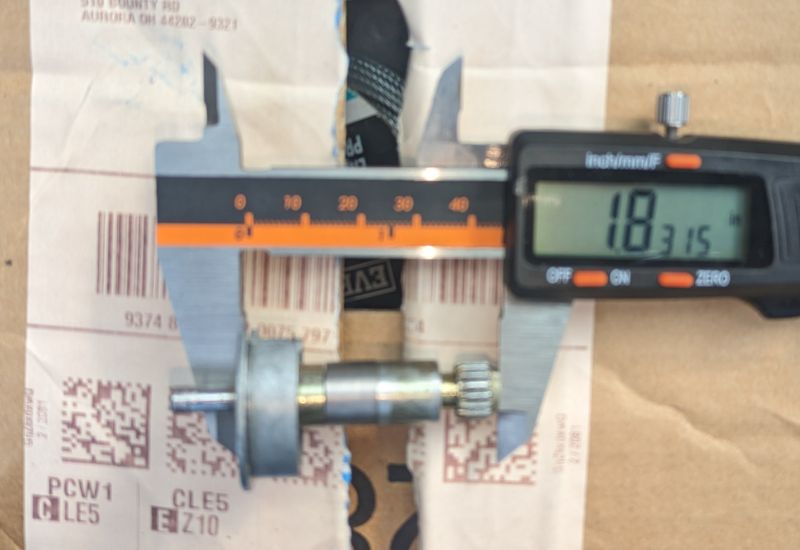

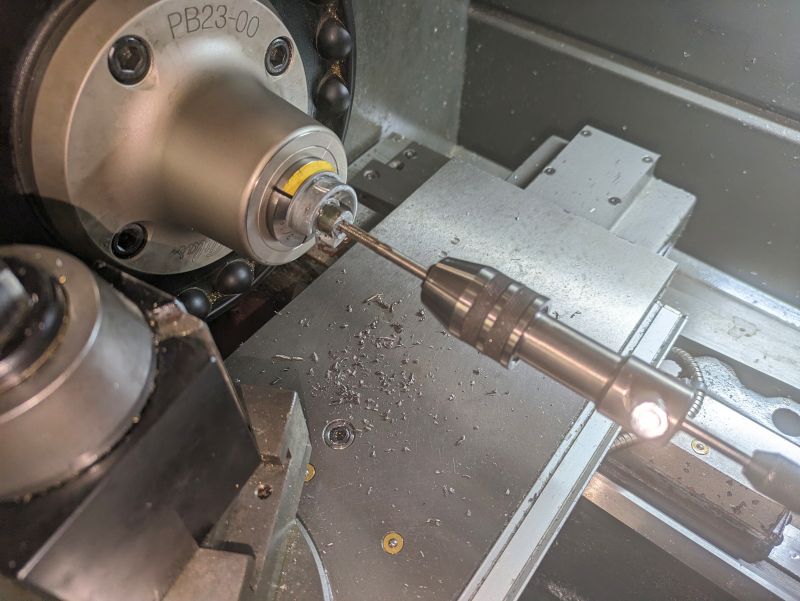

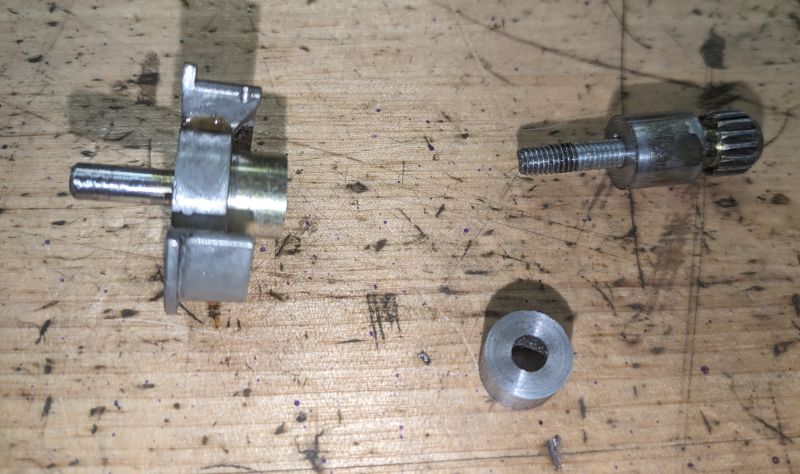

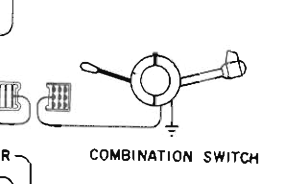

Here's some photographs of the two sets. Note that one is missing the plastic handle that fits over the adjustment lever. It still works. The plastic cover cracked and fell off. I might still have it but it would have to be glued on. They work fine but need some cleaning up and lubrication. I suspect shipping would be expensive to Finland.

Subscriber

Subscriber