Everything posted by duffymahoney

- Duffy's 1/71 Series 1 240z build

-

Duffy's 1/71 Series 1 240z build

I got some zinc parts back. Sadly the aluminum is more pitted then I would like. But nobody will know but me. Also I got my osgiken LSD. Sadly the K R180 I got was from a 87-88 200sx. So it has the beefier 11mm bolts instead of the truck 10mm which the osgiken is setup for. I have the silly expensive LSD at a machine shop having the holes inlarged now. Fingers crossed they don’t mess it up. He is a very good machinist.

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

-

Duffy's 1/71 Series 1 240z build

Powder coating masking is the worse, it's this terrible rigid tape. It works, but not nearly as well as this. If you can sacrifice something to do a firm mask off, it will turn out awesome. This is just my experience in years of powder coating car parts. I am sure there are other ways. My powder shop charges me a lot less if I do the prep/ masking.

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

-

Duffy's 1/71 Series 1 240z build

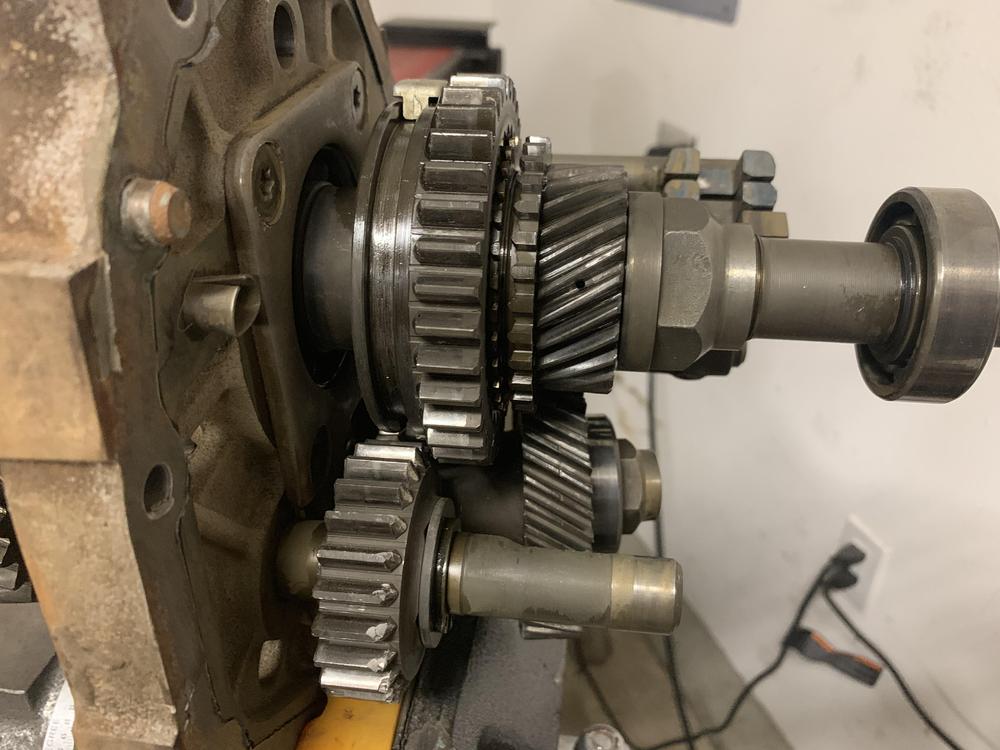

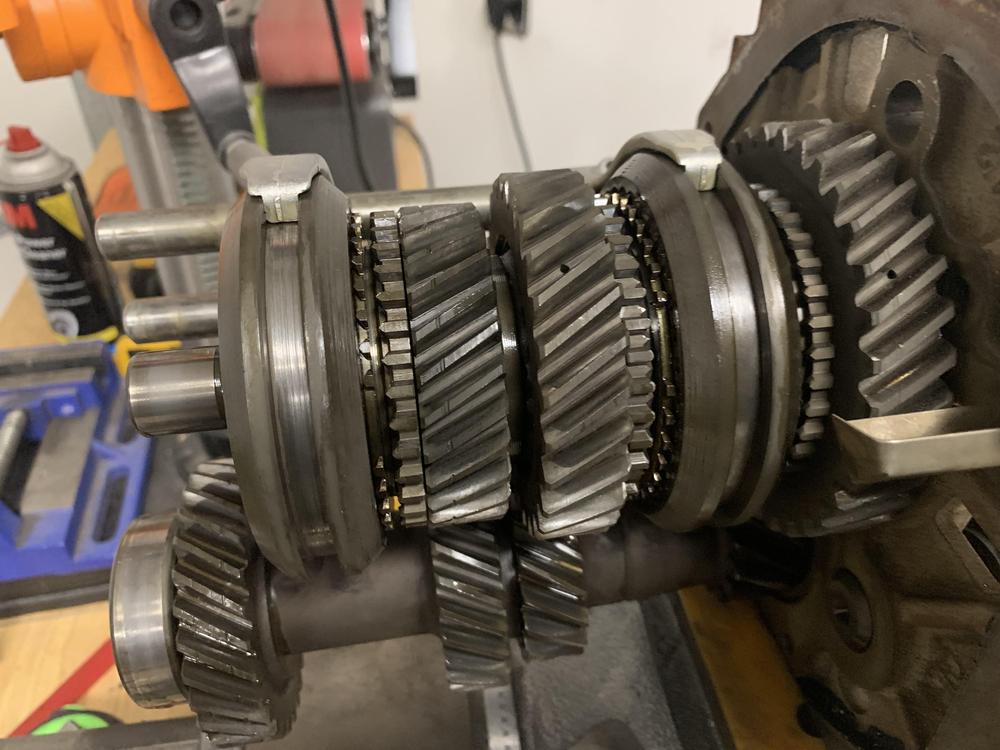

I have decided to do the 5 speed swap. A fellow z guy had a hoard of parts and hooked me up with a close ratio 5 speed and a later R-180. R180 will be 4.11 gears and OSGiken LSD. Trans will be rebuilt, vapor blasted, then all steel parts will be zinc, powder or professionally painted. Rear end will be powdercoated 60% gloss black, then all steel will be zinc coated. Should look super nice. I am also building a nice crate, which will hold all of my rebuilt original parts, in case I ever want to sell and go back to stock. I am trying to decide on a clutch/ flywheel combo. OSGiken Single clutch unit looks nice and streetable. I am having fun. I am convinced that dirty parts look the best later on. Since the grease protects them.

- Duffy's 1/71 Series 1 240z build

-

1970 Original Factory Finish of Exhaust Manifold and Heat Shield

The heat shield on my 71 series 1 was clear cadium . That was from my zinc shop that had a harder time removing it.

-

Looking For Plating Shop Recommendations

I have been zinc plating for a few years, I have used 3 shops, sadly I have zero local options. I ship via priority mail. Usually comes back in a week or two. Whatever shop it is, chat with them about prep. My current shop wants pretty minimal prep unless it's painted or rusty. Also will they do small batches? I prefer smaller batches for say 50-75$.

- Duffy's 1/71 Series 1 240z build

-

Duffy's 1/71 Series 1 240z build

Well I had to pull the hatch vent cover to get to the some of the parts for zinc. The cork had turned to the oddest goo/ glue. Anyone have a foam seal they used for this spot? Needs to be thin 1/8th? Also the tiny brackets for the vent had paint coming off so I had them powder coated. Should outlast the z body:) Only a tiny bit of surface rust in the vent area. I am thinking about converting the rust and doing cavity wax. Thoughts?