Everything posted by duffymahoney

-

BAT Series 1 over 40k after first day

It's just a great color:)

-

Rebuilt Nikki Fuel pump, NOS parts

200$ shipped. Nikki 2.4, 2.6 and 2.8 fuel pumps. Most of the parts are Nos. All internals are new. Only issue is the zinc on the hose barbs don’t perfectly match the screws. Base that attaches to the block and hose barbs are the only parts not NOS. PM me.

-

Camouflaged as carbs

A few z builds I follow on instagram have them. They look pretty sweet. I hope they do OER/ Mikuni copies as well.

- Duffy's 1/71 Series 1 240z build

-

Duffy's 1/71 Series 1 240z build

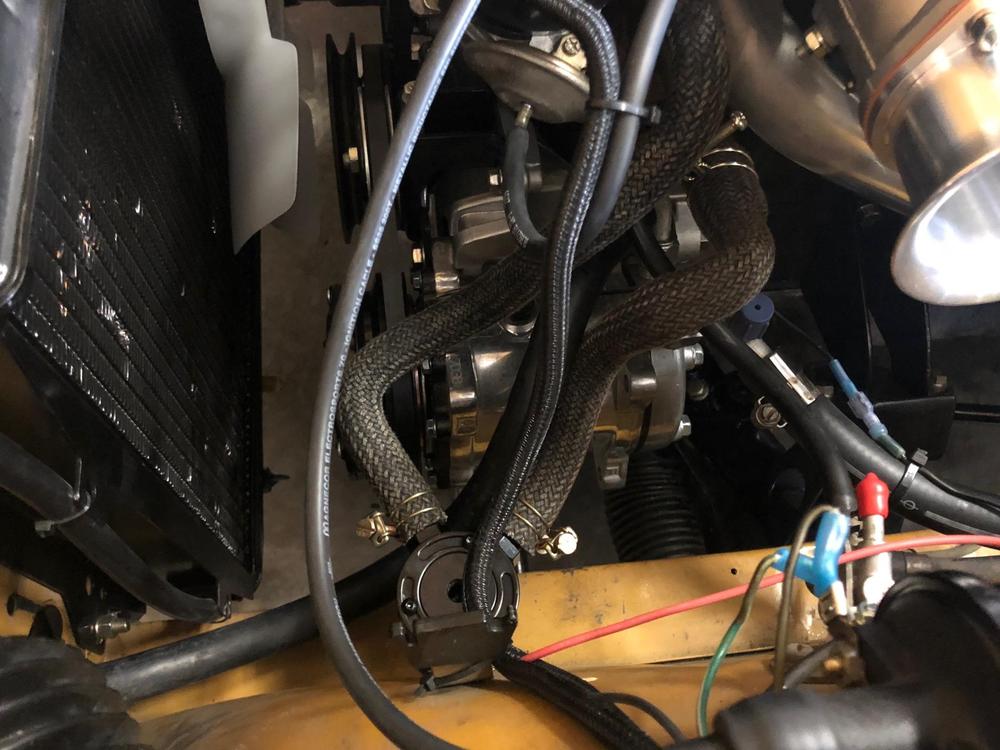

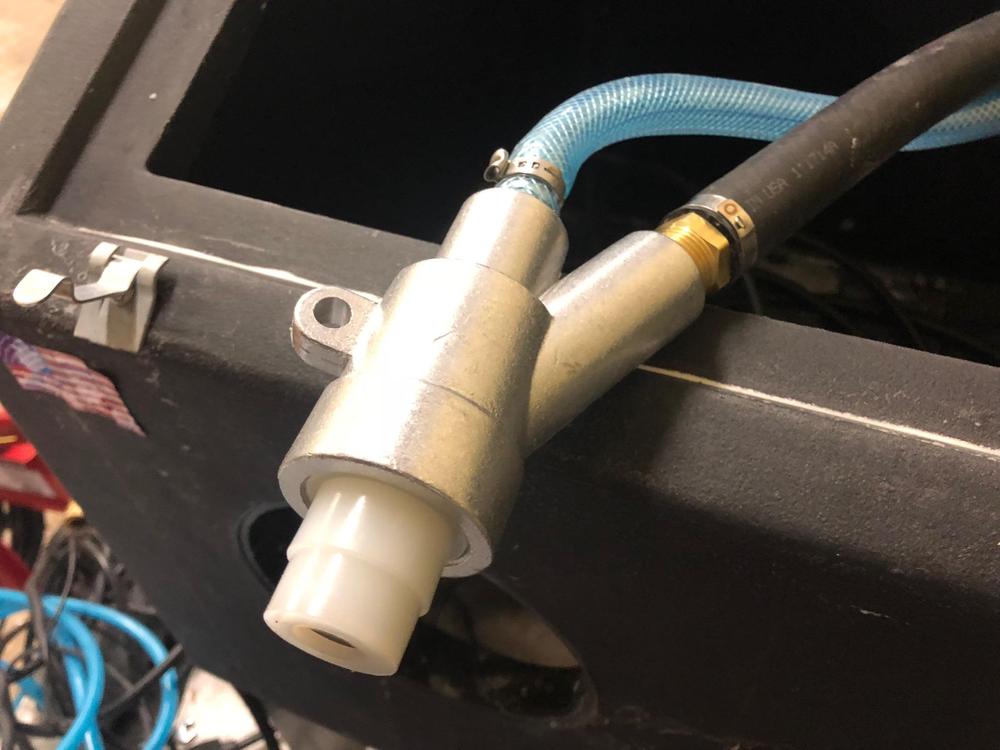

Oil catch can is done (some ebay smaller aluminum one). Time to drive it! The goal was stock looking as possible, also no holes drilled. This is two pvc hoses spliced together with a 5/8 brass union, the pre- bends worked awesome and looks like I meant it to happen. Catch can has a nice little drain on the bottom.

- Duffy's 1/71 Series 1 240z build

-

Duffy's 1/71 Series 1 240z build

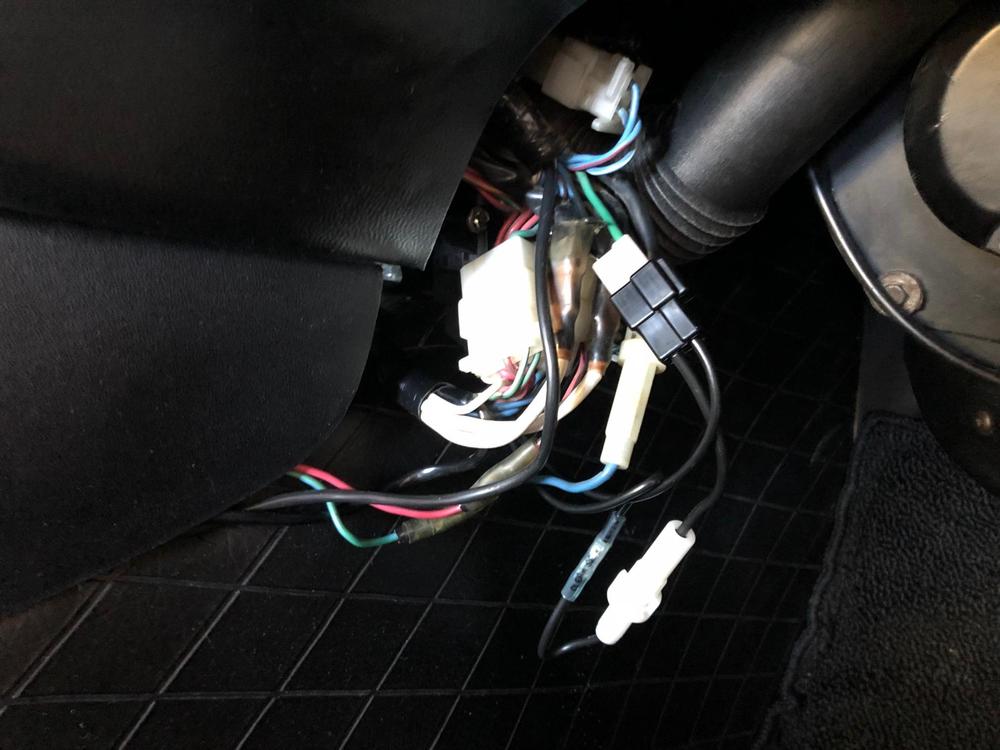

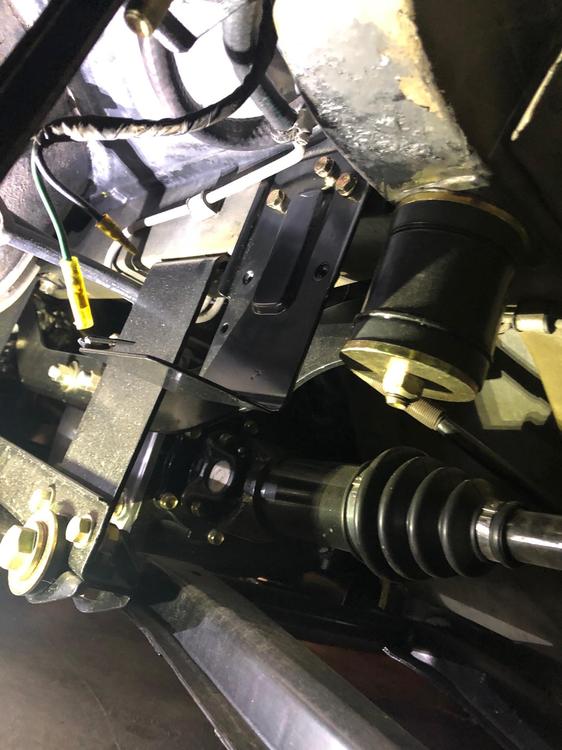

Thank you. I am trying to make whatever i do as nice as it can be done. By a hobbyist .The interia switch was actually the first hole I have drilled in my z. It worried me a little. I screwed up the the butterfly’s a little on the Mikuni’s. They are now all set pretty perfect. I can see a sliver of light when closed. The heat shield I bought doesn’t fit. Weirdly the carbs stay nice and cool. My header is ceramic coated. Maybe that’s enough? Also the header design keeps the pipes pretty far away from the carbs. Thoughts? Anyone? Next goals. Next is taking the starter apart and zinc, vapor blast and paint it. Re zinc the horns, they have over spray on them. Pull oil pan, powder coat and re zinc all the bolts

- Duffy's 1/71 Series 1 240z build

-

Duffy's 1/71 Series 1 240z build

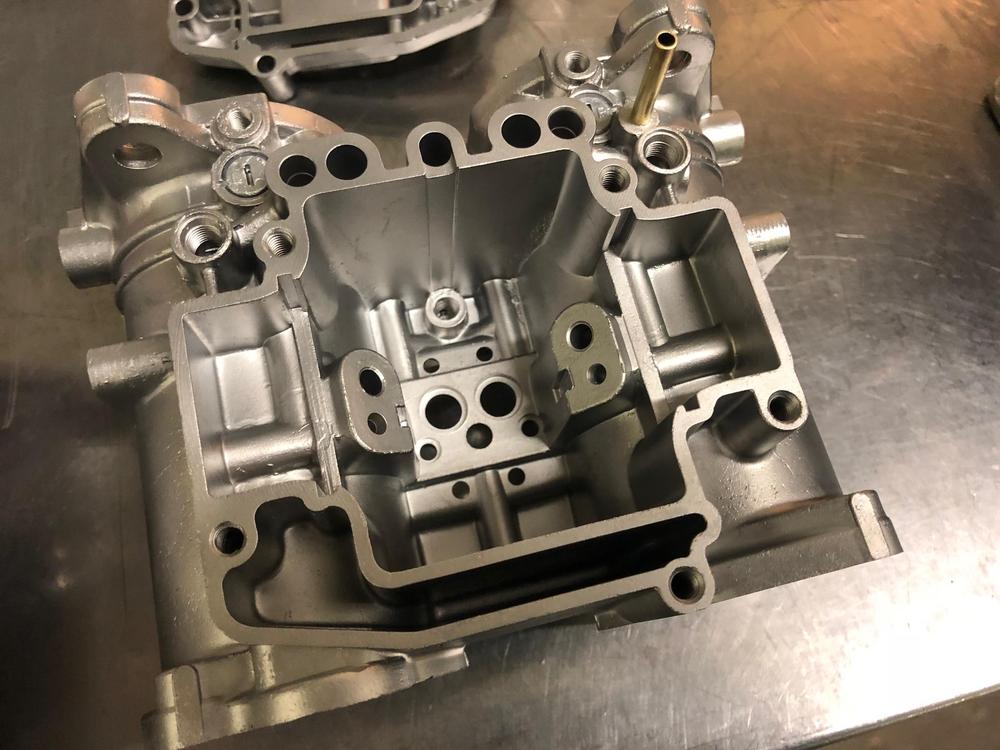

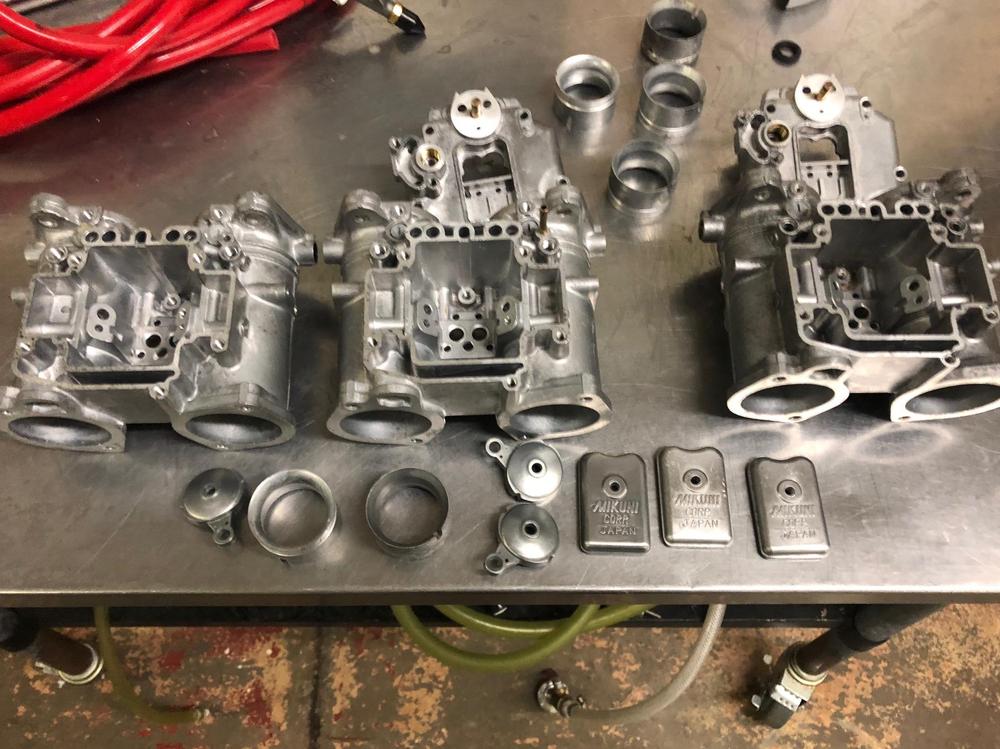

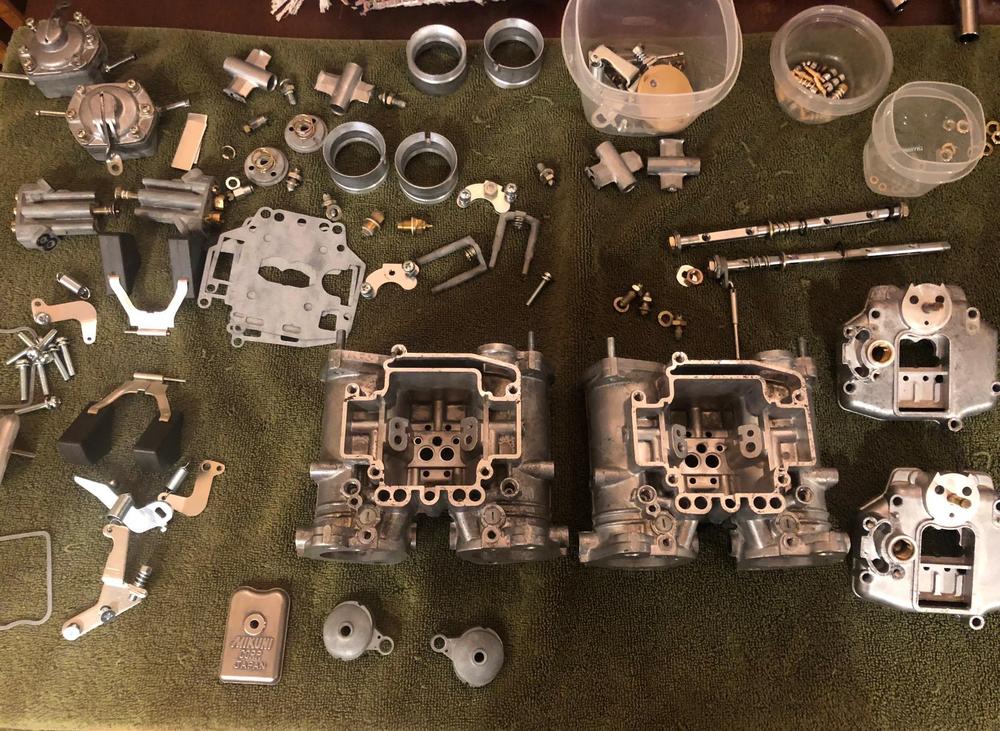

So my 3 best mikuni 44's didn't have the same patina, these had been rebuilt by a legend. I made the decision to try and take them 95% apart myself, vapor blast and put them back together. Honestly most of the process made perfect sense. I am pretty detail oriented, so I just took my time and took lots of pictures. The throttle shafts and pins are the hardest part. So far the only thing I think i screwed up is one of the butterfly valves isn't seated 100%. I am going to take each carb off and double check no light passes by when closed. I am getting a high idle, which I believe is from that. I installed a nismo fuel pump with my 73 bracket, bolted right in. Hoses were easy to install. I installed a inertia switch/ rollover switch for the electric fuel pump (factory used a oil pressure switch). Since I have it attached to the stock spot on the ignition. Also a 14amp fuse. Looks factory. I wanted to use the stock fuel rail, I like the way it looks. I also re- zinc'd a bunch of smalls for the intake and carbs. So far I am very happy with how they sound. Now time to sell my z therapy carbs. Don't judge the fuel fitting. The correct one is on order.

- DIY Home Built Vapor Blasting/ Honing Cabinet , wetblasting

-

DIY Home Built Vapor Blasting/ Honing Cabinet , wetblasting

I got a new gun/ nozzle system. I accidentally bought two so if anyone wants one let me know. Hose is now 3/4 for the slurry pump, air is 5/8. So much much bigger. Hopefully moves a lot more slurry. Also the nozzle tip can be changed out. It can be 4,5,6,8,10, 12 and 14mm. I found the nozzle by doing some youtube stalking of vapor honing stuff. I kind of feel bad about it.

-

So we're doing a 73 restoration project

Message me, I have a new check valves and diaphragm for your fuel pump.

-

DIY Home Built Vapor Blasting/ Honing Cabinet , wetblasting

It’s mostly submerged. The pump is a little tall for my cabinet. Manufacture claims the trash pump can handle just about anything. Also I know that this is the same pump the pro cabinets use. If I was to do this a lot I would just buy a vapor honing system. They are nicely made and take the guesswork out. I think stainless cabinet would be much nicer.

- DIY Home Built Vapor Blasting/ Honing Cabinet , wetblasting

-

DIY Home Built Vapor Blasting/ Honing Cabinet , wetblasting

I bought two. The first was this one. https://www.supplyhouse.com/sh/control/product/~product_id=506274 It gets amazing reviews, but the manufacture told me it wouldn't last that long in the vapor environment. I am now using this. It's called a trash pump and this is actually the unit a few vapor cabinet builders are using. Only issue is't pretty big. https://www.amazon.com/gp/product/B000PDU9EY/ref=oh_aui_detailpage_o05_s00?ie=UTF8&psc=1 It's not as powerful as my original pump, but it sits in my cabinet and mixes the slurry on it's own, so results are pretty much the same. It's nicer on my hands as well.

-

DIY Home Built Vapor Blasting/ Honing Cabinet , wetblasting

Got a new pump. It goes in the cabinet. It’s called a trash pump. It does a much better job of keeping the slurry mixed. It’s designed to pump up to 50% solids and can pump sand and silt. Works awesome. Only issue is it’s not as powerful. So I turned the air up slightly. Honestly man hands like the less pressure. Before vapor blasting for an hour and my hands would be very sore. M brass comes out perfect with vapor.

-

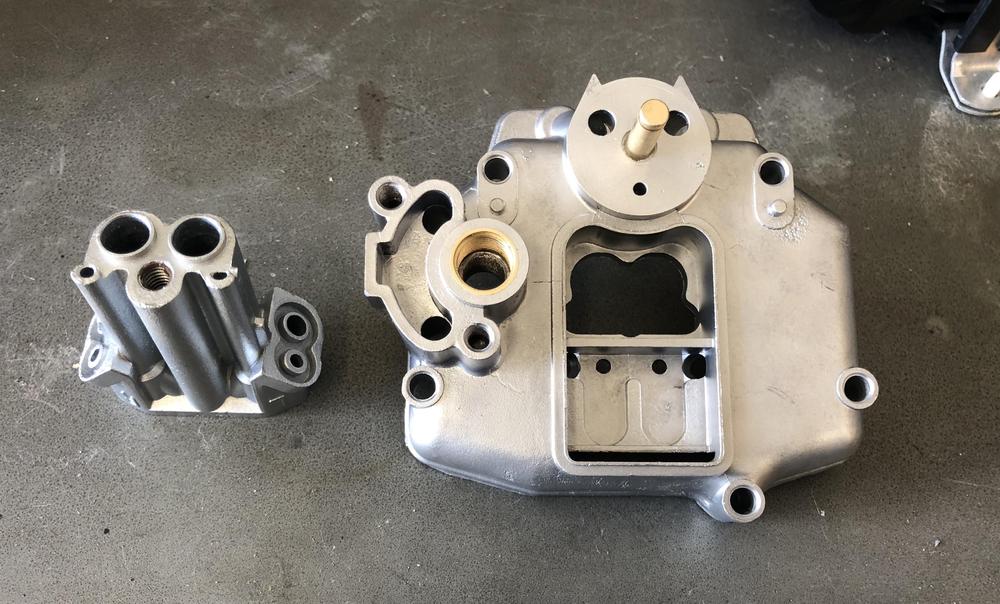

Difference between Nismo Mikuni 44phh and Mikuni 44phh

Copied from another thread. "Nismo" Mikuni / Solex 44 (Type 5). These tend to be known as Nismo colloquially because they were offered through Nismo catalogs in the late 70s, early 80s in North American markets. They have the externally adjustable float with the provision for it to be mounted on either side (dual fuel feed lid), unlike regular s5's. They also came with larger outer venturis too. https://www.viczcar.com/forum/topic/15654-mikuni-carburettor-id-thread-phh/

- DIY Home Built Vapor Blasting/ Honing Cabinet , wetblasting

- DIY Home Built Vapor Blasting/ Honing Cabinet , wetblasting

- Duffy's 1/71 Series 1 240z build

-

DIY Home Built Vapor Blasting/ Honing Cabinet , wetblasting

Well ruined another pump, I need to find something better. Some small that is high pressure and can take the tiny particles on a shaft. I believe they are my issue . I got this Sk intake looking pretty before the pump started to leak:( It looked pretty nice before, so it cleaned easily.

-

1971 240z (10/70) For Sale in Tampa, FL

Good start to a race car:)

-

LOOKING FOR A TRIPLE MIKUNI 44pph SET UP

Hung has a rebuilt set. He is in your area.

-

Triple Mikuni's question

There is a great facebook group for mikuni guys. Maybe ask there?

- Duffy's 1/71 Series 1 240z build

.jpg.3022cc8156fb0304cce63a240f534e2e.jpg)